The Fastlock⢠Connector - cedip

The Fastlock⢠Connector - cedip

The Fastlock⢠Connector - cedip

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

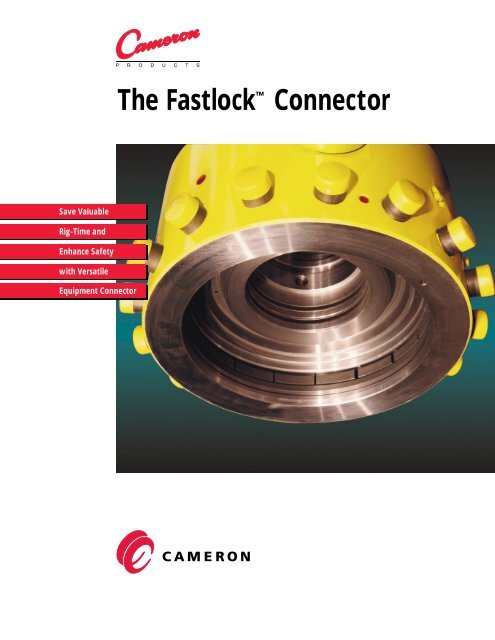

<strong>The</strong> Fastlock <strong>Connector</strong><br />

Save Valuable<br />

Rig-Time and<br />

Enhance Safety<br />

with Versatile<br />

Equipment <strong>Connector</strong>

Fastlock <strong>Connector</strong><br />

Self-Contained <strong>Connector</strong> Cuts Make-Up Time by 90 Percent<br />

In today’s market, contractors<br />

and operators are continually<br />

looking for ways to improve rig<br />

efficiency and enhance safety.<br />

To meet industry demands, Cameron<br />

engineers designed the Cameron<br />

Fastlock <strong>Connector</strong> to replace traditional<br />

connections for wellheads,<br />

BOPs and other equipment.<br />

A hub-to-flange connection is made on a platform in the<br />

Gulf of Mexico.<br />

By decreasing makeup time by<br />

as much as 90 percent, this new<br />

connector is able to reduce rig time,<br />

resulting in direct savings to the<br />

operator. Since there are no loose<br />

parts, the Fastlock <strong>Connector</strong> is easier<br />

to install.<br />

INCREASE RIG AND<br />

PERSONNEL SAFETY<br />

Added safety is provided by the<br />

Fastlock <strong>Connector</strong> since open-hole<br />

time is cut during makeup. <strong>The</strong><br />

connector is easy to handle and all<br />

parts are integral. Another safety<br />

feature is the low makeup torque,<br />

which means a single person can<br />

install the connector without using<br />

sledge hammers and hammer<br />

wrenches.<br />

<strong>The</strong> Fastlock <strong>Connector</strong> is<br />

offered in a full range of sizes from<br />

11" to 21-1/4" and pressure ratings<br />

from 2000 to 20,000 psi.<br />

<strong>The</strong> primary uses for the<br />

Fastlock <strong>Connector</strong>, both onshore<br />

and offshore, are for joining blowout<br />

preventers system components<br />

to wellheads, Christmas trees to<br />

wellheads and wellhead components<br />

to wellheads.<br />

SIMPLE, RUGGED DESIGN<br />

<strong>The</strong> Fastlock <strong>Connector</strong> has been<br />

designed to meet the needs of the<br />

industry. Finite element analysis was<br />

used<br />

extensively<br />

to assure<br />

that the<br />

connector<br />

meets API<br />

6A and<br />

ASME<br />

Section VIII<br />

allowable<br />

stresses at<br />

the load<br />

cases for<br />

makeup,<br />

working<br />

and test<br />

pressures.<br />

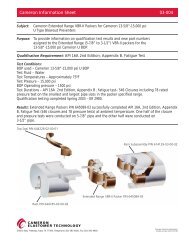

A 13-5/8" Fastlock <strong>Connector</strong><br />

undergoes an API 6FB, Part II fire<br />

test.<br />

<strong>Connector</strong>s are preloaded to 1.5<br />

times the working pressure end-load<br />

to assure there is no hub face<br />

separation while providing sufficient<br />

bending capacity in each connector<br />

at maximum working pressure.<br />

Since there are no industry<br />

standards specifying external load<br />

cases, Cameron's design philosophy<br />

produces an optimally designed connector.<br />

Fire-testing of the Fastlock<br />

<strong>Connector</strong> to API 6FB Part I and II,<br />

and thermal cycling to API 6A,<br />

Appendix F confirmed the rugged<br />

reliability of the design.<br />

VERSATILITY<br />

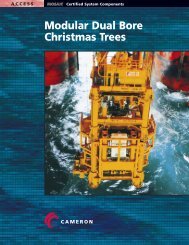

<strong>The</strong> Cameron Fastlock <strong>Connector</strong><br />

can be built for several additional<br />

applications including diver-assisted<br />

subsea operations where these<br />

connectors can be used to attach<br />

the subsea tree to the wellhead, as<br />

well as for flowline and manifold<br />

connections, etc.<br />

Fastlock <strong>Connector</strong>s can be<br />

integrated into the BOP and<br />

workover equipment for use in<br />

drilling operations on platforms so<br />

that a single system serves the entire<br />

platform.<br />

<strong>The</strong> Cameron Fastlock <strong>Connector</strong><br />

is an integral part of the MC2, the<br />

new generation modular compact<br />

wellhead — Cameron’s premium<br />

land and platform wellhead.<br />

Fastlock <strong>Connector</strong><br />

Metal<br />

End-Cap<br />

Seal<br />

Assembly<br />

Canh Metal<br />

Seal Assembly<br />

SD-10922-97<br />

MC2 Wellhead With Fastlock <strong>Connector</strong>

