Tech. Explanations - Kendrion Binder

Tech. Explanations - Kendrion Binder

Tech. Explanations - Kendrion Binder

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

the technical background<br />

Response delay (t 11 ):<br />

is the time between switching on the energisation<br />

current and the plunger beginning to move.<br />

Travel time (t 12 ):<br />

is the time taken by the plunger to move from its<br />

initial position to its end position.<br />

Release delay (t 21 ):<br />

is the time between switching off the energisation current<br />

and the plunger beginning to move back.<br />

Return time (t 22 ):<br />

is the time taken by the plunger to move from its end<br />

position back to its initial position.<br />

7. SI units and symbols used in equations<br />

The SI units and symbols used in equations as given on<br />

the product data sheets and in the technical data are<br />

taken from DIN 1304. The most important variables<br />

used in the design of the devices are listed on page 15.<br />

8. Testing of solenoids<br />

8.1 Test voltage<br />

All KENDRION solenoids are tested to ascertain their<br />

dielectric strength before leaving the factory. The test<br />

voltages used are given in DIN VDE 0580 point 5.3.1.<br />

8.1.2 Renewed voltage test<br />

The voltage test carried out during routine testing<br />

should not be repeated if it can be avoided. However,<br />

if a second test is called for, e.g. as an acceptance<br />

criterion, then this should be carried out with only 80%<br />

of the test voltage given in Tab. 4 below.<br />

9. Electromagnetic time constants ( )<br />

and inductances (L)<br />

The electromagnetic time constants (ms) for the initial<br />

and end positions of the plunger are specified on the<br />

product data sheets in order to determine the inductances<br />

of DC linear solenoids. These time constants allow the<br />

inductances to be calculated for various duty cycles and<br />

rated voltages according to the following example:<br />

Given:<br />

Wanted:<br />

Answer:<br />

solenoid type LHS060...<br />

duty cycle = 100%<br />

rated voltage = 24 VDC<br />

inductance LIP (H) for initial position of<br />

plunger inductance LEP (H) for end posi<br />

tion of plunger<br />

input power P20 = 26 W<br />

(specified on data sheet)<br />

According to Ohm’s law, the resistance of the energisation<br />

coil can be calculated from the input power as follows:<br />

2 2 2<br />

R = ——<br />

U<br />

= ———<br />

24 [V ]<br />

= 22 Ω<br />

26 [W]<br />

P 20<br />

Inductance at initial position:<br />

L IP =<br />

Inductance at end position:<br />

L EP =<br />

- -3<br />

IP · R = 4[ms] · 10 · 22 [Ω] = 88mH<br />

EP · R = 4,3 [ms] · 10 · 22 [Ω] = 95mH<br />

Make sure that the time constants are entered in milliseconds<br />

(ms) for these calculations, i.e. time constant<br />

values specified in seconds (s) must be multiplied by<br />

10 -3 .<br />

-3<br />

10. Operating conditions<br />

Our AC and DC linear solenoids are designed for the<br />

following operating conditions:<br />

10.1 An ambient temperature of 35°C. The minimum<br />

ambient temperature is -5°C.<br />

10.2 The Relative humidity of the air depends<br />

on the ambient temperature and is approx. 50% at<br />

35°C. Higher relative humidities are permissible at<br />

lower temperatures. Consideration should be given to<br />

the formation of condensation water.<br />

10.3 Please adhere to our installation guidelines<br />

when putting the devices into operation.<br />

11. Service life<br />

The service life of devices and associated wear parts<br />

depends on the installation and operating conditions,<br />

e.g. mounting position, load etc.<br />

12. Notes for DC and AC linear solenoids<br />

12.1 Installation<br />

Connect the plunger to the machine part by means of<br />

an interlocking, non-rigid link that allows sufficient<br />

play.<br />

12.2 Mounting position<br />

Our DC linear solenoids can be mounted in any position.<br />

The force transfer is preferably in the axial direction.<br />

12.3 Putting into operation<br />

The supply voltage must match the rated voltage as<br />

given on the rating plate. The user is responsible for<br />

observing the instructions and requirements described<br />

in DIN VDE 0580 (July 2000).<br />

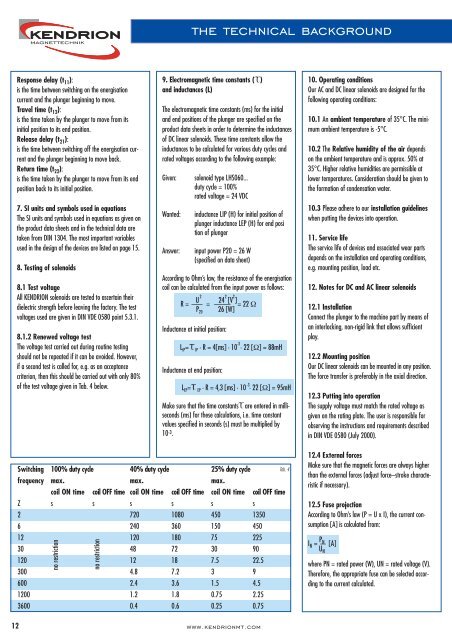

Switching<br />

frequency<br />

Z<br />

2<br />

6<br />

12<br />

30<br />

120<br />

300<br />

600<br />

1200<br />

3600<br />

100% duty cycle<br />

max.<br />

coil ON time coil OFF time<br />

s<br />

s<br />

no restriction<br />

no restriction<br />

40% duty cycle<br />

max.<br />

coil ON time coil OFF time<br />

s<br />

s<br />

720<br />

1080<br />

240<br />

360<br />

120<br />

180<br />

48<br />

72<br />

12<br />

18<br />

4.8<br />

7.2<br />

2.4<br />

3.6<br />

1.2<br />

1.8<br />

0.4<br />

0.6<br />

25% duty cycle<br />

max.<br />

coil ON time coil OFF time<br />

s<br />

s<br />

450<br />

1350<br />

150<br />

450<br />

75<br />

225<br />

30<br />

90<br />

7.5<br />

22.5<br />

3<br />

9<br />

1.5<br />

4.5<br />

0.75 2.25<br />

0.25 0.75<br />

Tab. 4<br />

12.4 External forces<br />

Make sure that the magnetic forces are always higher<br />

than the external forces (adjust force–stroke characteristic<br />

if necessary).<br />

12.5 Fuse projection<br />

According to Ohm’s law (P = U x I), the current consumption<br />

[A] is calculated from:<br />

P N IN = — [A]<br />

U N<br />

where PN = rated power (W), UN = rated voltage (V).<br />

Therefore, the appropriate fuse can be selected according<br />

to the current calculated.<br />

12<br />

www.kendrionmt.com