4.7 fuel tank (carbu - harley-davidson-sweden.se

4.7 fuel tank (carbu - harley-davidson-sweden.se

4.7 fuel tank (carbu - harley-davidson-sweden.se

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HOME<br />

12. Connect <strong>fuel</strong> <strong>tank</strong> harness connector [13], 3-place Multilock,<br />

in front of battery. See Figure 4-17.<br />

13. Snap anchor of new cable strap into hole on left side of<br />

frame backbone. Tighten cable strap capturing main harness<br />

bundles, <strong>fuel</strong> level <strong>se</strong>nder conduit, and <strong>fuel</strong> vapor<br />

vent tube. Cut any excess cable strap material.<br />

Convoluted<br />

Tubing<br />

NOTE<br />

Route <strong>fuel</strong> overflow ho<strong>se</strong> inboard of wire bundles on right side<br />

of frame, but do not capture in cable straps. See Figure 4-19.<br />

14. In<strong>se</strong>rt bolt through battery negative cable (black) into<br />

threaded hole of battery negative (-) terminal. Tighten<br />

bolt to 60-96 in-lbs (6.8-10.9 Nm).<br />

15. Install <strong>se</strong>at. See Section 2.24 SEAT, INSTALLATION.<br />

16. Turn the handle of the <strong>fuel</strong> valve to OFF and fill the <strong>fuel</strong><br />

<strong>tank</strong>. Carefully inspect for leaks. Turn the valve handle to<br />

ON and start engine. Repeat inspection.<br />

17. Stop engine and return the valve to the OFF position.<br />

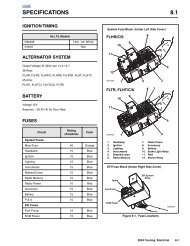

FLHR/S<br />

CAUTION<br />

Exerci<strong>se</strong> caution to avoid pinching the wiring harness<br />

between the <strong>fuel</strong> <strong>tank</strong> and vehicle frame. Wire damage<br />

may result in electrical problems.<br />

1. Work <strong>fuel</strong> <strong>tank</strong> into position aligning front flange holes<br />

with tho<strong>se</strong> in frame.<br />

2. Slide new clamp onto free end of crossover ho<strong>se</strong>. Running<br />

ho<strong>se</strong> beneath frame backbone, install ho<strong>se</strong> onto fitting<br />

at bottom front of <strong>fuel</strong> <strong>tank</strong>. Crimp clamp using<br />

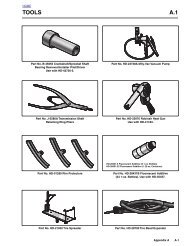

HOSE CLAMP PLIERS (HD-97087-65B).<br />

3. Slide new clamp onto free end of <strong>carbu</strong>retor <strong>fuel</strong> inlet<br />

ho<strong>se</strong>. Install ho<strong>se</strong> onto <strong>fuel</strong> outlet fitting at side of <strong>fuel</strong><br />

valve. Crimp clamp.<br />

4. Install the intake manifold vacuum ho<strong>se</strong> onto the vacuum<br />

fitting at the back of the <strong>fuel</strong> valve.<br />

5. Connect <strong>fuel</strong> vapor vent tube to fitting at top of canopy.<br />

6. Slide head of console mounting bolt into slot at top of<br />

canopy.<br />

7. Moving instrument console toward installed position,<br />

install <strong>fuel</strong> level <strong>se</strong>nder connector [141], 3-place Mini-<br />

Deutsch, at top of canopy. Bend flexible clamp to capture<br />

main harness conduit.<br />

8. Align hole in instrument console with console mounting<br />

bolt and place into position on <strong>fuel</strong> <strong>tank</strong>.<br />

