THE ECHO - Ferrostaal

THE ECHO - Ferrostaal

THE ECHO - Ferrostaal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

28<br />

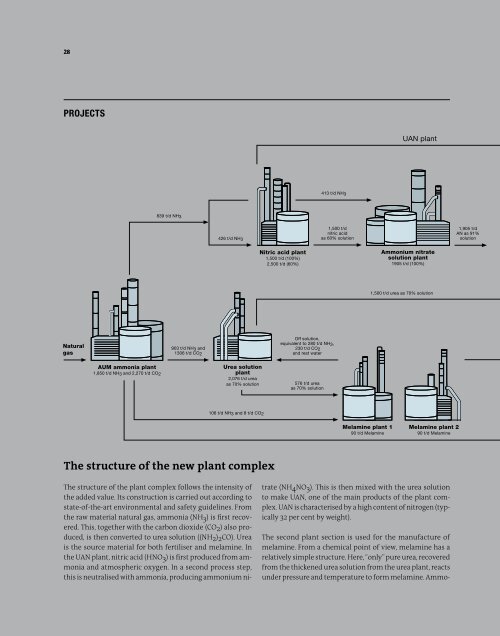

ProjECtS<br />

Natural<br />

gas<br />

AUM ammonia plant<br />

1,850 t/d NH3 and 2,270 t/d CO2<br />

839 t/d NH3<br />

903 t/d NH3 and<br />

1306 t/d CO2<br />

426 t/d NH3<br />

Urea solution<br />

plant<br />

2,076 t/d urea<br />

as 70% solution<br />

106 t/d NH3 and 8 t/d CO2<br />

The structure of the new plant complex<br />

The structure of the plant complex follows the intensity of<br />

the added value. Its construction is carried out according to<br />

state-of-the-art environmental and safety guidelines. From<br />

the raw material natural gas, ammonia (NH3) is first recovered.<br />

This, together with the carbon dioxide (CO2) also produced,<br />

is then converted to urea solution ((NH2)2CO). Urea<br />

is the source material for both fertiliser and melamine. In<br />

the UAN plant, nitric acid (HNO3) is first produced from ammonia<br />

and atmospheric oxygen. In a second process step,<br />

this is neutralised with ammonia, producing ammonium ni-<br />

Nitric acid plant<br />

1,500 t/d (100%)<br />

2,500 t/d (60%)<br />

413 t/d NH3<br />

Off solution,<br />

equivalent to 280 t/d NH3,<br />

230 t/d CO2<br />

and rest water<br />

576 t/d urea<br />

as 70% solution<br />

1,500 t/d<br />

nitric acid<br />

as 60% solution<br />

Melamine plant 1<br />

90 t/d Melamine<br />

UAN plant<br />

Ammonium nitrate<br />

solution plant<br />

1905 t/d (100%)<br />

1,500 t/d urea as 70% solution<br />

Melamine plant 2<br />

90 t/d Melamine<br />

trate (NH4NO3). This is then mixed with the urea solution<br />

to make UAN, one of the main products of the plant complex.<br />

UAN is characterised by a high content of nitrogen (typically<br />

32 per cent by weight).<br />

The second plant section is used for the manufacture of<br />

melamine. From a chemical point of view, melamine has a<br />

relatively simple structure. Here, “only” pure urea, recovered<br />

from the thickened urea solution from the urea plant, reacts<br />

under pressure and temperature to form melamine. Ammo-<br />

1,905 t/d<br />

AN as 91%<br />

solution<br />

<strong>THE</strong> <strong>ECHO</strong> August 2007<br />

UAN mixing tank<br />

4,274 t/d (UAN 32)<br />

UAN-32 solution<br />

Melamine powder<br />

Cold ammonia<br />

Normal 4,274 t/d<br />

Design 4,300 t/d<br />

Normal 180 t/d<br />

Design 180 t/d<br />

Normal 0 t/d<br />

Design 1,850 t/d<br />

nia and carbon dioxide are added to the process in small<br />

quantities for regulation of the chemical balance and for purification<br />

of the reaction product. A feature of Eurotecnica’s<br />

melamine process is that all the ammonia and carbon dioxide<br />

produced in the reaction and added to the process is returned<br />

to the urea process as input material. The technical<br />

process behind this, however, is very complex.<br />

29<br />

Chemical manufacturing processes<br />

AMMONIA MANUFACTURE<br />

KAAP Process (KBR, USA)<br />

(Pressure = 90 barg and temperature = 400 °C)<br />

3 H 2 + N 2 2 NH 3 + heat of reaction<br />

UREA MANUFACTURE<br />

ACES21 Process (Toyo Engineering Corporation, Japan)<br />

(Pressure = 150 barg and temperature = 180 °C)<br />

2NH 3 + CO 2 (NH 2 ) 2 CO + H 2 O - heat of reaction<br />

UAN MANUFACTURE<br />

A) NITRIC ACID MANUFACTURE<br />

Dual Pressure Process (Uhde GmbH, Germany)<br />

(Pressure = 4–6/10–12 barg and temperature = 890 °C)<br />

(I) 4 NH 3 + 5 O 2 4 NO + 6 H 2 O<br />

(II) 2 NO + O 2 2 NO 2<br />

(III) 3 NO 2 + H 2 O 2 HNO 3 + NO<br />

b) AMMONIUM NITRATE MANUFACTURE<br />

Vacuum Neutralisation (Uhde GmbH, Germany)<br />

(Pressure = 0.35 bar abs. and maximum temperature = 145 °C)<br />

NH 3 (gas) + HNO 3 (aqueous)<br />

NH 4 NO 3 (aqueous) + heat of reaction<br />

C) AMMONIUM NITRATE-UREA SOLUTION (UAN)<br />

Mixing Unit (Uhde GmbH, Germany)<br />

Ammonium nitrate solution + urea solution UAN<br />

MELAMINE MANUFACTURE<br />

Non-Catalytic Process (Eurotecnica, Italy)<br />

(Pressure = 80 barg and temperature = 380 °C)<br />

6 (NH 2 ) 2 CO C 3 H 6 N 6 (Melamine) + 3 CO 2 + 6 NH 3 - heat<br />

of reaction (return of NH 3 and CO 2 to the urea plant)<br />

H<br />

N +<br />

H H<br />

H<br />

H H<br />

O<br />

C<br />

N<br />

H<br />

H2 N NH 2<br />

O<br />

N +<br />

- O OH<br />

+ O -<br />

N<br />

N<br />

O O<br />

2 HN-C C-NH 2<br />

N N<br />

C<br />

NH 2

![Product information: Ryobi 3300CR [PDF, 3.1 mb] - Ferrostaal](https://img.yumpu.com/2745806/1/184x260/product-information-ryobi-3300cr-pdf-31-mb-ferrostaal.jpg?quality=85)