improved super debeaker installation and operation b281-153 - Lyon

improved super debeaker installation and operation b281-153 - Lyon

improved super debeaker installation and operation b281-153 - Lyon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1690 Br<strong>and</strong>ywine Avenue,<br />

Chula Vista, CA 91911, U.S.A.<br />

Telephone (619) 216-3400<br />

Fax (619) 216-3434<br />

Email: info@loynusa.com<br />

www.lyonusa.com<br />

IMPROVED SUPER<br />

DEBEAKER ® INSTALLATION<br />

AND OPERATION<br />

BULLETIN<br />

281-<strong>153</strong><br />

8/07<br />

SPECIFICATIONS<br />

CATALOG INPUT HERTZ WATTS<br />

NUMBER POWER<br />

950-088 120VAC<br />

950-089 230VAC<br />

50/60<br />

70-210<br />

WARNING: THE BLADE OF THE DEBEAKER® IS VERY<br />

HOT DURING OPERATION AND CAN CAUSE SERIOUS<br />

CUTS AND BURNS. OPERATING PERSONNEL<br />

SHOULD BE CAUTIONED TO AVOID CONTACT WITH<br />

THE BLADE AREA. TAPING OF THE OPERATOR’S<br />

FINGERS IS RECOMMENDED.<br />

CAUTION: REMOVE THE DEBEAKER® POWER CORD<br />

FROM THE POWER SOURCE BEFORE ATTEMPTING<br />

SERVICE OR REPAIRS TO THE UNIT. ELECTRICAL<br />

REPAIRS SHOULD BE PERFORMED BY A QUALIFIED<br />

ELECTRICIAN.<br />

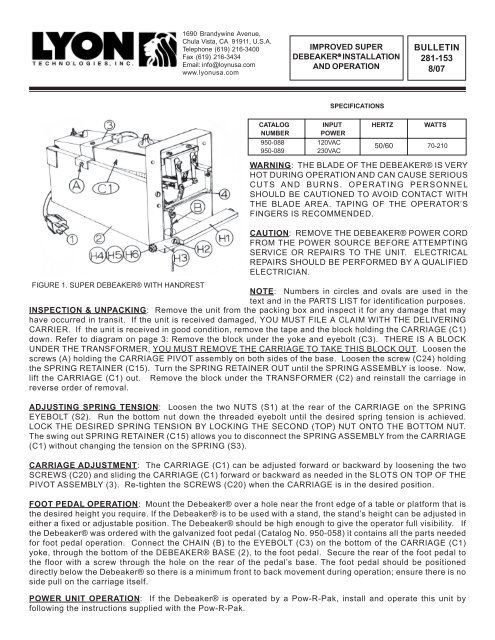

FIGURE 1. SUPER DEBEAKER® WITH HANDREST<br />

NOTE: Numbers in circles <strong>and</strong> ovals are used in the<br />

text <strong>and</strong> in the PARTS LIST for identification purposes.<br />

INSPECTION & UNPACKING: Remove the unit from the packing box <strong>and</strong> inspect it for any damage that may<br />

have occurred in transit. If the unit is received damaged, YOU MUST FILE A CLAIM WITH THE DELIVERING<br />

CARRIER. If the unit is received in good condition, remove the tape <strong>and</strong> the block holding the CARRIAGE (C1)<br />

down. Refer to diagram on page 3: Remove the block under the yoke <strong>and</strong> eyebolt (C3). THERE IS A BLOCK<br />

UNDER THE TRANSFORMER, YOU MUST REMOVE THE CARRIAGE TO TAKE THIS BLOCK OUT. Loosen the<br />

screws (A) holding the CARRIAGE PIVOT assembly on both sides of the base. Loosen the screw (C24) holding<br />

the SPRING RETAINER (C15). Turn the SPRING RETAINER OUT until the SPRING ASSEMBLY is loose. Now,<br />

lift the CARRIAGE (C1) out. Remove the block under the TRANSFORMER (C2) <strong>and</strong> reinstall the carriage in<br />

reverse order of removal.<br />

ADJUSTING SPRING TENSION: Loosen the two NUTS (S1) at the rear of the CARRIAGE on the SPRING<br />

EYEBOLT (S2). Run the bottom nut down the threaded eyebolt until the desired spring tension is achieved.<br />

LOCK THE DESIRED SPRING TENSION BY LOCKING THE SECOND (TOP) NUT ONTO THE BOTTOM NUT.<br />

The swing out SPRING RETAINER (C15) allows you to disconnect the SPRING ASSEMBLY from the CARRIAGE<br />

