CAPABILITY PROFILE - cedip

CAPABILITY PROFILE - cedip

CAPABILITY PROFILE - cedip

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

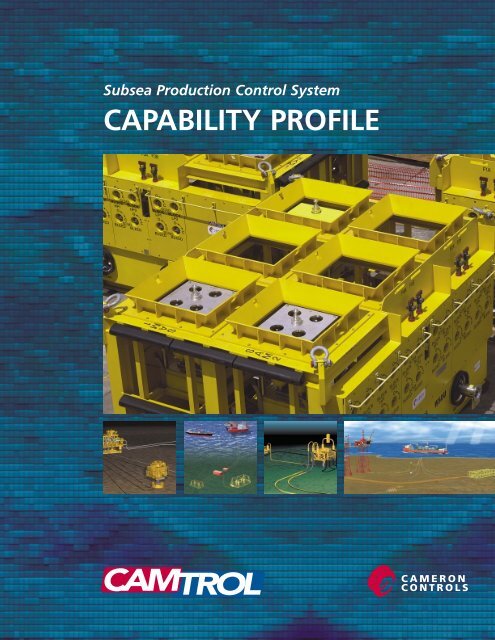

Subsea Production Control System<br />

<strong>CAPABILITY</strong> <strong>PROFILE</strong>

Platform<br />

Production<br />

Scenario<br />

Seabed<br />

Intervention<br />

Scenario<br />

Table of Contents<br />

Cameron Corporate History . . . . . . . . . . . . 1<br />

Cameron Controls Recent History . . . . . . . 1<br />

Cameron Controls Business Activities . . . . 2<br />

SCM/SAM<br />

Transportation<br />

Cage<br />

MMRT-SEM<br />

Cameron Control Locations . . . . . . . . . . . . 3<br />

Cameron Controls Primary<br />

Contacts & Key Personnel . . . . . . . . . . . . . 4<br />

Customer Service . . . . . . . . . . . . . . . . . . . . 6<br />

Project Reference List . . . . . . . . . . . . . . . . 10<br />

Main Controls<br />

Umbilical<br />

Subsea Control<br />

Module (SCM)<br />

SCM<br />

Mounting<br />

Base<br />

Controls Flying Leads

Subsea Production Control System Capability Profile<br />

CAMERON CORPORATE HISTORY<br />

The Cameron<br />

Division of the<br />

Cooper Cameron<br />

Corporation<br />

encompasses many well-established ‘Oilfield’<br />

product brands synonymous with quality oil<br />

tool products and services.<br />

Cameron Iron Works was founded<br />

in 1920 and remained for many<br />

years the principal family owned<br />

supplier of drilling, exploration<br />

and well completion equipment.<br />

Cameron Iron Works acquired<br />

McEvoy Willis in 1987, who had<br />

themselves combined in 1985.<br />

Cooper Industries purchased<br />

Cameron Iron Works in 1989, thereby<br />

amalgamating Cameron with previously<br />

acquired companies, Demco, WKM and<br />

Thornhill Craver under the company name<br />

Cooper Oil Tool.<br />

Cooper Industries spun off its oil tool, power<br />

generation and energy service interests under<br />

the newly formed Cooper Cameron Corporation,<br />

which was floated on the US<br />

Stock Exchange in 1995.<br />

Cooper Cameron Corporation<br />

acquired Ingram Cactus and<br />

Tundra in 1996, Wellhead Services<br />

Inc and Marta-co in 1997 and<br />

Orbit Valve in 1998.<br />

In August 1998, Cameron Controls<br />

Division acquired the Brisco<br />

Engineering Limited Aftermarket<br />

business to give a worldwide Aftermarket<br />

support base in Aberdeen.<br />

CAMERON CONTROLS RECENT HISTORY<br />

• Cameron Controls was formed as a separate<br />

division during the 4th Quarter 1996 to<br />

give focus on control system capabilities<br />

within Cooper Cameron.<br />

• CAMTROL New Generation Production<br />

Control Development started January 1997.<br />

• Dock trials performed on prototype system<br />

including SCM, Jumper Connection System<br />

and Running Tools in June 1998.<br />

• Acquisition of Brisco Engineering Customer<br />

Care facilities within the 3rd Quarter 1998,<br />

to give Cameron Controls full Aftermarket<br />

capability.<br />

• Shell Malampaya Controls contract<br />

awarded November 1998.<br />

• Purpose-built engineering and manufacturing<br />

facility in Celle opened in<br />

February 1999.<br />

• Texaco Captain Controls contract awarded<br />

February 1999.<br />

• Purpose-built engineering and manufacturing<br />

facility in Houston opened in<br />

May 1999.<br />

• Triton Energy Ceiba Early Production<br />

System Controls contract awarded<br />

January 2000.<br />

• Petrobaltic B-3 Controls contract awarded<br />

February 2000.<br />

• Repsol Chipiron Controls contract awarded<br />

April 2000.<br />

• Triton Energy Ceiba Full Field Development<br />

Phase 1A Controls contract awarded<br />

June 2000.<br />

