from inspiration to installation

Perhaps it’s an ability to be open, yet closed, at once. To reflect light directlyand indirectly, brilliantly and diffusely,together. To be rigid or flexible. Or, tobe geometrically simplistic at a distance, yet vexingly complex up close. Perhaps,it’s all of these unique characteristicsat work.Whatever the reason, what’s undeniableis woven metal fabric’s uncanny knackfor inspiring creative minds.Which is precisely where CambridgeArchitectural comes in: to ensure that architects and designers have the knowledge, products, systems,and support to transform visionary designs of today into lastingarchitectural realities of tomorrow.Welcome to CambridgeArchitectural.

Perhaps it’s an ability to be open, yet closed, at once. To reflect light directlyand indirectly, brilliantly and diffusely,together. To be rigid or flexible. Or, tobe geometrically simplistic at a distance, yet vexingly complex up close. Perhaps,it’s all of these unique characteristicsat work.Whatever the reason, what’s undeniableis woven metal fabric’s uncanny knackfor inspiring creative minds.Which is precisely where CambridgeArchitectural comes in: to ensure that architects and designers have the knowledge, products, systems,and support to transform visionary designs of today into lastingarchitectural realities of tomorrow.Welcome to CambridgeArchitectural.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cambridge Architectural Mesh<br />

<strong>from</strong><br />

<strong>inspiration</strong><br />

<strong>installation</strong><br />

<strong>to</strong>

We chose Cambridge mesh because of the unique<br />

shape it could produce, and because the material’s<br />

scrim-like properties created a beautiful and elegant<br />

shimmer.<br />

Peter Follett, Pelli Clarke Pelli Architects<br />

<strong>inspiration</strong>al<br />

2

ARIA Resort and Casino<br />

Las Vegas, Nevada<br />

Architect: Pelli Clarke Pelli Architects<br />

New Haven, Connecticut<br />

Perhaps it’s an ability <strong>to</strong> be open, yet<br />

closed, at once. To reflect light directly<br />

and indirectly, brilliantly and diffusely,<br />

<strong>to</strong>gether. To be rigid or flexible. Or, <strong>to</strong><br />

be geometrically simplistic at a distance,<br />

yet vexingly complex up close. Perhaps,<br />

it’s all of these unique characteristics<br />

at work.<br />

Whatever the reason, what’s undeniable<br />

is woven metal fabric’s uncanny knack<br />

for inspiring creative minds.<br />

Which is precisely where Cambridge<br />

Architectural comes in: <strong>to</strong> ensure that<br />

architects and designers have the<br />

knowledge, products, systems,<br />

and support <strong>to</strong> transform visionary<br />

designs of <strong>to</strong>day in<strong>to</strong> lasting<br />

architectural realities of <strong>to</strong>morrow.<br />

Welcome <strong>to</strong> Cambridge<br />

Architectural.<br />

Distinctive 4<br />

Original 6<br />

Visionary 8<br />

Cot<strong>to</strong>n Bowl 10<br />

Taylor Family Digital Library 16<br />

Iron Horse Trail Bridge 18<br />

Texas A&M 20<br />

UB Law 22<br />

TopGolf 24<br />

Awty International School 26<br />

Product Portfolio 28<br />

Vision 54<br />

Our vision for Cambridge mesh is not <strong>to</strong> be<br />

‘on’ or ‘in’ a building – but rather ‘of’ the built<br />

environment. Cambridge mesh is art and<br />

architecture, form and function, and one of<br />

<strong>to</strong>day’s most distinctive building materials.<br />

Tracy Tyler<br />

President & CEO<br />

3

4<br />

distinctive

ANY BUILDING TYPE<br />

WOVEN METAL FABRIC<br />

Each distinct pattern of Cambridge woven<br />

metal fabric is itself a work of art, designed<br />

with a specific geometry, open area, dimension,<br />

and flexibility. Woven by skilled artisans<br />

<strong>from</strong> a multitude of combinations of highly<br />

durable, yet readily recyclable metals,<br />

including stainless, bronze, aluminum,<br />

and brass, metal fabric is an intrinsically<br />

sustainable building material.<br />

ARCHITECTURAL FUNCTIONS<br />

The visual beauty of woven metal usually<br />

upstages the material’s critical functional<br />

offerings. These include: solar shading,<br />

acoustic transparency, ventilation, security<br />

and safety, space sculpting, and masking.<br />

From parking garages and pedestrian<br />

bridges, <strong>to</strong> performing arts venues and<br />

major sports complexes, Cambridge<br />

metal fabrics are gracing structures across<br />

the country and around the world. Woven<br />

through interiors and exteriors of museums,<br />

libraries, hospitals, research centers,<br />

universities, casinos, stadiums, hotels,<br />

retail establishments, government facilities,<br />

and religious facilities, Cambridge mesh<br />

is transforming the ordinary in<strong>to</strong> the<br />

extraordinary.<br />

ENGINEERED ATTACHMENT SYSTEMS<br />

Cambridge offers a large variety of flexible<br />

and rigid mesh patterns as well as the<br />

best-engineered attachment systems<br />

in the industry. Cambridge continually<br />

develops new mesh patterns, finishes,<br />

and innovative ways <strong>to</strong> use mesh material<br />

<strong>to</strong> achieve certain architectural looks or<br />

functionalities. A complete product catalog<br />

is located on page 28.<br />

POPULAR APPLICATIONS:<br />

• Canopies<br />

• Ceilings<br />

• Curtains<br />

• Eleva<strong>to</strong>rs<br />

• Facades<br />

• Handrail Infills<br />

• Parking Facilities<br />

• Solar Shading<br />

• Security Screens<br />

• Signage<br />

• Stair Towers<br />

• Walls<br />

PHOTOS: Top-National World War II Museum, New Orleans, Louisiana; Bot<strong>to</strong>m-Translational Research Institute, Orlando, Florida<br />

5

original<br />

While Cambridge <strong>to</strong>day is a recognized global leader, our<br />

roots were planted 100 years ago in the small <strong>to</strong>wn we still<br />

