course curriculum of advanced modules in sector - Directorate ...

course curriculum of advanced modules in sector - Directorate ...

course curriculum of advanced modules in sector - Directorate ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

COURSE CURRICULUM<br />

OF<br />

ADVANCED MODULES<br />

IN SECTOR<br />

“TEXTILE PROCESSING AND TECHNOLOGY”<br />

(To be implemented <strong>in</strong> ITIs <strong>of</strong>fer<strong>in</strong>g Multiskill <strong>course</strong>s under Craftsmen<br />

Tra<strong>in</strong><strong>in</strong>g Scheme or ITIs Upgraded as Centre <strong>of</strong> Excellence )<br />

<strong>Directorate</strong> General <strong>of</strong> Employment & Tra<strong>in</strong><strong>in</strong>g (DGE&T)<br />

M/o Labour & Employment<br />

Up-gradation <strong>of</strong> ITIs <strong>in</strong>to Centres <strong>of</strong> Excellence<br />

1

Broad Guidel<strong>in</strong>es for Implementation <strong>of</strong> Advanced Module <strong>in</strong> Sector<br />

“ TEXTILE PROCESSING AND TECHNOLOGY ”<br />

These Centres will be provid<strong>in</strong>g multi-skill tra<strong>in</strong><strong>in</strong>g to meet skill requirement <strong>of</strong> TEXTILE INDUSTRY with their<br />

active <strong>in</strong>volvement <strong>in</strong> all aspects <strong>of</strong> tra<strong>in</strong><strong>in</strong>g. The tra<strong>in</strong><strong>in</strong>g will be provided <strong>in</strong> three parts as given below.<br />

Broad Based Basic Tra<strong>in</strong><strong>in</strong>g (<strong>of</strong> Six Modules) <strong>in</strong> Basic skill areas for a period <strong>of</strong> one year.<br />

Tra<strong>in</strong><strong>in</strong>g <strong>in</strong> Advanced Modules for the First Six Months duration <strong>of</strong> II nd year after Broad Based Basic<br />

Tra<strong>in</strong><strong>in</strong>g (BBBT)<br />

Test<strong>in</strong>g & Certification both for the Broad Based Basic Tra<strong>in</strong><strong>in</strong>g (BBBT) & Advanced Modules Tra<strong>in</strong><strong>in</strong>g<br />

dur<strong>in</strong>g subsequent Six Months will be conducted under the aegis <strong>of</strong> NCVT.<br />

Tra<strong>in</strong><strong>in</strong>g <strong>in</strong> specialized <strong>modules</strong> (for the Second Six Months duration <strong>of</strong> II nd year) ma<strong>in</strong>ly by the <strong>in</strong>dustry.<br />

( The <strong>course</strong> curricula ,duration etc are designed <strong>in</strong> consultation with the IMC ). The trade test<strong>in</strong>g &<br />

certification for specialized <strong>modules</strong> will be done jo<strong>in</strong>tly by the State Government & Industry. Said<br />

Certificate will have reorganization from NCVT.<br />

As per the recommendations <strong>of</strong> the EFC , Tra<strong>in</strong><strong>in</strong>g <strong>in</strong> the shop floor should constitute at least 25-40% <strong>of</strong> the<br />

<strong>curriculum</strong>.<br />

2

The tra<strong>in</strong><strong>in</strong>g programme will have multi-entry and multi-exit provision as given below :<br />

Tra<strong>in</strong>ee can opt to go to the labour market after complet<strong>in</strong>g broad based basic tra<strong>in</strong><strong>in</strong>g <strong>of</strong> one year<br />

duration or after complet<strong>in</strong>g <strong>advanced</strong> <strong>modules</strong>.<br />

Multi-entry and multi-exit provision would enable a tra<strong>in</strong>ee to take admission for <strong>advanced</strong> / additional<br />

<strong>advanced</strong> / specialized module as per his/ her need.<br />

Guidel<strong>in</strong>es for tra<strong>in</strong><strong>in</strong>g <strong>in</strong> Advanced Modules<br />

A m<strong>in</strong>imum <strong>of</strong> three <strong>modules</strong> would be essentially needed , so as to ensure that all the 96 tra<strong>in</strong>ees are<br />

accommodated <strong>in</strong> the three Modules , may be selected <strong>in</strong> consultation with IMC for which <strong>in</strong> two shifts.<br />

If it is felt that available <strong>modules</strong> for which the <strong>course</strong> curricula has been developed at National Level are<br />

not sufficient to cater to the needs <strong>of</strong> Local Industry <strong>in</strong> a particular State , States are free to select Module<br />

as per need <strong>in</strong> consultation with Industry. They may develop suitable Module (s) accord<strong>in</strong>gly.<br />

A tra<strong>in</strong>ee at a time can opt only for One Advanced Module.<br />

<br />

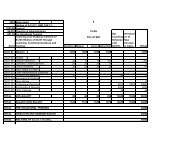

Admission Criteria , Space requirement , Qualification <strong>of</strong> Instructor <strong>of</strong> the various Advanced<br />

Modules <strong>of</strong> “ TEXTILE PROCESSING & TECHNOLOGY ” Sector are given below :<br />

3

Module<br />

No.<br />

Name <strong>of</strong> the Modules Admission Criteria Space<br />

Requirement<br />

ATPT-04 Advanced Textile<br />

Completed BBBT <strong>in</strong> 1. 80 Sq.mtr. for<br />

Technology<br />

Textile Process<strong>in</strong>g and Each Advanced<br />

Technology or or NTC Module &<br />

/NAC <strong>in</strong> related trade or height <strong>of</strong><br />

Diploma <strong>in</strong> Textile<br />

workshop<br />

Technology<br />

should be m<strong>in</strong>.<br />

ATPT-05 Technology <strong>of</strong> Siz<strong>in</strong>g , Completed BBBT <strong>in</strong> 5 mtr.<br />

Bleach<strong>in</strong>g and F<strong>in</strong>ish<strong>in</strong>g Textile Process<strong>in</strong>g and 2. 20 Sq. mtr. For<br />

Technology or or NTC Dark Room<br />

/NAC <strong>in</strong> related trade or Studio<br />

Diploma <strong>in</strong> Textile<br />

Technology<br />

ATPT-06 Technology <strong>of</strong> Dye<strong>in</strong>g Completed BBBT <strong>in</strong><br />

Textile Process<strong>in</strong>g and<br />

Technology or or NTC<br />

/NAC <strong>in</strong> related trade or<br />

Diploma <strong>in</strong> Textile<br />

Technology<br />

ATPT-07 Technology <strong>of</strong> Pr<strong>in</strong>t<strong>in</strong>g Completed BBBT <strong>in</strong><br />

Textile Process<strong>in</strong>g and<br />

Duration <strong>in</strong><br />

weeks<br />

26 Weeks<br />

for<br />

Each<br />

Advanced<br />

Module<br />

Qualification <strong>of</strong> Instructor<br />

Degree <strong>in</strong> Textile Technology<br />

with m<strong>in</strong>imum two years<br />

teach<strong>in</strong>g / <strong>in</strong>dustrial experience<br />

<strong>in</strong> the relevant field. OR<br />

Diploma <strong>in</strong> Textile Process<strong>in</strong>g<br />

& Technology with m<strong>in</strong>imum<br />

five years teach<strong>in</strong>g / <strong>in</strong>dustrial<br />

experience <strong>in</strong> the relevant field.<br />

4

ATPT-08 Computer Aided Textile ,<br />

Design & Colour<br />

ATPT-09 Test<strong>in</strong>g <strong>of</strong> Chemicals and<br />

Textiles<br />

Technology or or NTC<br />

/NAC <strong>in</strong> related trade or<br />

Diploma <strong>in</strong> Textile<br />

Technology<br />

Completed BBBT <strong>in</strong><br />

Textile Process<strong>in</strong>g and<br />

Technology or or NTC<br />

/NAC <strong>in</strong> related trade or<br />

Diploma <strong>in</strong> Textile<br />

Technology<br />

Completed BBBT <strong>in</strong><br />

Textile Process<strong>in</strong>g and<br />

Technology or or NTC<br />

/NAC <strong>in</strong> related trade or<br />

Diploma <strong>in</strong> Textile<br />

Technology<br />

5

FEE STRUCTURE : Fee Structure may be decided by States Govt. <strong>in</strong> consultation with IMCs . It may be desirable to<br />

prescribe a uniform tuition fee for a <strong>sector</strong> <strong>in</strong> all Centres <strong>of</strong> Excellence <strong>of</strong> a state.<br />

EMLOYMENT OPPORTUNITIES IN TEXTILE PROCESSING & TECHNOLOGY SECTOR<br />

JOB OPPORTUNITIES :<br />

a) Supervisor/ Incharge <strong>in</strong> Sp<strong>in</strong>n<strong>in</strong>g , Weav<strong>in</strong>g , Bleach<strong>in</strong>g, Dye<strong>in</strong>g, Pr<strong>in</strong>t<strong>in</strong>g, F<strong>in</strong>ish<strong>in</strong>g departments <strong>in</strong> Textile Mills.<br />

b) Technical Assist<strong>in</strong>g <strong>in</strong> Laboratory/Research and Development sections <strong>of</strong> textile chemical process<strong>in</strong>g units.<br />

c) Technician / Technical Assistant <strong>in</strong> textile committees, textile corporations, small scale <strong>in</strong>dustry organisation, and handloom<br />

<strong>in</strong>dustry.<br />

d) Technical Representatives manufacturers for Dyestuffs/textile auxiliaries.<br />

e) An entrepreneur <strong>of</strong> a textile process<strong>in</strong>g unit/ dyestuffs <strong>in</strong>dustry.<br />

COMPETENCY PROFILE IN TEXTILE PROCESSING & TECHNOLOGY SECTOR<br />

A Technician <strong>in</strong> textile process<strong>in</strong>g & technology should have follow<strong>in</strong>g competencies:-<br />