• ExxonMobil EPS contract awarded<br />

March 2001.<br />

• Triton Energy Ceiba Full Field Development<br />

Phase 1B Controls contract awarded<br />

June 2000.<br />

• ExxonMobil Kizomba A contract awarded<br />

July 2001.<br />

• OMV Patricia-Baleen contract awarded<br />

September 2001.<br />

• Triton Energy Okume EPS contract awarded<br />

October 2001.<br />

November 2001 1

Subsea Production Control System Capability Profile<br />

CAMERON CONTROLS BUSINESS ACTIVITIES<br />

As the world’s leading supplier of drilling<br />

and production equipment, Cameron offers<br />

integrated systems for surface and subsea<br />

applications. Cameron Controls commits the<br />

full resources of Cameron to a dedicated<br />

organisation formed specifically to design,<br />

manufacture and service control systems<br />

worldwide.<br />

Incorporating more than 25 years of controls<br />

experience, Cameron Controls offers the<br />

broadest product line in the industry and<br />

has a world wide network of sales and<br />

service locations to provide customers with<br />

integrated systems to meet their drilling<br />

and production needs.<br />

Cameron Controls offers an extended<br />

network of manufacturing, sales and service<br />

locations to serve the needs of controls<br />

customers worldwide. Cameron Controls has<br />

a large staff of mechanical and electrical<br />

engineers, designers and draughtsman<br />

dedicated to the latest controls technology.<br />

Cameron’s worldwide network of customer<br />

service locations provides an extensive<br />

inventory of spare parts, field service, and<br />

customer property management and total<br />

vendor management (TVM) services.<br />

Cameron Controls Systems include the<br />

following product groups that incorporate<br />

an integral part of the Cameron MOSAIC <br />

System providing Cameron with the ability<br />

to offer complete integrated systems:<br />

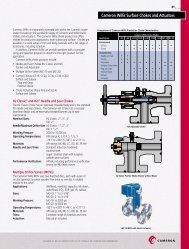

Surface Production Control Systems<br />

This product group includes Land Based<br />

Christmas Tree Control Systems and Safety<br />

Shutdown Controls Systems.<br />

Workover & Intervention<br />

Control Systems<br />

This product group includes Direct, Piloted,<br />

Electro-Hydraulic Multiplexed and Hybrid<br />

systems.<br />

Drilling Control Systems<br />

This product group includes Drilling Choke<br />

Remote Control Systems, Land and Platform<br />

Direct Hydraulic BOP Control Systems, Subsea<br />

Direct Hydraulic BOP Control Systems and<br />

Subsea Electro-Hydraulic Multiplex BOP<br />

Control Systems.<br />

Subsea Production Control Systems<br />

This product group includes Direct Hydraulic,<br />

Pilot Hydraulic, Sequenced Hydraulic, Electro-<br />

Hydraulic and Electro-Hydraulic Multiplexed<br />

Systems.<br />

Included within this product group<br />

is Cameron’s latest development<br />

the CAMTROL Advanced Electrohydraulic<br />

Multiplexed Subsea<br />

Production Control System that<br />

combines years of experience<br />

in the design, development<br />

and employment of subsea<br />

production systems with the<br />

industry’s most sophisticated<br />

control technology. The<br />

result is an advanced system<br />

engineered to meet the<br />

worldwide demand for costeffective<br />

production control of<br />

deepwater systems.<br />

2 November 2001

Subsea Production Control System Capability Profile<br />

CAMERON CONTROLS LOCATIONS<br />

Houston, Texas,<br />

United States of America<br />

Total = 32,400 square feet<br />

Offices = 42,000 square feet<br />

Cameron Controls (Controls Headquarters)<br />

6650 Bingle Road<br />

Houston, Texas 77092<br />

Tel: +713 683 4600<br />

Fax: +713 683 4700<br />