call home. Our manufacturing experience and passion for<br />

excellence is evident in the hands and on the faces of every<br />

craftsman who weaves our metal fabrics.<br />

6<br />

Tom Ross, COO

AN AMERICAN ORIGINAL<br />

Cambridge Architectural collaborates closely<br />

with architects, designers, and contrac<strong>to</strong>rs<br />

<strong>to</strong> specify, cus<strong>to</strong>mize, and install woven<br />

metal in<strong>to</strong> the built environment in ways<br />

that are both aesthetic and functional.<br />

HERITAGE<br />

Cambridge Architectural evolved <strong>from</strong><br />

a world-renowned American industrial<br />

wire belt manufacturer with a century<br />

of successful engineered solutions. The<br />

company’s first architectural application<br />

was installed in 1957 at the Seagram’s<br />

Building in New York City (cladding for<br />

the building’s eleva<strong>to</strong>r cabs that remain<br />

in place <strong>to</strong>day). After four decades<br />

of market experience, the Cambridge<br />

Architectural division was officially<br />

established in 2002.<br />

EXPERTISE<br />

Having established a leading position in<br />

the marketplace, Cambridge’s expertise<br />

extends far beyond materials manufacturing.<br />

Our 400+ employees call on collective and<br />

progressive experience with every facet<br />

of design, engineering, fabrication and<br />

<strong>installation</strong> at each stage of every project.<br />

Cambridge provides full-scale project<br />

management and engineering services with<br />

Located in Maryland near the shores<br />

of the Chesapeake Bay, Cambridge is<br />

an his<strong>to</strong>ric community. Cambridge is<br />

home <strong>to</strong> third generation artisans and<br />

professionals dedicated <strong>to</strong> making<br />

woven metal mesh the hallmark of<br />

beautiful, durable and sustainable<br />

environments.<br />

access <strong>to</strong> hundreds of skilled craftsmen,<br />

creative minds, and market experts <strong>to</strong><br />

execute the architect’s or designer’s vision.<br />

GLOBAL<br />

Today, Cambridge clients benefit <strong>from</strong> the<br />

company’s global manufacturing operations<br />

in combination with its North American<br />

headquarters, offering full-service consultation<br />

services, research and development,<br />

engineering, pro<strong>to</strong>typing, and more. Our<br />

expanding international portfolio in Europe,<br />

the Middle East and Latin America has<br />

introduced Cambridge’s ingenuity and<br />

know-how <strong>to</strong> these expanding markets.<br />

EDUCATION<br />

As trailblazers, Cambridge Architectural<br />

places high value on continuing education<br />

and offers two AIA-certified CEU courses.<br />

“Architectural Mesh Systems, Design<br />

Freedom and Functionality” and<br />

“Shading, a Daylighting Strategy for<br />

Sustainable Buildings” allow architects<br />

<strong>to</strong> receive LU/SD/HSW credits.<br />

We also offer a Cambridge CPD seminar for<br />

British architects through RIBA under the<br />

Designing and Building It curriculum.<br />

7

8<br />

visionary

INNOVATION<br />

Continuously striving <strong>to</strong> innovate new systems<br />

and designs, Cambridge’s track record for<br />

unique product development is evident in the<br />

almost two dozen U.S. and European patents<br />

including a special Miami-Dade certified<br />

attachment system capable of withstanding<br />

hurricane force winds. Another eight patents<br />

are currently granted provisionally or pending.<br />

EXECUTION<br />

Cambridge Architectural’s talented<br />

engineering team assists with any<br />

special design requirements and provides<br />

all required drawings, documentation and<br />

code approvals. Cambridge’s expansive<br />

project portfolio is testament <strong>to</strong> the<br />

company’s ability <strong>to</strong> execute the most<br />

technically challenging projects.<br />

Once specified, Cambridge project managers<br />

go <strong>to</strong> work, professionally interfacing with<br />

the contrac<strong>to</strong>rs <strong>to</strong> schedule a seamless,<br />

on-time <strong>installation</strong>. Cambridge’s U.S.-based<br />

manufacturing provides a significant<br />

delivery lead-time advantage.<br />

COLLABORATION<br />

Cambridge provides complete systems<br />

cus<strong>to</strong>mized <strong>to</strong> the application. Cambridge<br />

collaborates with architects and designers<br />

<strong>to</strong> develop mesh solutions that most fully<br />

realize the conceptual intent. Cambridge<br />

consultants also present possibilities that<br />

may not have even been considered and<br />

offer valuable expertise on how <strong>to</strong> properly<br />

specify architectural mesh for each project.<br />

SUSTAINABILITY<br />

As a member of the United States Green<br />

Building Council, Cambridge is committed<br />

<strong>to</strong> promoting methods, technology and<br />

products resulting in environmentally<br />

responsible and healthy buildings. Select<br />

Cambridge staff members receive ongoing<br />

education and training on pertinent issues.<br />

This team, in turn, develops systems that<br />

meet or exceed LEED requirements and<br />

provides consultation and direction on a<br />

project-by-project basis.<br />

The contemporary, shimmering,<br />

diaphanous look locked us in on<br />

this product.<br />

Raffi Tomassian<br />

DNK Architects, Inc.<br />

Cincinnati Children’s Hospital<br />

Parking Facility<br />

Cincinnati, Ohio<br />

Architect: DNK Architects, Inc.<br />

Cincinnati, Ohio<br />

PHOTOS:<br />

Top - Loewe Retail S<strong>to</strong>re,<br />

Valencia, Spain<br />

Bot<strong>to</strong>m - Salvation Army<br />

Kroc Center, Phoenix, Arizona<br />

9

129<br />

130<br />

131<br />

132<br />

58<br />

59<br />

60<br />

53<br />

54<br />

55<br />

56<br />

57<br />

<strong>from</strong> <strong>inspiration</strong> <strong>to</strong> <strong>installation</strong><br />

res<strong>to</strong>ring<br />

0<br />

49<br />

48<br />

52<br />

1<br />

pageantry<br />

and prestige<br />

<strong>to</strong> the<br />

NW-01<br />

47<br />

2<br />

Cot<strong>to</strong>n Bowl<br />

86345-NW-02<br />

46<br />

45<br />

44<br />

STA G E 1- N W Q UA DRA NT<br />

43<br />

1<br />

86345-NW-01<br />

42<br />

1<br />

86345-NW-02<br />

41<br />

40<br />

39<br />

38<br />

F<br />

E.9<br />

10

133<br />

134<br />

135<br />

136<br />

17<br />

6' - 10 1/4"<br />

TO F.O. HSS.VIF<br />

TOP OF HSS 4<br />

536' - 0 5/16"<br />

137<br />

138<br />

139<br />

2<br />

86345-NW-03<br />

2<br />

BEHIND<br />

TOP OF HSS 3<br />

531' - 4 3/16"<br />

140<br />

141<br />

142<br />

143<br />

144<br />

145<br />

Part of the Cot<strong>to</strong>n Bowl’s recent $57 million<br />

1<br />

renovation included cosmetic upgrades<br />

<strong>to</strong> the north and south exterior facades,<br />

or end zones, of the his<strong>to</strong>ric stadium. A<br />

design competition for this scope of the<br />

project was held. The winning design<br />

concept, entitled ‘Light Veil’, including<br />

26' - 3 11/16"<br />

TOP MESH HEIGHT<br />

REF E400<br />

two Cambridge Architectural flexible mesh<br />

patterns and an engineered attachment<br />

system, came <strong>from</strong> James Carpenter<br />

Design Associates, Inc. of New York City.<br />

15<br />

E.9.<br />

F.<br />

151<br />

150<br />

149<br />

148<br />

146<br />

147<br />

Katharine McClellan, Senior Designer<br />

at James Carpenter, in describing their<br />

design objective and challenges says,<br />

“Our design intent was <strong>to</strong> create an<br />

enclosure but <strong>to</strong> allow for views in<strong>to</strong><br />

and out of the stadium while allowing<br />

form <strong>to</strong> take shape. It was a very large<br />

area <strong>to</strong> cover so we had <strong>to</strong> use a<br />

material that was economical, yet<br />

able <strong>to</strong> achieve the aesthetics we<br />

were looking for, especially with<br />

respect <strong>to</strong> reaction with sunlight.”<br />

JCDA imagined the use of woven<br />

metal fabric. “We decided <strong>to</strong> do a series<br />

of ribbons that would come inward<br />

<strong>from</strong> the <strong>to</strong>p of the structure, then<br />

cinch and continue <strong>to</strong> flow downward<br />

<strong>to</strong> create an elegant form. Ribbons of<br />

metal mesh would allow us <strong>to</strong> maintain<br />

the curves of the stadium itself.”<br />

23' - 1 3/16"<br />

BOTTOM MESH<br />

HEIGHT<br />

REF E400<br />

3<br />

86345-NW-03<br />

5<br />

86345-NW-03<br />

TOP OF HSS 2<br />

510' - 5 13/16"<br />

13' - 4 9/16" VIF<br />

14<br />

9' - 6 3/4" VIF<br />

4<br />

86345-NW-03<br />

TOP OF HSS<br />

487' - 6 1/2"<br />

Renderings: ©2013, James Carpenter Design Associates, Inc. Commissioned<br />

by the City of Dallas through the Office of Cultural Affairs Public Art Program.<br />

