observations on 6-10 day old precision beak trimming b281 ... - Lyon

observations on 6-10 day old precision beak trimming b281 ... - Lyon

observations on 6-10 day old precision beak trimming b281 ... - Lyon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1690 Brandywine Avenue,<br />

Chula Vista, CA 91911, U.S.A.<br />

Teleph<strong>on</strong>e (619) 216-3400<br />

Fax (619) 216-3434<br />

Email: info@ly<strong>on</strong>usa.com<br />

www.ly<strong>on</strong>usa.com<br />

Observati<strong>on</strong>s <strong>on</strong><br />

6-<strong>10</strong> Day Old<br />

Precisi<strong>on</strong> Beak<br />

Trimming<br />

Bulletin No.<br />

281-150<br />

8/07<br />

STANDING VS. SITTING: it is often said “The mind can absorb <strong>on</strong>ly what the seat can endure”. This can more pr<strong>on</strong>ounced<br />

when standing. Try standing in a fixed positi<strong>on</strong> <strong>on</strong>e hour without moving around. Better still try it for <strong>on</strong>ly <strong>on</strong>e-half hour. when<br />

<strong>beak</strong> <strong>trimming</strong> in a standing positi<strong>on</strong> the problem can become more severe as the operator must move their arms<br />

through a rhythmical and c<strong>on</strong>stant moti<strong>on</strong>. Despite this we expect <strong>beak</strong> <strong>trimming</strong> d<strong>on</strong>e while standing to be accurate<br />

with maximum producti<strong>on</strong>.<br />

When the operator sits, the positi<strong>on</strong> of the body becomes basically stati<strong>on</strong>ary and <strong>on</strong>ly the arms move to accomplish the<br />

task. Even while <strong>beak</strong> <strong>trimming</strong> in a sitting positi<strong>on</strong>, c<strong>on</strong>siderati<strong>on</strong> must be given to the height of the table. Standard table<br />

tops vary in height from the floor from 29-34 inches. With the De<strong>beak</strong>er set <strong>on</strong> the table top, the positi<strong>on</strong> of the bird can<br />

be higher than the elbow <strong>on</strong> some people, adding to operator fatigue.<br />

We feel that the table top should be such that when the operator is <strong>beak</strong> <strong>trimming</strong>, the forearm is horiz<strong>on</strong>tal (approximately<br />

90 degrees to the upper arm). This positi<strong>on</strong> becomes the most natural <strong>on</strong>e for the pers<strong>on</strong> to functi<strong>on</strong> properly for<br />

l<strong>on</strong>g periods of time.<br />

One of the best 6-<strong>10</strong> <strong>day</strong> <strong>beak</strong> <strong>trimming</strong> set-ups we know of is the use of the <strong>old</strong> classroom type seat with its writing arm.<br />

The back of these chairs aided the students posture and permitted ease in writing. Mounting a De<strong>beak</strong>er <strong>on</strong> the arm at<br />

the proper distance from the operator produced good <strong>beak</strong> <strong>trimming</strong>, quantity and reduced operator fatigue.<br />

If possible have precisi<strong>on</strong> <strong>beak</strong> <strong>trimming</strong> d<strong>on</strong>e in a sitting positi<strong>on</strong>. It’s basic: if the operator is not comfortable-quality and<br />

quantity of <strong>beak</strong> <strong>trimming</strong> will suffer.<br />

POSITION THE DEBEAKER PROPERLY: From the previous paragraphs, it is obvious that the human element c<strong>on</strong>tributes to<br />

good or bad <strong>beak</strong> <strong>trimming</strong>. For this reas<strong>on</strong> the positi<strong>on</strong> of the De<strong>beak</strong>er with respect to the operator is also important.<br />

D<strong>on</strong>’t just set a De<strong>beak</strong>er <strong>on</strong> a table, sit the operator down and start <strong>beak</strong> <strong>trimming</strong>.<br />

We c<strong>on</strong>stantly see De<strong>beak</strong>ers positi<strong>on</strong>ed <strong>on</strong> a table with operator sitting centered <strong>on</strong> the De<strong>beak</strong>er . In precisi<strong>on</strong> <strong>beak</strong><br />

<strong>trimming</strong> this means the operators hands will be in a unnatural positi<strong>on</strong> while h<strong>old</strong>ing the bird being <strong>beak</strong> trimmed. Try it<br />

with the De<strong>beak</strong>er centered <strong>on</strong> the body, the hand will bend OUT to the forearm, tiring in time.<br />

C<strong>on</strong>sider centering the De<strong>beak</strong>er <strong>on</strong> the shoulder line of the operator. For right-handed operators center the De<strong>beak</strong>er<br />

<strong>on</strong> the right shoulder, for left-handed operators, center <strong>on</strong> the left shoulder.<br />

