Air-operated grease gun DFP 1000 - Hallbauer Viernheim

Air-operated grease gun DFP 1000 - Hallbauer Viernheim

Air-operated grease gun DFP 1000 - Hallbauer Viernheim

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Hallbauer</strong> Industries GmbH<br />

P.O. Box 1340 68503 <strong>Viernheim</strong><br />

Industriestrasse 18 68519 <strong>Viernheim</strong><br />

Germany<br />

Parts and technical service guide<br />

Product: <strong>Air</strong>-<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> „<strong>DFP</strong> <strong>1000</strong>”<br />

Part nos.: 10210/ 10211<br />

Issue: 11/2010<br />

Phone + 49 6204 7095-38 or-40<br />

Fax +49 6204 7095-33<br />

info@hallbauer-viernheim.de<br />

www.hallbauer-viernheim.de<br />

Description<br />

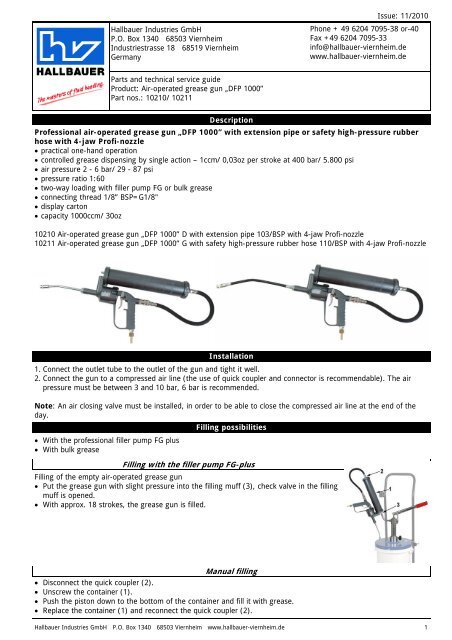

Professional air-<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> „<strong>DFP</strong> <strong>1000</strong>” with extension pipe or safety high-pressure rubber<br />

hose with 4-jaw Profi-nozzle<br />

�� practical one-hand operation<br />

�� controlled <strong>grease</strong> dispensing by single action – 1ccm/ 0,03oz per stroke at 400 bar/ 5.800 psi<br />

�� air pressure 2 - 6 bar/ 29 - 87 psi<br />

�� pressure ratio 1:60<br />

�� two-way loading with filler pump FG or bulk <strong>grease</strong><br />

�� connecting thread 1/8” BSP=G1/8"<br />

�� display carton<br />

�� capacity <strong>1000</strong>ccm/ 30oz<br />

10210 <strong>Air</strong>-<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> „<strong>DFP</strong> <strong>1000</strong>” D with extension pipe 103/BSP with 4-jaw Profi-nozzle<br />

10211 <strong>Air</strong>-<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> „<strong>DFP</strong> <strong>1000</strong>” G with safety high-pressure rubber hose 110/BSP with 4-jaw Profi-nozzle<br />

Installation<br />

1. Connect the outlet tube to the outlet of the <strong>gun</strong> and tight it well.<br />

2. Connect the <strong>gun</strong> to a compressed air line (the use of quick coupler and connector is recommendable). The air<br />

pressure must be between 3 and 10 bar, 6 bar is recommended.<br />

Note: An air closing valve must be installed, in order to be able to close the compressed air line at the end of the<br />

day.<br />

Filling possibilities<br />

�� With the professional filler pump FG plus<br />

�� With bulk <strong>grease</strong><br />

Filling with the filler pump FG-plus<br />

Filling of the empty air-<strong>operated</strong> <strong>grease</strong> <strong>gun</strong><br />

�� Put the <strong>grease</strong> <strong>gun</strong> with slight pressure into the filling muff (3), check valve in the filling<br />

muff is opened.<br />

�� With approx. 18 strokes, the <strong>grease</strong> <strong>gun</strong> is filled.<br />

Manual filling<br />

�� Disconnect the quick coupler (2).<br />

�� Unscrew the container (1).<br />

�� Push the piston down to the bottom of the container and fill it with <strong>grease</strong>.<br />

�� Replace the container (1) and reconnect the quick coupler (2).<br />

<strong>Hallbauer</strong> Industries GmbH P.O. Box 1340 68503 <strong>Viernheim</strong> www.hallbauer-viernheim.de 1

<strong>Air</strong> -<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> „<strong>DFP</strong> <strong>1000</strong>” Part nos.: 10210/ 10211<br />

Technical safety information<br />

Trouble shooting<br />

Symptoms Possible reason Solutions<br />

Issue: 11/2010<br />

�� The pressure may not exceed 7 bar in the air admission.<br />

�� Before each repair or maintenance work, the air connection must be disconnected and the pressure relased by<br />

pulling the trigger.<br />

�� Never point greasing pistol at people or animals. Danger of injury!<br />

�� Use only security tested parts as accessory.<br />

No <strong>grease</strong> delivery when the trigger No <strong>grease</strong> in the container. Fill the container.<br />

is pulled.<br />

<strong>Air</strong> pockets in the <strong>gun</strong> or container. Compact the <strong>grease</strong> in the container.<br />