11

536' - 0 5/16"<br />

17<br />

TOP OF HSS 3<br />

531' - 4 3/16"<br />

CAMBRIDGE CONSULTATION<br />

The Cambridge project team knew<br />

exactly how <strong>to</strong> take the first step in<br />

bringing JCDA’s ideas <strong>to</strong> life, providing all<br />

the <strong>to</strong>ols needed for proper architectural<br />

design review and presentation; including<br />

samples, education on available mesh and<br />

attachment system options and budgetary<br />

cost estimates. Through this process, JCDA<br />

was able <strong>to</strong> determine that Cambridge’s<br />

Mid-Balance and Pellican mesh patterns<br />

were ideally suited <strong>to</strong> achieve the aesthetic<br />

and light filtering objectives of Light Veil.<br />

M1 P1 M2 M1 P1<br />

M2<br />

16<br />

14<br />

TOP OF HSS 2<br />

510' - 5 13/16"<br />

TOP OF SUPPORT 2<br />

509' - 5 1/16"<br />

MIDBALANCE<br />

MESH SPLICE<br />

AREA (TYP)<br />

MIDBALANCE A PANELS.<br />

APPROXIMATELY<br />

360.00" MESH LENGTH<br />

ABOVE SPLICE AREA<br />

MIDBALANCE B PANELS.<br />

APPROXIMATELY<br />

233.25" MESH LENGTH<br />

BELOW SPLICE AREA<br />

Cambridge worked closely with James<br />

Carpenter Design Associates <strong>to</strong> explore the<br />

most appropriate metal mesh patterns and<br />

attachment hardware systems that would<br />

best achieve the firm’s vision.<br />

“We used two different scales of mesh,<br />

which became a design <strong>to</strong>ol,” says<br />

McClellan. “We placed long ribbons of<br />

smaller scale stainless mesh <strong>from</strong> the <strong>to</strong>p<br />

of the structure all the way down <strong>to</strong> the<br />

bot<strong>to</strong>m. Then, on the upper portion of the<br />

structure, we used the larger scale stainless<br />

mesh that reflects much more sunlight.<br />

When we overlap the two, you get a sense<br />

of depth between the two patterns. And<br />

even though the larger weave is behind<br />

the smaller, as it reflects so much more<br />

sunshine, it transforms the surface in<strong>to</strong><br />

a diaphanous veil.”<br />

There’s a certain ‘aha’<br />

moment in every project<br />

when a consultation<br />

transforms a design in<strong>to</strong> a<br />

cus<strong>to</strong>mized application.<br />

In my<br />

14<br />

12 years at Cambridge,<br />

I’ve watched our team create<br />

countless solutions that<br />

flawlessly execute the<br />

8<br />

architect’s vision.<br />

Ann Smith, Manager,<br />

Architectural<br />

4<br />

Business<br />

Development<br />

14<br />

8<br />

12<br />

TOP OF HSS<br />

487' - 6 1/2"

CAMBRIDGE ENGINEERING<br />

Cambridge engineering professionals<br />

worked closely with Heery International,<br />

the design/build firm on the project;<br />

supplying them with working drawings<br />

for this huge mesh panel <strong>installation</strong> as well<br />

as structural attachment recommendations<br />

and load details. The final Cot<strong>to</strong>n Bowl<br />

exterior renovation specification incorporated<br />

334 Mid-Balance mesh panels measuring<br />

28”x50’ (41,120 sq. ft.) and 174 Pellican mesh<br />

panels measuring 26”x20’ (8,232 sq. ft.).<br />

All mesh panels were mounted in-tension<br />

utilizing Cambridge’s Eclipse attachment<br />

system.<br />

Says McClellan, “The stainless mesh<br />

allowed us <strong>to</strong> create form for the end<br />

zones and <strong>to</strong> provide a sense of enclosure,<br />

while allowing views out and in, as well<br />

as air circulation and ventilation through<br />

the system.”<br />

Engineers are motivated <strong>to</strong><br />

solve seemingly impossible<br />

puzzles. My job at Cambridge<br />

invites me <strong>to</strong> imagine every<br />

day what is possible – and<br />

create cus<strong>to</strong>mized fabrication<br />

and <strong>installation</strong> solutions <strong>to</strong><br />

bring ideas <strong>to</strong> life.<br />

Jim Mitchell<br />

Engineering Manager<br />

<strong>from</strong> <strong>inspiration</strong> <strong>to</strong> <strong>installation</strong><br />

13

CAMBRIDGE PROJECT MANAGEMENT<br />

Collaboration between Cambridge’s<br />

project managers and the contrac<strong>to</strong>rs<br />

(NOW Specialties, Balfour Beatty<br />

Construction) began in January 2013<br />

<strong>to</strong> effectively transition design and<br />

structural requirements through the<br />

fabrication process. Installation <strong>to</strong>ok<br />

place at the stadium between July<br />

and September of 2013. Cambridge<br />

Architectural facilitated a professional<br />

<strong>installation</strong> and provided on-site<br />

support <strong>to</strong> assure satisfac<strong>to</strong>ry project<br />

completion.<br />

The Cot<strong>to</strong>n Bowl renovation was<br />

equal parts imagination, fabrication<br />

and execution. Cambridge mesh<br />

helped score a big win for this<br />

Dallas institution.<br />

Kenn Thompson,<br />

Direc<strong>to</strong>r of Project Management<br />

RESULTS<br />

The Cot<strong>to</strong>n Bowl’s stunning and imaginative<br />

new facade, now befittingly reflects the<br />

pageantry and prestige of the games held<br />

at the his<strong>to</strong>rically significant sports facility.<br />

McClellan concludes, “We were able <strong>to</strong> create<br />

a very large artwork that allowed us <strong>to</strong> use<br />

the sunlight which was very important<br />

<strong>to</strong> us. Plus, it allowed <strong>to</strong> stay within<br />

budget.”<br />

14<br />

Architect:<br />

Design/Build Firm:<br />

James Carpenter Design Associates, Inc., New York, New York<br />

Heery International, Atlanta, Georgia<br />

General Contrac<strong>to</strong>r: Balfour Beatty Construction, Dallas, Texas<br />

