Calcium Phosphate Excipients - Innophos

Calcium Phosphate Excipients - Innophos

Calcium Phosphate Excipients - Innophos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

For Direct Compression<br />

DI-TAB ® : Dicalcium phosphate, dihydrate,<br />

unmilled, USP/FCC grades. The most well-known<br />

of <strong>Innophos</strong>'s directly compressible excipients, it is<br />

used in major vitamin and mineral formulations, in<br />

over-the-counter drugs and in prescription drugs.<br />

TRI-TAB ® : Tricalcium phosphate, anhydrous, granular,<br />

NF/FCC grade. TRI-TAB ® has the highest percentage<br />

of calcium and is used in calcium supplements.<br />

A-TAB ® : Dicalcium phosphate, anhydrous, granular,<br />

USP/FCC grade. It is anhydrous (giving it good<br />

storage stability), very compressible and provides<br />

a high level of calcium and phosphorus.<br />

Our calcium phosphates are most effectively used<br />

in direct compression tableting. This three-step<br />

procedure - which consists of weighing (actives and<br />

excipients), mixing and compressing - is all that is<br />

required to manufacture a wide variety of tablets.<br />

Both wet and dry granulation take more steps.<br />

Eu and JP grades are available upon request.<br />

For Wet Granulation<br />

Calipharm-D ® : Dicalcium phosphate, dihydrate,<br />

powder, USP/FCC.<br />

Calipharm-T ® : Tricalcium phosphate, anhydrous,<br />

powder, NF/FCC.<br />

Calipharm-A ® : Dicalcium phosphate, anhydrous,<br />

powder, USP/FCC.<br />

The powder forms of calcium phosphates can<br />

be used in a wet granulation with a variety of<br />

commonly used binders, starches, gums, cellulosics<br />

and other polymers. Their water and solvent<br />

insolubility make the calcium phosphates ideal<br />

for wet granulation.<br />

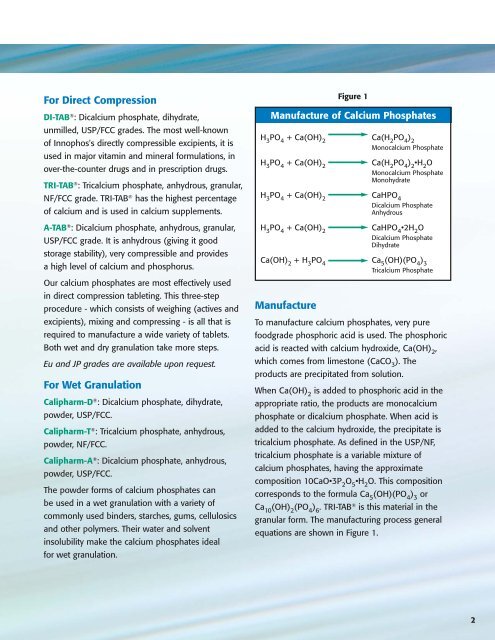

Manufacture of <strong>Calcium</strong> <strong>Phosphate</strong>s<br />

H 3<br />

PO 4<br />

+ Ca(OH) 2<br />

Ca(H 2<br />

PO 4<br />

) 2<br />

Monocalcium <strong>Phosphate</strong><br />

H 3<br />

PO 4<br />

+ Ca(OH) 2<br />

Manufacture<br />

Ca(H 2<br />

PO 4<br />

) 2<br />

•H 2<br />

O<br />

Monocalcium <strong>Phosphate</strong><br />

Monohydrate<br />

H 3<br />

PO 4<br />

+ Ca(OH) 2<br />

CaHPO 4<br />

Dicalcium <strong>Phosphate</strong><br />

Anhydrous<br />

H 3<br />

PO 4<br />

+ Ca(OH) 2<br />

Figure 1<br />

CaHPO 4<br />

•2H 2<br />

O<br />

Dicalcium <strong>Phosphate</strong><br />

Dihydrate<br />

Ca(OH) 2<br />

+ H 3<br />

PO 4<br />

Ca 5<br />

(OH)(PO 4<br />

) 3<br />

Tricalcium <strong>Phosphate</strong><br />

To manufacture calcium phosphates, very pure<br />

foodgrade phosphoric acid is used. The phosphoric<br />

acid is reacted with calcium hydroxide, Ca(OH) 2<br />

,<br />

which comes from limestone (CaCO 3<br />

). The<br />

products are precipitated from solution.<br />

When Ca(OH) 2<br />

is added to phosphoric acid in the<br />

appropriate ratio, the products are monocalcium<br />

phosphate or dicalcium phosphate. When acid is<br />

added to the calcium hydroxide, the precipitate is<br />

tricalcium phosphate. As defined in the USP/NF,<br />

tricalcium phosphate is a variable mixture of<br />

calcium phosphates, having the approximate<br />

composition 10CaO•3P 2<br />

O 5<br />

•H 2<br />

O. This composition<br />

corresponds to the formula Ca 5<br />

(OH)(PO 4<br />

) 3<br />

or<br />

Ca 10<br />

(OH) 2<br />

(PO 4<br />

) 6<br />

. TRI-TAB ® is this material in the<br />

granular form. The manufacturing process general<br />

equations are shown in Figure 1.<br />

2