Now the arm and hand is in a natural positi<strong>on</strong> when h<strong>old</strong>ing the bird at the <strong>beak</strong> <strong>trimming</strong> gauge. If the De<strong>beak</strong>er is<br />

positi<strong>on</strong>ed back so that <strong>on</strong>ly slight forward movement is required to insert <strong>beak</strong> into the gauge, less operator effort is<br />

required-thus less fatigue with time.<br />

When the De<strong>beak</strong>er is properly positi<strong>on</strong>ed the movement of the operator becomes a rhythm as they pick up the bird<br />

with <strong>on</strong>e hand while <strong>beak</strong> <strong>trimming</strong> a bird with other, then drop the trimmed bird and with an arc moti<strong>on</strong> transfer the next<br />

bird to be trimmed to the <strong>trimming</strong> hand, then pick up the next bird to be trimmed with the free hand, etc.<br />

Proper De<strong>beak</strong>er<br />

positi<strong>on</strong>ing aids in the rhythm of operati<strong>on</strong> with minimum operator fatigue.<br />

THE GAUGE: The basic gauge used in precisi<strong>on</strong> <strong>beak</strong> <strong>trimming</strong> has three holes in it. The size of these holes allows the operator<br />

to use the hole most suitable to the size and age of the bird (6-<strong>10</strong> <strong>day</strong>s).<br />

The gauges are supplied with or without an attached tube. The tube is used for water cooling the gauge. It takes a very<br />

small flow of water to keep the gauge cool.

Page 2<br />

Some operators prefer the gauge without the cooling tube and feel the hot gauge aids in the cauterizati<strong>on</strong> process. You<br />

should know however that a properly heated blade will approach 1400 o F and over a period of operati<strong>on</strong> can raise the<br />

gauge temperature to 600-<strong>10</strong>00 o F which can easily burn the operators fingers. When <strong>beak</strong> <strong>trimming</strong> this way the operators<br />

finger should be taped for protecti<strong>on</strong>. The positi<strong>on</strong> of the gauge (regardless of the <strong>on</strong>e used) to the blade is very<br />

important. It should be centered <strong>on</strong>, and be square with, the blade and adjusted to the inside to a point tat the blade<br />

strikes the back of the gauge slightly as it comes down. This produces a scissor acti<strong>on</strong> <strong>on</strong> the <strong>beak</strong> and makes a square<br />

cut. You will note that the top edge of the gauge is bent out at an angle to allow the blade to complete the acti<strong>on</strong> without<br />

jamming the blade and gauge.<br />

The gauge is made of stainless steel and is quite thin. It must be this way. Too thick of a gauge would cause areas of the<br />

gauge to sear any area of the <strong>beak</strong> it is in c<strong>on</strong>tact with and would not be flexible enough for good scissors acti<strong>on</strong>.<br />

Finally-but of utmost importance-it is at this point that a lot of poor precisi<strong>on</strong> <strong>beak</strong> <strong>trimming</strong> takes place. The birds <strong>beak</strong><br />

should be inserted into the hole with the birds head square and straight with the gauge. How the head is held is how the<br />

<strong>beak</strong> <strong>trimming</strong> will be d<strong>on</strong>e, square or crooked, (This is why we emphasize operator and De<strong>beak</strong>er positi<strong>on</strong>ing). The<br />

<strong>beak</strong> should be held in this positi<strong>on</strong> THE ENTIRE TIME THE BLADE IS IN CONTACT WITH BEAK. Failure to do this will result in<br />

improper cauterizati<strong>on</strong> time. The growth of the <strong>beak</strong> roots will not be inhibited properly and the <strong>beak</strong> may grow out again.<br />

If this does occur another <strong>beak</strong> <strong>trimming</strong> will required. A handrest will aid greatly in h<strong>old</strong>ing the bird properly and steady<br />

during the <strong>beak</strong> <strong>trimming</strong> operati<strong>on</strong>.<br />

THE BLADE: The blade most often used for precisi<strong>on</strong> <strong>beak</strong> <strong>trimming</strong> is the BC type. It has two cutting edges so that when<br />

<strong>on</strong>e edge becomes dull it can be turned over and the other edge used.<br />

The blade is mounted so that the FLAT EDGE of the cutting edge used is towards the operator (the beveled edge is away<br />

from the operator). This produces the scissor acti<strong>on</strong> discussed in the paragraph <strong>on</strong> the gauge. We are amazed at the<br />

amount of people who mount the blade with the beveled edge towards the operator.<br />