Installer:<br />

NOW Specialties, Inc., Hous<strong>to</strong>n, Texas<br />

Owner: City of Dallas / Office of Cultural Affairs Public Art Program /<br />

Dallas Park and Recreation Department<br />

Mesh:<br />

Attachment<br />

System:<br />

Mid-Balance & Pellican<br />

Eclipse

<strong>from</strong> <strong>inspiration</strong> <strong>to</strong> <strong>installation</strong><br />

15

preserving<br />

and protecting<br />

what’s priceless<br />

Taylor Family Digital Library<br />

Calgary, Alberta<br />

Architect:<br />

Kasian Architecture Interior Design and Planning, Vancouver, Canada<br />

Contrac<strong>to</strong>r: CANA Construction, Calgary, Canada<br />

Installer:<br />

Owner:<br />

Mesh:<br />

Flynn Canada Ltd., Rockyview, Canada<br />

University of Calgary<br />

Mid-Balance<br />

Attachment Eclipse<br />

System:<br />

16

PROJECT<br />

The University of Calgary’s Taylor Family<br />

Digital Library is a state-of-the-art facility<br />

housing one million maps and aerial<br />

pho<strong>to</strong>graphs, 850,000 architectural<br />

drawings, and 32,000 print monographs.<br />

Cambridge Architectural’s 5,630 square<br />

foot Mid-Balance mesh façade shades and<br />

protects these rare documents, and the<br />

library’s occupants, while giving the<br />

innovative research and learning center<br />

a 21st Century modern aesthetic.<br />

APPLICATION & BENEFITS<br />

The large Mid-Balance stainless steel façade<br />

shades and reduces glare, protecting the<br />

nine million library assets while reducing<br />

solar heat gain and optimizing energy<br />

performance in regularly occupied areas<br />

of the building. Anchored with the Eclipse<br />

attachment system, the large mesh panels<br />

filter intense sun, while still allowing sufficient<br />

ambient daylight and unobstructed views <strong>to</strong><br />

the campus quad outside of the Information<br />

Commons – a glassed-in area meant for<br />

students <strong>to</strong> learn and relax in while using<br />

the facility. The result is a comfortable and<br />

beautiful open space ideal for academic<br />

endeavors and collaboration. The stainless<br />

steel mesh and attachment materials are<br />

also 100% recyclable and require nearly<br />

zero maintenance.<br />

The mesh reduced the amount of<br />

solar heat gain, diminished glare,<br />

and lent an interesting and beautiful<br />

dimension <strong>to</strong> the building.<br />

Bill Chomik<br />

Principal Design Architect,<br />

Kasian Architecture Interior<br />

17

providing safety<br />

above all<br />

Iron Horse Trail<br />

Pedestrian Bridge<br />

Pleasant Hill, California<br />

18<br />

Architect:<br />

Engineer:<br />

Contrac<strong>to</strong>r:<br />

Owner:<br />

Mesh:<br />

Donald MacDonald Architects, San Francisco<br />

ARUP, San Francisco<br />

Robert A. Bothman Construction, San Jose<br />

Contra Costa County<br />

Plait<br />

Attachment U Frame<br />

System:

PROJECT<br />

The Iron Horse Trail Pedestrian Bridge, aka<br />

‘The Robert I. Schroder Overcrossing,’ is a<br />

500’ span routing pedestrians and cyclists<br />

on the Iron Horse Regional Trail, safely over<br />

a busy intersection. The trail is a popular<br />

byway for San Franciscans between two<br />

BART transit stations.<br />

APPLICATION & BENEFITS<br />

The Plait mesh pattern and design of the<br />

span were chosen <strong>to</strong> prevent people <strong>from</strong><br />

throwing objects over the side of the bridge<br />

and <strong>to</strong> deter climbing. Plait is a rigid metal<br />

fabric with a 64% open area ratio. The Plait<br />

mesh is welded inside modified U Frames<br />

and bolted <strong>to</strong> the bridge’s framework. The<br />

Plait/U Frame stainless steel mesh system<br />

is virtually indestructible and designed <strong>to</strong><br />

withstand the rigors of pedestrian traffic.<br />

The Robert I. Schroder Overcrossing<br />

received a 2012 IDEAS2 award for<br />

innovation in structural steel design<br />

<strong>from</strong> the American Institute of Steel<br />

Construction.<br />

The mesh makes the<br />

pedestrian bridge in<strong>to</strong><br />

a beautiful and inviting<br />

element, durable as well<br />

as attractive.<br />

Ignacio Barandiaran,<br />

Principal & Project<br />

Direc<strong>to</strong>r,<br />

ARUP<br />

19

a new brand<br />

of Texas pride<br />

Texas A&M<br />

University<br />

Memorial Student<br />

Center<br />

Architect:<br />

Contrac<strong>to</strong>r:<br />

Installer:<br />

Owner:<br />

Mesh:<br />

Attachment<br />

System:<br />

Perkins+Will<br />

Vaughn Construction<br />

Orozco Construction<br />

Texas A&M University<br />

Graph<br />

Rigid Mesh-In-Tension<br />

U Frame<br />

20

PROJECT<br />

Living up <strong>to</strong> the reputation in Texas that<br />

bigger is better was no problem for<br />

Cambridge Architectural. To accomplish<br />

Perkins+Will’s vision for a dramatic metal<br />

mesh entry in<strong>to</strong> the magnificent Texas<br />

A&M University Memorial Student Center,<br />

Cambridge forged a revolutionary<br />

attachment system <strong>to</strong> execute the<br />

large-scale <strong>installation</strong>.<br />

The function was key, but<br />

the aesthetic of the mesh was<br />

what drew us <strong>to</strong> Cambridge.<br />

The refinement the system<br />

brings <strong>to</strong> the student center<br />

is exactly what we hoped<br />

<strong>to</strong> achieve.<br />

Vance Cheatham<br />

Design Principal<br />

Perkins+Will Architects<br />

APPLICATION & BENEFITS<br />

Perkins+Will utilized Graph mesh<br />

throughout the project. For the building<br />

façade, Cambridge Architectural’s Rigid<br />

Mesh-in-Tension attachment system<br />

secured the mesh <strong>to</strong> the structure in two<br />

enormous side-by-side panels, each<br />

over 27 feet in height. Cambridge also<br />

blast-etched the University’s logo in<br />

the panels. The architect maintained<br />

continuity of design by incorporating<br />

the Graph mesh in<strong>to</strong> the adjacent stairwell<br />

and balcony railing infill panels. The overall<br />

result is a beautiful yet functional use<br />

of metal mesh as an advanced building<br />

material element.<br />

Perkins+Will designed the Texas A&M<br />

Memorial Student Center <strong>to</strong> be fully<br />

compliant with the Americans with<br />

Disabilities Act and <strong>to</strong> achieve LEED<br />

Silver standards.<br />

Cambridge mesh was chosen for its highquality<br />

appearance, sustainable features<br />

and fall-protection.<br />

21

ordinary walls<br />

wouldn’t do it<br />

justice<br />

University of Baltimore<br />

Law Center<br />

Baltimore, Maryland<br />

22

PROJECT<br />

A striking 33’ Shade mesh curtain designed<br />

and fabricated by Cambridge Architectural<br />

is a stunning centerpiece of the majestic<br />

John and Frances Angelos Law Center at<br />

the University of Baltimore. Commissioned<br />

by principal architect Behnisch Architekten<br />

<strong>to</strong> anchor the 7 th floor lobby in the almost<br />

200,000 square foot landmark building.<br />

The stainless steel metal space divider is<br />

one of the two applications produced by<br />

Cambridge at the $107 million Law Center.<br />

APPLICATION & BENEFITS<br />

Fabricated of Shade metal mesh and<br />

installed using Cambridge’s pioneering<br />

curtain attachment system, the 771 sq. ft.<br />

curtain conveys an ethereal aesthetic while<br />

providing strength. The flexible, open<br />

pattern optimizes light and ventilation.<br />

Designed also for ease of use, the mesh<br />

curtain moves smoothly and seamlessly<br />

along a concealed, ceiling mounted track.<br />

Cambridge developed a cus<strong>to</strong>mized<br />

anchor system <strong>to</strong> secure the draped<br />

mesh <strong>to</strong> the rollers.<br />

We wanted a sustainable<br />

solution in a durable<br />

curtain application.<br />

Cambridge’s stainless<br />

steel mesh satisfied these<br />

needs while exuding the<br />

elegant nature of a fabric<br />

curtain.<br />

Stefan Behnisch<br />

Partner,<br />

Behnisch Architekten<br />

Architect:<br />

Contrac<strong>to</strong>r:<br />

Installer:<br />

Owner:<br />

Mesh:<br />

Behnisch Architekten,<br />

Bos<strong>to</strong>n, Massachusetts<br />

Whiting Turner<br />

Baltimore<br />

Commercial Interiors<br />

Baltimore<br />

University of Baltimore<br />

Shade<br />

Attachment Curtain<br />

System:<br />

23

24<br />

remaining

at the <strong>to</strong>p<br />

of their game<br />

TopGolf<br />

Hous<strong>to</strong>n, Texas<br />

PROJECT<br />

TopGolf is the ultimate golf entertainment<br />

complex and the new Hous<strong>to</strong>n location is<br />

the company’s largest and most impressive,<br />

with 102 driving range hitting bays on three<br />

levels and a sprawling layout of bars, eateries<br />

and meeting rooms covering 65,000 square<br />

feet. At night, the front of the facility is awash<br />

with color, highlighted with the bright blue<br />

TopGolf logo, making for a most inviting<br />

entrance.<br />

APPLICATION & BENEFITS<br />

Panels of Cambridge Scale flexible mesh<br />

accent the building’s exterior and are<br />

mounted <strong>to</strong> the structure using our<br />

Eclipse attachment system. The mesh<br />

and attachment material is made of<br />

stainless steel, making it ideal for outdoor<br />

use and the textured surface of the mesh<br />

itself reflects brilliantly the multi-color<br />

LED lighting beamed up against it.<br />

Cambridge was willing <strong>to</strong> help us create the<br />

exact design we wanted. The mesh serves a<br />

dual function, at night it creates the backdrop<br />

for a sophisticated light show, and during the<br />

day it protects an interior decorative stair <strong>from</strong><br />

full sun exposure.<br />

Nicole Poole<br />

LEED AP, Project Designer,<br />

