PSPC MICRO AREA X-RAY STRESS ANALYZER - Rigaku

PSPC MICRO AREA X-RAY STRESS ANALYZER - Rigaku

PSPC MICRO AREA X-RAY STRESS ANALYZER - Rigaku

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3. Specifications<br />

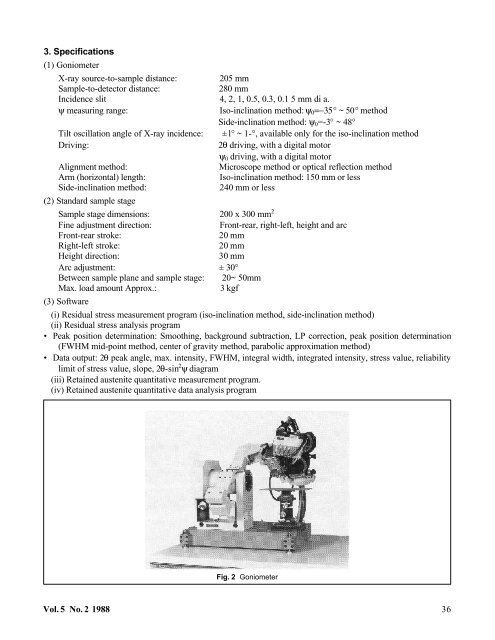

(1) Goniometer<br />

X-ray source-to-sample distance: 205 mm<br />

Sample-to-detector distance:<br />

280 mm<br />

Incidence slit 4, 2, 1, 0.5, 0.3, 0.1 5 mm di a.<br />

ψ measuring range:<br />

Iso-inclination method: ψ 0 =−35° ~ 50° method<br />

Side-inclination method: ψ 0 =-3° ~ 48°<br />

Tilt oscillation angle of X-ray incidence: ± l° ~ 1-°, available only for the iso-inclination method<br />

Driving:<br />

2θ driving, with a digital motor<br />

ψ 0 driving, with a digital motor<br />

Alignment method:<br />

Microscope method or optical reflection method<br />

Arm (horizontal) length:<br />

Iso-inclination method: 150 mm or less<br />

Side-inclination method:<br />

240 mm or less<br />

(2) Standard sample stage<br />

Sample stage dimensions: 200 x 300 mm 2<br />

Fine adjustment direction:<br />

Front-rear, right-left, height and arc<br />

Front-rear stroke:<br />

20 mm<br />

Right-left stroke:<br />

20 mm<br />

Height direction:<br />

30 mm<br />

Arc adjustment: ± 30°<br />

Between sample plane and sample stage: 20~ 50mm<br />

Max. load amount Approx.:<br />

3 kgf<br />

(3) Software<br />

(i) Residual stress measurement program (iso-inclination method, side-inclination method)<br />

(ii) Residual stress analysis program<br />

• Peak position determination: Smoothing, background subtraction, LP correction, peak position determination<br />

(FWHM mid-point method, center of gravity method, parabolic approximation method)<br />

• Data output: 2θ peak angle, max. intensity, FWHM, integral width, integrated intensity, stress value, reliability<br />

limit of stress value, slope, 2θ-sin 2 ψ diagram<br />

(iii) Retained austenite quantitative measurement program.<br />

(iv) Retained austenite quantitative data analysis program<br />

Fig. 2 Goniometer<br />

Vol. 5 No. 2 1988 36