Whole salmon grading and distribution system - Marel

Whole salmon grading and distribution system - Marel

Whole salmon grading and distribution system - Marel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

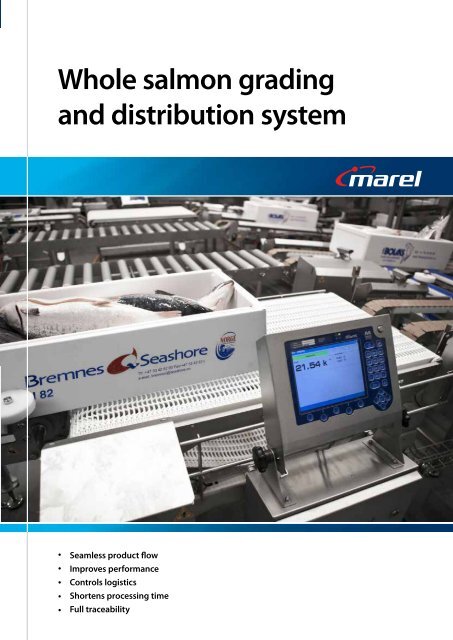

<strong>Whole</strong> <strong>salmon</strong> <strong>grading</strong><br />

<strong>and</strong> <strong>distribution</strong> <strong>system</strong><br />

Seamless product flow<br />

Improves performance<br />

Controls logistics<br />

Shortens processing time<br />

Full traceability

<strong>Whole</strong> <strong>salmon</strong> <strong>grading</strong><br />

<strong>and</strong> <strong>distribution</strong> <strong>system</strong><br />

Building on over 30 years of experience working in teampartnerships<br />

with fish processors large <strong>and</strong> small worldwide, <strong>Marel</strong><br />

has gained extensive knowledge in developing innovative<br />

processing solutions to fulfill the ever-changing needs of seafood<br />

processors.<br />

<strong>Marel</strong> is now introducing a highly advanced whole-<strong>salmon</strong><br />

<strong>grading</strong> <strong>and</strong> <strong>distribution</strong> <strong>system</strong> that features a seamless flow of<br />

<strong>salmon</strong> product all the way from slaughtering through processing<br />

to dispatching.<br />

It is the most advanced <strong>and</strong> innovative <strong>distribution</strong> <strong>system</strong> that<br />

<strong>Marel</strong> has ever developed for <strong>salmon</strong>. The <strong>system</strong>’s remarkably<br />

high level of automation ensures flexible processing capacity<br />

to meet seasonal- or order-book highs <strong>and</strong> lows – without<br />

pressures to increase or decrease the workforce.<br />

The comprehensive <strong>system</strong> consists of two distinct<br />

processing areas: a gutting area, <strong>and</strong> a packing <strong>and</strong><br />

<strong>distribution</strong> area. In addition, the complete <strong>system</strong> is<br />

powered by <strong>Marel</strong>’s INNOVA production management<br />

software, which enables managerial overview <strong>and</strong> control of<br />

every stage of the production process.<br />

The <strong>system</strong> can h<strong>and</strong>le an average of 120 fish per minute, or<br />

about 55,000 fish daily.<br />

Gutting area<br />

After slaughtering, <strong>salmon</strong> enters the gutting area where quality inspectors feed them into a dual-lane<br />

gutting grader. The grader weighs to high accuracy, <strong>and</strong> then directs the right size <strong>and</strong> quality of fish to<br />

the optimal gutting machines based on fixed-rate function, which ensures the optimal performance of<br />

gutting machines. The feeding into the gutters is fully automatic.<br />

By combining the optimized <strong>distribution</strong> of fish with automatic feeding into the gutting machines,<br />

overall performance of the gutting process is considerably improved. Moreover, the need for manual<br />

labor is significantly reduced - only one supervisor is needed to oversee the entire gutting <strong>system</strong>.<br />

The <strong>system</strong> has a capacity of up to 120 fish/min, <strong>and</strong> easily h<strong>and</strong>les the combined output rate of the<br />

seven gutting machines.<br />

Packing <strong>and</strong> <strong>distribution</strong> area<br />

The gutted fish enters the packing area. Salmon then pass through quality control where they are<br />

examined for any defects in appearance, before entering the whole-fish packing <strong>and</strong> <strong>distribution</strong> grader.<br />