Celle, Germany<br />

Workshop = 31,871 square feet<br />

Offices = 12,912 square feet<br />

Cameron GmbH<br />

Lueckenweg 1<br />

29227 Celle, Germany<br />

Tel: +49 5141 8060<br />

Fax: +49 5141 806333<br />

Aberdeen, Scotland<br />

Workshop = 25,000 square feet<br />

Offices = 6,000 square feet<br />

Cameron Controls (CAMSERV & Aftermarket)<br />

Badentoy Park, Badentoy Road<br />

Portlethen, Aberdeen AB12 4YA<br />

Scotland<br />

Tel: +44 1224 785500<br />

Fax: +44 1224 783355<br />

Macae, Brazil<br />

Workshop = 34,450 square feet<br />

Offices = 3,750 square feet<br />

Manufacturing<br />

CAMSERV Service Center<br />

Rodovia Amaral Peixoto Km 164,<br />

5 Imbosassica,<br />

Macae – RJ 27920-340<br />

Brazil<br />

Office<br />

November 2001 3

Subsea Production Control System Capability Profile<br />

CAMERON CONTROLS PRIMARY CONTACTS<br />

Vice President<br />

Don Schortgen<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston, Texas 77092 USA<br />

Tel: +713 683 4750<br />

Fax: +713 683 4306<br />

E-Mail: schortgend@camerondiv.com<br />

Product Integrity Director<br />

Dr. Bob Spears<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston,Texas 77092 USA<br />

Tel: +713 683 4348<br />

Fax: +713 683 4306<br />

E-Mail: spearr@camerondiv.com<br />

Engineering Director<br />

Dave Morgan<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston,Texas 77092 USA<br />

Tel: +713 683 4309<br />

Fax: +713 683 4306<br />

E-Mail: morgand@camerondiv.com<br />

Marketing & Projects Director<br />

Al Williams<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston,Texas 77092 USA<br />

Tel: +713 683 4650<br />

Fax: +713 683 4306<br />

E-Mail: williamsa@camerondiv.com<br />

Operations Director<br />

Britt Schmidt<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston,Texas 77092 USA<br />

Tel: +713 683 4606<br />

Fax: +713 683 4306<br />

E-Mail: schmidtb@camerondiv.com<br />

CAMSERV Director<br />

Ian Carrol<br />

Cameron Controls<br />

Badentoy Park, Badentoy Road<br />

Portlethen, Aberdeen AB12 4YA<br />

Scotland<br />

Tel: +44 1224 785500<br />

Fax: +44 1224 783355<br />

E-Mail: carroli@camerondiv.com<br />

Finance Director<br />

Wade Bitter<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston,Texas 77092 USA<br />

Tel: +713 683 4709<br />

Fax: +713 683 4306<br />

E-Mail: bitterw@camerondiv.com<br />

Manufacturing Manager –<br />

Celle, Germany<br />

Dierk Neuhaus<br />

Cameron GmbH<br />

Lueckenweg 1<br />

29227 Celle, Germany<br />

Tel: +49 5141 8060<br />

Fax: +49 5141 806333<br />

E-Mail: neuhausd@camerondiv.com<br />

Manufacturing Manager –<br />

Houston, Texas, USA<br />

Scott Johnson<br />

6650 Bingle Road<br />

Houston, TX 77092 USA<br />

Tel: +713 683 4621<br />

Fax: +713 683 4363<br />

Email: johnsonsa@camerondiv.com<br />

4 November 2001

Subsea Production Control System Capability Profile<br />

CAMERON CONTROLS PRIMARY CONTACTS (cont’d)<br />

MARKETING & PROPOSALS<br />

Product Manager –<br />

Production Controls<br />

John Bodine<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston, Texas 77092<br />

Tel: +713 683 4307<br />

Fax: +713 683 4700<br />

E-Mail: bodinej@camerondiv.com<br />

PROCUREMENT<br />

Worldwide Procurement Manager<br />

Todd Hoefler<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston, Texas 77092<br />

Tel: +713 683 4635<br />

Fax: +713 683 4344<br />

E-mail: hoeflert@camerondiv.com<br />

Product Manager –<br />

Drilling Controls<br />

Margaret Buckley<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston, Texas 77092<br />

Tel: +713 683 4367<br />

Fax: +713 683 4700<br />

E-mail: buckleym@camerondiv.com<br />

Proposals Manager<br />

David James<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston, Texas 77092<br />