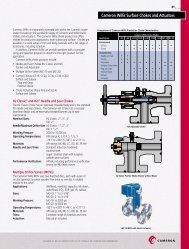

<strong>The</strong> CF gasket reduces<br />

pressure end-loads by as<br />

much as 20 percent and<br />

insures face to face make-up.<br />

Each screw forces a<br />

lock-ring segment into<br />

the hub profile.<br />

To run the connector,<br />

the locking segments<br />

are first retracted into<br />

the connector body.<br />

<strong>The</strong> connector is then<br />

lowered onto the<br />

mating hub. Once<br />

landed, the radially<br />

positioned drive<br />

screws are tightened<br />

to a specific torque.<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>The</strong> Fastlock<br />

<strong>Connector</strong> is selfcontained.<br />

<strong>The</strong>re are<br />

no loose parts.<br />

<strong>The</strong> Fastlock <strong>Connector</strong><br />

can be used with a wide<br />

variety of hubs and<br />

wellhead housings.<br />

•<br />

•<br />

SD-10968-97<br />

With smaller drive<br />

screws, lower makeup<br />

torque is required<br />

for pre-loading the<br />

connector.<br />

Grease Injection Port<br />

Fastlock <strong>Connector</strong> Options<br />

SD-10923-97<br />

Weld Prep to Hub Connection API Hub to API Hub Connection Fastlock to API Hub Connection<br />

Features:<br />

• Dramatic reduction in make-up<br />

time. A 13-5/8”,10,000 psi connection<br />

can be made up in less<br />

than 10 minutes.<br />

• Any operating component subject<br />

to wear, including working threads,<br />

can be replaced in the field.<br />

• <strong>The</strong> connector can be designed to<br />

run through most diverter stacks.<br />

• Minimal swallow on the Fastlock<br />

male hub reduces overall stack<br />

height.<br />

• <strong>Connector</strong> is designed for sour<br />

service according to NACE standards.<br />

• A low-friction coating applied to<br />

the sliding surfaces reduces makeup<br />

torque.<br />

• CF seal, a modified Cameron CX<br />

seal, reduces pressure end-loads<br />

and allows lower makeup torque<br />

and optimization of size and materials<br />

in the body, which results in a<br />

compact, totally integral connector.

Sales and Service Locations<br />

Domestic<br />

Bakersfield, California<br />

Woodland, California<br />

Denver, Colorado<br />

Lafayette, Louisiana<br />

New Orleans, Louisiana<br />

Mount Pleasant, Michigan<br />

Laurel, Mississippi<br />

Oklahoma City, Oklahoma<br />

Corpus Christi, Texas<br />

Dallas, Texas<br />

Houston, Texas<br />

Longview, Texas<br />

Odessa, Texas<br />

Casper, Wyoming<br />

Evanston, Wyoming<br />

International<br />

Buenos Aires, Argentina<br />

Perth, Australia<br />

Kuala Belait, Brunei<br />

Calgary, Canada<br />

Grande Prairie, Canada<br />

Punta Arenas, Chile,<br />

Pointe-Noire, Congo<br />

Cairo, Egypt,<br />

Great Yarmouth, England<br />

London, England<br />

Paris, France<br />

Pau, France<br />

Port Gentil, Gabon<br />

Jakarta, Indonesia<br />

Tokyo, Japan<br />

Kuala Lumpur, Malaysia<br />

Miri, Malaysia<br />

Terengganu, Malaysia<br />

Ciudad Del Carmen, Mexico<br />

Mexico CIty, Mexico<br />

Villahermosa, Mexico<br />

<strong>The</strong> Hague, <strong>The</strong> Netherlands<br />

Papakura, New Zealand<br />

Lagos, Nigeria<br />

Warri, Nigeria<br />

Bergen, Norway<br />

Muscat, Oman<br />

Moscow, Russia<br />

Al Khobar, Saudi Arabia<br />

Abu Dhabi, U.A.E.<br />

Maracaibo, Venezuela<br />

Manufacturing Plants and Aftermarket Facilities<br />

Domestic<br />

Anchorage, Alaska<br />

Berwick, Louisiana<br />

Patterson, Louisiana<br />

Ville Platte, Louisiana<br />

Oklahoma City, Oklahoma<br />

Brookshire, Texas<br />

Liberty, Texas<br />

International<br />

Zarate, Argentina<br />

Melbourne, Australia<br />

Edmonton, Canada<br />

Leeds, England<br />

Beziers, France<br />

Celle, Germany<br />

Longford, Ireland<br />

Veracruz, Mexico<br />

Hoogezand, <strong>The</strong> Netherlands<br />

Port Harcourt, Nigeria<br />

Stavanger, Norway<br />

Singapore, Republic of Singapore<br />

Aberdeen, Scotland<br />

This list includes major manufacturing and sales locations. Contact your nearest Cameron<br />

representative for locations not included on this list.<br />

P.O. Box 1212<br />

Houston, TX 77251-1212<br />

Telephone: 713/939-2211<br />

Fax: 713/939-2620<br />

© Cooper Cameron Cameron Division 04/96/PDF TC825