1. Knowledge and skills perta<strong>in</strong><strong>in</strong>g to fibre, yarn, dyes and chemicals: their characteristics, preparation, specifications and usage.<br />

2. Knowledge and skills <strong>of</strong> various process<strong>in</strong>g mach<strong>in</strong>es required for process<strong>in</strong>g <strong>of</strong> textiles <strong>in</strong> bleach<strong>in</strong>g; dye<strong>in</strong>g, pr<strong>in</strong>t<strong>in</strong>g and f<strong>in</strong>ish<strong>in</strong>g<br />

sections and upkeep <strong>of</strong> mach<strong>in</strong>ery.<br />

3. Competencies <strong>in</strong> textile designs and Knowledge <strong>of</strong> types, comb<strong>in</strong>ations, application and evaluation <strong>of</strong> colours.<br />

4. Competency to undertake test<strong>in</strong>g <strong>of</strong> fibre and yarn and fabrics and dyes understand<strong>in</strong>g various quality control operation and ability<br />

to <strong>in</strong>spect f<strong>in</strong>ished goods.'<br />

5. Competency to prepare material, equipment and manpower schedule for process<strong>in</strong>g <strong>of</strong> textile <strong>in</strong> various sections<br />

6. Awareness <strong>of</strong> environmental pollution due to textile process<strong>in</strong>g, procedure to control position and waste disposals and pollution<br />

6

Act.<br />

7. Ability to tackle simple shop floor related problems <strong>in</strong> the field <strong>of</strong> textile process<strong>in</strong>g.<br />

8. Basic skills <strong>in</strong> read<strong>in</strong>g draw<strong>in</strong>g<br />

RECOMMENDATIONS FOR EFFECTIVE IMPLEMENTATION OF CURRICULUM<br />

The follow<strong>in</strong>g recommendations are made for effective implementation <strong>of</strong> this <strong>curriculum</strong>. :<br />

a) While impart<strong>in</strong>g <strong>in</strong>structions, stress should be laid on the development <strong>of</strong> practical skills <strong>in</strong> the tra<strong>in</strong>ees. For this purpose, as far as<br />

possible, classes should be conducted <strong>in</strong> the laboratories itself.<br />

b) Industrial visits should be organized as and when required to clarify the concepts, pr<strong>in</strong>ciples and practices <strong>in</strong>volved. For this<br />

purpose, time has already been provided <strong>in</strong> tra<strong>in</strong>ees centered activities<br />

c) Extension lectures from pr<strong>of</strong>essionals should be organized to impart <strong>in</strong>structions <strong>in</strong> specialized areas<br />

d) There is no need <strong>of</strong> purchas<strong>in</strong>g very costly equipment. Efforts may be made to establish l<strong>in</strong>kages with local <strong>in</strong>dustrial organizations<br />

e) Considerable stress should be laid on repair and ma<strong>in</strong>tenance <strong>of</strong> equipment<br />

f) Instructors should generate competitiveness among the tra<strong>in</strong>ees for the development <strong>of</strong> pr<strong>of</strong>essional skills.<br />

g) ) Instructors should take work<strong>in</strong>g draw<strong>in</strong>gs from the <strong>in</strong>dustries and provide practices <strong>in</strong> read<strong>in</strong>g these draw<strong>in</strong>gs<br />

h) Hobby clubs and other co-curricular activities be promoted to develop creativity <strong>in</strong> tra<strong>in</strong>ees.<br />

i) ) Instructors should be sent for tra<strong>in</strong><strong>in</strong>g <strong>in</strong> the new areas <strong>in</strong>corporated <strong>in</strong> their <strong>curriculum</strong>.<br />

7

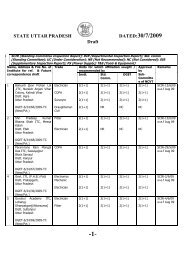

Sr.<br />

No.<br />

Name <strong>of</strong> Member<br />

Designation For<br />

Trade Committee<br />

Information about the Member<br />

01<br />

Mr. PRADIP P. ANDHARE<br />

Ph. No. 0 7 2 3 2 – 3 0 4 5 0 0<br />

Cell – 9 9 2 2 9 4 5 5 4 5<br />

CHAIRMAN<br />

D.G.M. ( HR & Admn.)<br />

RAYMOND UCO LTD<br />

( DENIM DIVISION )<br />

PLOT No. C-1 , M.I.D.C. ,<br />

LOHARA , YAVATMAL<br />

02<br />

Mr. RAJU RANA<br />

Ph. No. 0 7 2 3 2 – 3 2 0 7 5 0<br />

Cell – 9 8 2 2 6 9 5 5 4 1<br />

Fax No. 0 7 2 3 2 – 3 4 9 1 8 4<br />

TECHNICAL MEMBER<br />

CHAIRMAN ,<br />

RANA DENIM PVT. LTD ,<br />

PLOT No. 232 , NAGPUR ROAD , BHARI ,<br />

YAVATMAL<br />

03<br />

Mr. NARENDRA P. YETE<br />

Ph. No. 0 7 2 1 - 2 6 6 0 5 8 8<br />

Cell – 9 8 9 0 4 4 0 8 8 9<br />

TECHNICAL MEMBER<br />

INSPECTOR ,<br />

VOCATION EDUCATION AND TRAINING ,<br />

R.O. AMARAVATI<br />

04<br />

Mr. SANJAY V. TAYWADE<br />

Ph. No. 0 7 2 3 5 – 2 2 7 5 7 2<br />

Cell – 9 4 2 3 4 0 5 2 6 7<br />

CO-ORDINATOR<br />

PRINCIPAL ,<br />

INDUSTRIAL TRAINING INSTITUTE ,<br />

PANDHARKAWADA , DIST.YAVATMAL<br />

8

I N D E X<br />

UP-GRADATIION OF ITIs INTO CENTRES OF EXCELLANCE ( CoE)<br />

SECTOR : TEXTILE PROCESSING AND TECHNOLOGY<br />

ADVANCED MODULES IN II YEAR<br />

( FOR THE FIRST SIX MONTHS OF II YEAR )<br />

MODULE<br />

DURATION IN<br />

NAME OF THE MODULES<br />

No.<br />

WEEKS<br />

ATPT-04 Advanced Textile Technology 26 Weeks<br />

ATPT-05 Technology <strong>of</strong> Siz<strong>in</strong>g , Bleach<strong>in</strong>g and F<strong>in</strong>ish<strong>in</strong>g 26 Weeks<br />

ATPT-06 Technology <strong>of</strong> Dye<strong>in</strong>g 26 Weeks<br />

ATPT-07 Technology <strong>of</strong> Pr<strong>in</strong>t<strong>in</strong>g 26 Weeks<br />

ATPT-08 Computer Aided Textile , Design & Colour 26 Weeks<br />

ATPT-09 Test<strong>in</strong>g <strong>of</strong> Chemicals and Textiles 26 Weeks<br />

Note : 1) The tra<strong>in</strong>ees those who will passed BBBT will be eligible for above Second Year Advanced Module.<br />

2) Tra<strong>in</strong>ee has to select ANY ONE ONLY out <strong>of</strong> above Six Advanced Modules<br />

9

Module – ATPT-04 : ADVANCED TEXTILE TECHNOLOGY<br />

I ) COURSE CONTENT :<br />

PRACTICAL<br />

Skills to be developed :<br />

Intellectual skills:<br />

1) Objects <strong>of</strong> process <strong>in</strong> sp<strong>in</strong>n<strong>in</strong>g.<br />

2) Form <strong>of</strong> material <strong>in</strong> each process.<br />

3) Work<strong>in</strong>g <strong>of</strong> mach<strong>in</strong>es <strong>in</strong> sp<strong>in</strong>n<strong>in</strong>g department.<br />

4) Objects <strong>of</strong> weav<strong>in</strong>g & its preparatory process.<br />

5) Process flow for striped & check fabrics.<br />

6) Work<strong>in</strong>g <strong>of</strong> w<strong>in</strong>d<strong>in</strong>g, warp<strong>in</strong>g, siz<strong>in</strong>g & weav<strong>in</strong>g<br />

mach<strong>in</strong>e<br />

Motor skill:<br />

1) Draw sketches <strong>of</strong> different mach<strong>in</strong>es.<br />

2) Identify different forms <strong>of</strong> material.<br />

3) Identify different parts <strong>of</strong> mach<strong>in</strong>es.<br />

4) Draw flow <strong>of</strong> yarn & fabric through the mach<strong>in</strong>es.<br />

5) Identify different fabric structures, weaves.<br />

THEORY<br />

01. Introduction to Sp<strong>in</strong>n<strong>in</strong>g<br />

Introduction to the pr<strong>in</strong>ciple <strong>of</strong> manufactur<strong>in</strong>g yarn <strong>in</strong> r<strong>in</strong>g<br />

sp<strong>in</strong>n<strong>in</strong>g process.<br />

Overview <strong>of</strong> the various processes <strong>in</strong>volved <strong>in</strong> sp<strong>in</strong>n<strong>in</strong>g <strong>of</strong><br />

a yarn by r<strong>in</strong>g sp<strong>in</strong>n<strong>in</strong>g system and their objects.<br />

A flow chart show<strong>in</strong>g various processes for carded and<br />

combed yarns from blow room to r<strong>in</strong>g frame.<br />

Difference between carded and combed yarn.<br />

02. Raw Material<br />

Def<strong>in</strong>itions <strong>of</strong> terms: textile fibre, staple fibre, yarn, and<br />

filament.<br />

Properties <strong>of</strong> textile fibres: essential and desirable.<br />

Classification <strong>of</strong> textile fibres based on their orig<strong>in</strong>; brief<br />