Tel: +713 683 4607<br />

Fax: +713 683 4700<br />

E-mail: jamesd@camerondiv.com<br />

Worldwide Sales Executive<br />

Earnie Dunnam<br />

Cooper Cameron<br />

P.O. Box 1212<br />

Houston, TX 77251-1212<br />

Tel: +713 939 2350<br />

Fax: +713 569 4710<br />

Email: dunname@camerondiv.com<br />

CAMSERV & AFTERMARKET<br />

Western Hemisphere<br />

Mike Kneale<br />

Cameron Controls<br />

6650 Bingle Road<br />

Houston, Texas 77092<br />

Tel: +713 683 4755<br />

Fax: +713 683 4748<br />

E-mail: knealem@camerondiv.com<br />

Eastern Hemisphere<br />

Ian Carrol<br />

Cameron Controls<br />

Badentoy Park, Badentoy Road<br />

Portlethen, Aberdeen AB12 4YA<br />

Tel: +44 1224 785500<br />

Fax: +44 1224 783355<br />

E-Mail: carroli@camerondiv.com<br />

November 2001 5

Subsea Production Control System Capability Profile<br />

Customer Service<br />

Proper care and efficient<br />

utilization can reduce the Total<br />

Cost of Ownership of equipment. Cameron<br />

has developed a series of reconditioned<br />

products and services known as CAMSERV,<br />

which can be customized to meet your<br />

unique needs using our Through-Life Cost<br />

(TLC) Management Program. Non-value<br />

added activities can be eliminated, as well as<br />

hundreds of unnecessary manhours<br />

every day. Specifically, there<br />

are five areas in which we<br />

can help: Field Services,<br />

Customer Property<br />

Reconditioning, Customer<br />

Property Management,<br />

Reconditioned Products and<br />

Replacement Parts. We also offer<br />

CAMWARE software for use in<br />

schedule maintenance or workovers and<br />

tracking equipment.<br />

Field Services<br />

CAMSERV field service technicians are on call<br />

24-hours a day, 7-days a week to handle your<br />

on-site service needs. These individuals are<br />

highly skilled in providing installation assistance,<br />

making field repairs and performing<br />

routine, scheduled maintenance on your<br />

equipment. They also provide technical<br />

support along with these services.<br />

Installation –<br />

Cameron personnel<br />

are present during<br />

equipment installation<br />

and provide<br />

training for your<br />

operations personnel<br />

as specified.<br />

Field Repair –<br />

Whenever possible,<br />

CAMSERV<br />

technicians perform<br />

troubleshooting diagnostics and make repairs<br />

on-site, without removing your equipment<br />

from service.<br />

Maintenance – Preventative maintenance<br />

services help minimize wear and damage to<br />

extend the useful life of your equipment.<br />

CAMWARE asset management software can<br />

be used to schedule these services without<br />

burdening your maintenance or engineering<br />

staff.<br />

Technical Support – Experts in quality assurance,<br />

quality control, product engineering,<br />

field installation and preventable maintenance<br />

procedures can be provided on a<br />

project or contract basis.<br />

Well Services – CAMSERV<br />

technicians are available for a<br />

variety of special jobs, including<br />

de-completions, re-completions, trim<br />

changes and installation of safety equipment.<br />

Cameron Controls specializes in:<br />

Installation & Commissioning – On-site<br />

installation & commissioning of E-H MUX<br />

and Direct Hydraulic Drilling and Production<br />

Control Systems.<br />

Offshore Operators – Provision of skilled<br />

technicians to operate and maintain Drilling,<br />

Workover and Production Control Systems.<br />

Flushing – On-site flushing of hydraulic<br />

systems to nationally recognized standards.<br />

Both industrial and Zone 1 rated plant<br />

available.<br />

Customer Equipment<br />

Reconditioning<br />

A growing number of producers and drilling<br />

contractors trust their equipment to Cameron<br />

for repairs and re-manufacturing.<br />

Repair – CAMSERV Service Centers offer a full<br />

range of equipment repair services—and not<br />

just for Cameron products. We can bring your<br />

equipment back to the service level you<br />

specify, with warranties and installation<br />

support. CAMSERV repair services include<br />

disassembly, inspection, re-assembly, testing<br />

and parts replacement.<br />

6 November 2001

Subsea Production Control System Capability Profile<br />

