Volume 6, Number 4, December, 1998 - Noise News International

Volume 6, Number 4, December, 1998 - Noise News International

Volume 6, Number 4, December, 1998 - Noise News International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

specify in more detail relevant measurement<br />

methods, application-related assessment criteria,<br />

and design measures.<br />

Framework Standards and Safety<br />

Standards Specific to Machinery<br />

The framework standards (A or B standards) that<br />

have been developed for machinery safety - EN<br />

292-l 6 and EN 292-2,6 and EN 414 7 - specify<br />

principles for detecting and avoiding hazards and<br />

for increasing machinery safety. With regard to<br />

acoustics, there are framework standards (B standards)<br />

for determination of sound emission and for<br />

an explanation of principles of noise reduction of<br />

machines and the implementation of those principles:<br />

EN ISO 3740 ff,8 EN ISO 11200 ff,9 EN ISO<br />

4871,10 EN ISO 12001,11 EN ISO 11688,12 EN<br />

ISO 11689,13 EN ISO 11690. 14 The machine<br />

safely standards and an explanation of their purpose<br />

are given in Table 2.<br />

Appropriate safety standards (C standards) are<br />

prepared in support of the ED machinery directive<br />

for different groups of machines based on the framework<br />

standards. According to EN 414, these framework<br />

safety standards should contain:<br />

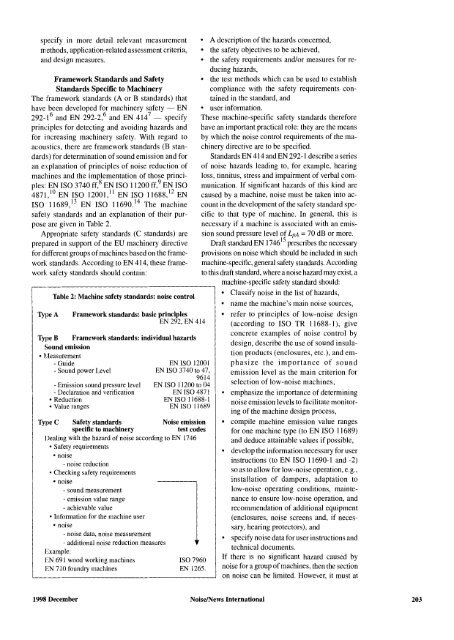

Type A<br />

Table 2: Machine safety standards: noise control<br />

Framework standards: basic principles<br />

EN 292, EN 414<br />

Type B Framework standards: individual hazards<br />

Sound emission<br />

• Measurement<br />

- Guide<br />

- Sound power Level<br />

- Emission sound pressure level<br />

- Declaration and verification<br />

• Reduction<br />

• Value ranges<br />

EN ISO 12001<br />

EN ISO 3740 to 47,<br />

9614<br />

EN ISO 11200 to 04<br />

EN ISO 4871<br />

EN ISO 11688-1<br />

EN ISO 11689<br />

Safety standards<br />

<strong>Noise</strong> emission<br />

specific to machinery<br />

test codes<br />

Dealing with the hazard of noise according to EN 1746<br />

• Safety requirements<br />

• noise<br />

- noise reduction<br />

• Checking safety requirements<br />

• noise<br />

- sound measurement<br />

- emission value range<br />

- achievable value<br />

• Information for the machine user<br />

• noise<br />

- noise data, noise measurement<br />

- additional noise reduction measures<br />

Example:<br />

EN 691 wood working machines<br />

ISO 7960<br />

EN 710 foundry machines<br />

EN 1265.<br />

• A description of the hazards concerned,<br />

• the safety objectives to be achieved,<br />

• the safety requirements and/or measures for reducing<br />

hazards,<br />

• the test methods which can be used to establish<br />

compliance with the safety requirements contained<br />

in the standard, and<br />

• user information.<br />

These machine-specific safety standards therefore<br />

have an important practical role: they are the means<br />

by which the noise control requirements of the machinery<br />

directive are to be specified.<br />

Standards EN 414 and EN 292-1 describe a series<br />

of noise hazards leading to, for example, hearing<br />

loss, tinnitus, stress and impairment of verbal communication.<br />

If significant hazards of this kind are<br />

caused by a machine, noise must be taken into account<br />

in the development of the safety standard specific<br />

to that type of machine. In general, this is<br />

necessary if a machine is associated with an emission<br />

sound pressure level of LpA =70 dB or more.<br />

Draft standard EN 1746 15 prescribes the necessary<br />

provisions on noise which should be included in such<br />

machine-specific, general safety standards. According<br />

to this draft standard, where a noise hazard may exist, a<br />

machine-specific safety standard should:<br />

• Classify noise in the list of hazards,<br />

• name the machine's main noise sources,<br />

• refer to principles of low-noise design<br />

(according to ISO TR 11688-1), give<br />

concrete examples of noise control by<br />

design, describe the use of sound insulation<br />

products (enclosures, etc.), and emphasize<br />

the importance of sound<br />

emission level as the main criterion for<br />

selection of low-noise machines,<br />

• emphasize the importance of determining<br />

noise emission levels to facilitate monitoring<br />

of the machine design process,<br />

• compile machine emission value ranges<br />

for one machine type (to EN ISO 11689)<br />

and deduce attainable values if possible,<br />

• develop the information necessary for user<br />

instructions (to EN ISO 11690-1 and -2)<br />

so as to allow for low-noise operation, e.g.,<br />

installation of dampers, adaptation to<br />

low-noise operating conditions, maintenance<br />

to ensure low-noise operation, and<br />

recommendation of additional equipment<br />

(enclosures, noise screens and, if necessary,<br />

hearing protectors), and<br />

• specify noise data for user instructions and<br />

technical documents.<br />

If there is no significant hazard caused by<br />

noise for a group of machines, then the section<br />

on noise can be limited. However, it must at<br />

<strong>1998</strong> <strong>December</strong> <strong>Noise</strong>l<strong>News</strong> <strong>International</strong> 203