When the blade is mounted wr<strong>on</strong>g, the cutting takes place away from the gauge hole (Blade thickness and the balance<br />

of the <strong>beak</strong> is literally seared off to the back of the gauge. A mutilated <strong>beak</strong> results, often with tenderness to the <strong>beak</strong><br />

that inhibits eating for the life of the bird. A needless loss.<br />

We stressed the point that the birds head must be square and straight during the <strong>beak</strong> <strong>trimming</strong> and cauterizati<strong>on</strong><br />

process. If the birds head is not square, a blade cut made at an angel can leave a sharp protrusi<strong>on</strong> that negates the<br />

whole value of <strong>beak</strong> <strong>trimming</strong> as the bird still has an effective means to peck despite the end of the <strong>beak</strong> being g<strong>on</strong>e.<br />

DETERMINED BLADE TEMPERATURE BY COLOR: When the precisi<strong>on</strong> <strong>beak</strong> <strong>trimming</strong> method was first introduced, the innovator<br />

said the blade must be “Cherry Red”. It didn’t take too l<strong>on</strong>g to find however, that what <strong>on</strong>e pers<strong>on</strong> called “cherry red”<br />

was c<strong>on</strong>siderably different from another. We found that the difference between peoples interpretati<strong>on</strong> of “cherry red”<br />

resulted in temperature differences by measurement of up to 600 o F.<br />

When the blade is first heated (each time, new or <strong>old</strong>) it builds up resistance to current as it heats up. This increase of resistance<br />

lowers the current flow through the blade up to 6% when it becomes completely hot. For this reas<strong>on</strong> a slight readjustment<br />

of color may be required about 5 minutes first being turned <strong>on</strong>.<br />

Another factor to c<strong>on</strong>sider in determining blade color vs. temperature is that a new blade is bright in color when new. As<br />

it heats, oxides are produced <strong>on</strong> its surface causing the blade to become a dull color. It is the color observed <strong>on</strong> an oxidized<br />

blade that is most accurate in determining temperature. Once a setting is determined for use it should be left there.<br />

The <strong>on</strong>ly change necessary would be if the line voltage for the De<strong>beak</strong>er should drop and stay lower for a period of time.<br />

A new c<strong>on</strong>tact high temperature thermometer which can accurately and quickly measure precise blade temperature is<br />

now available from Ly<strong>on</strong> at a reas<strong>on</strong>able cost. It enables you to set your De<strong>beak</strong>er (s) at the correct temperature setting<br />

and to maintain that temperature for optimum results. WE HIGHLY RECOMMEND THIS DEVICE TO ALL USERS! Inquire<br />

about Catalog# 500-025.

You might ask why we have such a wide range of heat? We have 20 different types of blades used <strong>on</strong> many types of<br />

<strong>beak</strong> <strong>trimming</strong>: broilers, layers, turkeys, ducks, game birds for <strong>day</strong>-<strong>old</strong>, 6-<strong>10</strong> <strong>day</strong>, 12-14 weeks etc. All require different<br />

blades, different temperatures. A separate De<strong>beak</strong>er for each method would be prohibitive, hence <strong>on</strong>e De<strong>beak</strong>er with<br />

full range to accomplish all the various needs.<br />

A final note <strong>on</strong> blades. When new they are tempered (hardened <strong>on</strong> the surface). Running a blade at high heat (above<br />

1500 o F) tends to anneal the hardness out of the blade. The blade may bow or warp badly resulting in poor c<strong>on</strong>tact with<br />

gauge. Blade life is also reduced from very high temperature as the cutting edge will lose its sharpness faster than with<br />

the lower heat.<br />

Remember: to read the color properly, shield the blade from surrounding light.<br />

Page 3<br />

GAUGE & BLADE CONTACT: Many people like to keep the blade in c<strong>on</strong>tact with the gauge even when the blade is up.<br />

They say it helps the operator insert the <strong>beak</strong> in the gauge and push forward to maintain full c<strong>on</strong>tact during the cauterizati<strong>on</strong><br />

time. This is true, but a lot of pressure isn’t needed and there is a drawback to maintaining c<strong>on</strong>tact between the<br />

blade and gauge.<br />

First, the gauge becomes very hot (can go over <strong>10</strong>00 o F). The gauge blackens and carb<strong>on</strong>izes and so<strong>on</strong> loses its strength.<br />

This results in a diminished gauge life.<br />

Sec<strong>on</strong>d, due to the input voltage of the De<strong>beak</strong>er 120 or 240 volts, the entire case is grounded as a safety precauti<strong>on</strong>.<br />

The output leads to the blades are very low in voltage (less than <strong>on</strong>e volt)but high in current. WHEN THE BLADE IS LEFT IN<br />

CONTACT WITH THE GAUGE IT IS PARTIALLY GROUNDED. THIS DRAINS OFF CURRENT FROM THE BLADE AND THEREFORE DRAINS<br />

HEAT. All of us have seen the dark area develop around the birds <strong>beak</strong> <strong>on</strong> the blade while cutting. This is simply heat leaving<br />

the blade to a c<strong>old</strong> surface (the birds <strong>beak</strong> is c<strong>old</strong> in relati<strong>on</strong> to blade heat), to do its job. The color recovers immediately<br />

as the <strong>beak</strong> cauterizes. The blade in c<strong>on</strong>tact with the gauge works the same way except the drain of heat is c<strong>on</strong>stant.<br />