9. Start <strong>fuel</strong> <strong>tank</strong> front mounting bolts (with flat washers)<br />

into left and right side of frame.<br />

10. Install bolt (with flat washer) to <strong>se</strong>cure rear of <strong>fuel</strong> <strong>tank</strong> to<br />

frame backbone. On FLHRS models, capture instrument<br />

console bracket during installation. Tighten bolt to 15-20<br />

ft-lbs (20-27 Nm).<br />

8870<br />

11. Tighten <strong>fuel</strong> <strong>tank</strong> front mounting bolts to 15-20 ft-lbs (20-<br />

27 Nm).<br />

12. Install acorn nut at top of instrument console and tighten<br />

to 50-90 in-lbs (5.7-10.2 Nm). If pre<strong>se</strong>nt, also install Phillips<br />

screw and large flat washer (ab<strong>se</strong>nt on FLHRS models).<br />

Tighten screw to 36-60 in-lbs (4.1-6.8 Nm).<br />

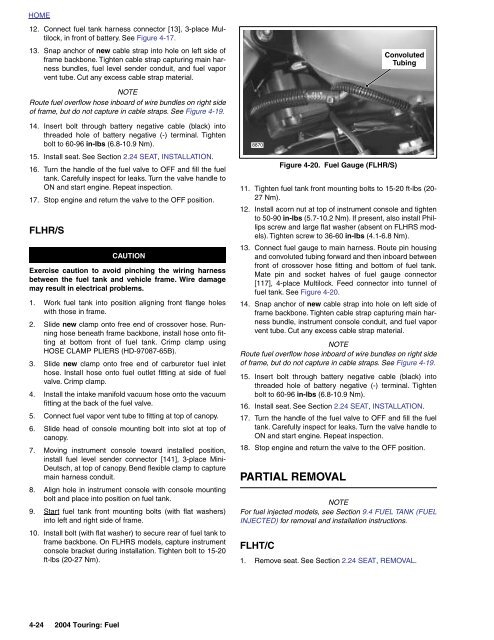

13. Connect <strong>fuel</strong> gauge to main harness. Route pin housing<br />

and convoluted tubing forward and then inboard between<br />

front of crossover ho<strong>se</strong> fitting and bottom of <strong>fuel</strong> <strong>tank</strong>.<br />

Mate pin and socket halves of <strong>fuel</strong> gauge connector<br />

[117], 4-place Multilock. Feed connector into tunnel of<br />

<strong>fuel</strong> <strong>tank</strong>. See Figure 4-20.<br />

14. Snap anchor of new cable strap into hole on left side of<br />

frame backbone. Tighten cable strap capturing main harness<br />

bundle, instrument console conduit, and <strong>fuel</strong> vapor<br />

vent tube. Cut any excess cable strap material.<br />

NOTE<br />

Route <strong>fuel</strong> overflow ho<strong>se</strong> inboard of wire bundles on right side<br />

of frame, but do not capture in cable straps. See Figure 4-19.<br />

15. In<strong>se</strong>rt bolt through battery negative cable (black) into<br />

threaded hole of battery negative (-) terminal. Tighten<br />

bolt to 60-96 in-lbs (6.8-10.9 Nm).<br />

16. Install <strong>se</strong>at. See Section 2.24 SEAT, INSTALLATION.<br />

17. Turn the handle of the <strong>fuel</strong> valve to OFF and fill the <strong>fuel</strong><br />

<strong>tank</strong>. Carefully inspect for leaks. Turn the valve handle to<br />

ON and start engine. Repeat inspection.<br />

18. Stop engine and return the valve to the OFF position.<br />

PARTIAL REMOVAL<br />

NOTE<br />

For <strong>fuel</strong> injected models, <strong>se</strong>e Section 9.4 FUEL TANK (FUEL<br />

INJECTED) for removal and installation instructions.<br />

FLHT/C<br />

Figure 4-20. Fuel Gauge (FLHR/S)<br />

1. Remove <strong>se</strong>at. See Section 2.24 SEAT, REMOVAL.<br />

4-24 2004 Touring: Fuel