<strong>in</strong>formation <strong>of</strong> fibres.<br />

Properties <strong>of</strong> cotton fibres: length, strength, f<strong>in</strong>eness,<br />

trash, maturity and convolutions.<br />

Objects and brief description <strong>of</strong> cultivation and pick<strong>in</strong>g –<br />

manual, mechanical; g<strong>in</strong>n<strong>in</strong>g, bal<strong>in</strong>g & press<strong>in</strong>g.<br />

03. Study <strong>of</strong> Sp<strong>in</strong>n<strong>in</strong>g Preparatory Processes<br />

Passage <strong>of</strong> material, object\function<strong>in</strong>g <strong>of</strong> follow<strong>in</strong>g<br />

mach<strong>in</strong>es; Blow room, card<strong>in</strong>g, draw frame, sliver lap and<br />

ribbon lap, comber, speed frame.<br />

6) Identify knitted fabric & woven fabric.<br />

10

List <strong>of</strong> Practicals:<br />

1.Mill visit for overview <strong>of</strong> sp<strong>in</strong>n<strong>in</strong>g process <strong>of</strong> carded<br />

and combed yarn. Visit to g<strong>in</strong>n<strong>in</strong>g and press<strong>in</strong>g<br />

factory.<br />

2. Brief study <strong>of</strong> modern B.R. process with chute feed to<br />

card, high-speed card<strong>in</strong>g process.<br />

3. Brief study <strong>of</strong> high-speed draw frame, comber lap<br />

preparation, comber.<br />

4. Brief study <strong>of</strong> modern fly frame, modern r<strong>in</strong>g frame.<br />

5. Brief study <strong>of</strong> doubl<strong>in</strong>g, TFO, reel<strong>in</strong>g.<br />

6. Brief study <strong>of</strong> open end sp<strong>in</strong>n<strong>in</strong>g mach<strong>in</strong>e, Air jet<br />

sp<strong>in</strong>n<strong>in</strong>g.<br />

7. Brief study <strong>of</strong> wrapp<strong>in</strong>g and hank/count calculation <strong>of</strong><br />

materials <strong>in</strong> sp<strong>in</strong>n<strong>in</strong>g.<br />

8. Lay out <strong>of</strong> weav<strong>in</strong>g workshop (sizes, names, speeds,<br />

width & HP).<br />

04. Sp<strong>in</strong>n<strong>in</strong>g<br />

Object <strong>of</strong> r<strong>in</strong>g frame, passage <strong>of</strong> material through it.<br />

The quality parameters <strong>of</strong> the yarn (strength, evenness,<br />

imperfection, CV%, count, CV% strength) and some <strong>of</strong><br />

important norms like, U%, CV%, CSP, CSP and count<br />

CV%, s<strong>in</strong>gle thread strength, hair<strong>in</strong>ess.<br />

Brief idea about modern sp<strong>in</strong>n<strong>in</strong>g methods like, open end,<br />

friction, air jet, core spun yarn, compact sp<strong>in</strong>n<strong>in</strong>g and<br />

their ma<strong>in</strong> yarn properties.<br />

Brief idea about doubl<strong>in</strong>g, TFO and it advantages with<br />

respect to yarn properties.<br />

Brief idea about yarn reel<strong>in</strong>g, object, description <strong>of</strong><br />

method. Condition<strong>in</strong>g <strong>of</strong> yarn its advantages.<br />

Yarn number<strong>in</strong>g system and calculations e.g. count,<br />

denier, tex.<br />

Brief description <strong>of</strong> special yarns and their end uses: fancy<br />

yarns, blended yarns, texturised yarns, voile yarns, hosiery<br />

yarns, woolen and worsted yarns.<br />

05. Introduction to Fabric Manufactur<strong>in</strong>g.<br />

Various methods <strong>of</strong> fabric form<strong>in</strong>g: (with yarn and without<br />

yarn) weav<strong>in</strong>g, knitt<strong>in</strong>g, braid<strong>in</strong>g, felt<strong>in</strong>g, non-woven fabric<br />

manufactur<strong>in</strong>g, and res<strong>in</strong> bond<strong>in</strong>g.<br />

Description <strong>of</strong> various processes <strong>in</strong> weav<strong>in</strong>g and their objects:<br />

W<strong>in</strong>d<strong>in</strong>g, warp<strong>in</strong>g, siz<strong>in</strong>g, draw<strong>in</strong>g-<strong>in</strong>, cone dye<strong>in</strong>g, beam<br />

dye<strong>in</strong>g, pirn w<strong>in</strong>d<strong>in</strong>g, weav<strong>in</strong>g. Flow charts for various types<br />

<strong>of</strong> fabrics mention<strong>in</strong>g the processes <strong>in</strong>volved <strong>in</strong> manufactur<strong>in</strong>g<br />

<strong>of</strong> these fabrics for pla<strong>in</strong> 1oom and automatic loom: a) Grey<br />

fabric b) Monocolour fabric (dyed warp and gray weft), c)<br />

Warp or weft stripes d) Check pattern, e) warp and weft both<br />

coloured.<br />

06.Weav<strong>in</strong>g Preparatory<br />

W<strong>in</strong>d<strong>in</strong>g: Object <strong>of</strong> w<strong>in</strong>d<strong>in</strong>g, yarn passage through modern<br />

11

9. Passage <strong>of</strong> yarn through the loom. (Names,<br />

objects<br />

<strong>of</strong> primary, secondary & Auxiliary motions).<br />

10. Yarn passage through modern w<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>e.<br />

Important assemblies & their functions<br />

Classimat<br />

11. Study <strong>of</strong> warp<strong>in</strong>g mach<strong>in</strong>e for yarn passage, creel<br />

drum and brake.<br />

12. Passage <strong>of</strong> warp through siz<strong>in</strong>g mach<strong>in</strong>e.<br />

Observe<br />

creel, sawbox cyl<strong>in</strong>ders, leas<strong>in</strong>g and w<strong>in</strong>d<strong>in</strong>g<br />

zones.<br />

13. Study <strong>of</strong> knitt<strong>in</strong>g mach<strong>in</strong>e for yarn path, loop<br />

formation, tuck, knit, float & cam.<br />

14. Sample analysis (pla<strong>in</strong>, mat, rib, twill & sat<strong>in</strong>)<br />

w<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>e, yarn clearer and its function, electronic yarn<br />

clearers, W<strong>in</strong>d<strong>in</strong>g <strong>of</strong> packages for yarn dye<strong>in</strong>g. Types <strong>of</strong> cones<br />

available to w<strong>in</strong>d packages for dye<strong>in</strong>g.<br />

Information <strong>of</strong> Classimat and its use on w<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>e,<br />

features on modern w<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>es.<br />

Warp<strong>in</strong>g: Object <strong>of</strong> warp<strong>in</strong>g, Passage <strong>of</strong> yarn through the<br />

mach<strong>in</strong>e, Description <strong>of</strong> creel and head stock.<br />

Siz<strong>in</strong>g: Object <strong>of</strong> siz<strong>in</strong>g. Effect <strong>of</strong> concentration, viscosity on<br />

size add-on.<br />

General description <strong>of</strong> siz<strong>in</strong>g mach<strong>in</strong>e. Passage <strong>of</strong> warp<br />

through the mach<strong>in</strong>e. Characteristics <strong>of</strong> good beam.<br />

07.Fabric Form<strong>in</strong>g<br />

Weav<strong>in</strong>g: Objects <strong>of</strong> primary, secondary, and auxiliary<br />

motions. Important defects <strong>in</strong> the fabrics and their description.<br />

Study <strong>of</strong> dobby, jacquard, and their uses.<br />

Knitted fabric: <strong>in</strong>troduction, loop structure, warp and weft<br />

knitted fabrics, comparison <strong>of</strong> knitted and woven fabrics,<br />

properties <strong>of</strong> knitted fabrics.<br />

Non-woven: Process and their applications.<br />

08. Fabric Structure<br />

Introduction to <strong>in</strong>terlacements, weaves, and design.<br />

The method to represent the warp, weft, and <strong>in</strong>tersection on<br />

graph (po<strong>in</strong>t) paper with universal convention.<br />

Design, draft, dent<strong>in</strong>g, and peg plan for follow<strong>in</strong>g weaves:<br />

pla<strong>in</strong> (ornamentation), warp rib, weft rib, matt, twill and its<br />

derivatives, twill check, sat<strong>in</strong> and sateen, sat<strong>in</strong> (sateen) checks.<br />

12

II ) OBJECTIVES AND ACHIVEMENTS :<br />

The tra<strong>in</strong>ees will be able to :<br />

1. Get the knowledge <strong>of</strong> various raw materials used <strong>in</strong> sp<strong>in</strong>n<strong>in</strong>g.<br />

2. Predict the properties <strong>of</strong> yarns produced from the sp<strong>in</strong>n<strong>in</strong>g process.<br />

3. Get the skills to identify/differentiate between yarns produced by different sp<strong>in</strong>n<strong>in</strong>g methods e.g. r<strong>in</strong>g sp<strong>in</strong>n<strong>in</strong>g, open-end<br />

sp<strong>in</strong>n<strong>in</strong>g etc.<br />

4. Use this knowledge for enhanc<strong>in</strong>g, modify<strong>in</strong>g properties <strong>of</strong> f<strong>in</strong>al product <strong>of</strong> wet process<strong>in</strong>g.<br />

5. The basic knowledge <strong>of</strong> fabric types and their methods <strong>of</strong> manufactur<strong>in</strong>g.<br />

6. Study different weaves and end-uses.<br />

13

SPINNING MACHINES<br />

List <strong>of</strong> Tools , Equipment and Mach<strong>in</strong>ery Required for<br />

“ ADVANCED TEXTILE TECHNOLOGY MODULE ”<br />

Sr.<br />

No.<br />

Name <strong>of</strong> Item with Specification<br />

Qty. Reqd.<br />

1 Complete B/R l<strong>in</strong>e <strong>of</strong> 4 to 5 beat<strong>in</strong>g po<strong>in</strong>ts with sentcher (s<strong>in</strong>gle process) 1<br />

