Driveshafts for Industrial Applications - GWB

Driveshafts for Industrial Applications - GWB

Driveshafts for Industrial Applications - GWB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

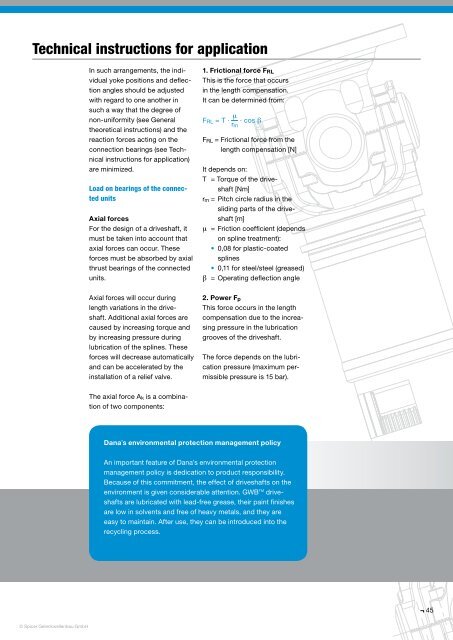

Technical instructions <strong>for</strong> application<br />

In such arrangements, the individual<br />

yoke positions and deflection<br />

angles should be adjusted<br />

with regard to one another in<br />

such a way that the degree of<br />

non-uni<strong>for</strong>mity (see General<br />

theoretical instructions) and the<br />

reaction <strong>for</strong>ces acting on the<br />

connection bearings (see Technical<br />

instructions <strong>for</strong> application)<br />

are minimized.<br />

Load on bearings of the connected<br />

units<br />

Axial <strong>for</strong>ces<br />

For the design of a driveshaft, it<br />

must be taken into account that<br />

axial <strong>for</strong>ces can occur. These<br />

<strong>for</strong>ces must be absorbed by axial<br />

thrust bearings of the connected<br />

units.<br />

1. Frictional <strong>for</strong>ce F RL<br />

This is the <strong>for</strong>ce that occurs<br />

in the length compensation.<br />

It can be determined from:<br />

m<br />

F RL = T · · cos b<br />

r m<br />

F RL = Frictional <strong>for</strong>ce from the<br />

length compensation [N]<br />

It depends on:<br />

T = Torque of the driveshaft<br />

[Nm]<br />

r m = Pitch circle radius in the<br />

sliding parts of the driveshaft<br />

[m]<br />

m = Friction coefficient (depends<br />

on spline treatment):<br />

• 0,08 <strong>for</strong> plastic-coated<br />

splines<br />

• 0,11 <strong>for</strong> steel/steel (greased)<br />

b = Operating deflection angle<br />

Axial <strong>for</strong>ces will occur during<br />

length variations in the driveshaft.<br />

Additional axial <strong>for</strong>ces are<br />

caused by increasing torque and<br />

by increasing pressure during<br />

lubrication of the splines. These<br />

<strong>for</strong>ces will decrease automatically<br />

and can be accelerated by the<br />

installation of a relief valve.<br />

2. Power F p<br />

This <strong>for</strong>ce occurs in the length<br />

compensation due to the increasing<br />

pressure in the lubrication<br />

grooves of the driveshaft.<br />

The <strong>for</strong>ce depends on the lubrication<br />

pressure (maximum permissible<br />

pressure is 15 bar).<br />

The axial <strong>for</strong>ce A k is a combination<br />

of two components:<br />

Dana’s environmental protection management policy<br />

An important feature of Dana’s environmental protection<br />

management policy is dedication to product responsibility.<br />

Because of this commitment, the effect of driveshafts on the<br />

environment is given considerable attention. <strong>GWB</strong> TM driveshafts<br />

are lubricated with lead-free grease, their paint finishes<br />

are low in solvents and free of heavy metals, and they are<br />

easy to maintain. After use, they can be introduced into the<br />

recycling process.<br />

45<br />

© Spicer Gelenkwellenbau GmbH