Aria Group Architects, Inc.<br />

Architect:<br />

Engineer:<br />

Contrac<strong>to</strong>r:<br />

Owner:<br />

Mesh:<br />

Aria Group Architects, Inc.<br />

Oak Park, IL<br />

Richard Adams Engineers<br />

& Consultants<br />

Terra Associates<br />

Arco/Murray<br />

TopGolf<br />

Scale<br />

Attachment Eclipse<br />

System:<br />

25

achieving<br />

a cooler shade of<br />

Awty International School<br />

Parking Facility, Hous<strong>to</strong>n, Texas<br />

26<br />

Architect:<br />

Engineer:<br />

Contrac<strong>to</strong>r:<br />

Owner:<br />

Mesh:<br />

Attachment<br />

System:<br />

Bailey Architects, Inc., Hous<strong>to</strong>n, Texas<br />

Haynes Whaley Associates, Hous<strong>to</strong>n, Texas<br />

Ellipse Builders<br />

The Awty International School<br />

Mid-Balance<br />

Eclipse

green<br />

PROJECT<br />

The Awty International School is the<br />

largest international prep school in<br />

the United States, with <strong>to</strong>tal enrollment<br />

of over 1,500 students. Awty’s rapid<br />

growth has spurred the need for facility<br />

expansion, including most recently a<br />

new 5-s<strong>to</strong>ry, 174,000 square foot parking<br />

facility with 440 additional spaces for<br />

faculty, staff, students and visi<strong>to</strong>rs.<br />

APPLICATION & BENEFITS<br />

Cambridge Architectural mesh was<br />

incorporated in<strong>to</strong> the exterior façade<br />

design of the parking facility by the<br />

architect not only for functionality<br />

(solar shading, headlight attenuation,<br />

fall protection, ventilation) but for the<br />

way it visually enhances the appearance<br />

of this large structure both by day and<br />

by night.<br />

Cambridge provided a turn-key<br />

solution by supplying the mesh and<br />

attachment components which offer<br />

a consistent, elegant look without<br />

having <strong>to</strong> bring multiple trades in<strong>to</strong><br />

the <strong>installation</strong>.<br />

Cambridge’s Mid-Balance mesh pattern<br />

and Eclipse attachment system was<br />

specified by the architect <strong>to</strong> create<br />

multiple vertical panels <strong>to</strong> cover the<br />

open areas of the garage. LED lighting<br />

was added <strong>to</strong> illuminate the mesh panels<br />

in Awty’s school color – green.<br />

Cope Bailey<br />

Vice President/Designer,<br />

Bailey Architects, Inc.<br />

27

mesh and attachments<br />

Cambridge’s woven metal fabrics come<br />

in dozens of unique repeating geometric<br />

patterns <strong>to</strong> suit any design. Many weaves<br />

change dramatically in appearance<br />

depending on the angle viewed.<br />

Several identical geometries are<br />

available in a variety of scales <strong>to</strong> match<br />

specific application requirements.<br />

Each Cambridge woven metal fabric<br />

pattern creates a distinct texture,<br />

allowing you <strong>to</strong> mix, match and<br />

contrast with other building materials.<br />

MESH<br />

Architectural mesh is offered in two<br />

basic types: flexible and rigid.<br />

Flexible mesh can be made in<strong>to</strong> flat<br />

panels held in tension by attachments.<br />

Some flexible mesh patterns are used<br />

<strong>to</strong> produce huge panels, up <strong>to</strong> 20’ wide<br />

and 100’ tall. Flexible mesh can also<br />

be hung like drapery <strong>from</strong> a curtain<br />

attachment system. Rigid mesh is<br />

typically framed but some patterns<br />

can also be held in tension.<br />

Rigid mesh patterns with minimal<br />

open area are typically mounted <strong>to</strong> a<br />

Medium Density Fiberboard (MDF)<br />

substrate and joined <strong>to</strong> the substructure.<br />

ATTACHMENTS<br />

Cambridge Architectural’s hardware<br />

and attachment systems are specifically<br />

designed <strong>to</strong> be compatible with our<br />

metal mesh fabrics.<br />

28

FLEXIBLE MESH<br />

ALLIANCE3<br />

Material: Stainless Steel<br />

Open Area: 73.4%<br />

Weight: 2.84 lbs./sq. ft.<br />

Max. Width: 144”<br />

Patent Pending<br />

AZTEC<br />

Material: Stainless Steel<br />

Open Area: 90%<br />

Weight: 0.8 lbs./sq. ft.<br />

Max. Width: 120”<br />

29

FLEXIBLE MESH<br />

BALANCE<br />

Material: Stainless Steel<br />

Open Area: 55%<br />

Weight: 2.01 lbs./sq. ft.<br />

Max. Width: 240”<br />

BRAID<br />

Material: Stainless Steel<br />

Open Area: 65%<br />

Weight: 1.80 lbs./sq. ft.<br />

Max. Width: 240”<br />

30

FLEXIBLE MESH<br />

CUBIST<br />

Material: Stainless Steel<br />

Open Area: 83%<br />

Weight: 1.85 lbs./sq. ft.<br />

Max. Width: 144”<br />

DIAMOND<br />

Material: Stainless Steel<br />

Open Area: 65%<br />

Weight: 1.4 lbs./sq. ft.<br />

Max. Width: 240”<br />

31

FLEXIBLE MESH<br />

MATTE<br />

Material: Stainless Steel<br />

Open Area: 50%<br />

Weight: 1.06 lbs./sq. ft.<br />

Max. Width: 240”<br />

MID-BALANCE<br />

Material: Stainless Steel<br />

Open Area: 61%<br />

Weight: 1.57 lbs./sq. ft.<br />

Max. Width: 240”<br />

32

FLEXIBLE MESH<br />

MID-SHADE<br />

Material: Stainless Steel<br />

Open Area: 54%<br />

Weight: 1.4 lbs./sq. ft.<br />

Max. Width: 240”<br />

PELLICAN<br />

Material: Stainless Steel<br />

Open Area: 36%<br />

Weight: 2.5 lbs./sq. ft.<br />

Max. Width: 240”<br />

33

FLEXIBLE MESH<br />

RITZ<br />

Material: Stainless Steel<br />

Open Area: 1%<br />

Weight: 3.90 lbs./sq. ft.<br />

Max. Width: 120”<br />

ROPE<br />

Material: Stainless Steel<br />

Open Area: 42%<br />

Weight: 2.25 lbs./sq. ft.<br />

Max. Width: 240”<br />

34

FLEXIBLE MESH<br />

SCALE<br />

Material: Stainless Steel<br />

Open Area: 66%<br />

Weight: 1.94 lbs./sq. ft.<br />

Max. Width: 240”<br />

SHADE<br />

Material: Stainless Steel<br />

Open Area: 43%<br />

Weight: 0.94 lbs./sq. ft.<br />

Max. Width: 240”<br />

35

FLEXIBLE MESH<br />

SLINK<br />

Material: Stainless Steel<br />

Open Area: 32%<br />

Weight: 1.5 lbs./sq. ft.<br />

Max. Width: 120”<br />

STRAND<br />

Material: Stainless Steel<br />

Open Area: 76%<br />

Weight: 0.75 lbs./sq. ft.<br />

Max. Width: 120”<br />

36

FLEXIBLE MESH<br />

STRIPE ®<br />

Material: Stainless Steel<br />

Open Area: 54%<br />

Weight: 1.70 lbs./sq. ft.<br />

Max. Width: 240”<br />

TWEED<br />

Material: Stainless Steel,<br />

Brass<br />

Open Area: 1%<br />

Weight: 4.00 lbs./sq. ft.<br />

Max. Width: 72”<br />

37

FLEXIBLE MESH<br />

VINE<br />

Material: Stainless Steel<br />

Open Area: 32%<br />

Weight: 1.50 lbs./sq. ft.<br />

Max. Width: 120”<br />

RIGID MESH<br />

BEAD<br />

Material: Stainless Steel,<br />

Brass<br />

Open Area: 32%<br />

Weight: 1.81 lbs./sq. ft.<br />

Max. Width: 72”<br />

Thickness: 0.135”<br />

Large Pho<strong>to</strong>: Bead 880SB<br />

38<br />

BEAD 880S

RIGID MESH<br />

CHANNEL<br />

Material: Stainless Steel,<br />

Brass<br />

Open Area: 0%<br />

Weight: 4.00 lbs./sq. ft.<br />

Max. Width: 120”<br />

Thickness: 0.21”<br />

Large Pho<strong>to</strong>: Channel 29SS<br />

CHANNEL 29K<br />