2 Card<strong>in</strong>g mach<strong>in</strong>e 1<br />

3 Draw frame 1<br />

4 Simplex mach<strong>in</strong>e 1<br />

5 R<strong>in</strong>g frame 1<br />

6 Doubl<strong>in</strong>g mach<strong>in</strong>e 1<br />

7 Sliver lap mach<strong>in</strong>e 1<br />

8 Ribbon lapmach<strong>in</strong>e 1<br />

9 Comber 1<br />

14

WEAVING WORKSHOP<br />

Sr. No. Name <strong>of</strong> Item with Specification Qty. Reqd.<br />

1 Power loom for shirt<strong>in</strong>g reed space 48" 2<br />

2 Power loom for Blanket reed space 80" 1<br />

3 Power loom fitted with terry mechanism reed space 48" 1<br />

4 Power loom fitted with jacquard 200 hooks reed space 48" 2<br />

5 Power loom fitted with jacquared 400 hook Reed Space 48" 1<br />

6 Power Loom fitted with Jacquard 600 hook 2<br />

7 Reed space 48" 2<br />

8 Power loom fitted with drop box 4x1 48" 1<br />

9 Han loom 40" 4<br />

10 Hand loom fitted with jacquard 200' Hooks 1<br />

11<br />

Sectional Warp<strong>in</strong>g Mach<strong>in</strong>e with Creel(Creel capacity 208 cones seclian<br />

width 2 mtr.)<br />

12 Card Cutt<strong>in</strong>g Mach<strong>in</strong>e Coarse Pitch 1<br />

13 Card Cutt<strong>in</strong>g Mach<strong>in</strong>e F<strong>in</strong>e Pitch 1<br />

14 F<strong>in</strong>e PitchJacquard 1<br />

15 Pim ord<strong>in</strong>ary w<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>e 8 sp<strong>in</strong>dle 1<br />

16 Automatic (Hacoba)pim W<strong>in</strong>d<strong>in</strong>g 4 Sp<strong>in</strong>dle 1<br />

17 Dobby 16 lever 2<br />

18 Cam Dobby 24 levers 1<br />

19 Hollow cop Pim w<strong>in</strong>der 6 sp<strong>in</strong>dle 1<br />

20 Pim Chang<strong>in</strong>g Loom 1<br />

21 Shuttle less loom 1<br />

22 Air Jet loom 1<br />

23 Wap<strong>in</strong>g Mach<strong>in</strong>e ( Sectional wap<strong>in</strong>g Mach<strong>in</strong>e ) 1<br />

24 P<strong>in</strong> W<strong>in</strong>d<strong>in</strong>g 2<br />

1<br />

15

WEAVING WORKSHOP<br />

Sr. No. Name <strong>of</strong> Item with Specification Qty. Reqd.<br />

26 Hand Loom , Reed Width 24 “ & 36 “ ( 2 Nos. Each ) 4<br />

27 Hand Loom , 48 “ with dobby & 60 “ with jacquard (1 No. each) 2<br />

28 Power Loom ( for 24 jack dobby fitt<strong>in</strong>g ) 1<br />

29 Power Loom ( 400 hook jacquard fitt<strong>in</strong>g ) 1<br />

16

Module – ATPT- 05 : TECHNOLOGY OF SIZING , BLEACHING AND FINISHING<br />

I ) COURSE CONTENT :<br />

Skills to be developed:<br />

Intellectual skills:<br />

PRACTICAL<br />

1) Learn desiz<strong>in</strong>g, scour<strong>in</strong>g & bleach<strong>in</strong>g method.<br />

2) Identify mercerized goods.<br />

3) Understand<strong>in</strong>g mercerization process.<br />

4) Understand f<strong>in</strong>ish<strong>in</strong>g process.<br />

5) Determ<strong>in</strong>e effect <strong>of</strong> different f<strong>in</strong>ish <strong>in</strong>gredients.<br />

6) Learn f<strong>in</strong>ish<strong>in</strong>g mach<strong>in</strong>e.<br />

7) Understand f<strong>in</strong>ish<strong>in</strong>g process<br />

8) Determ<strong>in</strong>e effect <strong>of</strong> different f<strong>in</strong>ish<strong>in</strong>g method.<br />

9) Learn f<strong>in</strong>ish technique.<br />

THEORY<br />

01. Siz<strong>in</strong>g<br />

Objects <strong>of</strong> siz<strong>in</strong>g, siz<strong>in</strong>g <strong>in</strong>gredients and their functions,<br />

chemistry <strong>of</strong> siz<strong>in</strong>g <strong>in</strong>gredients. Properties <strong>of</strong> adhesives,<br />

properties <strong>of</strong> s<strong>of</strong>teners. Test<strong>in</strong>g <strong>of</strong> adhesives and s<strong>of</strong>teners.<br />

02.Grey Inspection<br />

Po<strong>in</strong>t system, Tag system, Types <strong>of</strong> stitch<strong>in</strong>g, Segregation<br />

and rejection, Inspection mach<strong>in</strong>es for woven and knit<br />

goods.<br />

03. Shear<strong>in</strong>g and Cropp<strong>in</strong>g<br />

Importance <strong>of</strong> grey <strong>in</strong>spection, shear<strong>in</strong>g and cropp<strong>in</strong>g.<br />

Study <strong>of</strong> shear<strong>in</strong>g and cropp<strong>in</strong>g mach<strong>in</strong>es.<br />

04. S<strong>in</strong>ge<strong>in</strong>g<br />

Object <strong>of</strong> s<strong>in</strong>ge<strong>in</strong>g, Methods <strong>of</strong> s<strong>in</strong>ge<strong>in</strong>g, Various types <strong>of</strong><br />

gas s<strong>in</strong>ge<strong>in</strong>g m/cs., S<strong>in</strong>ge<strong>in</strong>g <strong>of</strong> yarn, woven, knit,<br />

synthetic & blended fabrics., Evaluation <strong>of</strong> the efficiency<br />

<strong>of</strong> s<strong>in</strong>ge<strong>in</strong>g.<br />

05.Desiz<strong>in</strong>g<br />

Object, methods <strong>of</strong> desiz<strong>in</strong>g, cont<strong>in</strong>uous desiz<strong>in</strong>g, desiz<strong>in</strong>g<br />

<strong>of</strong> blends, concept <strong>of</strong> grey chemick<strong>in</strong>g.<br />

06.Scour<strong>in</strong>g<br />

Object, reactions <strong>in</strong>volved <strong>in</strong> scour<strong>in</strong>g, study <strong>of</strong> kier, J-box,<br />

17

JT-10, Jigger. Scour<strong>in</strong>g <strong>of</strong> cotton, wool, silk, acrylic,<br />

nylon, polyester and their blends. Scour<strong>in</strong>g <strong>of</strong> knit goods,<br />

scour<strong>in</strong>g <strong>of</strong> coloured woven goods, solvent scour<strong>in</strong>g, concept <strong>of</strong> bio-scour<strong>in</strong>g<br />

Motor skill:<br />

1) Acid desiz<strong>in</strong>g, open scour<strong>in</strong>g, peroxide bleach <strong>of</strong><br />

cellulosic material.<br />

2) Correlat<strong>in</strong>g mercerization efficiency with BAN.<br />

3) Res<strong>in</strong>, s<strong>of</strong>tner & OBA application on cellulosic<br />

material.<br />

4) Us<strong>in</strong>g CCM for whiteness <strong>in</strong>dex.<br />

5) To operate f<strong>in</strong>ish<strong>in</strong>g mach<strong>in</strong>e.<br />

6) F<strong>in</strong>ish <strong>of</strong> wool, silk, polyester & blends.<br />

7) F<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> garments with different effects.<br />

List <strong>of</strong> Practical ( Siz<strong>in</strong>g & Bleach<strong>in</strong>g) :<br />

1. Desiz<strong>in</strong>g <strong>of</strong> cotton with acids and enzymes.<br />

2. Desiz<strong>in</strong>g <strong>of</strong> cotton with hypochlorite.<br />

3. Scour<strong>in</strong>g <strong>of</strong> cotton yarn / fabric by pressure boil<br />

technique.<br />

4. Open boil scour<strong>in</strong>g <strong>of</strong> cotton.<br />

5. Scour<strong>in</strong>g <strong>of</strong> coloured goods.<br />

6. Comb<strong>in</strong>ed desiz<strong>in</strong>g and scour<strong>in</strong>g <strong>of</strong> woven and<br />

knitted goods.<br />

7. Bio scour<strong>in</strong>g <strong>of</strong> knit goods.<br />

8. Scour<strong>in</strong>g <strong>of</strong> wool and silk.<br />

9. Scour<strong>in</strong>g <strong>of</strong> acrylic.<br />

07. Bleach<strong>in</strong>g<br />

Object, classification <strong>of</strong> bleach<strong>in</strong>g agents, Bleach<strong>in</strong>g <strong>of</strong><br />

cotton, wool, silk, acrylic, nylon, polyester and their<br />

blends. Study <strong>of</strong> bleach<strong>in</strong>g <strong>of</strong> knitted fabric and top dyed<br />

goods. Study <strong>of</strong> mach<strong>in</strong>ery used for semi-cont<strong>in</strong>uous and<br />

cont<strong>in</strong>uous bleach<strong>in</strong>g. Developments <strong>in</strong> bleach<strong>in</strong>g.<br />

08. Mercerization<br />

Object, various changes brought about by mercerization,<br />

concept <strong>of</strong> cellulose conversion dur<strong>in</strong>g mercerization,<br />

factors affect<strong>in</strong>g the mercerization process. Yarn<br />

mercerization, mach<strong>in</strong>es used for woven and knitted fabric.<br />

