PAT & QbD brochure (PDF) - JMP

PAT & QbD brochure (PDF) - JMP

PAT & QbD brochure (PDF) - JMP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

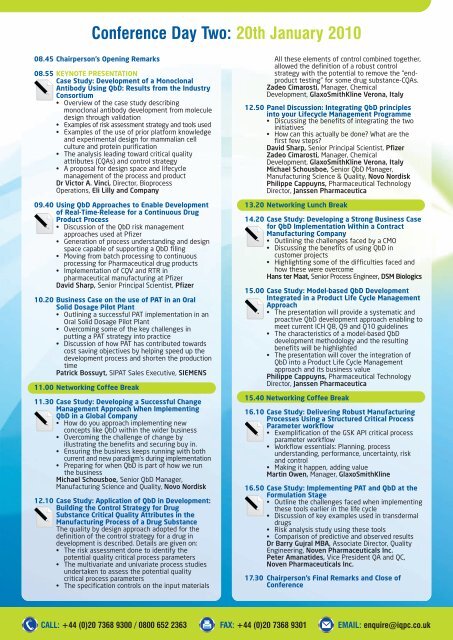

Conference Day Two: 20th January 2010<br />

08.45 Chairperson’s Opening Remarks<br />

08.55 KEYNOTE PRESENTATION<br />

Case Study: Development of a Monoclonal<br />

Antibody Using <strong>QbD</strong>: Results from the Industry<br />

Consortium<br />

• Overview of the case study describing<br />

monoclonal antibody development from molecule<br />

design through validation<br />

• Examples of risk assessment strategy and tools used<br />

• Examples of the use of prior platform knowledge<br />

and experimental design for mammalian cell<br />

culture and protein purification<br />

• The analysis leading toward critical quality<br />

attributes (CQAs) and control strategy<br />

• A proposal for design space and lifecycle<br />

management of the process and product<br />

Dr Victor A. Vinci, Director, Bioprocess<br />

Operations, Eli Lilly and Company<br />

09.40 Using <strong>QbD</strong> Approaches to Enable Development<br />

of Real-Time-Release for a Continuous Drug<br />

Product Process<br />

• Discussion of the <strong>QbD</strong> risk management<br />

approaches used at Pfizer<br />

• Generation of process understanding and design<br />

space capable of supporting a <strong>QbD</strong> filing<br />

• Moving from batch processing to continuous<br />

processing for Pharmaceutical drug products<br />

• Implementation of CQV and RTR in<br />

pharmaceutical manufacturing at Pfizer<br />

David Sharp, Senior Principal Scientist, Pfizer<br />

10.20 Business Case on the use of <strong>PAT</strong> in an Oral<br />

Solid Dosage Pilot Plant<br />

• Outlining a successful <strong>PAT</strong> implementation in an<br />

Oral Solid Dosage Pilot Plant<br />

• Overcoming some of the key challenges in<br />

putting a <strong>PAT</strong> strategy into practice<br />

• Discussion of how <strong>PAT</strong> has contributed towards<br />

cost saving objectives by helping speed up the<br />

development process and shorten the production<br />

time<br />

Patrick Bossuyt, SI<strong>PAT</strong> Sales Executive, SIEMENS<br />

11.00 Networking Coffee Break<br />

11.30 Case Study: Developing a Successful Change<br />

Management Approach When Implementing<br />

<strong>QbD</strong> in a Global Company<br />

• How do you approach implementing new<br />

concepts like <strong>QbD</strong> within the wider business<br />

• Overcoming the challenge of change by<br />

illustrating the benefits and securing buy in.<br />

• Ensuring the business keeps running with both<br />

current and new paradigm’s during implementation<br />

• Preparing for when <strong>QbD</strong> is part of how we run<br />

the business<br />

Michael Schousboe, Senior <strong>QbD</strong> Manager,<br />

Manufacturing Science and Quality, Novo Nordisk<br />

12.10 Case Study: Application of <strong>QbD</strong> in Development:<br />

Building the Control Strategy for Drug<br />

Substance Critical Quality Attributes in the<br />

Manufacturing Process of a Drug Substance<br />

The quality by design approach adopted for the<br />

definition of the control strategy for a drug in<br />

development is described. Details are given on:<br />

• The risk assessment done to identify the<br />

potential quality critical process parameters<br />

