KODAK VERSAMARK DS4300 Printing System and DS4350 UV ...

KODAK VERSAMARK DS4300 Printing System and DS4350 UV ...

KODAK VERSAMARK DS4300 Printing System and DS4350 UV ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

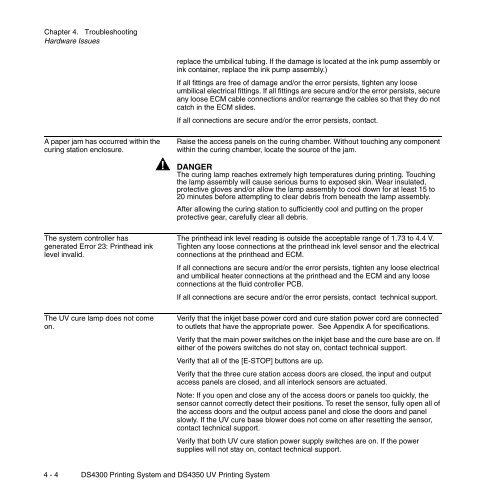

Chapter 4. Troubleshooting<br />

Hardware Issues<br />

replace the umbilical tubing. If the damage is located at the ink pump assembly or<br />

ink container, replace the ink pump assembly.)<br />

If all fittings are free of damage <strong>and</strong>/or the error persists, tighten any loose<br />

umbilical electrical fittings. If all fittings are secure <strong>and</strong>/or the error persists, secure<br />

any loose ECM cable connections <strong>and</strong>/or rearrange the cables so that they do not<br />

catch in the ECM slides.<br />

If all connections are secure <strong>and</strong>/or the error persists, contact.<br />

A paper jam has occurred within the<br />

curing station enclosure.<br />

Raise the access panels on the curing chamber. Without touching any component<br />

within the curing chamber, locate the source of the jam.<br />

! DANGER<br />

The curing lamp reaches extremely high temperatures during printing. Touching<br />

the lamp assembly will cause serious burns to exposed skin. Wear insulated,<br />

protective gloves <strong>and</strong>/or allow the lamp assembly to cool down for at least 15 to<br />

20 minutes before attempting to clear debris from beneath the lamp assembly.<br />

After allowing the curing station to sufficiently cool <strong>and</strong> putting on the proper<br />

protective gear, carefully clear all debris.<br />

The system controller has<br />

generated Error 23: Printhead ink<br />

level invalid.<br />

The <strong>UV</strong> cure lamp does not come<br />

on.<br />

The printhead ink level reading is outside the acceptable range of 1.73 to 4.4 V.<br />

Tighten any loose connections at the printhead ink level sensor <strong>and</strong> the electrical<br />

connections at the printhead <strong>and</strong> ECM.<br />

If all connections are secure <strong>and</strong>/or the error persists, tighten any loose electrical<br />

<strong>and</strong> umbilical heater connections at the printhead <strong>and</strong> the ECM <strong>and</strong> any loose<br />

connections at the fluid controller PCB.<br />

If all connections are secure <strong>and</strong>/or the error persists, contact technical support.<br />

Verify that the inkjet base power cord <strong>and</strong> cure station power cord are connected<br />

to outlets that have the appropriate power. See Appendix A for specifications.<br />

Verify that the main power switches on the inkjet base <strong>and</strong> the cure base are on. If<br />

either of the powers switches do not stay on, contact technical support.<br />

Verify that all of the [E-STOP] buttons are up.<br />

Verify that the three cure station access doors are closed, the input <strong>and</strong> output<br />

access panels are closed, <strong>and</strong> all interlock sensors are actuated.<br />

Note: If you open <strong>and</strong> close any of the access doors or panels too quickly, the<br />

sensor cannot correctly detect their positions. To reset the sensor, fully open all of<br />

the access doors <strong>and</strong> the output access panel <strong>and</strong> close the doors <strong>and</strong> panel<br />

slowly. If the <strong>UV</strong> cure base blower does not come on after resetting the sensor,<br />

contact technical support.<br />

Verify that both <strong>UV</strong> cure station power supply switches are on. If the power<br />

supplies will not stay on, contact technical support.<br />

4 - 4 <strong>DS4300</strong> <strong>Printing</strong> <strong>System</strong> <strong>and</strong> <strong>DS4350</strong> <strong>UV</strong> <strong>Printing</strong> <strong>System</strong>