The highly advanced <strong>grading</strong> <strong>and</strong> <strong>distribution</strong> <strong>system</strong> automatically controls the <strong>distribution</strong> of each fish,<br />

directing it to the optimum process, for example freezing, filleting, or to the automatic box filling station for<br />

whole gutted <strong>salmon</strong>.<br />

The <strong>distribution</strong> is based on weight <strong>and</strong> quality, <strong>and</strong> it is also possible to apply the condition factor<br />

(K-factor) to direct specially designated fish to pre-determined processing stations. This can be of great<br />

value for the filleting process where fish of similar condition (size) will provide improved yield <strong>and</strong> quality of<br />

finished products.<br />

With all of the plant’s logistics operating on <strong>Marel</strong>’s Innova production management software, the<br />

<strong>distribution</strong> to the various processes will also be matched to purchase orders.<br />

The <strong>system</strong> h<strong>and</strong>les up to 120 fish/minute, <strong>and</strong> box packing has a capacity of up to 28 boxes per minute.

Packing <strong>and</strong> <strong>distribution</strong> grader<br />

• Distribution control to different processes<br />

• K-factor optimized yield management<br />

• Capacity: up to 120 fish/min, 28 boxes/min<br />

Elevator to palletizing<br />

Rework station<br />

Box packing<br />

Automatic infeed of br<strong>and</strong>ed boxes. Boxes<br />

automatically fed to match batches from grader<br />

<strong>and</strong> pre-defined target weight based on PO (28<br />

boxes/minute)<br />

<strong>Whole</strong> fish grader<br />

Distributes up to 120 fish/min to<br />

different processes <strong>and</strong> creates batches<br />

of whole fish based on PO<br />

Ergonomic infeed<br />

Up to four quality inspectors feed<br />

fish into gutting grader<br />

Dynamic weighing<br />

For weight <strong>grading</strong> of each fish

Seamless flow of <strong>salmon</strong> product all<br />

the way from slaughtering through<br />

processing to dispatching.<br />

Palletizing<br />

Robots automatically load boxes<br />

on pallets according to PO<br />

Ergonomic infeed<br />

Up to four quality inspectors<br />

feeding fish into grader<br />

Cooling tank<br />

Manual gutting<br />

Automatic gutting<br />

Fish slides gently, correctly aligned into infeed<br />

buffer from where it is automatically fed into<br />

the gutting machine<br />

If the gutting machine misses or rejects a fish,<br />

the machine will automatically pause while<br />

the fish is re-directed to manual gutting<br />

Gutting grader<br />

Grading<br />

• Fully automatic infeed into gutters<br />

• Optimised utilisation of gutters<br />

• Capacity: up to 120 fish/min<br />

Dual-lane gutting grader directs fish<br />

to the optimal gutting machine,<br />

based on fixed rate function

Customer corner<br />

Bremnes, Norway<br />

When Norwegian <strong>salmon</strong> processor Bremnes Seashore embarked on a<br />

major upgrade of its Bømlo plant, the project included a whole <strong>salmon</strong><br />

<strong>grading</strong> <strong>and</strong> <strong>distribution</strong> <strong>system</strong>, the most advanced <strong>distribution</strong> <strong>system</strong><br />

that <strong>Marel</strong> has ever installed in a <strong>salmon</strong> factory.<br />

Bremnes was founded in 1937 on the isl<strong>and</strong> of Bømlo<br />

just off Norway’s southwest coast as a seaweed<br />

reception plant. Since 1958, the company has been<br />

producing farmed <strong>salmon</strong>, <strong>and</strong> is a pioneer in Norway’s<br />

aquaculture industry. Today, Bremnes operates <strong>salmon</strong><br />

farms at 22 locations in the Stavanger-Hardanger<br />

region, processing some 250 tons of live <strong>salmon</strong> daily<br />

– into 100 different products sold worldwide, many of<br />

them under the company’s own multi-award winning<br />

Salma <strong>and</strong> Bømlo br<strong>and</strong>s.<br />

Achieving optimum quality<br />

“The main reasons behind the upgrade are to boost<br />

production capacity of gutted <strong>salmon</strong>, <strong>and</strong> to exp<strong>and</strong><br />

