PDF Download - Glidewell Dental Labs

PDF Download - Glidewell Dental Labs

PDF Download - Glidewell Dental Labs

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

would be designed and milled from the digital scanning<br />

data without the use of stone models.<br />

Treatment<br />

The patient agreed to the placement of two implants in the<br />

areas of tooth #4 and #5 with the aid of a tooth-supported<br />

surgical guide, and the immediate insertion of two provisional<br />

screw-retained abutments and cement-retained crowns. The<br />

treatment was divided into four phases: planning, placement,<br />

provisionalization and final restoration.<br />

Phase I: Planning<br />

Cone beam computed tomography (CBCT) imaging was<br />

performed to produce digital data in the DICOM file format<br />

(Fig. 2). In order to produce an accurate data field of the<br />

surface morphology of the coronal portions of the maxillary<br />

arch, a digital scan was performed with the iTero ® digital<br />

scanning system (Align Technology; San Jose, Calif.) (Fig. 3).<br />

The iTero scan produced STL files, the standard CAD/CAM<br />

file format. These STL files are easily exported directly from<br />

the iTero scanning machine to the user’s computer. Using<br />

file merge software, the DICOM files and STL files were<br />

merged to create an accurate 3-D rendering for the computer-aided<br />

treatment planning and design phase (Fig. 4).<br />

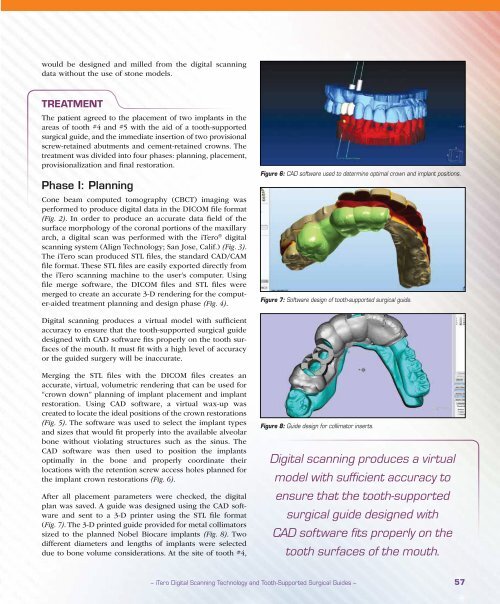

Figure 6: CAD software used to determine optimal crown and implant positions.<br />

Figure 7: Software design of tooth-supported surgical guide.<br />

Digital scanning produces a virtual model with sufficient<br />

accuracy to ensure that the tooth-supported surgical guide<br />

designed with CAD software fits properly on the tooth surfaces<br />

of the mouth. It must fit with a high level of accuracy<br />

or the guided surgery will be inaccurate.<br />

Merging the STL files with the DICOM files creates an<br />

accurate, virtual, volumetric rendering that can be used for<br />

“crown down” planning of implant placement and implant<br />

restoration. Using CAD software, a virtual wax-up was<br />

created to locate the ideal positions of the crown restorations<br />

(Fig. 5). The software was used to select the implant types<br />

and sizes that would fit properly into the available alveolar<br />

bone without violating structures such as the sinus. The<br />

CAD software was then used to position the implants<br />

optimally in the bone and properly coordinate their<br />

locations with the retention screw access holes planned for<br />

the implant crown restorations (Fig. 6).<br />

After all placement parameters were checked, the digital<br />

plan was saved. A guide was designed using the CAD software<br />

and sent to a 3-D printer using the STL file format<br />

(Fig. 7). The 3-D printed guide provided for metal collimators<br />

sized to the planned Nobel Biocare implants (Fig. 8). Two<br />

different diameters and lengths of implants were selected<br />

due to bone volume considerations. At the site of tooth #4,<br />

Figure 8: Guide design for collimator inserts.<br />

Digital scanning produces a virtual<br />

model with sufficient accuracy to<br />

ensure that the tooth-supported<br />

surgical guide designed with<br />

CAD software fits properly on the<br />

tooth surfaces of the mouth.<br />

– iTero Digital Scanning Technology and Tooth-Supported Surgical Guides – 57