Concept <strong>of</strong> hot mercerization and liquid ammonia<br />

mercerization. Test methods like Barium Activity Number,<br />

axial Ratio, Lustre ratio, deconvolution count etc. to<br />

evaluate the efficiency <strong>of</strong> mercerization<br />

09. Preparation <strong>of</strong> Prote<strong>in</strong><br />

Preparatory process, sequence for woolen goods.<br />

Scour<strong>in</strong>g <strong>of</strong> wool <strong>in</strong> top & fabric form, Carbonization,<br />

Crabb<strong>in</strong>g., Mill<strong>in</strong>g, Pott<strong>in</strong>g.<br />

Preparatory process sequence for silk goods., Degumm<strong>in</strong>g <strong>of</strong> silk.<br />

18

10. Scour<strong>in</strong>g <strong>of</strong> nylon.<br />

11. Scour<strong>in</strong>g <strong>of</strong> polyester and its blend.<br />

12. Bleach<strong>in</strong>g <strong>of</strong> yarn, woven and knitted goods.<br />

13. Bleach<strong>in</strong>g <strong>of</strong> wool and silk.<br />

14. Bleach<strong>in</strong>g <strong>of</strong> nylon and acrylics.<br />

15. Bleach<strong>in</strong>g <strong>of</strong> polyester and its blends.<br />

16. Comb<strong>in</strong>ed desiz<strong>in</strong>g, scour<strong>in</strong>g and bleach<strong>in</strong>g <strong>of</strong><br />

cellulosic material.<br />

17. Determ<strong>in</strong>ation <strong>of</strong> BAN <strong>of</strong> mercerized goods.<br />

18. Determ<strong>in</strong>ation <strong>of</strong> Axial Ratio <strong>of</strong> mercerized goods.<br />

List <strong>of</strong> Practical (F<strong>in</strong>ish<strong>in</strong>g) :<br />

1) Preparation <strong>of</strong> UF, MF, DMEU, DMDHEU and KVS<br />

(2 Experiments) Res<strong>in</strong> f<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> cotton.<br />

2) Application <strong>of</strong> s<strong>of</strong>teners on various fibres<br />

(2 Experiments)<br />

3) Preparation <strong>of</strong> Blue tone, Red tone, etc.<br />

(2 Experiments)<br />

4) F<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> knitted fabric.<br />

5) Application <strong>of</strong> OBA on various fibres. (2<br />

Experiments)<br />

6) Application <strong>of</strong> Flame Retardant on cotton.<br />

7) Application <strong>of</strong> Water pro<strong>of</strong>, water repellant .<br />

10. Classification Of F<strong>in</strong>ishes<br />

Object <strong>of</strong> f<strong>in</strong>ish<strong>in</strong>g, temporary and permanent f<strong>in</strong>ishes,<br />

mechanical and chemical f<strong>in</strong>ishes.<br />

Concept <strong>of</strong> light, medium and heavy f<strong>in</strong>ishes.<br />

11. Res<strong>in</strong> F<strong>in</strong>ish<strong>in</strong>g<br />

Object <strong>of</strong> res<strong>in</strong> f<strong>in</strong>ish<strong>in</strong>g, mechanism <strong>of</strong> creas<strong>in</strong>g, types <strong>of</strong> res<strong>in</strong><br />

f<strong>in</strong>ish<strong>in</strong>g, wash & wear, permanent f<strong>in</strong>ishes, Role <strong>of</strong> catalyst <strong>in</strong><br />

res<strong>in</strong> f<strong>in</strong>ish<strong>in</strong>g and its classifications. Draw backs <strong>of</strong> res<strong>in</strong><br />

f<strong>in</strong>ish<strong>in</strong>g, various types <strong>of</strong> cur<strong>in</strong>g process<strong>in</strong>g.<br />

Study <strong>of</strong> preparation, properties and uses <strong>of</strong> UF, MF, DMEU,<br />

DMDHEU and KVS.<br />

Shop floor practices <strong>of</strong> res<strong>in</strong> f<strong>in</strong>ish<strong>in</strong>g.<br />

12. Optical Brighten<strong>in</strong>g Agent F<strong>in</strong>ish<strong>in</strong>g<br />

Chemistry, mechanism and application methods <strong>of</strong> OBA on<br />

cellulosic materials, stripp<strong>in</strong>g <strong>of</strong> OBA and its detection on<br />

cellulosics.<br />

13. Flame Retardancy F<strong>in</strong>ish<strong>in</strong>g<br />

Concept <strong>of</strong> flame pro<strong>of</strong><strong>in</strong>g and flame retardancy. Limit<strong>in</strong>g<br />

oxygen <strong>in</strong>dex and its importance. Factors affect<strong>in</strong>g the flame<br />

retardancy, study <strong>of</strong> temporary, semi-durable and permanent<br />

flame-retardants for cotton.<br />

14. Water Repellent And Soil Release F<strong>in</strong>ishes<br />

Concept <strong>of</strong> water pro<strong>of</strong> & water repellent f<strong>in</strong>ishes for cellulosic<br />

material, object <strong>of</strong> soil release f<strong>in</strong>ishes, various soil release<br />

f<strong>in</strong>ishes for cotton materials.<br />

8) Use <strong>of</strong> C.C.M. to study Whiteness Index <strong>of</strong> Bleached,<br />

OBA treated fabrics.<br />

9) F<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> silk fabric.<br />

19

10) F<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> wool fabric.<br />

11) F<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> 100% polyester fabric<br />

12) F<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> carbonized goods<br />

13) F<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> p/c, p/w, blends (2 Experiments)<br />

14) Study <strong>of</strong> various wash-down effects – on garments.<br />

( 3 Experiments)<br />

15) Application <strong>of</strong> enzymes <strong>in</strong> garment f<strong>in</strong>ish<strong>in</strong>g. (2<br />

Experiments)<br />

16) Bio-polish<strong>in</strong>g treatment on garments.<br />

15. Study <strong>of</strong> Heat Sett<strong>in</strong>g<br />

Mechanism <strong>of</strong> heat sett<strong>in</strong>g, types <strong>of</strong> sett<strong>in</strong>g, process sequence<br />

<strong>of</strong> gray, <strong>in</strong>termediate and after sett<strong>in</strong>g, comparative study <strong>of</strong><br />

gray, <strong>in</strong>termediate and after heat sett<strong>in</strong>g. Heat sett<strong>in</strong>g <strong>of</strong> 100%<br />

polyester, p/c, p/v, nylon and acrylic, various methods to<br />

evaluate the degree <strong>of</strong> heat sett<strong>in</strong>g<br />

16. Sp<strong>in</strong> F<strong>in</strong>ish<strong>in</strong>g<br />

Objects <strong>of</strong> sp<strong>in</strong> f<strong>in</strong>ish, sp<strong>in</strong> f<strong>in</strong>ish<strong>in</strong>g <strong>in</strong>gredients and their<br />

functions. Concept <strong>of</strong> turbo-electric series and its significance.<br />

Chemistry <strong>of</strong> sp<strong>in</strong>- f<strong>in</strong>ish<strong>in</strong>g <strong>in</strong>gredients. Various methods <strong>of</strong><br />

application <strong>of</strong> sp<strong>in</strong>-f<strong>in</strong>ish. Sp<strong>in</strong> f<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> texturised<br />

polyester.<br />

17.Anti-pill<strong>in</strong>g<br />

Mechanism <strong>of</strong> pill<strong>in</strong>g, Factors affect<strong>in</strong>g pill<strong>in</strong>g. Various<br />

physical & chemical methods to m<strong>in</strong>imize pill<strong>in</strong>g.<br />

18. Foam F<strong>in</strong>ish<strong>in</strong>g<br />

Def<strong>in</strong>ition <strong>of</strong> foam & blow ratio, properties <strong>of</strong> foam, stability<br />

<strong>of</strong> foam, various methods to prepare foam, factors affect<strong>in</strong>g<br />

stability <strong>of</strong> foam, methods to determ<strong>in</strong>e stability <strong>of</strong> foam,<br />

various methods <strong>of</strong> foam application.<br />

19. Special F<strong>in</strong>ishes<br />

Concepts <strong>of</strong> mildew pro<strong>of</strong> & rot pro<strong>of</strong>, mildew pro<strong>of</strong> & rot<br />

pro<strong>of</strong> f<strong>in</strong>ish<strong>in</strong>g, preparation <strong>of</strong> silk like polyester, soil release<br />

f<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> synthetics, f<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> woolen goods. F<strong>in</strong>ish<strong>in</strong>g <strong>of</strong><br />

hosiery goods, f<strong>in</strong>ish<strong>in</strong>g <strong>of</strong> knit goods.<br />

20

20. Garment F<strong>in</strong>ish<strong>in</strong>g<br />

Study <strong>of</strong> mach<strong>in</strong>es : Drum washer, Tumble drier, Paddle<br />

dye<strong>in</strong>g m/c., Fus<strong>in</strong>g mach<strong>in</strong>es for <strong>in</strong>terl<strong>in</strong><strong>in</strong>g, Laundry<br />

equipments.<br />

Wash down effects on garments:<br />

Denim wash – R<strong>in</strong>se wash, Sand blast<strong>in</strong>g effect, Peach wash<br />

effect, Stone wash effect, Acid wash effect, Chalk wash,<br />

feather – wash<strong>in</strong>g effect, Ultra s<strong>of</strong>t wash<strong>in</strong>g effect.<br />

21. Recent developments <strong>in</strong> f<strong>in</strong>ish<strong>in</strong>g<br />

Study <strong>of</strong> multifunctional f<strong>in</strong>ishes, Moisture management<br />

f<strong>in</strong>ishes, UV protective f<strong>in</strong>ishes, Oil repellent f<strong>in</strong>ishes<br />

21

II ) OBJECTIVES AND ACHIVEMENTS :<br />

Tra<strong>in</strong>ees will be able to :<br />

1. Get the knowledge <strong>of</strong> various siz<strong>in</strong>g <strong>in</strong>gredients and their role <strong>in</strong> siz<strong>in</strong>g process.<br />

