FactSheet HELiA - Roth & Rau AG

FactSheet HELiA - Roth & Rau AG

FactSheet HELiA - Roth & Rau AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

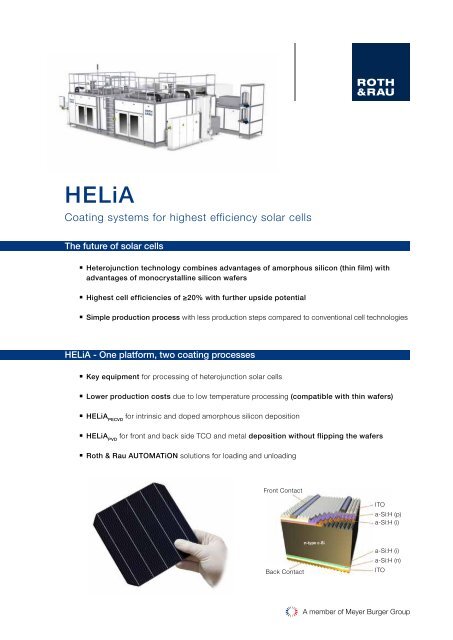

<strong>HELiA</strong><br />

Coating systems for highest efficiency solar cells<br />

The future of solar cells<br />

Heterojunction technology combines advantages of amorphous silicon (thin film) with<br />

advantages of monocrystalline silicon wafers<br />

Highest cell efficiencies of ≥20% with further upside potential<br />

Simple production process with less production steps compared to conventional cell technologies<br />

<strong>HELiA</strong> - One platform, two coating processes<br />

Key equipment for processing of heterojunction solar cells<br />

Lower production costs due to low temperature processing (compatible with thin wafers)<br />

<strong>HELiA</strong> PECVD<br />

for intrinsic and doped amorphous silicon deposition<br />

<strong>HELiA</strong> PVD<br />

for front and back side TCO and metal deposition without flipping the wafers<br />

<strong>Roth</strong> & <strong>Rau</strong> AUTOMATiON solutions for loading and unloading<br />

Front Contact<br />

ITO<br />

a-Si:H (p)<br />

a-Si:H (i)<br />

Back Contact<br />

a-Si:H (i)<br />

a-Si:H (n)<br />

ITO<br />

A member of Meyer Burger Group

Texturing<br />

PECVD 1<br />

Back Side i/n<br />

PECVD 2<br />

Front Side i/p<br />

PVD<br />

TCO Front/ Back Side<br />

Back Contact<br />

Screen<br />

Printing<br />

Curing<br />

Cell Tester<br />

& Sorter<br />

Heterojunction Technology process<br />

The Silicon heterojunction technology is an appealing<br />

concept that combines thin amorphous silicon layers with<br />

monocrystalline silicon wafers to realize cell efficiencies<br />

above 20%. The simple structure of the HJT cells needs<br />

less processing steps compared to conventional cell<br />

designs. The excellent surface passivation of the a-Si:H<br />

layer results in high cell efficiency potential.<br />

The superior temperature coefficient of T C<br />

= -0.27%/K<br />

results in a higher energy yield at operating conditions.<br />

Low temperature processing (

Texturing<br />

PECVD 1<br />

Back Side i/n<br />

PECVD 2<br />

Front Side i/p<br />

PVD<br />

TCO Front/ Back Side<br />

Back Contact<br />

Screen<br />

Printing<br />

Curing<br />

Cell Tester<br />

& Sorter<br />

Heterojunction Technology process<br />

Applications<br />

Heterojunction technology applying intrinsic, p- and n-doped a-Si:H layers using PECVD techniques. TCO and<br />

metal layers are sputtered in a PVD process.<br />

Platform<br />

The <strong>Roth</strong> & <strong>Rau</strong> <strong>HELiA</strong> platforms (PECVD and PVD) represent the key devices for processing of heterojunction<br />

solar cells. The PECVD system is capable of depositing uniform, well controlled, thin layers of intrinsic and doped<br />

a-Si:H onto a textured Si-wafer surface. The PVD system provides for front- and backside deposition without<br />

flipping the wafer. Both systems are designed for a throughput of 2400 w/h. The <strong>HELiA</strong> system platform is based<br />

on a modular design, similar to the well known SiNA ® and MAiA ® systems by <strong>Roth</strong> & <strong>Rau</strong>.<br />