THE CONTROL METHOD: Two types of De<strong>beak</strong>er<br />

the Foot Switch.<br />

c<strong>on</strong>trols are used to actuate the machine, the Finger Touch c<strong>on</strong>trol and<br />

The Finger Touch C<strong>on</strong>trol was the most popular method with operators. It has in our opini<strong>on</strong> draw backs that caused the<br />

introducti<strong>on</strong> of the Foot Switch which is rapidly growing in popularity.<br />

Previously, we made reference of the importance of operator positi<strong>on</strong> and De<strong>beak</strong>er positi<strong>on</strong> to reduce operator fatigue<br />

and obtain quality <strong>beak</strong> <strong>trimming</strong>.<br />

So we have the operator positi<strong>on</strong>ed correctly, the De<strong>beak</strong>er in the right place, the birds <strong>beak</strong> is inserted in the gauge<br />

square and straight-ready to trim and cauterize. If a Finger Touch C<strong>on</strong>trol is used, it is now necessary to move <strong>on</strong>e or two<br />

of the fingers h<strong>old</strong>ing the bird in place to trigger the unit into operati<strong>on</strong>. Everything is right unless the operator moves the<br />

bird when actuating the Finger Touch C<strong>on</strong>trol.<br />

A Foot Switch sits <strong>on</strong> the floor and is easily operated with the operators toes. This leaves the operators hands free at all<br />

times throughout the <strong>beak</strong> <strong>trimming</strong> cycle to c<strong>on</strong>centrate <strong>on</strong> doing a quality job.<br />

CONCLUSION: We have attempted in this bulletin to explain in additi<strong>on</strong>al detail, some of the things we feel important to<br />

the <strong>beak</strong> <strong>trimming</strong> operati<strong>on</strong> not covered in specific bulletins.<br />

Quality <strong>beak</strong> <strong>trimming</strong> is the result of proper equipment usage, operator training and proper set up. Producti<strong>on</strong> comes<br />

from good <strong>beak</strong> <strong>trimming</strong> practice and developed operator skill with proper supervisi<strong>on</strong>. We hope this bulletin has been<br />

of help to you in achieving quality <strong>beak</strong> <strong>trimming</strong>.

Page 4<br />

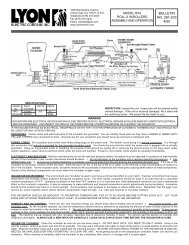

LYON EQUIPMENT FOR 6-<strong>10</strong> DAY-OLD PRECISION BEAK TRIMMING<br />

SUPER V PRECISION DEBEAKER<br />

The Super V Precisi<strong>on</strong> De<strong>beak</strong>er is a complete powered unit equipped and ready to operate with minimum adjustment.<br />

For full informati<strong>on</strong>, send for Bulletin SV-2. FOOT SWITCH STANDARD WITH UNITS.<br />

CATALOG NUMBER<br />

A-C INPUT VOLTAGE<br />

TYPE OF ATTACHMENT GAUGE<br />

950-092<br />

950-093<br />

950-094<br />

950-095<br />

120 VAC<br />

230 VAC<br />

120 VAC<br />

230 VAC<br />

BP GAUGE (Waterless)<br />

BP GAUGE (Waterless)<br />

B GAUGE (Water-cooled)<br />

B GAUGE (Water-cooled)<br />

PRECISION DEBEAKING-PAK<br />

C<strong>on</strong>sists of a Super De<strong>beak</strong>er , Pow-R-Pak Unit and Attachment selected by user and C<strong>on</strong>trol as selected by user. System<br />

is completely assembled at the factory prior to shipment.<br />

CATALOG NUMBER<br />

A-C INPUT VOLTAGE<br />

TYPE OF ATTACHMENT GAUGE<br />

960-030<br />

960-031<br />

960-032<br />

960-033<br />

960-034<br />

960-035<br />

120 VAC<br />

230 VAC<br />

120 VAC<br />

230 VAC<br />

120 VAC<br />

230 VAC<br />

B ATTACHMENT (Water-cooled)<br />

B ATTACHMENT (Water-cooled)<br />

BP ATTACHMENT (Waterless)<br />

BP ATTACHMENT (Waterless)<br />

8BC ATTACHMENT (Water-cooled)<br />

8BC ATTACHMENT (Water-cooled)<br />

To order a system with a Finger Touch C<strong>on</strong>trol, add the suffix TC to Catalog Number. To order a system with a Foot Switch<br />

C<strong>on</strong>trol, add suffix FS to the catalog number. (See current price schedule).