Sales policy for domestic USA customers.

Sales policy for domestic USA customers.

Sales policy for domestic USA customers.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Castable Mounting Compounds<br />

Tips, Tricks & Techniques:<br />

For best results using epoxy systems:<br />

■ Mix using accurate resin to hardener ratios<br />

■ Mix thoroughly: using a 3 cup mixing technique, mixing is<br />

more thorough<br />

■ Post cure heating <strong>for</strong> 2 hours at 50° C (122 °F) can increase<br />

hardness<br />

■ Preheating unmixed systems reduces viscosity<br />

■ Heat mixed epoxy except EpoKwick, to decrease cure time;<br />

every increase of 10° C (50 °F) reduces gel time by 50%.<br />

■ Mix 25-90ml of epoxy in a single batch; mixing more than<br />

90ml at a time can cause over-exotherming even when poured<br />

into smaller mounts<br />

■ Use EpoHeat® <strong>for</strong> very large mounts in single pours<br />

■ Clean up any spills or drips with paper towel and ethanol<br />

■ Wear gloves<br />

■ Prepare sample under a fume hood, if possible<br />

■ Use Cast’N Vac or Cast’N Vac 1000<br />

■ Better to use the EPDM molds, reduces leakage<br />

■ Use release agent to coat mold <strong>for</strong> easy removal of sample<br />

■ For a video demonstration on measuring and mixing go to<br />

www.buehler.com/epoheat.htm<br />

What you should know:<br />

■ Do not use disposable plastic castable mounting cups with<br />

high exotherm systems.<br />

■ Do not use Conductive Filler with EpoHeat® because of the low<br />

viscosity; the filler will sink to the bottom so the entire mount<br />

will NOT be conductive. Best to sputter coat the sample if it<br />

needs to be conductive. Conductive Filler works with any other<br />

Buehler Epoxy or Acrylic system.<br />

■ EpoHeat® systems may crystallize, due to the chemical purity of<br />

the product, ranging from gelled to rock hard consistency<br />

inside the container. To relieve this condition, the entire<br />

container should be placed in an oven up to 50 °C (122 °F) <strong>for</strong><br />

approximately two hours. If product is still crystallized after two<br />

hours, extend the time in the oven until the crystallization is<br />

relieved.<br />

Castable Accessories:<br />

Release Agent – Used <strong>for</strong> coating the mounting cup <strong>for</strong> easy<br />

release. Use every time with EPDM mounting cups. See pg 21 <strong>for</strong> a<br />

list of part numbers.<br />

SamplKlip®, SamplKlip® 1, Specimen Support Clips, UniClips®<br />

– Good <strong>for</strong> supporting sample orientation in the mounting cup.<br />

See pg 20 <strong>for</strong> a list of part numbers.<br />

Reusable EPDM Mounting Cups -Can use with any Castable or<br />

Compression Mounting System. See page 19 <strong>for</strong> a list of part<br />

numbers.<br />

Conductive Filler - If you need conductive castable mounts <strong>for</strong><br />

SEM, EDS, and WDS, use Conductive Filler. See page 22 <strong>for</strong> a list of<br />

part numbers.<br />

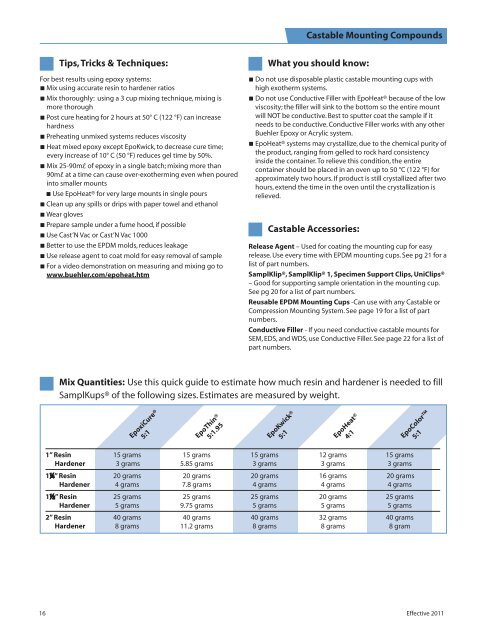

Mix Quantities: Use this quick guide to estimate how much resin and hardener is needed to fill<br />

SamplKups® of the following sizes. Estimates are measured by weight.<br />

EpoxiCure®<br />

5:1<br />

EpoThin®<br />

5:1.95<br />

EpoKwick®<br />

5:1<br />

EpoHeat®<br />

4:1<br />

EpoColor<br />

5:1<br />

1” Resin 15 grams 15 grams 15 grams 12 grams 15 grams<br />

Hardener 3 grams 5.85 grams 3 grams 3 grams 3 grams<br />

14” ”Resin 20 grams 20 grams 20 grams 16 grams 20 grams<br />

Hardener 4 grams 7.8 grams 4 grams 4 grams 4 grams<br />

12” Resin 25 grams 25 grams 25 grams 20 grams 25 grams<br />

Hardener 5 grams 9.75 grams 5 grams 5 grams 5 grams<br />

2” Resin 40 grams 40 grams 40 grams 32 grams 40 grams<br />

Hardener 8 grams 11.2 grams 8 grams 8 grams 8 gram<br />

16 Effective 2011