Calcium Phosphate Excipients - Innophos

Calcium Phosphate Excipients - Innophos

Calcium Phosphate Excipients - Innophos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

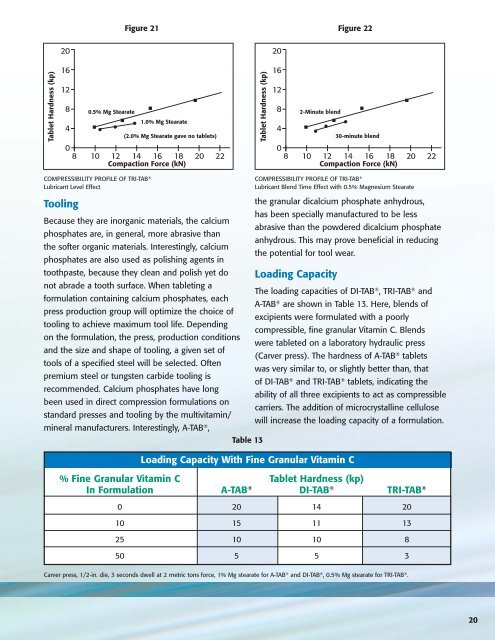

Figure 21 Figure 22<br />

20<br />

20<br />

Tablet Hardness (kp)<br />

16<br />

12<br />

8<br />

4<br />

0<br />

8<br />

0.5% Mg Stearate<br />

1.0% Mg Stearate<br />

(2.0% Mg Stearate gave no tablets)<br />

10 12 14 16 18 20 22<br />

Compaction Force (kN)<br />

Tablet Hardness (kp)<br />

16<br />

12<br />

8<br />

4<br />

0<br />

8<br />

2-Minute blend<br />

30-minute blend<br />

10 12 14 16 18 20<br />

Compaction Force (kN)<br />

22<br />

COMPRESSIBILITY PROFILE OF TRI-TAB ®<br />

Lubricant Level Effect<br />

Tooling<br />

Because they are inorganic materials, the calcium<br />

phosphates are, in general, more abrasive than<br />

the softer organic materials. Interestingly, calcium<br />

phosphates are also used as polishing agents in<br />

toothpaste, because they clean and polish yet do<br />

not abrade a tooth surface. When tableting a<br />

formulation containing calcium phosphates, each<br />

press production group will optimize the choice of<br />

tooling to achieve maximum tool life. Depending<br />

on the formulation, the press, production conditions<br />

and the size and shape of tooling, a given set of<br />

tools of a specified steel will be selected. Often<br />

premium steel or tungsten carbide tooling is<br />

recommended. <strong>Calcium</strong> phosphates have long<br />

been used in direct compression formulations on<br />

standard presses and tooling by the multivitamin/<br />

mineral manufacturers. Interestingly, A-TAB ® ,<br />

Table 13<br />

COMPRESSIBILITY PROFILE OF TRI-TAB ®<br />

Lubricant Blend Time Effect with 0.5% Magnesium Stearate<br />

the granular dicalcium phosphate anhydrous,<br />

has been specially manufactured to be less<br />

abrasive than the powdered dicalcium phosphate<br />

anhydrous. This may prove beneficial in reducing<br />

the potential for tool wear.<br />

Loading Capacity<br />

The loading capacities of DI-TAB ® , TRI-TAB ® and<br />

A-TAB ® are shown in Table 13. Here, blends of<br />

excipients were formulated with a poorly<br />

compressible, fine granular Vitamin C. Blends<br />

were tableted on a laboratory hydraulic press<br />

(Carver press). The hardness of A-TAB ® tablets<br />

was very similar to, or slightly better than, that<br />

of DI-TAB ® and TRI-TAB ® tablets, indicating the<br />

ability of all three excipients to act as compressible<br />

carriers. The addition of microcrystalline cellulose<br />

will increase the loading capacity of a formulation.<br />

Loading Capacity With Fine Granular Vitamin C<br />

% Fine Granular Vitamin C Tablet Hardness (kp)<br />

In Formulation A-TAB ® DI-TAB ® TRI-TAB ®<br />

0 20 14 20<br />

10 15 11 13<br />

25 10 10 8<br />

50 5 5 3<br />

Carver press, 1/2-in. die, 3 seconds dwell at 2 metric tons force, 1% Mg stearate for A-TAB ® and DI-TAB ® , 0.5% Mg stearate for TRI-TAB ® .<br />

20