(C1) without changing the tension on the SPRING (S3).<br />

CARRIAGE ADJUSTMENT: The CARRIAGE (C1) can be adjusted forward or backward by loosening the two<br />

SCREWS (C20) <strong>and</strong> sliding the CARRIAGE (C1) forward or backward as needed in the SLOTS ON TOP OF THE<br />

PIVOT ASSEMBLY (3). Re-tighten the SCREWS (C20) when the CARRIAGE is in the desired position.<br />

FOOT PEDAL OPERATION: Mount the Debeaker® over a hole near the front edge of a table or platform that is<br />

the desired height you require. If the Debeaker® is to be used with a st<strong>and</strong>, the st<strong>and</strong>’s height can be adjusted in<br />

either a fixed or adjustable position. The Debeaker® should be high enough to give the operator full visibility. If<br />

the Debeaker® was ordered with the galvanized foot pedal (Catalog No. 950-058) it contains all the parts needed<br />

for foot pedal <strong>operation</strong>. Connect the CHAIN (B) to the EYEBOLT (C3) on the bottom of the CARRIAGE (C1)<br />

yoke, through the bottom of the DEBEAKER® BASE (2), to the foot pedal. Secure the rear of the foot pedal to<br />

the floor with a screw through the hole on the rear of the pedal’s base. The foot pedal should be positioned<br />

directly below the Debeaker® so there is a minimum front to back movement during <strong>operation</strong>; ensure there is no<br />

side pull on the carriage itself.<br />

POWER UNIT OPERATION: If the Debeaker® is operated by a Pow-R-Pak, install <strong>and</strong> operate this unit by<br />

following the instructions supplied with the Pow-R-Pak.

GENERAL OPERATING INFORMATION<br />

IMPORTANT: BLADE NUTS MUST BE KEPT TIGHT FOR PROPER HEAT CONTROL. METAL EXPANDS WHEN<br />

HEATED AND CONTRACTS AS IT COOLS. IT IS IMPORTANT TO CHECK NUT TIGHTNESS AT START-UP<br />

TIME AND OCCASIONALLY DURING OPERATION.<br />

If the optional HAND REST is used, adjust the HAND REST (H1) to the proper position for operator comfort.<br />

Plug the POWER CORD (1) into a GROUNDED OUTLET power source. Blade temperature is adjusted by turning<br />

the HEAT CONTROL KNOB (C16) clockwise. Turning the HEAT CONTROL KNOB (C16) all the way to the LEFT<br />

turns the unit OFF. Three areas of heat are shown on the DIAL (C17), LOW-MEDIUM-HIGH. Turning the KNOB<br />

(C16) all the way to the RIGHT is the HOT or maximum heat setting. In most cases the MEDIUM heat range will<br />

be used. However, the heat setting can he affected by the type of blade used, the condition of the blade, the<br />

condition of the lead ends of the TRANSFORMER (C2) secondary, <strong>and</strong> the tightness of the BLADE NUTS (C8).<br />

Low incoming VOLTAGE to the Debeaker® will require a higher setting of the HEAT CONTROL (C5) to<br />

compensate. NEVER USE MORE HEAT THAN NECESSARY TO CAUTERIZE PROPERLY. Normally, the HEAT<br />

CONTROL (C5) can be adjusted until the blade is a DULL RED COLOR (view blade color in a subdued light).<br />

Shade the blade area if necessary to view the proper blade color.<br />

The Debeaker® blade is installed as shown on the illustration to the left. NOTE:<br />

THE BLADE IS INSTALLED ON THE ENDS OF THE TRANSFORMER LEAD<br />

ENDS AND BEHIND THE BLADE BARS. The blade bars are slotted to allow<br />

them to swing out for changing the blade or for maintenance. Due to the heat<br />

levels the blade bars are subjected to, they should be changed monthly if the<br />

Debeaker® is in constant use. The use of BLADE BARS (C9) on older<br />

transformers that do not have the ROUND TRANSFORMER LEAD ENDS (C7)<br />

IS NOT RECOMMENDED.<br />

MAINTENANCE: Properly used <strong>and</strong> maintained, your Super Debeaker® will supply you with years of service.<br />

As with any electrical device, exercise caution when servicing the unit. BE SAFE, DISCONNECT THE<br />

POWER CORD FROM THE POWER SOURCE WHEN SERVICING THIS UNIT.<br />

To maintain the Debeaker® in top operating condition, the front end (blade <strong>and</strong> holder area) should be serviced<br />

once a month, more often if subjected to daily use. Recommended front-end maintenance is as follows:<br />

