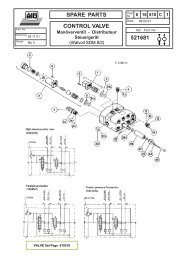

VALVE SET - Hjallerup Maskinforretning A/S

VALVE SET - Hjallerup Maskinforretning A/S

VALVE SET - Hjallerup Maskinforretning A/S

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CONTROL<br />

- Disconnect the safety catch (E) and check that the<br />

control device lever always returns to neutral position<br />

except when the lever is brought maximally forwards to<br />

floating position.<br />

The lever should then remain in this position.<br />

Lever movement:<br />

Backwards - Lifting of loader beam<br />

Forwards - Sinking of loader beam + floating function<br />

Left - The implement is crowded upwards 1)<br />

Right - The implement is emptied 1)<br />

1) Tobtain the reverse lever movement (LH fitting), the<br />

hoses marked yellow and red (implement function)<br />

will have to change places. Check that the direction<br />

indicator on the MONO-lever corresponds to the<br />

movements of the loader - the handle will be supplied<br />

with a new top for left hand fitting. The ref no of this<br />

top is 50 20 385. See fig.A.<br />

The loader shall be connected to the valve acc. to the<br />

colour marking:<br />

GREEN (B1) = Sink<br />

BLUE (A1) = Lift<br />

YELLOW (A2) = Tip<br />

RED (B2) = Crowd<br />

YELLOW (A2) = Tip<br />

Connect the valve to the tractor hydraulics acc. to<br />

separate mounting instruction. Therefore only general<br />

information is given here.<br />

ENGLISH (105 -157)<br />

- Connect the tractor pump ( pressure) to the valve port<br />

(P).<br />

- Port T - connect to tank (return).<br />

- Port LS - aimed for signalling circuit.<br />

Test run all the functions of the loader (towards end<br />

positions) and check that there are no oil leakages.<br />

Check after test run that the oil level in the tractor's<br />

hydraulics system is sufficient ( all hydraulic rams<br />

compressed). Fasten the hydraulic hoses with clamps<br />

so that they do not wear against pedals and control<br />

stays, if any.<br />

REMARK !<br />

The valve is equipped with safety valves (M) for the<br />

lifting function (240 bar) of the loader.<br />

GREASING<br />

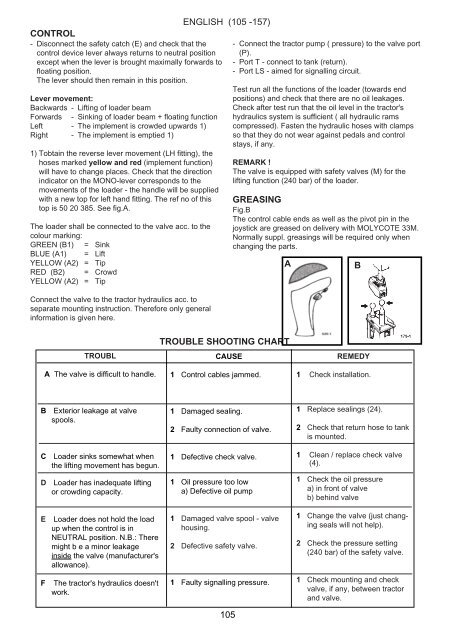

Fig.B<br />

The control cable ends as well as the pivot pin in the<br />

joystick are greased on delivery with MOLYCOTE 33M.<br />

Normally suppl. greasings will be required only when<br />

changing the parts.<br />

A<br />

B<br />

TROUBL<br />

A The valve is difficult to handle.<br />

TROUBLE SHOOTING CHART<br />

CAUSE<br />

1 Control cables jammed.<br />

REMEDY<br />

1 Check installation.<br />

B<br />

Exterior leakage at valve<br />

spools.<br />

1 Damaged sealing.<br />

2 Faulty connection of valve.<br />

1 Replace sealings (24).<br />

2 Check that return hose to tank<br />

is mounted.<br />

C<br />

Loader sinks somewhat when<br />

the lifting movement has begun.<br />

1 Defective check valve.<br />

1 Clean / replace check valve<br />

(4).<br />

D<br />

Loader has inadequate lifting<br />

or crowding capacity.<br />

1 Oil pressure too low<br />

a) Defective oil pump<br />

1 Check the oil pressure<br />

a) in front of valve<br />

b) behind valve<br />

E<br />

Loader does not hold the load<br />

up when the control is in<br />

NEUTRAL position. N.B.: There<br />

might b e a minor leakage<br />

inside the valve (manufacturer's<br />

allowance).<br />

1 Damaged valve spool - valve<br />

housing.<br />

2 Defective safety valve.<br />

1 Change the valve (just changing<br />

seals will not help).<br />

2 Check the pressure setting<br />

(240 bar) of the safety valve.<br />

F<br />

The tractor's hydraulics doesn't<br />

work.<br />

1 Faulty signalling pressure.<br />

1 Check mounting and check<br />

valve, if any, between tractor<br />

and valve.<br />

105