DeBAKEy CARDIOvASCuLAR JOuRNAL - Methodist Hospital

DeBAKEy CARDIOvASCuLAR JOuRNAL - Methodist Hospital

DeBAKEy CARDIOvASCuLAR JOuRNAL - Methodist Hospital

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Figure 1. Lazar<br />

Greenfield, vascular<br />

surgeon<br />

positive impact on patient welfare. One such example<br />

is the Kimray-Greenfield inferior vena cava filter that<br />

is used clinically to prevent clots passing from the<br />

legs to the lungs. Dr. Lazar Greenfield (Figure 1) was<br />

prompted by a case of pulmonary embolus in a young<br />

trauma patient. After opening the chest and performing<br />

a pulmonary embolectomy, the patient died. Dr.<br />

Greenfield sought better techniques to prevent pulmonary<br />

embolus and asked Garman Kimmell (Figure 2),<br />

an entrepreneur-inventor from the oil and gas industry,<br />

for his help. Kimmell recognized the similar problem of<br />

sludge in oil pipelines and how a conical filter trapped<br />

the sludge at its center while still allowing flow around<br />

it on the sides. Together they designed a prototype and<br />

tested it in animals before implanting it in patients in the<br />

early 1970s. The modern descendant is the stainless steel<br />

Greenfield filter that has been implanted in more than<br />

200,000 patients to date (Figure 3).<br />

“Great invention is always metaphor,” says John Abele,<br />

a co-founder of Boston Scientific Corporation, which<br />

has manufactured the<br />

Greenfield filter since<br />

it acquired Kimmell’s<br />

medical-device company<br />

in 1980. “you look at the<br />

problem, and then you<br />

try to connect it to other<br />

areas which may have<br />

nothing to do with the<br />

problem you’re working<br />

on.”<br />

Figure 3. Greenfield vena cava<br />

filter.<br />

Figure 2. Garman Kimmel,<br />

oil-industry engineer, suggested<br />

an implantable filter for trapping<br />

blood clots before they can reach<br />

the lungs.<br />

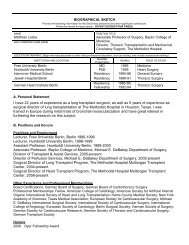

Figure 4. Spiral Flow Vascular Access Graft (Tayside Flow<br />

Technologies).<br />

A. The novel graft design imparts a spiral laminar flow to the blood<br />

delivering less turbulent flow energy to the venous anastomosis site.<br />

B. Spiral Flow Inducer consists of an injection molded polyurethane<br />

component that forms one 360° helical turn (HT) running along the<br />

outside distal end of the graft.<br />

C. Pre-cut venous anastomosis cuff.<br />

D. Cross-section view of Spiral Flow Inducer showing injection molded<br />

component (*).<br />

E. Inside view of Spiral Flow Inducer showing ePTFE ridge (R) on the<br />

graft lumen that imparts a rotational force on the blood exiting the graft<br />

resulting in spiral laminar flow at the venous anastomosis site.<br />

A Synergy of Industries<br />

Tayside Flow Technologies, a small Scottish startup<br />

company and participant in the Pumps and Pipes 3<br />

Conference, has developed an artificial blood vessel that<br />

mimics naturally occurring spiral flow patterns (Figure<br />

4), thereby improving patency of bypass grafts. The same<br />

technology is being studied to move oil through pipelines<br />

with less frictional energy loss, thereby improving<br />

efficiency. Indeed, pipeline engineers have long understood<br />

the benefits of spiral flow patterns. There are other<br />

crossovers as well. Remote monitoring, remote visualization,<br />

3-D reconstruction of imaging data, automated<br />

data analyses, use of simulators, robotics, and quality<br />

improvement processes are all techniques common to<br />

both industries, where opportunities exist for accelerated<br />

learning.<br />

The public was recently amazed at the clarity of visualization<br />

and the dexterity of remote-controlled robots<br />

in severing and capping the leaking blowout preventer<br />

46 vII (1) 2011 | MDCvJ