2. Know the various pretreatments given to different textile fibres and their importance <strong>in</strong> textile wet process<strong>in</strong>g.<br />

3. Study the check po<strong>in</strong>ts and test<strong>in</strong>g procedures at various levels <strong>in</strong> pretreatments.<br />

4. Know the basic concepts and types <strong>of</strong> f<strong>in</strong>ish<strong>in</strong>g.<br />

5. Have the knowledge <strong>of</strong> various formulations <strong>in</strong> the f<strong>in</strong>ish<strong>in</strong>g.<br />

6. Study the functional f<strong>in</strong>ishes.<br />

7. Study the effect <strong>of</strong> heat sett<strong>in</strong>g on physico-chemical changes <strong>in</strong> synthetic fibres.<br />

8. Get the knowledge <strong>of</strong> mechanical and chemical f<strong>in</strong>ishes<br />

9. Get the knowledge <strong>of</strong> different f<strong>in</strong>ishes applied on textile fabric.<br />

10.Get the knowledge <strong>of</strong> garment f<strong>in</strong>ish<strong>in</strong>g<br />

11.Study the recent f<strong>in</strong>ishes for textiles<br />

22

List <strong>of</strong> Tools , Equipment and Mach<strong>in</strong>ery Required for<br />

“ TECHNOLOGY OF SIZING , BLEACHING & FINISHING ”<br />

23

Module – ATPT- 06 : TECHNOLOGY OF DYEING<br />

I ) COURSE CONTENT :<br />

PRACTICAL<br />

Skills to be developed :<br />

Intellectual skills:<br />

1) Understand dy<strong>in</strong>g process.<br />

2) Learn after treatments.<br />

3) Learn dye<strong>in</strong>g mach<strong>in</strong>e.<br />

4) Understand<strong>in</strong>g dye<strong>in</strong>g process for synthetic fabric.<br />

5) Learn dye<strong>in</strong>g mach<strong>in</strong>e.<br />

6) Learn blend dye<strong>in</strong>g.<br />

Motor skill:<br />

1) Dye<strong>in</strong>g if cellulosic & prote<strong>in</strong> fibre with different dyes.<br />

2) To operate dye<strong>in</strong>g mach<strong>in</strong>e.<br />

3) H.T. H.P., carrier & thermosol methods <strong>of</strong> dye<strong>in</strong>g.<br />

4) To operate dye<strong>in</strong>g mach<strong>in</strong>e.<br />

5) Dye<strong>in</strong>g <strong>of</strong> polyester blends with different method.<br />

THEORY<br />

01. Introduction <strong>of</strong> Dye<strong>in</strong>g<br />

Basic concepts and requirements <strong>of</strong> dye and pigment.<br />

Def<strong>in</strong>itions <strong>of</strong> aff<strong>in</strong>ity, reactivity, exhaustion, percentage<br />

shade, percent expression & diffusion. Classification <strong>of</strong> dyes<br />

Influence <strong>of</strong> pre-treatments on dye<strong>in</strong>g properties, selection <strong>of</strong><br />

dyes & chemicals from ecological view.<br />

02. Direct Dye<strong>in</strong>g<br />

General properties, pr<strong>in</strong>ciples and methods <strong>of</strong> application <strong>of</strong><br />

direct dye on Cellulosic materials. Classification <strong>of</strong> direct<br />

dyes, various shop floor practices <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> cellulosic<br />

materials with direct dye, various after treatments to improve<br />

fastness <strong>of</strong> direct dyed goods, faults and remedies <strong>in</strong> direct<br />

dye<strong>in</strong>g.<br />

03. Reactive Dye<strong>in</strong>g<br />

Concept <strong>of</strong> hot brand, cold brand, HE, ME & v<strong>in</strong>yl sulphone<br />

reactive dyes. Important steps <strong>in</strong>volved <strong>in</strong> reactive dye<strong>in</strong>g,<br />

different shop floor practices <strong>of</strong> reactive dye<strong>in</strong>g on cellulosic<br />

materials, general properties <strong>of</strong> reactive dyes, stripp<strong>in</strong>g <strong>of</strong><br />

reactive dyes, faults and remedies <strong>in</strong> reactive dye<strong>in</strong>g.<br />

04. Vat Dye<strong>in</strong>g<br />

General properties <strong>of</strong> vat dyes, classification <strong>of</strong> vat dyes.<br />

Important steps <strong>in</strong>volved <strong>in</strong> vat dye<strong>in</strong>g, various methods <strong>of</strong><br />

application <strong>of</strong> vat dyes on cellulosic material, faults and<br />

remedies <strong>in</strong> vat dye<strong>in</strong>g.<br />

25

List <strong>of</strong> Practicals:<br />

1. Dye<strong>in</strong>g <strong>of</strong> cotton with direct dye.<br />

2. After treatment with direct dyed goods.<br />

3. Dye<strong>in</strong>g <strong>of</strong> cotton with hot brand & HE brand reactive<br />

dyes.<br />

4. Dye<strong>in</strong>g <strong>of</strong> cotton with ME & ramazol reactive dyes.<br />

5. Dye<strong>in</strong>g <strong>of</strong> cotton with vat dyes.<br />

6. Dye<strong>in</strong>g <strong>of</strong> cotton with solubilised vat dye.<br />

7. Dye<strong>in</strong>g <strong>of</strong> cotton with sulphur dye.<br />

8. After treatments <strong>of</strong> sulphur dyed goods.<br />

9. Dye<strong>in</strong>g <strong>of</strong> cotton with azoic colours.<br />

10. Dye<strong>in</strong>g <strong>of</strong> wool & silk with basic dye.<br />

11. Dye<strong>in</strong>g <strong>of</strong> wool & silk with acid dye.<br />

12. Dye<strong>in</strong>g <strong>of</strong> wool & with metal complex dye.<br />

13. Cotton fabric dye<strong>in</strong>g with jigger, padd<strong>in</strong>g mangle<br />

and w<strong>in</strong>ch.<br />

14. Carrier dye<strong>in</strong>g <strong>of</strong> polyester.<br />

05. Solubalised Vat Dye<strong>in</strong>g<br />

General properties <strong>of</strong> solublised vat dyes, important steps<br />

<strong>in</strong>volved <strong>in</strong> dye<strong>in</strong>g with solublised vat dyes, shop floor<br />

practices <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> cellulosic materials with solublised vat<br />

dyes, faults and remedies <strong>in</strong> solublised vat dye<strong>in</strong>g.<br />

06. Sulphur Dye<strong>in</strong>g<br />

General properties <strong>of</strong> sulphur dye, important steps <strong>in</strong>volved <strong>in</strong><br />

sulphur dye<strong>in</strong>g, different oxidation methods <strong>in</strong> sulphur dye<strong>in</strong>g,<br />

shop floor properties <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> cellulosic materials with<br />

sulphur dyes, stripp<strong>in</strong>g <strong>of</strong> sulphur dyes, faults and remedies <strong>in</strong><br />

sulphur dye<strong>in</strong>g.<br />

07. Azoic Dye<strong>in</strong>g<br />

General properties <strong>of</strong> azoic colours, concept <strong>of</strong> napthols and<br />

bases, important steps <strong>in</strong>volved <strong>in</strong> Azoic dye<strong>in</strong>g, various shop<br />

floor properties <strong>of</strong> azoic dye<strong>in</strong>g method to improve rubb<strong>in</strong>g<br />

fastness <strong>of</strong> azoic dyed goods, fault and remedies <strong>in</strong> azoic<br />

dye<strong>in</strong>g<br />

08. Dye<strong>in</strong>g with Basic Dyes<br />

General properties <strong>of</strong> basic dyes, different retard<strong>in</strong>g agents<br />

uses <strong>in</strong> basic dye<strong>in</strong>g. Dye<strong>in</strong>g <strong>of</strong> wool & silk, important steps<br />

<strong>in</strong>volved <strong>in</strong> dye<strong>in</strong>g <strong>of</strong> cotton with basic dyes us<strong>in</strong>g mordant,<br />

faults and remedies <strong>in</strong> basic dye<strong>in</strong>g.<br />

09. Dye<strong>in</strong>g With Acid Dyes<br />

General Properties <strong>of</strong> acid dyes classification <strong>of</strong> acid dyes,<br />

different methods for level dye<strong>in</strong>g for wool & silk, dye<strong>in</strong>g <strong>of</strong><br />

wool & silk with acid dyes & metal complex dyes.<br />

15. H.T.H.P. dye<strong>in</strong>g <strong>of</strong> polyester.<br />

26

16. Thermosol dye<strong>in</strong>g <strong>of</strong> polyester. Dye<strong>in</strong>g <strong>of</strong> texturised<br />

polyester.<br />

17. Production <strong>of</strong> compound shades us<strong>in</strong>g disperse<br />

dye.<br />

18. Dye<strong>in</strong>g <strong>of</strong> acrylic with Basic, Cationic and disperse<br />

dyes.<br />

19. Computer colour match<strong>in</strong>g. Preparation <strong>of</strong> at least<br />

3 formulations for p, p/c, and p/v.<br />

20. Dye<strong>in</strong>g <strong>of</strong> Nylon with acid, metal complex &<br />

disperse dyes.<br />

21. Dye<strong>in</strong>g <strong>of</strong> polyester/ cellulosic blends with various<br />

classes <strong>of</strong> dyes<br />

10. Dye<strong>in</strong>g With Natural Dyes<br />

Dye<strong>in</strong>g with natural colours, pigments and oxidation colour<br />

classification <strong>of</strong> natural colour<strong>in</strong>g matters, general properties<br />

<strong>of</strong> natural dyes & pigments, their application on cellulosic<br />

materials, faults & remedies <strong>in</strong> dye<strong>in</strong>g with natural dye.<br />

