Waalbot - NanoRobotics Lab - Carnegie Mellon University

Waalbot - NanoRobotics Lab - Carnegie Mellon University

Waalbot - NanoRobotics Lab - Carnegie Mellon University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

334 IEEE/ASME TRANSACTIONS ON MECHATRONICS, VOL. 12, NO. 3, JUNE 2007<br />

It can be shown that the preload converges to the intersection<br />

preload (L ∗ ) through an iterative proof using the update rule<br />

( a<br />

L i+1 = L<br />

m)<br />

( 1 n )<br />

i (6)<br />

which mathematically represents a single step, where L i is the<br />

preload for step number i. The steady-state operating preload<br />

(L ∞ ) is given by<br />

( a<br />

) A<br />

(<br />

L ∞ = lim L 1 n )<br />

n→∞<br />

0 (7)<br />

m<br />

A =1+ 1 (<br />

1+ 1 (1+ 1 ))<br />

n n n (...) = n<br />

n − 1 . (8)<br />

Therefore,<br />

( a<br />

n<br />

n −1<br />

L ∞ = = L<br />

m) ∗ . (9)<br />

The steady-state operating preload (L ∞ ) converges to the<br />

preload at the intersection of the two lines (L ∗ ) from (5). The<br />

steady-state operating adhesion (F ∞ ) is then equal to mL ∞ .<br />

These two values define a steady-state operating point, point S<br />

in Fig. 7. There is also a minimum safe adhesion value (F safe ),<br />

which is a function of the area of the footpads and the surface<br />

slope angle θ, and can be calculated from (2) and foot size. The<br />

steady state operating adhesion (F ∞ ) must be greater than the<br />

minimum safe adhesion value (F safe ) to prevent the robot from<br />

detaching from the climbing surface. The margin between the<br />

steady-state operating adhesion and the minimum safe adhesion<br />

is the margin of safety (M s ). Since the robot will not always<br />

have ideal force transfer on every step, it is important to have a<br />

large margin of safety so that the robot can recover from a problematic<br />

step, or continue to operate if the adhesives become<br />

contaminated and function with degraded performance.<br />

It is possible to increase the margin of safety by increasing<br />

the area of the adhesives (foot pad size), which lowers the<br />

minimum adhesion pressure requirement. However, there is a<br />

tradeoff because the motors then need to provide more torque to<br />

peel the larger feet. This causes an increased power requirement,<br />

which leads to larger batteries, and also necessitates a larger and<br />

heavier motor.<br />

C. Robot Fabrication<br />

A printed circuit board (PCB) acts as the chassis for the robot<br />

instead of using an additional body frame in order to keep the<br />

mass low. The leg and feet assemblies are fabricated via 3-D<br />

printing (Z-Corp. ZPrinter and 3-D Systems Invision HR). The<br />

heaviest components of the system are the leg assemblies, motors,<br />

and batteries. In order to move the center of gravity as close<br />

as possible to the surface and balanced around the motor axes, all<br />

these parts are located close to the shaft axes with the batteries<br />

beneath the PCB, nearly in contact with the climbing surface.<br />

The robot is controlled by a PIC microcontroller<br />

(PIC16F737), and is able to perform preprogrammed actions<br />

such as climbing and turning without instructions from the user.<br />

Gait is controlled with feedback from foot position sensors.<br />

Limit switches are triggered when the legs are aligned so that<br />

only one foot on each side is in contact with the surface. This<br />

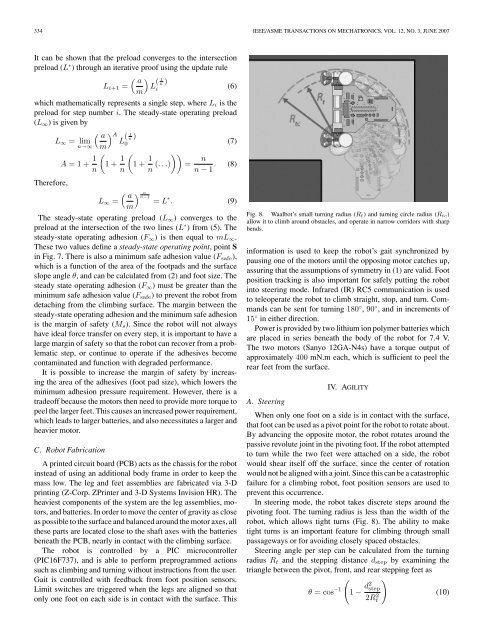

Fig. 8. <strong>Waalbot</strong>’s small turning radius (R t ) and turning circle radius (R tc )<br />

allow it to climb around obstacles, and operate in narrow corridors with sharp<br />

bends.<br />

information is used to keep the robot’s gait synchronized by<br />

pausing one of the motors until the opposing motor catches up,<br />

assuring that the assumptions of symmetry in (1) are valid. Foot<br />

position tracking is also important for safely putting the robot<br />

into steering mode. Infrared (IR) RC5 communication is used<br />

to teleoperate the robot to climb straight, stop, and turn. Commands<br />

can be sent for turning 180 ◦ , 90 ◦ , and in increments of<br />

15 ◦ in either direction.<br />

Power is provided by two lithium ion polymer batteries which<br />

are placed in series beneath the body of the robot for 7.4 V.<br />

The two motors (Sanyo 12GA-N4s) have a torque output of<br />

approximately 400 mN.m each, which is sufficient to peel the<br />

rear feet from the surface.<br />

IV. AGILITY<br />

A. Steering<br />

When only one foot on a side is in contact with the surface,<br />

that foot can be used as a pivot point for the robot to rotate about.<br />

By advancing the opposite motor, the robot rotates around the<br />

passive revolute joint in the pivoting foot. If the robot attempted<br />

to turn while the two feet were attached on a side, the robot<br />

would shear itself off the surface, since the center of rotation<br />

would not be aligned with a joint. Since this can be a catastrophic<br />

failure for a climbing robot, foot position sensors are used to<br />

prevent this occurrence.<br />

In steering mode, the robot takes discrete steps around the<br />

pivoting foot. The turning radius is less than the width of the<br />

robot, which allows tight turns (Fig. 8). The ability to make<br />

tight turns is an important feature for climbing through small<br />

passageways or for avoiding closely spaced obstacles.<br />

Steering angle per step can be calculated from the turning<br />

radius R t and the stepping distance d step by examining the<br />

triangle between the pivot, front, and rear stepping feet as<br />

( )<br />

θ =cos −1 1 − d2 step<br />

2Rt<br />

2 (10)