What really does cause induction contamination? - TAT - The ...

What really does cause induction contamination? - TAT - The ...

What really does cause induction contamination? - TAT - The ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

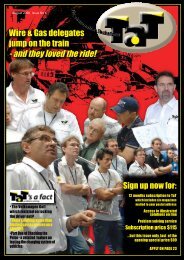

4.<br />

<strong>The</strong> sensor is a pressure transducer that<br />

generates a voltage proportional to the<br />

amount of pressure in the high side. In<br />

order to simulate a similar output voltage<br />

5.<br />

range of between zero and five volts, a<br />

linear potentiometer (pic 5) was arranged<br />

with 10 kilo ohms resistance. This is<br />

to minimise impedance loading effects<br />

on the control unit (see TaT issue 23,<br />

October 2011).<br />

<strong>The</strong> potentiometer was fitted with the<br />

wiper centre arm in the centre of the<br />

sensor’s connector terminal (pic 6)<br />

and resistance slowly varied from one<br />

<strong>The</strong> turning on and off thresholds were<br />

double checked with a scan tool data list<br />

and all were OK (pic 7).<br />

Range of hysteresis<br />

Hysteresis is where the operating<br />

parameters such as the cutting-in and<br />

cutting-out are not at the same setting.<br />

This is to minimise the hunting effect.<br />

Here are the two set of<br />

hysteresis:<br />

a) <strong>The</strong>rmo fan operation – the second<br />

fan (driver’s side) cuts in at 2033 kPa<br />

3.46 volts and cuts out at 1552 kPa 2.83<br />

volts.<br />

b) A/c clutch drop out – when<br />

excessive pressure is noted, perhaps<br />

due to malfunctioning cooling fan, and<br />

pressure begins to build up the a/c clutch<br />

drops out at 2928 kPa 4.6 volts and the<br />

clutch cuts back in at 2336 kPa 3.9 volts.<br />

Fan operation<br />

a) First thermo fan and clutch cuts in at<br />

240 kPa 1.02 volts<br />

b) Second fan (driver’s side) cuts in at<br />

2033 kPa 3.46 volts<br />

<strong>The</strong> culprit was the sensor. <strong>The</strong> system<br />

was degassed and a new sensor fitted<br />

(pic 8). It was then evacuated and<br />

the correct amount of refrigerant was<br />

introduced into the system while the<br />

output voltage was being measured from<br />

the new sensor (pic 9).<br />

9.<br />

10.<br />

11.<br />

<strong>The</strong> first was to directly illustrate the<br />

intricacy of the chain of command and<br />

how to follow this chain of command<br />

using appropriate tools such as circuit<br />

diagrams.<br />

6. 8.<br />

extreme to the other. Presto! Everything<br />

came to life.<strong>The</strong> compressor clutch did<br />

cut in, fans started to operate and as it<br />

was dialled more the compressor cut out.<br />

Pure magic.<br />

In order to measure dynamic current<br />

draw (spikes, slippage, ripples and all) a<br />

0.1 ohm 5 watt ceramic resistor (pic 10)<br />

was positioned in place of relay terminals<br />

30 and 87 and the current draw noted<br />

(pic 11). Current draw was 3.5 amps<br />

and there were no spikes in the pattern,<br />

which is good.<br />

In conclusion<br />

<strong>The</strong> second was to indirectly illustrate<br />

that sometimes replacing components<br />

to remedy symptoms may not be<br />

the appropriate solution without fully<br />

appreciating how the system ought to<br />

work.<br />

Armed with this information, where would<br />

your next starting diagnosis point be?<br />

Should you be confronted with the same<br />

symptom, would you simply replace the<br />

pressure sensor or relay? Where <strong>does</strong><br />

one stop and step back to opt for an<br />

informed holistic approach.<br />

7.<br />

You’re probably asking yourself did we<br />

<strong>really</strong> have to go through all this effort to<br />

decipher the <strong>cause</strong> of the problem. While<br />

the answer may seem simplistic, the<br />

thrust of this article was twofold.<br />

Invest in a 10-kilo ohm linear<br />

potentiometer and substitute it for the<br />

air conditioning pressure sensor and<br />

note the range of hysteresis as fans and<br />

clutch are cutting in and out – it’s fun.<br />

<strong>The</strong> Automotive Technician 25