1. Remove Blade, Insulator <strong>and</strong> Blade Bars.<br />

2. Inspect insulator <strong>and</strong> clean with a wire brush. Replace if required.<br />

3. Inspect blade bars. Replace them if they are pitted <strong>and</strong>/or burned.<br />

4. Wire brush the ends of the transformer secondary leads. DO NOT FILE.<br />

5. Run a 8-32 die down the transformer lead studs all the way to the transformer lead. Use the REVERSE SIDE OF<br />

THE DIE. The front side is tapered <strong>and</strong> will not clean the threads close enough to the transformer lead.<br />

6. Assemble the insulator <strong>and</strong> blade bars on the carriage. LEAVE THE INSULATOR LOOSE.<br />

7. Mount the blade <strong>and</strong> tighten into place with 8-32 nuts.<br />

8. Tighten the insulator block into place.<br />

9. Inspect the rear of the blade bars to be sure there is full contact of the blade to the transformer leads.<br />

For more detailed maintenance information, send for Bulletin 281-131B, “General Debeaker® Maintenance”.<br />

For a complete listing of all blades <strong>and</strong> attachments available, send for the <strong>Lyon</strong> Catalog, LEC-4.

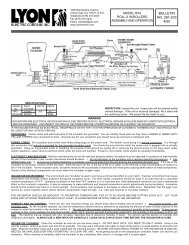

REPLACEMENT PARTS LIST<br />

The letters <strong>and</strong> numbers in the circles <strong>and</strong> ovals in all the illustrations included in this bulletin correspond to the<br />

Item Number in the Parts List below. All letters <strong>and</strong> numbers are also shown in ( ) in the text for identification<br />

of the part or the assembly.<br />

See Instructions sent with optional h<strong>and</strong> rest assembly for H1, H2, H3, H4, H5, H6 identification.<br />

ITEM 950-088 950-089 DESCRIPTION QTY<br />

NO. 120VAC 230VAC<br />

1 200-028 200-029 Power Cord 1<br />

1 n/a 200-008 European Cord 1<br />

2 110-058 110-058 Base (No Parts) 1<br />

3 110-059 110-059 Carriage Pivot 1<br />

4 120-002 120-002 Beak Support 1<br />

C1 110-060 110-060 Carriage 1<br />

C2 480-002 480-003 Transformer 1<br />

C3 260-002 260-002 Eyebolt 1<br />

C4 120-156 120-156 Guard 1<br />

C5 400-004 400-005 Rheostat 1<br />

C6 200-014 200-014 Terminal Block 1<br />

* C7 200-036 200-036 Lead End 2<br />

C8 NC008-32-HST NC008-32-HST 8-32 Hex Nut 2<br />

** C9 120-165 120-165 Blade Bars 2<br />

** C10 SC006-32-014 SC006-32-014 6-32 x 7/8"Screw 2<br />

** C11 NC006-32-WST NC006-32-WST Wing Nut 2<br />

** C12 300-004 300-004 Insulator 1<br />

C13 NC008-32-HST NC008-32-HST 8-32 Hex Nut 2<br />

ITEM 950-088 950-089 DESCRIPTION QTY<br />

NO. 120VAC 230VAC<br />

C14 SC008-32-110 SC008-32-110 Screw 8-32 x 15/8" 2<br />

C15 120-203 120-203 Retainer Tab 1<br />

C16 240-008 240-008 Knob 1<br />

C17 280-011 280-012 Dial Plate 1<br />

C18 SC008-32-010 SC008-32-010 Screw 8-32 x 5/8" 2<br />

C19 300-007 300-007 Strain Relief 1<br />

C20 SC008-32-007 SC008-32-007 Screw 8-32 x 7/8" 4<br />

C21 WC008-LW-HSP WC008-LW-HSP Lock Washer 4<br />

C22 NC008-32-HST NC008-32-HST 8-32 Hex Nut 4<br />

C23 SC008-32-007 SC008-32-007 Screw 1<br />

C24 260-063 260-063 Flat Washer 1<br />

*** S1 NC008-32-HST NC008-32-HST 8-32 Hex Nut 2<br />

*** S2 260-041 260-041 Eyebolt 1<br />

*** S3 260-024 260-024 Spring 1<br />

*** S4 260-042 260-042 S Clip 1<br />

*Part Number For Transformer Lead Ends Only.<br />

**Part Number 900-114 For Complete Assy.<br />

***Part Number 120-248 For Complete Assy.