11. Basic Concept <strong>of</strong> Dye<strong>in</strong>g Mach<strong>in</strong>es<br />

Exhaust, semi-cont<strong>in</strong>uous, cont<strong>in</strong>uous m/cs. Parameters,<br />

advantages and disadvantages <strong>of</strong> various systems.<br />

12. Cont<strong>in</strong>uous Dye<strong>in</strong>g Methods<br />

Dye<strong>in</strong>g <strong>of</strong> cellulosic and its blends with pigments.<br />

Introduction to m<strong>in</strong>eral khaki, Anil<strong>in</strong>e Black,<br />

Phthalogen Blue<br />

13. Dye<strong>in</strong>g <strong>of</strong> polyester<br />

Various mechanisms <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> polyester with<br />

disperse dye. Various theories <strong>of</strong> carrier dye<strong>in</strong>g <strong>of</strong><br />

polyester. Detailed study <strong>of</strong> carrier dye<strong>in</strong>g, high temp,<br />

high pressure, thermosol dye<strong>in</strong>g, and solvent dye<strong>in</strong>g <strong>of</strong><br />

polyester. Dye<strong>in</strong>g <strong>of</strong> texturised & micro denier PET.<br />

Effect <strong>of</strong> pretreatments and heat sett<strong>in</strong>g on dye<strong>in</strong>g<br />

behaviour <strong>of</strong> polyester. Concept <strong>of</strong> rapid dye<strong>in</strong>g<br />

techniques. Concept <strong>of</strong> low liquor dye<strong>in</strong>g techniques.<br />

Faulty dye<strong>in</strong>g & their corrections. Recent developments<br />

<strong>of</strong> jet dye<strong>in</strong>g mach<strong>in</strong>e, mass colouration <strong>of</strong> polyester.<br />

14. Dye<strong>in</strong>g <strong>of</strong> acrylic<br />

Dye<strong>in</strong>g <strong>of</strong> acrylic with basic, cationic, disperse dyes.<br />

Concept <strong>of</strong> defitherm dye<strong>in</strong>g technique <strong>of</strong> acrylic. Concept<br />

<strong>of</strong> sancowd dye<strong>in</strong>g technique <strong>of</strong> acrylic. Shop floor<br />

practices <strong>of</strong> acrylic dye<strong>in</strong>g. Use <strong>of</strong> different retarders <strong>in</strong><br />

acrylic dye<strong>in</strong>g.<br />

27

22. Dye<strong>in</strong>g <strong>of</strong> polyester/ wool blends with various<br />

classes <strong>of</strong> dyes<br />

23. Dye<strong>in</strong>g <strong>of</strong> polyester/ acrylic blends with various<br />

classes <strong>of</strong> dyes<br />

24. Cross dye<strong>in</strong>g <strong>of</strong> polyester / cellulosic blends with<br />

various classes <strong>of</strong> dyes.<br />

25. Production <strong>of</strong> compound shades us<strong>in</strong>g azoic<br />

colours<br />

26. Production <strong>of</strong> compound shade on polyester /<br />

cellulosic blends<br />

15. Dye<strong>in</strong>g <strong>of</strong> nylon<br />

Dye<strong>in</strong>g <strong>of</strong> nylon with various classes <strong>of</strong> dyes. Shop floor<br />

practices <strong>of</strong> nylon dye<strong>in</strong>g. Faults & remedies <strong>in</strong> Nylon<br />

dye<strong>in</strong>g<br />

16. Dye<strong>in</strong>g <strong>of</strong> Blended Union Fabrics<br />

Pretreatments & dye<strong>in</strong>g <strong>of</strong> polyester/cotton,<br />

polyester/viscose, polyester/wool, polyester/acrylic,<br />

polyester /viscose/acrylic, nylon/wool, wool/ acrylic,<br />

acrylic/viscose & polyester/silk<br />

17. Dye<strong>in</strong>g <strong>of</strong> Special Fabrics<br />

Various methods <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> knitted goods. Terry<br />

towel, dye<strong>in</strong>g <strong>of</strong> jute fabric with various classes <strong>of</strong> dyes<br />

like direct, sulphur, reactive, basic, acid, etc. S<strong>in</strong>gle<br />

stage <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> polyester / cellulosic materials, cross<br />

dye<strong>in</strong>g <strong>of</strong> polyester / cellulosic blends.<br />

18. Wet Process<strong>in</strong>g <strong>of</strong> Denim & Top Dyed Goods<br />

Mechanical & chemical process<strong>in</strong>g <strong>of</strong> denim & top dyed<br />

fabric mach<strong>in</strong>ery used for denim. Wet process<strong>in</strong>g <strong>of</strong> denim<br />

fabric.<br />

19. Process control <strong>in</strong> dye<strong>in</strong>g<br />

Study <strong>of</strong> various process parameters <strong>of</strong> dye<strong>in</strong>g processes.<br />

20. Quality control <strong>in</strong> dye<strong>in</strong>g<br />

Methods <strong>of</strong> test<strong>in</strong>g fastness properties <strong>of</strong> dyed goods to<br />

wash<strong>in</strong>g, rubb<strong>in</strong>g, light, sublimation & perspiration.<br />

Concept and application <strong>of</strong> Computer Colour Match<strong>in</strong>g<br />

<strong>in</strong> dye<strong>in</strong>g<br />

28

II ) OBJECTIVES AND ACHIVEMENTS :<br />

Tra<strong>in</strong>ees will be able to :<br />

1. Get the basic concepts <strong>in</strong> dye<strong>in</strong>g <strong>of</strong> cellulosic material.<br />

2. Know the technology <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> cellulosic material with various classes <strong>of</strong> dyes.<br />

3. Differentiate the various dye<strong>in</strong>g techniques and their advantages and disadvantages.<br />

4. Get the basic concepts <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> synthetic fibres.<br />

5. Know application methods <strong>of</strong> dye<strong>in</strong>g <strong>of</strong> synthetic fibres by various dyes.<br />

6. Study process control and Quality control parameters.<br />

7. Study dye<strong>in</strong>g methods <strong>of</strong> blended fabrics, denim, and various special fabrics.<br />

29

List <strong>of</strong> Tools , Equipment and Mach<strong>in</strong>ery Required for<br />

“ TECHNOLOGY OF DYEING ”<br />

Sr. No. Name <strong>of</strong> Item with Specification Qty. Reqd.<br />

1 High Temperature high pressure water bath beaker dye<strong>in</strong>g mach<strong>in</strong>e 1<br />

2 Glycer<strong>in</strong> bath beaker dye<strong>in</strong>g mach<strong>in</strong>e 1<br />

3 Dye baths 15<br />

4 Laboratory jigger 1<br />

5 Laboratory w<strong>in</strong>ch 1<br />

6 Laund rometer 1<br />

7 Padd<strong>in</strong>g mangle 1<br />

8 Hank dye<strong>in</strong>g mach<strong>in</strong>e 1<br />

9 Rota dyer 1<br />

10 Basket centrifuge 1<br />

11 Wrap reel 4<br />

12 Electronic balance 2<br />

13 Hot plates 5<br />

14 Semi automatic wash<strong>in</strong>g mach<strong>in</strong>e 1<br />

15 Refrigerator 1<br />

16 Analytical balance 6<br />

17 pH meter (electronic) 1<br />

18<br />

Measur<strong>in</strong>g cyl<strong>in</strong>ders <strong>of</strong> different capacity (10ml, 50ml, 100ml,<br />

250ml,500ml, and 1lt)<br />

21 Sta<strong>in</strong>less steel glasses for dye baths 50<br />

22 Electric oven 2<br />

5 each<br />

23 Colour mix<strong>in</strong>g conta<strong>in</strong>ers <strong>of</strong> plastic and steel (mugs) 20 each<br />

24 Glass rods 200<br />

25 Grey scale (set) 1<br />

30

Module – ATPT- 07 : TECHNOLOGY OF PRINTING<br />

I ) COURSE CONTENT :<br />

PRACTICAL<br />

Skills to be developed:<br />

Intellectual skills:<br />

1) Understand screen preparation.<br />

2) Understand pr<strong>in</strong>t<strong>in</strong>g process.<br />

3) Learn different styles <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g<br />

Motor skill:<br />

1) Draw<strong>in</strong>g a design & prepare screen <strong>of</strong> same.<br />

2) Direct, discharge & resist style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g.<br />

List <strong>of</strong> Practicals:<br />

1) Preparation <strong>of</strong> screen for pr<strong>in</strong>t<strong>in</strong>g<br />

2) Batick style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g<br />

3) Tie & dye style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g<br />

4) Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on cotton us<strong>in</strong>g direct dye<br />

5) Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on cotton us<strong>in</strong>g Reactive dye<br />

6) Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on cotton us<strong>in</strong>g Azoic colours<br />

7) Magic style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g, crimp style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g<br />

8) White & colour discharge on cotton us<strong>in</strong>g direct and<br />

reactive dyes<br />

9) White & colour discharge on cotton us<strong>in</strong>g vat dyes<br />

10) Azoic colour discharge pr<strong>in</strong>t<strong>in</strong>g on direct dyed<br />

ground<br />

11) White & colour resist style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on cotton<br />

12) Silk pr<strong>in</strong>t<strong>in</strong>g with acid dyes<br />

THEORY<br />

1. Introduction To Textile Pr<strong>in</strong>t<strong>in</strong>g<br />

Preparation <strong>of</strong> cloth for pr<strong>in</strong>t<strong>in</strong>g with emphasis on cotton fabric.<br />

Pr<strong>in</strong>t<strong>in</strong>g paste <strong>in</strong>gredients and their functions, different types <strong>of</strong><br />

thickeners. Rheological behaviour <strong>of</strong> thickeners, Selection criteria<br />