accountability for lost materials. We also can<br />

provide inspection for Naturally Occurring<br />

Radioactive Materials (NORM) and prestorage,<br />

disassembly and cleaning to properly<br />

manage hazardous wastes.<br />

Remanufacture – Equipment remanufacturing<br />

services are offered for all types and brands<br />

of oilfield equipment. In addition to disassembly,<br />

inspection, re-assembly and<br />

testing services, Cameron provides the full<br />

complement of machining, welding, heattreating<br />

and other manufacturing operations<br />

necessary to return customer equipment to<br />

useable condition.<br />

Cameron Controls specializes in:<br />

Repair – On-site and in-house repair of<br />

Drilling, Workover, Wellhead Production<br />

Control systems and equipment associated<br />

with instrumentation packages.<br />

Testing/Calibration – On-site and in-house<br />

pressure testing/calibration facilities using<br />

hydraulic, aqueous or gaseous test mediums.<br />

Flushing – In-house flushing of hydraulic<br />

systems to nationally recognized standards.<br />

Both industrial and Zone 1 rated plant<br />

available.<br />

Inspection – On-site and in-house inspection<br />

from component to package level.<br />

Customer Property<br />

Management<br />

Property management services can be<br />

arranged to augment and complement your<br />

warehousing capabilities and to help reduce<br />

your Total Cost of Ownership.<br />

Storage/Warehousing – Basic storage services<br />

are offered for your equipment, including<br />

physical tracking services, inventory reporting<br />

(including global visibility systems), inventory<br />

tracking, secured holding areas, and financial<br />

Utilization – Cameron’s mainframe SAP<br />

computer system provides secure, worldwide<br />

access to your inventory records. Buying<br />

hierarchies specified by each customer are<br />

followed to ensure that suitable inventory<br />

items are used before new equipment is<br />

purchased.<br />

Brokering – Inventory brokering services can<br />

be provided to eliminate or reduce obsolete<br />

or surplus equipment. Cameron’s global<br />

network of Service Centers helps facilitate<br />

this process through faster identification of<br />

resale opportunities.<br />

Buy-Back – Cameron is constantly seeking<br />

unrepaired material for our Reconditioned<br />

Equipment Program. Buy-Back agreements<br />

can be written on a per lot or per product<br />

basis.<br />

Cameron Controls specializes in:<br />

Management & Maintenance – Total<br />

Management of Maintenance Contracts,<br />

including compilation of examination/<br />

maintenance procedures, stock holding of<br />

emergency and consumable spares, and<br />

full on-site support services.<br />

Rental – Rental of Direct Hydraulic<br />

Intervention/Workover Control systems,<br />

Flushing Rigs, Fluid Analysis and Pressure<br />

Test Equipment.<br />

Procurement Office – Dedicated team with<br />

vast network for procurement of spare parts.<br />

Reconditioned<br />

Equipment<br />

Reconditioned drilling and production<br />

equipment meeting API standards is available<br />

from Cameron in three forms: (1) Direct<br />

Purchase from CAMSERV Service Centers,<br />

November 2001 7

Subsea Production Control System Capability Profile<br />

(2) Equipment Exchange Programs where<br />

used equipment is traded-in, and (3) Rental<br />

Programs with purchase options.<br />

Cameron offers<br />

reconditioned<br />

products to “First<br />

Class”, “Fit for Function”<br />

or “Working<br />

Condition” specifications.<br />

First Class<br />

products are fully<br />

reconditioned to<br />

original specifications.<br />

Fit for<br />

Function products<br />

are partially reconditioned to satisfy specific<br />

operating requirements. Working Condition<br />

products have been repaired or serviced to<br />

correct specific problems or malfunctions.<br />

Drilling Products – Fully refurbished blowout<br />

preventers and choke manifolds can be<br />

furnished to various quality standards. These<br />

products may also be obtained under product<br />

exchange or rental program agreements.<br />

Wellhead Products – Reconditioned wellheads<br />

for surface or subsea applications can<br />

