Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

i,cllipr-:;,*r' :i*ri:c,r iJ{:**-:1,..!,:;n, *r;11r,:rlrl.;rnd :r*t-vl':e 605<br />

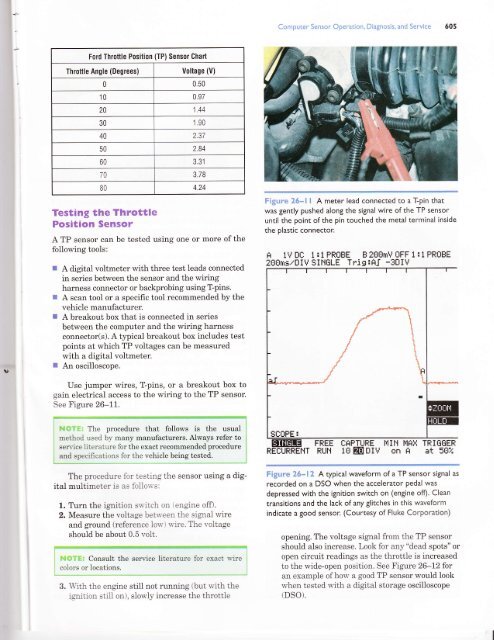

Ford Throtlle Posilion (TP) Sensor <strong>Ch</strong>art<br />

Throttle Angle (Degrees)<br />

Voltage (V)<br />

0 0.50<br />

10 0.97<br />

20<br />

1 lA<br />

30 1.90<br />

40 2.37<br />

50 2.84<br />

60 .t.J I<br />

70 3.78<br />

BO 4.24<br />

Testing the Tlerm'&tfre<br />

Fosition Semser<br />

A TP sensor can be tested using one or more of the<br />

following tools:<br />

x A digital voltmeter with three test leads connected<br />

in series between the sensor and the wiring<br />

harness connector or backprobing using T-pins.<br />

€ A scan tool or a specific tool recommended by the<br />

vehicle manufacturer.<br />

tr Abreakout box that is connected in series<br />

between the computer and the wiring harness<br />

connector(s). A typical breakout box includes test<br />

points at which TP voltages can be measured<br />

with a digital voltmeter.<br />

ffi An oscilloscope.<br />

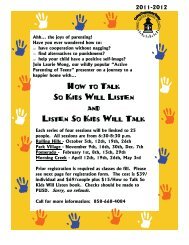

i::!;41ii:re* ?**E E A meter lead connected to a T-pin that<br />

was gently pushed along the signal wire of the TP sensor<br />

until the point of the pin touched the metal terminal inside<br />

the olastic connector.<br />

A 1V nC I :1 PRS8E B 2S0mV tlFF 1 r l PRilBE<br />

200msrBIV $IN&LE f.igrAJ -3nIU<br />

Use jumper wires, T-pins, or a breakout box to<br />

gain electrical access to the wiring to the TP sensor.<br />

See Figure <strong>26</strong>-17.<br />

r. r , lrlr irii'ltt*.ci:xilj:!\i:UIiqiirS{n4fillii{ilisFt$rli$lirui{ii$ill$i{lritiiil]riiliirlirlt{rilliqj*l<br />

The procedure that follows is the usual 1<br />

method ,rsed by many manufacturers. Always refer to I<br />

serrice literature for the exact tecommended procedure I<br />

, .and specifications for the vehicle bein9 fested,<br />

I<br />

The procedure fol testing the sensor using a digital<br />

multimeter is as follos's:<br />

I". Turn the ignition ss'itch on rengine offl.<br />

2. Measure the voltage benr-een the signai wire<br />

and ground (reference ios- s-ire. The r-oltage<br />

should be about 0.5 volt.<br />

' Consult the service literature for exact rvire<br />

colors or locations.<br />

3. \\-ith the engine still not running (but ivith the<br />

igmtion sti11 on ), slowly increase the thlottle<br />

FREE I*PTURE l,lil{ ltlAH<br />

EUH 10 milIV on A<br />

TRIGGER<br />

at 5t3X<br />

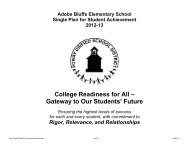

Fig:irre ?#"*i? A typical waveform of a TP sensor signal as<br />

recorded on a DSO when the accelerator pedal was<br />

depressed with the ignition switch on (engine off). Clean<br />

transitions and the lacl< of any glitches in this waveform<br />

indicate a good sensor. (Courtesy of Fluke Corporation)<br />

opening. The voltage signal from the TP sensor<br />

should also increase. Look for any "dead spots" or<br />

open circuit readings as the throttle is increased<br />

to the wide-open position. See Figure <strong>26</strong>-12 for<br />

an example of how a good TP sensor would look<br />

u'hen tested rvith a digital storage oscilloscope<br />

(DSO).