Roof fans - Troges

Roof fans - Troges

Roof fans - Troges

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RF Fans<br />

Installation, Maintenance and Service<br />

table #6, page 62. Three-phase motors are always connected<br />

for 3x400V - Y voltage in the factory; if the fan is<br />

controlled using a 3x230V - Δ frequency inverter (motor<br />

outputs up to 1.5 kW) it is necessary to reconnect the<br />

terminal box on the motor for delta connection! RF<br />

71/50-4D and RF 10/71-6D line <strong>fans</strong> are always connected<br />

for 3x400V –Y connection.<br />

The wiring cables are led into the terminal box through<br />

the tube which is routed through the fan and roof<br />

adaptor interior into the ventilated room. The power<br />

supply cable and thermal protection cable must be led<br />

separately.<br />

The cable must be firmly fixed, and it must not load<br />

the connection in the terminal box with its weight.<br />

When dimensioning the conductors, it is necessary<br />

to take into account the current loading by the device as<br />

well as the length of the conductor. The following cables<br />

are recommended to connect fan motors:<br />

HO5VVH2 - F 2Ax0.75 – circuit<br />

CYKY 3Cx …<br />

CYKY 4Bx …<br />

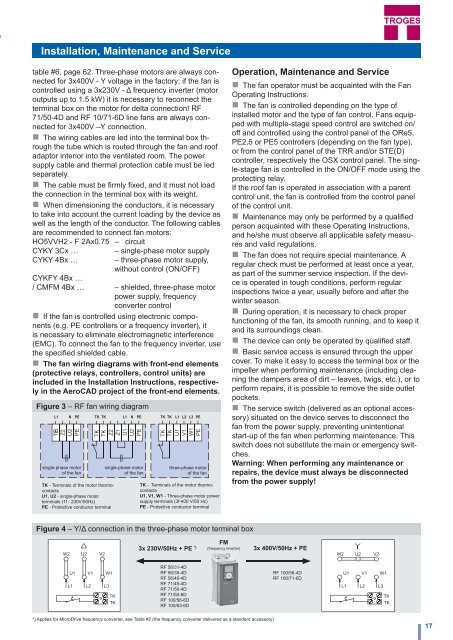

Figure 3 – RF fan wiring diagram<br />

single-phase motor<br />

of the fan<br />

TK - Terminals of the motor thermocontacts<br />

U1, U2 - single-phase motor<br />

terminals (1f - 230V/50Hz)<br />

PE - Protective conductor terminal<br />

– single-phase motor supply<br />

– three-phase motor supply,<br />

without control (ON/OFF)<br />

CYKFY 4Bx …<br />

/ CMFM 4Bx … – shielded, three-phase motor<br />

power supply, frequency<br />

converter control<br />

If the fan is controlled using electronic components<br />

(e.g. PE controllers or a frequency inverter), it<br />

is necessary to eliminate electromagnetic interference<br />

(EMC). To connect the fan to the frequency inverter, use<br />

the specified shielded cable.<br />

The fan wiring diagrams with front-end elements<br />

(protective relays, controllers, control units) are<br />

included in the Installation Instructions, respectively<br />

in the AeroCAD project of the front-end elements.<br />

single-phase motor<br />

of the fan<br />

three-phase motor<br />

of the fan<br />

TK - Terminals of the motor thermocontacts<br />

U1, V1, W1 - Three-phase motor power<br />

supply terminals (3f-400 V/50 Hz)<br />

PE - Protective conductor terminal<br />

Operation, Maintenance and Service<br />

The fan operator must be acquainted with the Fan<br />

Operating Instructions.<br />

The fan is controlled depending on the type of<br />

installed motor and the type of fan control. Fans equipped<br />

with multiple-stage speed control are switched on/<br />

off and controlled using the control panel of the ORe5,<br />

PE2,5 or PE5 controllers (depending on the fan type),<br />

or from the control panel of the TRR and/or STE(D)<br />

controller, respectively the OSX control panel. The single-stage<br />

fan is controlled in the ON/OFF mode using the<br />

protecting relay.<br />

If the roof fan is operated in association with a parent<br />

control unit, the fan is controlled from the control panel<br />

of the control unit.<br />

Maintenance may only be performed by a qualified<br />

person acquainted with these Operating Instructions,<br />

and he/she must observe all applicable safety measures<br />

and valid regulations.<br />

The fan does not require special maintenance. A<br />

regular check must be performed at least once a year,<br />

as part of the summer service inspection. If the device<br />

is operated in tough conditions, perform regular<br />

inspections twice a year, usually before and after the<br />

winter season.<br />

During operation, it is necessary to check proper<br />

functioning of the fan, its smooth running, and to keep it<br />

and its surroundings clean.<br />

The device can only be operated by qualified staff.<br />

Basic service access is ensured through the upper<br />

cover. To make it easy to access the terminal box or the<br />

impeller when performing maintenance (including cleaning<br />

the dampers area of dirt – leaves, twigs, etc.), or to<br />

perform repairs, it is possible to remove the side outlet<br />

pockets.<br />

The service switch (delivered as an optional accessory)<br />

situated on the device serves to disconnect the<br />

fan from the power supply, preventing unintentional<br />

start-up of the fan when performing maintenance. This<br />

switch does not substitute the main or emergency switches.<br />

Warning: When performing any maintenance or<br />

repairs, the device must always be disconnected<br />

from the power supply!<br />

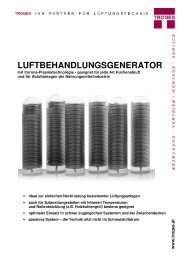

Figure 4 – Y/Δ connection in the three-phase motor terminal box<br />

3x 230V/50Hz + PE *)<br />

FM<br />

(frequency inverter)<br />

3x 400V/50Hz + PE<br />

RF 56/31-4D<br />

RF 56/35-4D<br />

RF 56/40-4D<br />

RF 71/45-4D<br />

RF 71/50-4D<br />

RF 71/50-6D<br />

RF 100/56-6D<br />

RF 100/63-6D<br />

RF 100/56-4D<br />

RF 100/71-6D<br />

*) Applies for MicroDrive frequency converter, see Table #2 (the frequency converter delivered as a standard accessory)<br />

17