be provided to all quality standards. Product<br />

exchange or rental programs are available.<br />

Gate Valves – Drilling and production system<br />

gate valves for surface or subsea applications<br />

are reconditioned to applicable performance<br />

standards and offered for sale, rental or<br />

exchange.<br />

Replacement Parts<br />

CAMSERV facilities stock replacement parts<br />

for many Cameron products for immediate<br />

delivery. Less frequently needed items or<br />

parts for older equipment can be quickly<br />

located through our Global Product Search<br />

Engine (GPSE). Customers with special needs<br />

can structure consignment agreements where<br />

critical parts availability is assured, but no<br />

billing occurs until the parts are shipped.<br />

Local Distribution – Cameron Service Centers<br />

stock replacement parts based on the anticipated<br />

needs of<br />

local customers.<br />

As your needs<br />

change, so does<br />

our inventory. We<br />

strive to have the<br />

replacement parts<br />

you need in stock<br />

when you call.<br />

When you order<br />

something that’s<br />

not in stock, we<br />

have GPSE.<br />

Global Product Search Engine – GPSE is a<br />

Windows-based method of quickly finding<br />

parts from any of Cameron’s Service Centers.<br />

The system locates the closest available<br />

requested part and/or recommends<br />

acceptable alternatives when applicable.<br />

Internet Commerce – A secure, restrictedaccess<br />

“Transact” section of our web-site<br />

has been set-up to offer electronic ordering<br />

(drilling replacement parts are available<br />

now, and other product parts will be in the<br />

future). If you’re interested in ordering parts<br />

via the Internet, obtain an access code from<br />

your CAMSERV sales representative.<br />

Through-Life Cost<br />

Through-Life Cost (TLC) Management is a<br />

comprehensive program to reduce the Total<br />

Cost of Ownership of equipment. TLC starts<br />

at the equipment acquisition stage and<br />

covers equipment ownership, usage, maintenance<br />

and finally, disposal. It is truly a<br />

“cradle to grave” perspective.<br />

Throughout the 75-year history of Cameron,<br />

we’ve seen some customers squeeze every<br />

last ounce of service from our equipment<br />

while others give up on it far too soon. We<br />

will work with our customers to make sure<br />

our equipment is fully utilized. Cameron<br />

experts will sit down with the customer’s<br />

experts to map out your product and service<br />

needs. Goals and metrics will be determined.<br />

Decision trees will be developed and responsibilities<br />

assigned.<br />

8 November 2001

Subsea Production Control System Capability Profile<br />

Cameron develops TLC programs for as little<br />

as an annual maintenance agreement or for<br />

as much as a global alliance covering all<br />

product and service needs worldwide. These<br />

programs can include maintenance, training,<br />

inventory management, product reconditioning,<br />

purchasing and disposal responsibilities.<br />

One of the tools we use is our proprietary<br />

CAMWARE software. It is designed to track,<br />

manage and report on customer<br />

equipment from acquisition<br />

to disposal. CAMWARE is<br />

available in mainframe and<br />

stand-alone PC versions for<br />

virtually any aftermarket<br />

service situation.<br />

It provides a full history of all<br />

serialized equipment, including maintenance<br />

and performance factors. At any time, no<br />

matter the equipment location, you can<br />

check equipment specs, next-scheduled<br />

service, even the status of service jobs<br />

completed from your computer.<br />

Cameron field service teams use CAMWARE<br />

to schedule workovers and product maintenance.<br />

Because maintenance schedules can<br />

be pre-determined, crews and materials can<br />

be efficiently arranged and duplicated effort<br />

eliminated.<br />

It is also possible to document well conditions<br />

throughout the life of each well. CAMWARE<br />

can be used to monitor equipment performance,<br />

such as flow rates, flowing pressures<br />

and temperatures, dry barrels, water barrels<br />

and sand size statistics.<br />

