Annual Report 2008-2009 - Bharat Petroleum

Annual Report 2008-2009 - Bharat Petroleum

Annual Report 2008-2009 - Bharat Petroleum

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

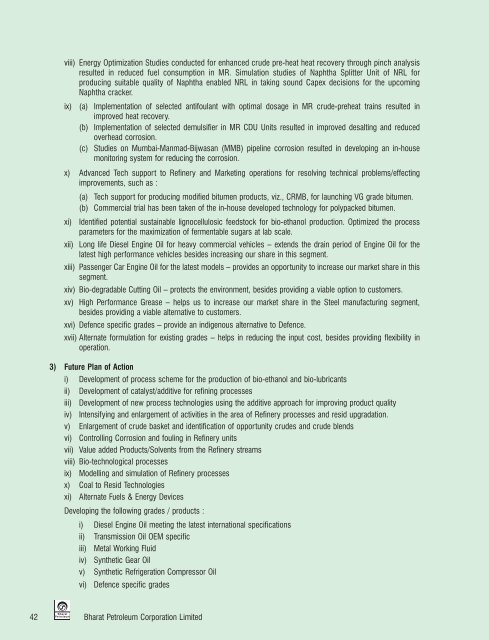

viii) Energy Optimization Studies conducted for enhanced crude pre-heat heat recovery through pinch analysis<br />

resulted in reduced fuel consumption in MR. Simulation studies of Naphtha Splitter Unit of NRL for<br />

producing suitable quality of Naphtha enabled NRL in taking sound Capex decisions for the upcoming<br />

Naphtha cracker.<br />

ix) (a) Implementation of selected antifoulant with optimal dosage in MR crude-preheat trains resulted in<br />

improved heat recovery.<br />

(b) Implementation of selected demulsifier in MR CDU Units resulted in improved desalting and reduced<br />

overhead corrosion.<br />

(c) Studies on Mumbai-Manmad-Bijwasan (MMB) pipeline corrosion resulted in developing an in-house<br />

monitoring system for reducing the corrosion.<br />

x) Advanced Tech support to Refinery and Marketing operations for resolving technical problems/effecting<br />

improvements, such as :<br />

(a) Tech support for producing modified bitumen products, viz., CRMB, for launching VG grade bitumen.<br />

(b) Commercial trial has been taken of the in-house developed technology for polypacked bitumen.<br />

xi) Identified potential sustainable lignocellulosic feedstock for bio-ethanol production. Optimized the process<br />

parameters for the maximization of fermentable sugars at lab scale.<br />

xii) Long life Diesel Engine Oil for heavy commercial vehicles – extends the drain period of Engine Oil for the<br />

latest high performance vehicles besides increasing our share in this segment.<br />

xiii) Passenger Car Engine Oil for the latest models – provides an opportunity to increase our market share in this<br />

segment.<br />

xiv) Bio-degradable Cutting Oil – protects the environment, besides providing a viable option to customers.<br />

xv) High Performance Grease – helps us to increase our market share in the Steel manufacturing segment,<br />

besides providing a viable alternative to customers.<br />

xvi) Defence specific grades – provide an indigenous alternative to Defence.<br />

xvii) Alternate formulation for existing grades – helps in reducing the input cost, besides providing flexibility in<br />

operation.<br />

3) Future Plan of Action<br />

i) Development of process scheme for the production of bio-ethanol and bio-lubricants<br />

ii) Development of catalyst/additive for refining processes<br />

iii) Development of new process technologies using the additive approach for improving product quality<br />

iv) Intensifying and enlargement of activities in the area of Refinery processes and resid upgradation.<br />

v) Enlargement of crude basket and identification of opportunity crudes and crude blends<br />

vi) Controlling Corrosion and fouling in Refinery units<br />

vii) Value added Products/Solvents from the Refinery streams<br />

viii) Bio-technological processes<br />

ix) Modelling and simulation of Refinery processes<br />

x) Coal to Resid Technologies<br />

xi) Alternate Fuels & Energy Devices<br />

Developing the following grades / products :<br />

i) Diesel Engine Oil meeting the latest international specifications<br />

ii) Transmission Oil OEM specific<br />

iii) Metal Working Fluid<br />

iv) Synthetic Gear Oil<br />

v) Synthetic Refrigeration Compressor Oil<br />

vi) Defence specific grades<br />

42 <strong>Bharat</strong> <strong>Petroleum</strong> Corporation Limited