Annual Report 2008-2009 - Bharat Petroleum

Annual Report 2008-2009 - Bharat Petroleum

Annual Report 2008-2009 - Bharat Petroleum

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

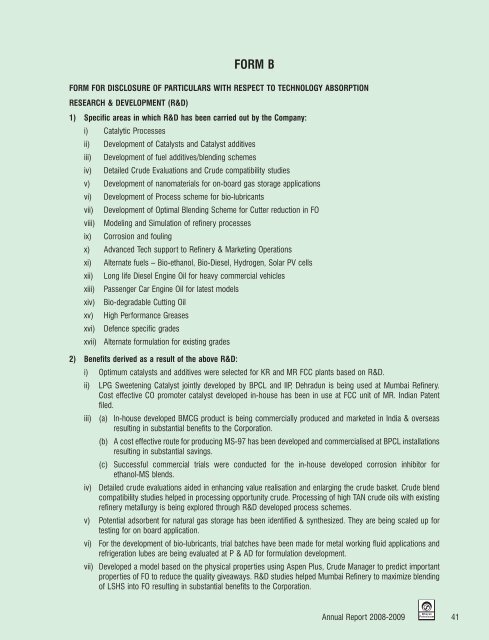

FORM B<br />

FORM FOR DISCLOSURE OF PARTICULARS WITH RESPECT TO TECHNOLOGY ABSORPTION<br />

RESEARCH & DEVELOPMENT (R&D)<br />

1) Specific areas in which R&D has been carried out by the Company:<br />

i) Catalytic Processes<br />

ii) Development of Catalysts and Catalyst additives<br />

iii) Development of fuel additives/blending schemes<br />

iv) Detailed Crude Evaluations and Crude compatibility studies<br />

v) Development of nanomaterials for on-board gas storage applications<br />

vi) Development of Process scheme for bio-lubricants<br />

vii) Development of Optimal Blending Scheme for Cutter reduction in FO<br />

viii) Modeling and Simulation of refinery processes<br />

ix) Corrosion and fouling<br />

x) Advanced Tech support to Refinery & Marketing Operations<br />

xi) Alternate fuels – Bio-ethanol, Bio-Diesel, Hydrogen, Solar PV cells<br />

xii) Long life Diesel Engine Oil for heavy commercial vehicles<br />

xiii) Passenger Car Engine Oil for latest models<br />

xiv) Bio-degradable Cutting Oil<br />

xv) High Performance Greases<br />

xvi) Defence specific grades<br />

xvii) Alternate formulation for existing grades<br />

2) Benefits derived as a result of the above R&D:<br />

i) Optimum catalysts and additives were selected for KR and MR FCC plants based on R&D.<br />

ii) LPG Sweetening Catalyst jointly developed by BPCL and IIP, Dehradun is being used at Mumbai Refinery.<br />

Cost effective CO promoter catalyst developed in-house has been in use at FCC unit of MR. Indian Patent<br />

filed.<br />

iii) (a) In-house developed BMCG product is being commercially produced and marketed in India & overseas<br />

resulting in substantial benefits to the Corporation.<br />

(b) A cost effective route for producing MS-97 has been developed and commercialised at BPCL installations<br />

resulting in substantial savings.<br />

(c) Successful commercial trials were conducted for the in-house developed corrosion inhibitor for<br />

ethanol-MS blends.<br />

iv) Detailed crude evaluations aided in enhancing value realisation and enlarging the crude basket. Crude blend<br />

compatibility studies helped in processing opportunity crude. Processing of high TAN crude oils with existing<br />

refinery metallurgy is being explored through R&D developed process schemes.<br />

v) Potential adsorbent for natural gas storage has been identified & synthesized. They are being scaled up for<br />

testing for on board application.<br />

vi) For the development of bio-lubricants, trial batches have been made for metal working fluid applications and<br />

refrigeration lubes are being evaluated at P & AD for formulation development.<br />

vii) Developed a model based on the physical properties using Aspen Plus, Crude Manager to predict important<br />

properties of FO to reduce the quality giveaways. R&D studies helped Mumbai Refinery to maximize blending<br />

of LSHS into FO resulting in substantial benefits to the Corporation.<br />

<strong>Annual</strong> <strong>Report</strong> <strong>2008</strong>-<strong>2009</strong> 41