Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

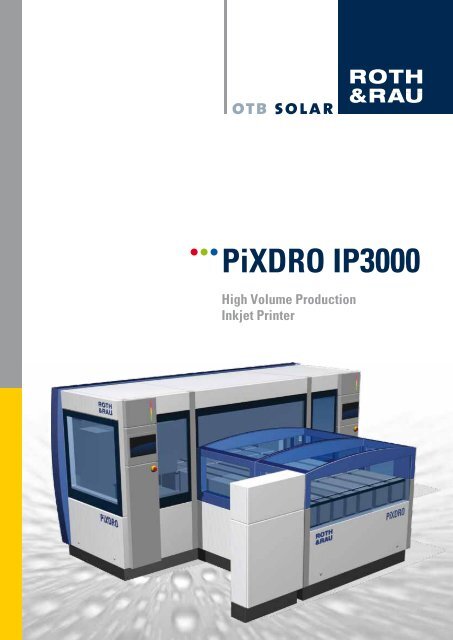

<strong>PiXDRO</strong> <strong>IP3000</strong><br />

High Volume Production<br />

Inkjet Printer

<strong>PiXDRO</strong> <strong>IP3000</strong><br />

High Volume Production<br />

Inkjet Printer<br />

System Description<br />

The <strong>IP3000</strong> Industrial Inkjet Printer is designed to run high volume mass production for various applications within the solar industry.<br />

The advantages of ink-jet printing with small feature sizes, exact positioning and contactless deposition are important for high efficiency<br />

solar cells. (e.g. thin contact lines, local etching and low breakage rates).<br />

Combined with OTB Solar - <strong>Roth</strong> & <strong>Rau</strong>’s unique Single Step Selective Emitter Process which is based on direct printing of dopant<br />

material, the <strong>IP3000</strong> production system delivers lowest cost of ownership. The doping level is determined by selecting the related ink<br />

composition. The <strong>IP3000</strong> inkjet printer is fully compatible with <strong>Roth</strong> & <strong>Rau</strong> automation solutions.<br />

Solar Applications<br />

Single Step Selective Emitter by direct dopant ink<br />

Mask printing with hot-melt or UV curable inks<br />

Contact patterns and dopants with nano particle inks<br />

Direct etch printing (e.g. KOH)<br />

Various aqueous and solvent based inks<br />

Diffusion barriers<br />

Sheet resistance<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

ref (T)<br />

ink 1<br />

ink 2<br />

Lightly doped<br />

(between fingers)<br />

ink 3<br />

Highly doped (under<br />

fingers and busbars)<br />

ink 4<br />

ink 5<br />

ink 6<br />

Ink composition<br />

Main Product Features<br />

Wafer size:<br />

Wafer thickness:<br />

Wafer type:<br />

Throughput:*<br />

Uptime:<br />

Position accuracy:<br />

Smallest feature size:*<br />

Alignment:<br />

Substrate transport:<br />

Substrate table:<br />

Clean room:<br />

Conditioning:<br />

Process configuration:<br />

Size:<br />

Weight:<br />

Integration:<br />

5 and 6 inch (8 inch on request)<br />

80 µm - 300 µm<br />

Mono or multi, square or semi square<br />

Up to 3000 w/h<br />

≥ 95% with external head maintenance<br />

5µm<br />

30 µm positive and 10 µm negative<br />

Edge or fiducial, free programmable<br />

Belt transport, no front contact<br />

Temperature controlled up to 80°C<br />

Internal class 100<br />

Integrated down flow box<br />

Single or double process in one system<br />

W 2300 mm; L 5600 mm; H 2000 mm<br />

1800 Kg<br />

Available as upgrade or within complete turnkey projects<br />

*depending on process and head selection<br />

Options<br />

OTB Solar - <strong>Roth</strong> & <strong>Rau</strong><br />

Luchthavenweg 10<br />

5657 EB Eindhoven<br />

The Netherlands<br />

Phone +31 40 2581 581<br />

Fax +31 40 2509 871<br />

E-mail pixdro@otb-solar.com<br />

www.roth-rau.com/otb-solar<br />

External head maintenance station<br />

(for test and calibration of complete print head assemblies)<br />

Laser head assembly integration<br />

Laser marking on input section (for wafer identification and fiducial marking)<br />

Input wafer check with reject station<br />

Print quality check with reject station<br />

Cassette Input / Output<br />

Inline Input / Output station including cassette buffer