CHANNEL 135A<br />

CHAOS<br />

Material: Stainless Steel<br />

Open Area: 69%<br />

Weight: 1.38 lbs./sq. ft.<br />

Max. Width: 120”<br />

39

RIGID MESH<br />

CIRCUIT<br />

Material: Stainless Steel,<br />

Brass<br />

Open Area: 0%<br />

Weight: 3.38 lbs./sq. ft.<br />

Max. Width: 60”<br />

Thickness: 0.196”<br />

Large Pho<strong>to</strong>: Circuit 114A<br />

CIRCUIT 105A CIRCUIT 108A CIRCUIT 113A CIRCUIT 141A<br />

GRAPH<br />

Material: Stainless Steel<br />

Open Area: 25%<br />

Weight: 1.90 lbs./sq. ft.<br />

Max. Width: 120”<br />

Thickness: 0.105”<br />

40

RIGID MESH<br />

HASHTAG<br />

Material: Stainless Steel<br />

Open Area: 45%<br />

Weight: 1.368 lbs./sq. ft.<br />

Max. Width: 96”<br />

Thickness: 0.102”<br />

INFINITY<br />

Material: Stainless Steel,<br />

Brass<br />

Open Area: 58%<br />

Weight: 2.00 lbs./sq. ft.<br />

Max. Width: 60”<br />

Thickness: 0.225”<br />

Large Pho<strong>to</strong>: Infinity 507A<br />

INFINITY 504A INFINITY 506A INFINITY 508A INFINITY 510A INFINITY 512A INFINITY 516A<br />

41

RIGID MESH<br />

PLAIT<br />

Material: Stainless Steel<br />

Open Area: 64%<br />

Weight: 1.80 lbs./sq. ft.<br />

Max. Height: 120”<br />

Thickness: 0.370”<br />

PLANK<br />

Material: Stainless Steel<br />

Open Area: 56%<br />

Weight: 1.30 lbs./sq. ft.<br />

Max. Height: 96”<br />

Thickness: 0.225”<br />

42

RIGID MESH<br />

PLAZA<br />

Material: Stainless Steel,<br />

Brass<br />

Open Area: 18%<br />

Weight: 3.70 lbs./sq. ft.<br />

Max. Width: 60”<br />

Thickness: 0.225”<br />

Large Pho<strong>to</strong>: Plaza 75A<br />

PLAZA 70A PLAZA 75B PLAZA 78A<br />

RANGE<br />

Material: Stainless Steel<br />

Open Area: 42%<br />

Weight: 2.08 lbs./sq. ft.<br />

Max. Height: 120”<br />

43

RIGID MESH<br />

RIDGE<br />

Material: Stainless Steel<br />

Open Area: 40%<br />

Weight: 1.48 lbs./sq. ft.<br />

Max. Height: 96”<br />

Thickness: 0.13”<br />

SAWGRASS<br />

Material: Stainless Steel<br />

Open Area: 0%<br />

Weight: 3.57 lbs./sq. ft.<br />

Max. Width: 60”<br />

Thickness: 0.13”<br />

Large Pho<strong>to</strong>: Sawgrass 88A<br />

44<br />

Sawgrass 32a Sawgrass 33B Sawgrass 51a Sawgrass 51B Sawgrass 88B

RIGID MESH<br />

STIPPLE<br />

Material: Stainless Steel,<br />

Brass<br />

Open Area: 0%<br />

Weight: 3.57 lbs./sq. ft.<br />

Max. Width: 60”<br />

Thickness: 0.13”<br />

Large Pho<strong>to</strong>: Stipple 19A<br />

STIPPLE 11A STIPPLE 11B STIPPLE 12A STIPPLE 12B STIPPLE 19B STIPPLE 19H<br />

TARTAN<br />

Material: Stainless Steel<br />

Open Area: 77%<br />

Weight: 1.0 lbs./sq. ft.<br />

Max. Width: 120”<br />

45

RIGID MESH<br />

THATCH<br />

Material: Stainless Steel<br />

Open Area: 62%<br />

Weight: 1.5 lbs./sq. ft.<br />

Max. Height: 120”<br />

TIDAL<br />

Material: Stainless Steel,<br />

Brass<br />

Open Area: 0%<br />

Weight: 3.70 lbs./sq. ft.<br />

Max. Width: 60”<br />

Thickness: 0.193”<br />

Large Pho<strong>to</strong>: Tidal 96A<br />

46 TIDAL 79B TIDAL 79BB TIDAL 95A TIDAL 108A

RIGID MESH<br />

TILE<br />

Material: Stainless Steel,<br />

Brass, Copper<br />

Open Area: 6%<br />

Weight: 3.9 lbs./sq. ft.<br />

Max. Width: 60”<br />

Thickness: 0.125”<br />

Large Pho<strong>to</strong>: Tile 50B<br />

TILE 35A TILE 35B TILE 50A TILE 52A TILE 52B TILE 501A<br />

TIMBER<br />

Material: Stainless Steel<br />

Open Area: 58%<br />

Weight: 1.58 lbs./sq. ft.<br />

Max. Height: 120”<br />

47

RIGID MESH<br />

TREO<br />

Material: Stainless Steel<br />

Open Area: 60%<br />

Weight: 1.63 lbs./sq. ft.<br />

Max. Width: 120”<br />

Thickness: 0.360”<br />

VILLA<br />

Material: Stainless Steel<br />

Open Area: 0%<br />

Weight: 2.1 lbs./sq. ft.<br />

Max. Height: 72”<br />

Thickness: 0.155”<br />

48

ATTACHMENT<br />

CURTAIN<br />

ATTACHMENT<br />

SWIVEL<br />

ASSEMBLY<br />

ARCHITECTURAL<br />

MESH<br />

Curtain attachment hardware<br />

attaches flexible metal fabric<br />

<strong>to</strong> carriers and permits it <strong>to</strong><br />

roll smoothly along the track<br />

length as a window treatment<br />

or draping space divider.<br />

Flexible metal fabrics are<br />

hung sideways <strong>to</strong> maximize the<br />

draping effect. This attachment<br />

hardware can also be specified<br />

for mo<strong>to</strong>rized operation, where<br />

the curtain of metal fabric is<br />

opened or closed with the<br />

<strong>to</strong>uch of a but<strong>to</strong>n.<br />

COMPATIBLE MESH<br />

Diamond<br />

Mid-Balance<br />

Mid-Shade<br />

Scale<br />

Shade<br />

Slink<br />

Stripe<br />

TOP<br />

ATTACHMENT<br />

ECLIPSE<br />

INTERMEDIATE<br />

ATTACHMENT<br />

AS REQUIRED<br />

Eclipse tension attachment<br />

hardware provides tailored<br />

edges for expanses of flexible<br />

metal fabric. Elegant, cus<strong>to</strong>m<br />

cut apertures receive the metal<br />

fabric ends in tubing that is<br />

integrated in<strong>to</strong> a bracket and<br />

structural support design.<br />

The tube provides a visual<br />

reveal between panel lengths,<br />

and tube sizes may vary <strong>to</strong><br />

emphasize or de-emphasize<br />

the attachment. Eclipse is<br />

appropriate for lengths of<br />

metal fabric up <strong>to</strong> 100’.<br />

BOTTOM<br />

ATTACHMENT<br />

COMPATIBLE MESH<br />

FRONT VIEW<br />

SIDE VIEW<br />

Alliance3<br />

Balance<br />

Braid<br />

Cubist<br />

Diamond<br />

Matte<br />

Mid-Balance<br />

Mid-Shade<br />

Pellican<br />

Rope<br />

Scale<br />

Shade<br />

Slink<br />

Stripe<br />

*Patent Pending<br />

49

ATTACHMENT<br />

EYEBOLT<br />

The Eyebolt attachment is<br />

a less elegant but lower<br />

cost mesh mounting system.<br />

Contact your Cambridge<br />

Architectural representative<br />

for weight load limitations.<br />

COMPATIBLE MESH<br />

Alliance3<br />

Balance<br />

Braid<br />

Cubist<br />

Diamond<br />

Matte<br />

Mid-Balance<br />

Mid-Shade<br />

Pellican<br />

Rope<br />

Scale<br />

Shade<br />

Slink<br />

Stripe<br />

SIDE VIEW<br />

BUSHING<br />

SPRING<br />

SPRING<br />

BUSHING<br />

LOCK NUT<br />

A<br />

MESH<br />

EYEBOLT<br />

C-CHANNEL<br />

FRONT VIEW<br />

PANEL<br />

Panel attachment hardware<br />

fastens closed metal fabric <strong>to</strong><br />

a substrate such as Medium<br />

Density Fiberboard (MDF).<br />

Z-clips join panels <strong>to</strong> the<br />

substructure<br />

COMPATIBLE MESH<br />

Channel<br />

Circuit<br />

Plaza<br />

Ritz<br />

Sawgrass<br />

Stipple<br />

Tidal<br />

Tile<br />

Tweed<br />

Villa<br />

50

ATTACHMENT<br />

METAL FABRIC ALONG<br />

STAIRWAYS OR INCLINES<br />

TO RUN PARALLEL TO SLOPE<br />

HANDRAIL<br />

METAL FABRIC PANEL<br />

RAILFLEX <br />

Railflex tension attachment<br />

hardware is specifically designed<br />

for handrail systems. The ends<br />

of flexible metal fabric panels<br />

are concealed in handrail tubing,<br />

allowing for a seamless transition<br />

<strong>from</strong> rail <strong>to</strong> flexible mesh. Cus<strong>to</strong>mcut<br />