The ease of reporting makes CAMWARE<br />

very attractive. Equipment can be listed by<br />

location. Wells can be reported by profit<br />

center. Maintenance jobs can be scheduled<br />

and tracked by profit each month.<br />

CAMWARE also features an inventory control<br />

module for controlling non-serialized inventory.<br />

Reports can be generated to show<br />

inventory by product category and summaries<br />

of products ordered. Certificate numbers and<br />

document references, including part numbers<br />

and serial numbers, are recorded in your<br />

CAMWARE data. The system even references<br />

a storage location for original documents.<br />

Cameron Controls specializes in:<br />

Through-Life Cost (TLC)<br />

In markets, such as the North Sea, where<br />

there is a large investment in the equipment<br />

and facilities to drill for and produce oil and<br />

gas, there is also a tremendous need for long<br />

term maintenance required to protect these<br />

investments.<br />

TLC is a performance-based,<br />

long-term contract in which<br />

Cameron becomes fully<br />

responsible for all aspects of<br />

equipment service, repair and<br />

maintenance. The goal is to<br />

reduce the total life cycle cost<br />

of equipment. TLC also reduces<br />

operational costs as Cameron and the<br />

operator work in conjunction to co-ordinate<br />

scheduling, manpower requirements,<br />

maintenance, inspection and other activities.<br />

With several TLC contracts already in place,<br />

Cameron leads the industry in the implementation<br />

and operation of successful<br />

TLC programs.<br />

Four key factors position Cameron to be<br />

successful with TLC:<br />

• Cameron is the leading supplier of surface<br />

wellheads, trees and subsea production<br />

systems in the North Sea area,<br />

• Worldwide, well established Aftermarket<br />

and repair facilities,<br />

• Large and experienced service support<br />

staff group,<br />

• Proprietary Software may be used<br />

exclusively in TLC applications.<br />

All in all, this combines to produce:<br />

• Relationships of trust,<br />

• Reduction in the total cost of ownership,<br />

• A win-win arrangement.<br />

November 2001 9

Subsea Production Control System Capability Profile<br />

PROJECT REFERENCE LIST<br />

Client Field Development Client Field Development<br />

SUBSEA PRODUCTION CONTROL SYSTEMS<br />

Electro-Hydraulic Multiplexed<br />

Shell . . . . . . . . . . . . . Malampaya<br />

ExxonMobil . . . . . Early Production System<br />

Texaco . . . . . . . . . . . Captain B<br />

Triton Energy . . . Ceiba Phase 1B<br />

Triton Energy . . . . . . Ceiba EPS<br />

ExxonMobil . . . . . Kizomba A<br />

Petrobaltic . . . . . . . . B-3 Expansion<br />

OMV . . . . . . . . . . Patricia-Baleen<br />

Repsol YPF . . . . . . . . Chipiron<br />

Triton Energy . . . Okume EPS<br />

Triton Energy . . . . . . Ceiba Phase 1A<br />

Electro-Hydraulic Multiplexed<br />

Agip . . . . . . . . . . . . . Toni<br />

NAM . . . . . . . . . . . . L13<br />

BP . . . . . . . . . . . . . . Newsham<br />

USSR . . . . . . . . . . . . Caspian Sea<br />

Electro-Hydraulic<br />

Shell . . . . . . . . . . . . . Fairley ‘A’<br />

Shell . . . . . . . . . . . . . SW Ampa<br />

Petrobras . . . . . . . . . Garoupa<br />

Amerada Hess . . . Durward and Dauntless<br />

NAM . . . . . . . . . . Q16<br />

Conoco . . . . . . . . MacCulloch<br />

British Borneo . . . Morpeth<br />

British Borneo . . . Allegheny<br />

The Ceiba Field is located about 20 miles off<br />

the coast of Equatorial Guinea, Africa. The<br />

CAMTROL system controls and monitors four<br />

oil production trees with expansion capability<br />

to accommodate up to 34 full-field<br />

development wells.<br />

Texaco-operated Captain Field Development is<br />

off the coast of Scotland in the North Sea. The<br />

CAMTROL system controls and monitors up to<br />

21 trees as well as all valve blocks located on<br />

the template manifold.<br />

10 November 2001

Subsea Production Control System Capability Profile<br />

PROJECT REFERENCE LIST (cont’d)<br />

Client Field Development Client Field Development<br />

SUBSEA PRODUCTION CONTROL SYSTEMS<br />

Pilot/Sequence Hydraulic<br />

Enserch . . . . . . . . . . Garden Banks 441 Agip . . . . . . . . . . Nilde 2<br />

