sound resisting details for loft conversions

sound resisting details for loft conversions

sound resisting details for loft conversions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

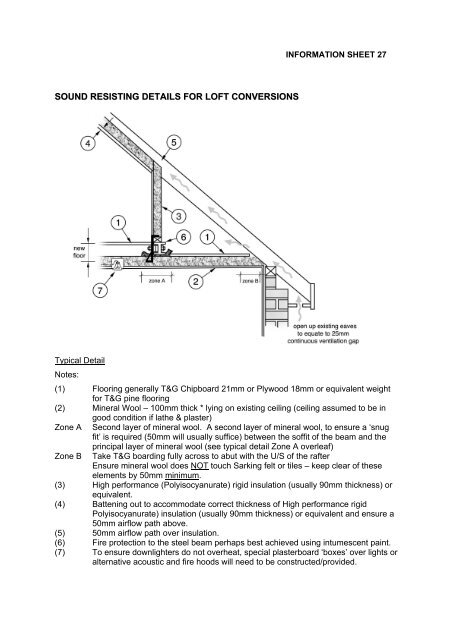

INFORMATION SHEET 27<br />

SOUND RESISTING DETAILS FOR LOFT CONVERSIONS<br />

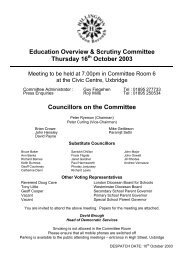

Typical Detail<br />

Notes:<br />

(1) Flooring generally T&G Chipboard 21mm or Plywood 18mm or equivalent weight<br />

<strong>for</strong> T&G pine flooring<br />

(2) Mineral Wool – 100mm thick * lying on existing ceiling (ceiling assumed to be in<br />

good condition if lathe & plaster)<br />

Zone A Second layer of mineral wool. A second layer of mineral wool, to ensure a ‘snug<br />

fit’ is required (50mm will usually suffice) between the soffit of the beam and the<br />

principal layer of mineral wool (see typical detail Zone A overleaf)<br />

Zone B Take T&G boarding fully across to abut with the U/S of the rafter<br />

Ensure mineral wool does NOT touch Sarking felt or tiles – keep clear of these<br />

elements by 50mm minimum.<br />

(3) High per<strong>for</strong>mance (Polyisocyanurate) rigid insulation (usually 90mm thickness) or<br />

equivalent.<br />

(4) Battening out to accommodate correct thickness of High per<strong>for</strong>mance rigid<br />

Polyisocyanurate) insulation (usually 90mm thickness) or equivalent and ensure a<br />

50mm airflow path above.<br />

(5) 50mm airflow path over insulation.<br />

(6) Fire protection to the steel beam perhaps best achieved using intumescent paint.<br />

(7) To ensure downlighters do not overheat, special plasterboard ‘boxes’ over lights or<br />

alternative acoustic and fire hoods will need to be constructed/provided.

INFORMATION SHEET 27<br />

Typical Details [Zone A]<br />

Sound Insulation 2-storey extensions<br />

Detail of 1 st Floor<br />

Notes:<br />

(1) 21mm Chipboard tongue and grooved flooring (18mm ply)<br />

(2) 100mm Mineral Wool<br />

(3) 12mm Plasterboard e.g. Soundblock by British Gypsum or equal product and Skim