production of value-added products, such as fillets,<br />

while maintaining our focus on high-quality wholefish<br />

products,” says Vidar Helvik, Bremnes Seashore<br />

Processing Manager.<br />

“For <strong>salmon</strong> processors, speed <strong>and</strong> temperature are<br />

essential to achieving optimum product quality <strong>and</strong><br />

consistency. To ensure this,” adds Vidar Helvik, “fish are<br />

kept at a constant year-round temperature before being<br />

slaughtered, <strong>and</strong> high-speed processing keeps them at<br />

a quality-retaining low temperature.<br />

A powerful combination<br />

The equipment, as well as all of the plant’s logistics, operates<br />

with <strong>Marel</strong>’s INNOVA production management software,<br />

which provides managerial overview <strong>and</strong> control of every<br />

stage of the production process, including quality control,<br />

order processing <strong>and</strong> packing. At the same time, INNOVA<br />

provides Bremnes’ customers with complete traceability for<br />

every fish – from the time they are hatched until they leave<br />

the factory as a processed product.<br />

“The new <strong>system</strong> gives us the option of processing several<br />

different types of products at the same time, resulting in<br />

an uninterrupted flow of product on-line, while INNOVA<br />

provides us with logistics relating to production planning,<br />

packing, labeling <strong>and</strong> registration for a variety of purposes,<br />

among them traceability,” explains Bremnes Seashore COO,<br />

Bjørn Willy Sæverud.<br />

He continues: “Each fish that leaves our factory can be traced<br />

back to the egg from which it was hatched, <strong>and</strong> the labeling<br />

on our boxes has bar-coded data on a host of details, for<br />

example size, quality, tracking number, packing date/plant<br />

<strong>and</strong> shelf life, among other key information.“<br />

“Our objective is supplying higher-quality products for<br />

customers worldwide, with a stronger mix of valueadded<br />

products. <strong>Marel</strong> equipment <strong>and</strong> software play a<br />

key role in these efforts.”

Empowered by INNOVA<br />

<strong>Marel</strong>’s INNOVA production management software solution is the<br />

backbone to its entire whole-fish <strong>grading</strong> <strong>and</strong> <strong>distribution</strong> <strong>system</strong>.<br />

It enables managers full control <strong>and</strong> comprehensive details of every step of the production process, from slaughter to<br />

dispatch, including order processing <strong>and</strong> planning, quality control <strong>and</strong> logistics management.<br />

Throughout the entire process, INNOVA:<br />

• collects <strong>and</strong> registers relevant data such as flow <strong>and</strong> rate of production.<br />

• enables monitoring online, in real time, of key performance indicators such as yield, throughput <strong>and</strong> quality.<br />

• includes order processing (PO) software that oversees precise specifications on factors such as size, weight, quality,<br />

packing requirements, ice dosing <strong>and</strong> other critical parameters.<br />

• has an integrated automatic alarm monitoring function that oversees all alerts <strong>and</strong> incidents along the line, which helps<br />

to significantly reduce downtime.<br />

The continuous <strong>and</strong> reliable data collection also ensures full traceability of the products, throughout the entire production<br />

process. This function enables operators to trace products back to their original source, thereby minimizing the risk of<br />

large recalls. The <strong>system</strong> also supports quality inspection points as set up in the process according to the plant’s quality<br />

specifications. INNOVA’s built-in traceability <strong>and</strong> quality functions enable <strong>salmon</strong> processors to keep in step with food<br />

safety regulations <strong>and</strong> increased dem<strong>and</strong>s on quality assurance within the industry.<br />

Information automatically generated by INNOVA helps plant operators to identify opportunities for processing<br />

improvements. Ultimately, INNOVA empowers <strong>salmon</strong> processors to optimize their overall plant performance.<br />

“Sitting here at my screen, I can monitor fish as it<br />

passes through the factory <strong>and</strong> see exactly what’s<br />

going on in real time. If there are any unexpected<br />

hitches or delays likely to affect delivery schedules,<br />

I can react to them immediately, or even see them<br />

coming before they actually occur. INNOVA has<br />

also made prioritizing orders for dispatching much<br />

simpler <strong>and</strong> effective,” says Anne Meling Brathen,<br />

Logistics Department, Bremnes Seashore.<br />

Subject to change without notice / 850-5000-36310 / <strong>Marel</strong> hf. / Jan.2013