• The multivariate and univariate process studies<br />

undertaken to assess the potential quality<br />

critical process parameters<br />

• The specification controls on the input materials<br />

All these elements of control combined together,<br />

allowed the definition of a robust control<br />

strategy with the potential to remove the “endproduct<br />

testing” for some drug substance-CQAs.<br />

Zadeo Cimarosti, Manager, Chemical<br />

Development, GlaxoSmithKline Verona, Italy<br />

12.50 Panel Discussion: Integrating <strong>QbD</strong> principles<br />

into your Lifecycle Management Programme<br />

• Discussing the benefits of integrating the two<br />

initiatives<br />

• How can this actually be done? What are the<br />

first few steps?<br />

David Sharp, Senior Principal Scientist, Pfizer<br />

Zadeo Cimarosti, Manager, Chemical<br />

Development, GlaxoSmithKline Verona, Italy<br />

Michael Schousboe, Senior <strong>QbD</strong> Manager,<br />

Manufacturing Science & Quality, Novo Nordisk<br />

Philippe Cappuyns, Pharmaceutical Technology<br />

Director, Janssen Pharmaceutica<br />

13.20 Networking Lunch Break<br />

14.20 Case Study: Developing a Strong Business Case<br />

for <strong>QbD</strong> Implementation Within a Contract<br />

Manufacturing Company<br />

• Outlining the challenges faced by a CMO<br />

• Discussing the benefits of using <strong>QbD</strong> in<br />

customer projects<br />

• Highlighting some of the difficulties faced and<br />

how these were overcome<br />

Hans ter Maat, Senior Process Engineer, DSM Biologics<br />

15.00 Case Study: Model-based <strong>QbD</strong> Development<br />

Integrated in a Product Life Cycle Management<br />

Approach<br />

• The presentation will provide a systematic and<br />

proactive <strong>QbD</strong> development approach enabling to<br />

meet current ICH Q8, Q9 and Q10 guidelines<br />

• The characteristics of a model-based <strong>QbD</strong><br />

development methodology and the resulting<br />

benefits will be highlighted<br />

• The presentation will cover the integration of<br />

<strong>QbD</strong> into a Product Life Cycle Management<br />

approach and its business value<br />

Philippe Cappuyns, Pharmaceutical Technology<br />

Director, Janssen Pharmaceutica<br />

15.40 Networking Coffee Break<br />

16.10 Case Study: Delivering Robust Manufacturing<br />

Processes Using a Structured Critical Process<br />

Parameter workflow<br />

• Exemplification of the GSK API critical process<br />

parameter workflow<br />

• Workflow essentials: Planning, process<br />

understanding, performance, uncertainty, risk<br />

and control<br />

• Making it happen, adding value<br />

Martin Owen, Manager, GlaxoSmithKline<br />

16.50 Case Study: Implementing <strong>PAT</strong> and <strong>QbD</strong> at the<br />

Formulation Stage<br />

• Outline the challenges faced when implementing<br />

these tools earlier in the life cycle<br />

• Discussion of key examples used in transdermal<br />

drugs<br />

• Risk analysis study using these tools<br />

• Comparison of predictive and observed results<br />

Dr Barry Gujral MBA, Associate Director, Quality<br />

Engineering, Noven Pharmaceuticals Inc.<br />

Peter Amanatides, Vice President QA and QC,<br />

Noven Pharmaceuticals Inc.<br />

17.30 Chairperson’s Final Remarks and Close of<br />

Conference<br />

CALL: +44 (0)20 7368 9300 / 0800 652 2363 FAX: +44 (0)20 7368 9301 EMAIL: enquire@iqpc.co.uk