apertures receive the metal<br />

fabric in the handrail tubing<br />

which is integrated in<strong>to</strong> a bracket<br />

and structural support design.<br />

COMPATIBLE MESH<br />

Alliance3<br />

Balance<br />

Cubist<br />

Diamond<br />

Mid-Balance<br />

Mid-Shade<br />

Pellican<br />

Scale<br />

Shade<br />

Slink<br />

Stripe<br />

RIGID MESH-IN-TENSION<br />

Rigid Mesh-In-Tension<br />

attachment hardware is<br />

specifically designed for<br />

the mounting of rigid mesh<br />

panels <strong>to</strong> a structure without<br />

additional framing. Eclipse,<br />

clevis and hem versions are<br />

offered.<br />

FRONT VIEW<br />

SECTION VIEW<br />

COMPATIBLE MESH<br />

Chaos<br />

Hashtag<br />

Graph<br />

Plait<br />

Plank<br />

Range<br />

Ridge<br />

Tartan<br />

Thatch<br />

Timber<br />

Treo<br />

51

ATTACHMENT<br />

SCROLL<br />

Scroll tension attachment<br />

hardware keeps the focus<br />

on the metal fabric by hiding<br />

the attachment behind it.<br />

Scroll conceals the bracket<br />

that attaches <strong>to</strong> the structural<br />

support. Scroll uniquely grips<br />

the metal fabric, holding it in<br />

tension. Scroll is appropriate<br />

for lengths of metal fabric<br />

up <strong>to</strong> 100’.<br />

TOP<br />

ATTACHMENT<br />

INTERMEDIATE<br />

ATTACHMENT<br />

AS REQUIRED<br />

COMPATIBLE MESH<br />

Alliance3<br />

Braid<br />

Cubist<br />

Diamond<br />

Matte<br />

Mid-Balance<br />

Mid-Shade<br />

Rope<br />

Scale<br />

Shade<br />

Slink<br />

Stripe<br />

FRONT VIEW<br />

SIDE VIEW<br />

BOTTOM<br />

ATTACHMENT<br />

*U.S. Patent Number 7,779,888<br />

TABLEAU<br />

Tableau attachment hardware<br />

folds metal fabric around<br />

the corners of an angle frame<br />

for an elegant concealed<br />

attachment.<br />

COMPATIBLE MESH<br />

Bead<br />

Chaos<br />

Graph<br />

Hashtag<br />

Infinity<br />

Plait<br />

Plank<br />

Range<br />

Ridge<br />

Tartan<br />

Thatch<br />

Tile<br />

Timber<br />

Treo<br />

Villa<br />

52

ATTACHMENT<br />

U FRAME<br />

With U Frame attachment<br />

hardware, metal fabric is tack<br />

welded <strong>to</strong> a u-binding frame<br />

with mitered corners that are<br />

welded and ground smooth<br />

for a brushed finish.<br />

COMPATIBLE MESH<br />

Bead<br />

Channel<br />

Chaos<br />

Circuit<br />

Graph<br />

Hashtag<br />

Infinity<br />

Plait<br />

Plank<br />

Plaza<br />

Range<br />

Ridge<br />

Ritz<br />

Sawgrass<br />

Stipple<br />

Tartan<br />

Thatch<br />

Tidal<br />

Tile<br />

Timber<br />

Treo<br />

Tweed<br />

Villa<br />

VELOCITY<br />

Velocity tension attachment<br />

hardware is engineered<br />

specifically for coastal areas<br />

that are subject <strong>to</strong> hurricane<br />

force winds. The certified<br />

attachment is designed <strong>to</strong><br />

re-tension the metal fabric<br />

au<strong>to</strong>matically after high<br />

wind conditions have passed.<br />

The attachment can also be<br />

specified <strong>to</strong> protect property<br />

and people <strong>from</strong> materials<br />

that are propelled at a building<br />

during high wind conditions.<br />

COMPATIBLE MESH<br />

Alliance3<br />

Balance<br />

Braid<br />

Cubist<br />

Diamond<br />

Mid-Balance<br />

Mid-Shade<br />

Pellican<br />

Scale<br />

Shade<br />

Stripe<br />

*U.S. Patent Number 8,579,009<br />

53

the future<br />

So, what does the future hold for<br />

architecture and interior design? Surely<br />

it will lead us down a path of continued<br />

innovation and an enlightened use of<br />

advanced building materials. Woven<br />

metal mesh has the opportunity <strong>to</strong> play<br />

a pivotal role in this evolution and we at<br />

Cambridge Architectural look forward<br />

<strong>to</strong> that challenge.<br />

We are dedicated <strong>to</strong> continuous new<br />

product development; <strong>to</strong> the introduction<br />

of new mesh patterns, finishes, materials<br />

and systems; <strong>to</strong> identifying exciting new<br />

applications for our products; and <strong>to</strong><br />

stretching the boundaries of our thinking.<br />

But we realize that true innovation doesn’t<br />

happen in a vacuum and the best ideas<br />

often arise <strong>from</strong> our collaboration with the<br />

architectural and design community. So we<br />

look forward <strong>to</strong> working with you and are<br />

open <strong>to</strong> your ideas.<br />

Imagine Cambridge Architectural mesh in<br />

your future. Contact us and discover how<br />

we can transform your design vision in<strong>to</strong><br />

an architectural and engineering marvel.<br />

What would you like <strong>to</strong> build?<br />

54

of mesh<br />

PHOTOS: Top Left-LSU Student Union, Ba<strong>to</strong>n Rouge, Louisiana; Bot<strong>to</strong>m Left-Air Force Academy, Colorado Springs, Colorado;<br />

Right-McCarran International Airport, Las Vegas, Nevada<br />

55

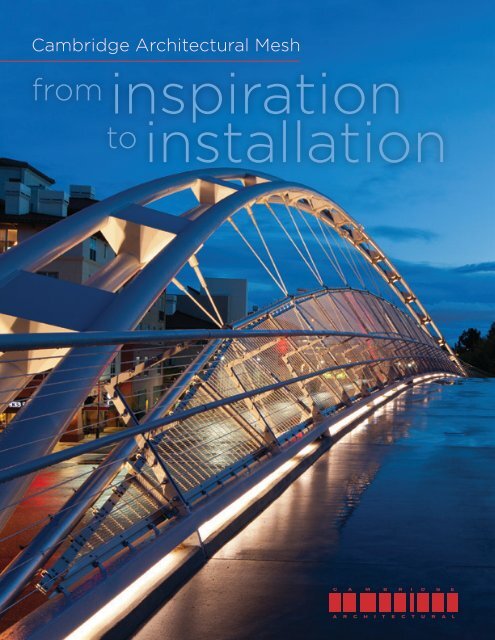

Front Cover:<br />

Iron Horse Trail Pedestrian Bridge<br />

Pleasant Hill, California<br />

Architect: Donald MacDonald Architects,<br />

San Francisco, California<br />

Cambridge Architectural<br />

105 Goodwill Road<br />

Cambridge, MD 21613<br />

Toll Free 866 806 2385<br />

Intl. 00+1-410-901-8686<br />

CambridgeArchitectural.com<br />

/CambridgeArchitectural @CambridgeArch /CambridgeArch1