<strong>of</strong> thickeners.<br />

2.Methods <strong>of</strong> Pr<strong>in</strong>t<strong>in</strong>g<br />

General pr<strong>in</strong>ciples <strong>of</strong> methods <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g, study <strong>of</strong> mach<strong>in</strong>ery used<br />

for pr<strong>in</strong>t<strong>in</strong>g such as table, roller, flat bed screen pr<strong>in</strong>t<strong>in</strong>g and rotary<br />

screen pr<strong>in</strong>t<strong>in</strong>g, preparation <strong>of</strong> screens for flat bed & rotary screen<br />

pr<strong>in</strong>t<strong>in</strong>g, different types <strong>of</strong> squeezes for flat bed and rotary screen<br />

pr<strong>in</strong>t<strong>in</strong>g, faults and remedies <strong>in</strong> roller, rotary & flat bed pr<strong>in</strong>t<strong>in</strong>g,<br />

advantages & limitation <strong>of</strong> roller, rotary & flat bed pr<strong>in</strong>t<strong>in</strong>g.<br />

3.Styles Of Pr<strong>in</strong>t<strong>in</strong>g<br />

Introduction to the pr<strong>in</strong>ciple <strong>of</strong> styles <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g.<br />

Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on cellulosic material us<strong>in</strong>g direct, reactive dyes and<br />

azoic colours. Pr<strong>in</strong>t<strong>in</strong>g paste formulation. Pr<strong>in</strong>t<strong>in</strong>g operational sequence.<br />

Introduction to work<strong>in</strong>g <strong>of</strong> mach<strong>in</strong>es like star and loop ager, soaper.<br />

Discharge and resist<strong>in</strong>g agents. Pr<strong>in</strong>t paste formulation, process sequence <strong>of</strong><br />

white and colour discharge / resist pr<strong>in</strong>t<strong>in</strong>g on cotton us<strong>in</strong>g direct, reactive,<br />

azoic and vat dyes.<br />

Special pr<strong>in</strong>t<strong>in</strong>g effects such as stencil, batick, tie & dye, Khadi,<br />

magic and crimp styles.<br />

4. Pr<strong>in</strong>t<strong>in</strong>g with Pigments<br />

Pr<strong>in</strong>ciple <strong>of</strong> pigment pr<strong>in</strong>t<strong>in</strong>g on cellulosic material.<br />

Advantages and limitations <strong>of</strong> emulsion and synthetic thickeners.<br />

Pr<strong>in</strong>t<strong>in</strong>g paste formulation and process sequence.<br />

31

Skills to be developed;<br />

Intellectual skills:<br />

1) Understand different thicken<strong>in</strong>g paste.<br />

2) Understand pr<strong>in</strong>t<strong>in</strong>g process.<br />

3) Learn different styles <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on synthetic fabric.<br />

Motor skill:<br />

1) Direct, discharge & resist style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on<br />

synthetic fabric.<br />

2) Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> polyester / cotton blend.<br />

List <strong>of</strong> Experiments:<br />

1. Stock & reduction thicken<strong>in</strong>g <strong>in</strong> pr<strong>in</strong>t<strong>in</strong>g.<br />

2. Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on 100 % polyester us<strong>in</strong>g<br />

disperse dye.<br />

3. Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on 100 % polyester us<strong>in</strong>g<br />

Pigments.<br />

4. Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g by us<strong>in</strong>g carrier.<br />

5. Discharge style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> polyester by us<strong>in</strong>g<br />

various reduc<strong>in</strong>g agents.<br />

6. Resist style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on polyester.<br />

7. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> acrylic fabric by us<strong>in</strong>g cationic dyes dyes.<br />

8. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> acrylic fabric by us<strong>in</strong>g disperse dyes.<br />

9. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> nylon with acid dyes.<br />

10. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> nylon with disperse dyes.<br />

11. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> PET/CO blended fabrics by disperse/<br />

reactive dyes.<br />

12. Brasso style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g<br />

5. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> wool and silk<br />

Preparation <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g paste and process sequence for direct style<br />

<strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> wool and silk us<strong>in</strong>g acid dyes.<br />

6. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> Polyester<br />

Preparation <strong>of</strong> polyester fabric for pr<strong>in</strong>t<strong>in</strong>g, study <strong>of</strong><br />

various thickeners for synthetic pr<strong>in</strong>t<strong>in</strong>g. Direct, discharge<br />

and resist style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on polyester. Recent<br />

developments <strong>in</strong> pigment pr<strong>in</strong>t<strong>in</strong>g. Various methods <strong>of</strong><br />

fixation and after treatments.<br />

7. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> Acrylics<br />

Direct, discharge and resist style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g on acrylic<br />

fabric<br />

Study <strong>of</strong> cationic dyes and retard<strong>in</strong>g agents<br />

8. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> Nylon<br />

Various classes <strong>of</strong> dyes required for nylon pr<strong>in</strong>t<strong>in</strong>g direct,<br />

discharge and resist style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> nylon various aftertreatments<br />

<strong>of</strong> pr<strong>in</strong>ted fabric<br />

9. Pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> Blended Fabrics<br />

Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> various blends <strong>of</strong> polyester/<br />

cellulosic with pigment, disperse/ reactive.<br />

Direct style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> polyester / wool, polyester/<br />

acrylic & wool/ acrylic.<br />

Braso style <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g<br />

10.Transfer Pr<strong>in</strong>t<strong>in</strong>g<br />

Process sequence <strong>of</strong> transfer pr<strong>in</strong>t<strong>in</strong>g, advantages and<br />

disadvantages <strong>of</strong> transfer pr<strong>in</strong>t<strong>in</strong>g, mechanism <strong>of</strong> transfer<br />

pr<strong>in</strong>t<strong>in</strong>g, criteria <strong>of</strong> paper, <strong>in</strong>k, and disperse dye suitable for<br />

transfer pr<strong>in</strong>t<strong>in</strong>g<br />

11. Recent Developments In Pr<strong>in</strong>t<strong>in</strong>g<br />

Concept <strong>of</strong> <strong>in</strong>k jet pr<strong>in</strong>t<strong>in</strong>g, carpet pr<strong>in</strong>t<strong>in</strong>g, natural dyes for<br />

pr<strong>in</strong>t<strong>in</strong>g & faults <strong>in</strong> pr<strong>in</strong>t<strong>in</strong>g, their prevention, and<br />

correction.<br />

32

II ) OBJECTIVES AND ACHIVEMENTS :<br />

Tra<strong>in</strong>ees will be able to :<br />

1. Know the various thickeners and their selection criteria<br />

2. Have knowledge <strong>of</strong> various methods <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g.<br />

3. Have knowledge <strong>of</strong> various styles <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g.<br />

4. Know the pr<strong>in</strong>t<strong>in</strong>g technique for prote<strong>in</strong> fibres like wool and silk.<br />

5. Get the knowledge <strong>of</strong> pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> synthetic fibres with different classes <strong>of</strong> dyes.<br />

6. Get the knowledge <strong>of</strong> transfer pr<strong>in</strong>t<strong>in</strong>g.<br />

7. Know the recent developments <strong>in</strong> textile pr<strong>in</strong>t<strong>in</strong>g.<br />

33

List <strong>of</strong> Tools , Equipment and Mach<strong>in</strong>ery Required for<br />

“ TECHNOLOGY OF PRINTING ”<br />

Sr. No. Name <strong>of</strong> Item with Specification Qty. Reqd.<br />

1 Steam Heated Pr<strong>in</strong>t<strong>in</strong>g Tables 4<br />

2 Free hand Pr<strong>in</strong>t<strong>in</strong>g Frames (Wooden) 1<br />

3 Trac<strong>in</strong>g Tables 6<br />

4 Slant<strong>in</strong>g Pr<strong>in</strong>t<strong>in</strong>g Tables 2<br />

5 Flat Pr<strong>in</strong>t<strong>in</strong>g Table (for block pr<strong>in</strong>t<strong>in</strong>g) 2<br />

34

Module – ATPT- 08 : COMPUTER AIDED TEXTILE DESIGNING AND<br />

I ) COURSE CONTENT :<br />

COLOUR<br />

PRACTICAL<br />

THEORY<br />

Skills to be developed:<br />

Intellectual Skill:<br />

1) The students will understand computer added<br />

design<strong>in</strong>g process.<br />

2) The students will appreciate the tools & facilities<br />

provided <strong>in</strong> CAD systems.<br />

Motor Skill:<br />

01Textile Repeat<br />

02 Colour Reduction<br />

03 Scann<strong>in</strong>g<br />

04 Scanned Images<br />

05 Draw<strong>in</strong>g, Pa<strong>in</strong>t<strong>in</strong>g and Edit<strong>in</strong>g tools<br />

1) The students will creat textile design with CAD<br />

s<strong>of</strong>tware.<br />

2) The students will use different motif /colour patterns<br />

as per need and end use <strong>of</strong><br />

textile design.<br />

35

List <strong>of</strong> Practiclas:-<br />

1) Development <strong>of</strong> motifs – natural.<br />

2) Development <strong>of</strong> motifs- Geometrical.<br />

3) Development <strong>of</strong> motifs- Decorative.<br />

4) Development <strong>of</strong> motifs- Abstract.<br />

5) Development <strong>of</strong> shirt<strong>in</strong>g design – Stripes.<br />

06 Colour management and auto-colour ways wizard.<br />

07 Colour separation and plott<strong>in</strong>g<br />

08 Auto plott<strong>in</strong>g<br />

09 Drap<strong>in</strong>g and Texture mapp<strong>in</strong>g<br />

6) Development <strong>of</strong> shirt<strong>in</strong>g design – Checks.<br />

7) Development <strong>of</strong> ladies dress- material design.<br />

8) Development <strong>of</strong> textile design with squire rectangle<br />

base.<br />

9) Development <strong>of</strong> textile design with half drop base.<br />

10) Development <strong>of</strong> textile design with diamond base.<br />

11) Development <strong>of</strong> textile design with ogee base.<br />

12) Development <strong>of</strong> textile design with sat<strong>in</strong> base.<br />

13) Image development and colour process<strong>in</strong>g for<br />

textile pr<strong>in</strong>t<strong>in</strong>g.<br />

14) Development <strong>of</strong> half tone design.<br />

36