Release the air with the relief valve.<br />

Grease outlet obstructed. Disassemble and clean the outlet<br />

valve. Remove the screw and clean<br />

the conduit between the container<br />

and the outlet.<br />

Grease comes out without pulling the Dirt in the outlet valve. Disassemble and clean the outlet<br />

trigger.<br />

valve, replace in case of damage.<br />

<strong>Air</strong> leaks from the air valve needle. Damaged air valve O ring. Replace the O ring.<br />

The air motor does not function Damaged air valve. Replace the air valve.<br />

when the trigger is pulled.<br />

Damaged piston plate or air piston. Replace the damaged part.<br />

Damaged air motor O ring. Replace the O ring.<br />

Accumulation of <strong>grease</strong> in the bottom<br />

of the container.<br />

Worn out <strong>grease</strong> plunger. Replace the container assembly.<br />

Repair and cleaning precedures<br />

ATTENTION: Before starting any kind of maintenance or repairing, disconnect the compressed air supply and pull<br />

the trigger to release the <strong>grease</strong> pressure.<br />

Outlet valve<br />

1. Unscrew the outlet nut (A1) and remove the spring (A2) and the ball (A3).<br />

2. Clean these parts as well as the ball seat in the <strong>gun</strong> body. Replace if necessary.<br />

ATTENTION: Assemble the parts in their original positions.<br />

<strong>Air</strong> valve<br />

1. Unscrew and remove the threaded plug (C1).<br />

2. Remove the spring (C2) and the valve (C3). Clean or replace.<br />

3. Remove the trigger pin and the trigger (C6). Unscrew the needle guide (C4)<br />

and remove it together with the air valve needle (C5). Replace the O ring<br />

(C7).<br />

<strong>Air</strong> motor<br />

1. Unscrew and remove the five screws (B1) and remove the handle (B2) and O ring<br />

(B3).<br />

2. Take out the air motor assembly by pulling the nut (B4) and replace the damaged<br />

parts.<br />

<strong>Hallbauer</strong> Industries GmbH P.O. Box 1340 68503 <strong>Viernheim</strong> www.hallbauer-viernheim.de 2

<strong>Air</strong> -<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> „<strong>DFP</strong> <strong>1000</strong>” Part nos.: 10210/ 10211<br />

Kit Part no. Description<br />

A 716950 Outlet valve<br />

B 716951 <strong>Air</strong> motor<br />

C 716956 Trigger assy<br />

D 716957 Container assy<br />

Spare parts list<br />

Pos Part no. Description<br />

1 250014 Quick coupling<br />

2 65001 Filling nipple<br />

3 02831 Outlet hose<br />

Issue: 11/2010<br />

4 07123 Hydraulic connector<br />

5 716100 Gun handle<br />

6 716215 <strong>Air</strong> hose<br />

7 816503 Piston<br />

8 816502 Gasket<br />

<strong>Hallbauer</strong> Industries GmbH P.O. Box 1340 68503 <strong>Viernheim</strong> www.hallbauer-viernheim.de 3

<strong>Air</strong> -<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> „<strong>DFP</strong> <strong>1000</strong>” Part nos.: 10210/ 10211<br />

EC declaration of conformity<br />

Declaration of conformity<br />

according to the EC directive Machines 89/392/EEC, appendix II A<br />

Issue: 11/2010<br />

We hereby declare that the air-<strong>operated</strong> <strong>grease</strong> <strong>gun</strong>s <strong>DFP</strong> <strong>1000</strong> correspond to the general safety and health requirements<br />

of the EC directives with respect to concept and type as well as to the model launched by us. When modifying<br />

something at the air-<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> without our agreement, this declaration is no longer valid.<br />

Description of the product:: <strong>Air</strong>-<strong>operated</strong> <strong>grease</strong> <strong>gun</strong> <strong>DFP</strong> <strong>1000</strong><br />

<strong>DFP</strong> <strong>1000</strong> D with extension pipe<br />

<strong>DFP</strong> <strong>1000</strong> G with safety high-pressure rubber hose<br />

Applicable EC directives: EG directive Machines 89/392/EEC<br />

i.d.F. 91/368/EEC, 93/44/EEC and 93/68/EEC<br />

Applied harmonized<br />

specification, especially: EN 292-I and EN 292-2 and EN 809<br />

Applied national and<br />

technical specification: DIN 20 022, DIN 1283 Point 2.2.1.1<br />

<strong>Viernheim</strong>, 12.03.03 ________________________________<br />

Lothar <strong>Hallbauer</strong>, General Manager<br />

Certificate for safety high-pressure rubber hoses according to DIN 1283<br />

He hereby declare, that the safety high-pressure rubber hoses are manufactured according to DIN 1283 and have<br />

been subjected to a pressure examination with 200 000 impulses. The result was without any complaint.<br />

<strong>Viernheim</strong>, 12.03.03 _______________________________<br />

Lothar <strong>Hallbauer</strong>, General Manager<br />

<strong>Hallbauer</strong> Industries GmbH P.O. Box 1340 68503 <strong>Viernheim</strong> www.hallbauer-viernheim.de 4