magazine

magazine

magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Feature<br />

Grain by Grain:<br />

Drying Frac Sand<br />

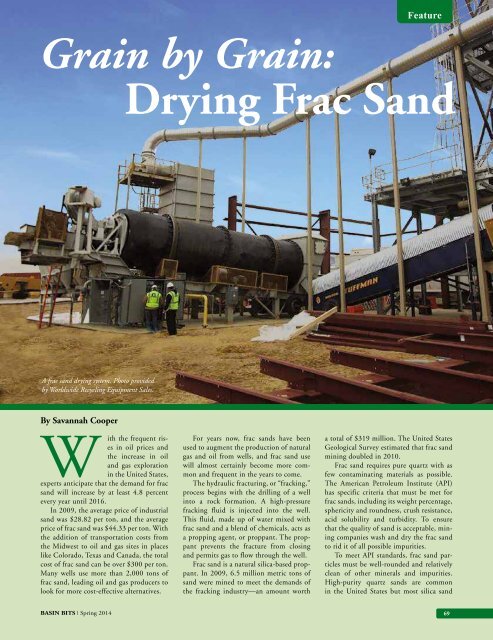

A frac sand drying system. Photo provided<br />

by Worldwide Recycling Equipment Sales.<br />

By Savannah Cooper<br />

W<br />

ith the frequent rises<br />

in oil prices and<br />

the increase in oil<br />

and gas exploration<br />

in the United States,<br />

experts anticipate that the demand for frac<br />

sand will increase by at least 4.8 percent<br />

every year until 2016.<br />

In 2009, the average price of industrial<br />

sand was $28.82 per ton, and the average<br />

price of frac sand was $44.33 per ton. With<br />

the addition of transportation costs from<br />

the Midwest to oil and gas sites in places<br />

like Colorado, Texas and Canada, the total<br />

cost of frac sand can be over $300 per ton.<br />

Many wells use more than 2,000 tons of<br />

frac sand, leading oil and gas producers to<br />

look for more cost-effective alternatives.<br />

For years now, frac sands have been<br />

used to augment the production of natural<br />

gas and oil from wells, and frac sand use<br />

will almost certainly become more common<br />

and frequent in the years to come.<br />

The hydraulic fracturing, or “fracking,”<br />

process begins with the drilling of a well<br />

into a rock formation. A high-pressure<br />

fracking fluid is injected into the well.<br />

This fluid, made up of water mixed with<br />

frac sand and a blend of chemicals, acts as<br />

a propping agent, or proppant. The proppant<br />

prevents the fracture from closing<br />

and permits gas to flow through the well.<br />

Frac sand is a natural silica-based proppant.<br />

In 2009, 6.5 million metric tons of<br />

sand were mined to meet the demands of<br />

the fracking industry—an amount worth<br />

a total of $319 million. The United States<br />

Geological Survey estimated that frac sand<br />

mining doubled in 2010.<br />

Frac sand requires pure quartz with as<br />

few contaminating materials as possible.<br />

The American Petroleum Institute (API)<br />

has specific criteria that must be met for<br />

frac sands, including its weight percentage,<br />

sphericity and roundness, crush resistance,<br />

acid solubility and turbidity. To ensure<br />

that the quality of sand is acceptable, mining<br />

companies wash and dry the frac sand<br />

to rid it of all possible impurities.<br />

To meet API standards, frac sand particles<br />

must be well-rounded and relatively<br />

clean of other minerals and impurities.<br />

High-purity quartz sands are common<br />

in the United States but most silica sand<br />

BASIN BITS | Spring 2014 69