<strong>HELiA</strong> PECVD<br />

- High quality a-Si:H and p/n-Si:H deposition<br />

This system is based on a modular design and,<br />

therefore, it can be configured to the specific customer<br />

needs. The layers are deposited with a PECVD process,<br />

powered by a direct RF-plasma.<br />

The high quality of the amorphous silicon layers enables<br />

the tool also for processing advanced high efficiency<br />

cells such as cells with a heterojunction rear emitter in<br />

combination with a diffused front surface field on n-type<br />

silicon. It can also be used to realize amorphous silicon<br />

backside passivated cells with a diffused emitter on<br />

p-type silicon.<br />

<strong>HELiA</strong> PVD<br />

- Large area high throughput sputtering at lowest costs<br />

This system has been developed for deposition of TCO<br />

and metal layers by sputter deposition. The tool design<br />

provides for face-up and face-down deposition – front<br />

and back side can be coated without flipping the wafer.<br />

Rotary magnetrons are used for high target utilization,<br />

good uniformity and high throughput at simultaneously<br />

low production costs. Due to its modular concept<br />

various TCO layers, metal layers and layer stacks can<br />

be deposited and make the tool applicable for the<br />

production of different solar cell concepts.<br />

Front Side<br />

Back Side

Texturing<br />

PECVD 1<br />

Back Side i/n<br />

PECVD 2<br />

Front Side i/p<br />

PVD<br />

TCO Front/ Back Side<br />

Back Contact<br />

Screen<br />

Printing<br />

Curing<br />

Cell Tester<br />

& Sorter<br />

Heterojunction Technology process<br />

<strong>HELiA</strong> PECVD<br />

- Three tool options available<br />

High level tool<br />

Medium level tool<br />

Entry level tool<br />

Cross contamination free solution<br />

Cross contamination may occur<br />

(i-, p-, n-layers)<br />

2,400 w/h throughput (both sides)<br />

optional: 4,800 w/h throughput (both sides)<br />

2,400 w/h throughput<br />

(both sides)<br />

2,400 w/h<br />

throughput<br />

(one side)<br />

Back side processing Front side processing Back side Front side Single side<br />

PM<br />

(i)<br />

PM<br />

PM<br />

(i)<br />

PM<br />

(p)<br />

PM<br />

(i)<br />

PM<br />

(i)<br />

PM<br />

(i)<br />

Cassette Loader<br />

TM<br />

TM<br />

PM<br />

(i)<br />

Handling<br />

(n)<br />

TM TM<br />

TM<br />

Flip<br />

Handling<br />

TM TM TM<br />

(n) (i)<br />

(p)<br />

PM PM PM<br />

Cassette Loader<br />

Cassette Loader<br />

TM<br />

Handling<br />

TM<br />

PM<br />

(n)<br />

Flip<br />

TM<br />

Handling<br />

TM<br />

PM<br />

(p)<br />

Cassette Loader<br />

Cassette Loader<br />

TM<br />

Handling<br />

TM<br />

PM<br />

(p)<br />

Cassette Loader<br />

Option for higher throughput<br />

<strong>HELiA</strong> PVD<br />

Waferload LM TM Transfer BM<br />

Module (In)<br />

PM<br />

(TCO)<br />

BM<br />

(Out)<br />

TM<br />

BM<br />

(In)<br />

PM<br />

(Metal)<br />

BM<br />

(Out)<br />

TM<br />

Waferload<br />

LM - Load Module<br />

TM - Transfer Module<br />

BM - Buffer Module<br />

PM - Process Module<br />

Data sheet <strong>HELiA</strong><br />

Wafer size<br />

6“ wafer<br />

Wafer type<br />

Throughput<br />

n-, or p-type mono<br />

2,400 w/h (optional: 4,800 w/h)<br />

<strong>Roth</strong> & <strong>Rau</strong> <strong>AG</strong>, info@roth-rau.com, www.roth-rau.com