2012 - PageSuite

2012 - PageSuite

2012 - PageSuite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INfOCUS<br />

Georgia Tech study:<br />

Sales, Lean, skilled worker help needed<br />

The <strong>2012</strong> edition of the Georgia Manufacturing Survey,<br />

conducted by Georgia Tech University, points to four areas<br />

of concern for manufacturers in that state. Topping the list<br />

is a need for more help in sales and marketing, with 36% of<br />

manufacturers citing this as a significant need.<br />

Manufacturers also want more help with the Lean manufacturing<br />

operation, cited by 32% of manufacturers, and worker<br />

skills, with 24% needing more technical workers and 16%<br />

needing more workers with basic skills. Energy cost management<br />

is cited by 21% of manufacturers as an area of concern.<br />

That percentage has doubled since 1999.<br />

The study also noted a significant increase in re-shoring<br />

of jobs to the state. According to a press release issued by<br />

Georgia Tech, nearly 16% of the companies responding to the<br />

survey said work had been transferred to them from outside<br />

Georgia, compared to slightly more than 14% that lost work<br />

to out-of-state facilities.<br />

“We have finally seen a crossing of the lines so that more<br />

companies are benefiting from in-sourcing than are losing<br />

to outsourcing,” said Jan Youtie, director of policy<br />

research services in the Enterprise Innovation Institute at<br />

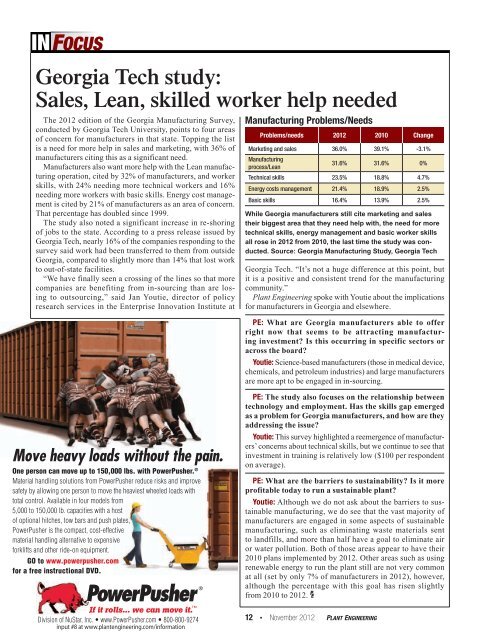

Manufacturing Problems/Needs<br />

Problems/needs <strong>2012</strong> 2010 Change<br />

Marketing and sales 36.0% 39.1% -3.1%<br />

Manufacturing<br />

process/Lean<br />

31.6% 31.6% 0%<br />

Technical skills 23.5% 18.8% 4.7%<br />

Energy costs management 21.4% 18.9% 2.5%<br />

Basic skills 16.4% 13.9% 2.5%<br />

While Georgia manufacturers still cite marketing and sales<br />

their biggest area that they need help with, the need for more<br />

technical skills, energy management and basic worker skills<br />

all rose in <strong>2012</strong> from 2010, the last time the study was conducted.<br />

Source: Georgia Manufacturing Study, Georgia Tech<br />

Georgia Tech. “It’s not a huge difference at this point, but<br />

it is a positive and consistent trend for the manufacturing<br />

community.”<br />

Plant Engineering spoke with Youtie about the implications<br />

for manufacturers in Georgia and elsewhere.<br />

PE: What are Georgia manufacturers able to offer<br />

right now that seems to be attracting manufacturing<br />

investment Is this occurring in specific sectors or<br />

across the board<br />

Youtie: Science-based manufacturers (those in medical device,<br />

chemicals, and petroleum industries) and large manufacturers<br />

are more apt to be engaged in in-sourcing.<br />

Move heavy loads without the pain.<br />

One person can move up to 150,000 lbs. with PowerPusher. ®<br />

Material handling solutions from PowerPusher reduce risks and improve<br />

safety by allowing one person to move the heaviest wheeled loads with<br />

total control. Available in four models from<br />

5,000 to 150,000 lb. capacities with a host<br />

of optional hitches, tow bars and push plates,<br />

PowerPusher is the compact, cost-effective<br />

material handling alternative to expensive<br />

forklifts and other ride-on equipment.<br />

GO to www.powerpusher.com<br />

for a free instructional DVD.<br />

PowerPusher<br />

If it rolls... we can move it.<br />

Division of NuStar, Inc. • www.PowerPusher.com • 800-800-9274<br />

input #8 at www.plantengineering.com/information<br />

®<br />

PE: The study also focuses on the relationship between<br />

technology and employment. Has the skills gap emerged<br />

as a problem for Georgia manufacturers, and how are they<br />

addressing the issue<br />

Youtie: This survey highlighted a reemergence of manufacturers’<br />

concerns about technical skills, but we continue to see that<br />

investment in training is relatively low ($100 per respondent<br />

on average).<br />

PE: What are the barriers to sustainability Is it more<br />

profitable today to run a sustainable plant<br />

Youtie: Although we do not ask about the barriers to sustainable<br />

manufacturing, we do see that the vast majority of<br />

manufacturers are engaged in some aspects of sustainable<br />

manufacturing, such as eliminating waste materials sent<br />

to landfills, and more than half have a goal to eliminate air<br />

or water pollution. Both of those areas appear to have their<br />

2010 plans implemented by <strong>2012</strong>. Other areas such as using<br />

renewable energy to run the plant still are not very common<br />

at all (set by only 7% of manufacturers in <strong>2012</strong>), however,<br />

although the percentage with this goal has risen slightly<br />

from 2010 to <strong>2012</strong>. P E<br />

12 • November <strong>2012</strong> plant engineering