Phillips Petroleum . . Ekofisk Agip . . . . . . . . . . Nilde 6<br />

Superior . . . . . . . . . . Middle East<br />

Agip . . . . . . . . . . Norma<br />

Phillips Petroleum . . Hewitt<br />

Agip . . . . . . . . . . Elena<br />

Shell . . . . . . . . . . . . . Brent 7<br />

Total . . . . . . . . . . Austral<br />

Shell . . . . . . . . . . . . . Brunei<br />

Apache Energy . . Gipsy<br />

Agip . . . . . . . . . . . . . Nilde 2<br />

Wintershall . . . . . L8A-West<br />

Direct Hydraulic<br />

ONGC . . . . . . . . . . . . B22/25<br />

Agip . . . . . . . . . . . . . Safueiro<br />

Placid . . . . . . . . . . . . L14<br />

Placid . . . . . . . . . . . . K12<br />

Amoco . . . . . . . . . P15<br />

Petrobaltic . . . . . B3<br />

Hardy Oil . . . . . . . PY3<br />

BP . . . . . . . . . . . . North Davy<br />

The Petrobaltic-operated B3<br />

oilfield is located in the Baltic Sea<br />

off the shore of Poland. The<br />

upgrade to the CAMTROL system<br />

provides the field with control of<br />

up to nine subsea wells, plus<br />

manifold valves; monitoring of<br />

data for the wells and the<br />

manifold; and greatly improved<br />

system response times.<br />

The Malampaya Field is located about 50 miles<br />

off the coast of the Philippines. The CAMTROL<br />

system controls and monitors 10 gas<br />

production trees and the manifold.<br />

November 2001 11

Subsea Production Control System Capability Profile<br />

PROJECT REFERENCE LIST (cont'd)<br />

Client<br />

SUBSEA PRODUCTION WORKOVER CONTROL SYSTEMS<br />

Electro-Hydraulic Multiplexed<br />

Norsk Hydro, TOGI<br />

ExxonMobil, EPS<br />

BP, Schiehallion<br />

ExxonMobil, Kizomba A<br />

Shell, Malampaya<br />

Direct Hydraulic<br />

Sudoimport. IWOCS<br />

Statoil, Gulfaks A<br />

Statoil, Gulfaks A II<br />

Total, IWOCS<br />

Rospo, Mare<br />

Saga Petroleum, Snorre<br />

Amerada Hess, Scott<br />

Amoco, P15<br />

Agip, Toni<br />

Amerada Hess, Scott II<br />

Maersk, Regnar<br />

Conoco, Lyell<br />

Texaco, Strathspey<br />

Kerr McGee, Gryphon<br />

ELF, Tchendo<br />

Shell, South Brent<br />

Repsol, Albaga<br />

BP, Pampano<br />

NAM, L13<br />

BP, Swift<br />

BP, Foinaven<br />

Hardy Oil and Gas, IWOCS<br />

Kerr McGee, Janice<br />

Enterprise, Pierce<br />

British Gas, Scarab<br />

Schlumberger, Open Water, IWOCS<br />

12 November 2001

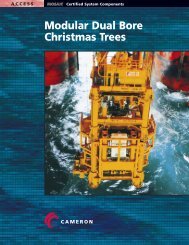

FPSO Production Scenario<br />

MODU Workover Scenario<br />

Main<br />

Controls<br />

Umbilical<br />

Subsea Control<br />

Module (SCM)<br />

Umbilical<br />

Termination<br />

Assembly<br />

(UTA)<br />

Subsea Accumulator<br />

Module (SAM)<br />

Subsea Distribution<br />

Unit (SDU)<br />

Manifold<br />

Subsea Accumulator<br />

Module (SAM)<br />

Subsea Distribution<br />

Unit (SDU)<br />

Controls<br />

Flying Leads<br />

Emergency<br />

Disconnect<br />

Unit (EDU)<br />

Workover<br />

Umbilical<br />

Workover<br />

Flying Lead<br />

Umbilical<br />

Termination<br />

Assembly (UTA)

Cameron Controls<br />

6650 Bingle Road<br />

Houston, Texas 77092<br />

Tel 713 683 4600<br />

Fax 713 683 4700<br />

Cameron Controls<br />

Lueckenweg 1<br />

29227 Celle, Germany<br />

Tel 49 5141 8060<br />

Fax 49 5141 806333<br />

Cameron Controls<br />

Badentoy Park, Badentoy Road<br />

Portlethen Aberdeenshire,<br />

Scotland AB12 4YA<br />

Tel 44 1224 785 500<br />

Fax 44 1224 783 355<br />

CAMSERV Service Center<br />

Rodovia Amaral Peixoto<br />

Km 164, 5 Imbosassica,<br />

Macae, RJ 27920-340 Brazil<br />

Visit our website at www.camerondiv.com<br />

or contact us at camtrolinfo@camerondiv.com<br />

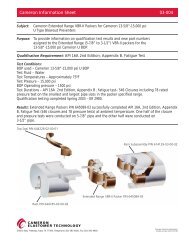

API Q1 Quality System Certificate; API 16D Control Systems<br />

for Drilling Well Control Equipment; API 17D Subsea<br />

Wellhead and Christmas Tree Equipment; ISO 9001 Quality<br />

System Certificate; API License # 16D-0012; API License<br />

# 17D-0015; ISO 9001 License # 0001<br />

MOSAIC, SpoolTree, Cameron, CAMSERV, CAMTROL, and HydraQuad<br />

are trademarks of the Cooper Cameron Corporation, Cameron Division.<br />

© Cooper Cameron Corporation, Cameron Division, Hearn Litho, 11/01, 1000, TC1616