You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

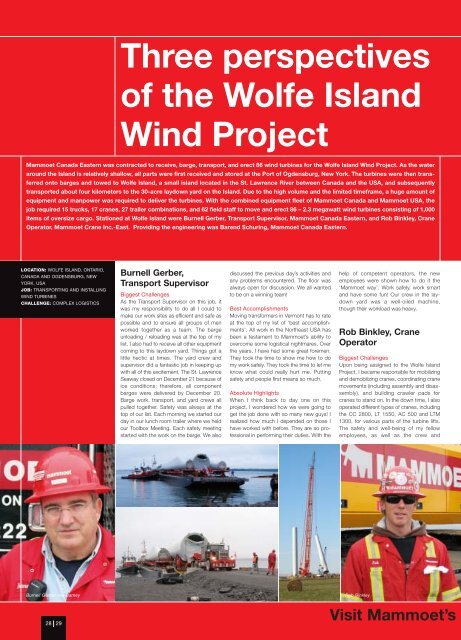

<strong>Mammoet</strong> Canada Eastern was contracted to receive, barge, transport, and erect 86 wind turbines for the Wolfe Island Wind Project. As the water<br />

around the Island is relatively shallow, all parts were first received and stored at the Port of Ogdensburg, New York. The turbines were then transferred<br />

onto barges and towed to Wolfe Island, a small island located in the St. Lawrence River between Canada and the USA, and subsequently<br />

transported about four kilometers to the 30-acre laydown yard on the Island. Due to the high volume and the limited timeframe, a huge amount of<br />

equipment and manpower was required to deliver the turbines. With the combined equipment fleet of <strong>Mammoet</strong> Canada and <strong>Mammoet</strong> USA, the<br />

job required 15 trucks, 17 cranes, 27 trailer combinations, and 62 field staff to move and erect 86 – 2.3 megawatt wind turbines consisting of 1,000<br />

items of oversize cargo. Stationed at Wolfe Island were Burnell Gerber, Transport Supervisor, <strong>Mammoet</strong> Canada Eastern, and Rob Binkley, Crane<br />

Operator, <strong>Mammoet</strong> Crane Inc.-East. Providing the engineering was Barend Schuring, <strong>Mammoet</strong> Canada Eastern.<br />

LOCATION: WOLFE ISLAND, ONTARIO,<br />

CANADA AND OGDENSBURG, NEW<br />

YORK, USA<br />

JOB: TRANSPORTING AND INSTALLING<br />

WIND TURBINES<br />

CHALLENGE: COMPLEX LOGISTICS<br />

Burnell Gerber aka Barney<br />

Three perspectives<br />

of the Wolfe Island<br />

Wind Project<br />

Burnell Gerber,<br />

Transport Supervisor<br />

Biggest Challenges<br />

As the Transport Supervisor on this job, it<br />

was my responsibility to do all I could to<br />

make our work sites as efficient and safe as<br />

possible and to ensure all groups of men<br />

worked together as a team. The barge<br />

unloading / reloading was at the top of my<br />

list. I also had to receive all other equipment<br />

coming to this laydown yard. Things got a<br />

little hectic at times. The yard crew and<br />

supervisor did a fantastic job in keeping up<br />

with all of this excitement. The St. Lawrence<br />

Seaway closed on December 21 because of<br />

ice conditions; therefore, all component<br />

barges were delivered by December 20.<br />

Barge work, transport, and yard crews all<br />

pulled together. Safety was always at the<br />

top of our list. Each morning we started our<br />

day in our lunch room trailer where we held<br />

our Toolbox Meeting. Each safety meeting<br />

started with the work on the barge. We also<br />

discussed the previous day’s activities and<br />

any problems encountered. The floor was<br />

always open for discussion. We all wanted<br />

to be on a winning team!<br />

Best Accomplishments<br />

Moving transformers in Vermont has to rate<br />

at the top of my list of ‘best accomplishments’.<br />

All work in the Northeast USA has<br />

been a testament to <strong>Mammoet</strong>’s ability to<br />

overcome some logistical nightmares. Over<br />

the years, I have had some great foremen.<br />

They took the time to show me how to do<br />

my work safely. They took the time to let me<br />

know what could really hurt me. Putting<br />

safety and people first means so much.<br />

Absolute Highlights<br />

When I think back to day one on this<br />

project, I wondered how we were going to<br />

get the job done with so many new guys! I<br />

realized how much I depended on those I<br />

have worked with before. They are so professional<br />

in performing their duties. With the<br />

help of competent operators, the new<br />

employees were shown how to do it the<br />

‘<strong>Mammoet</strong> way’. Work safely, work smart<br />

and have some fun! Our crew in the laydown<br />

yard was a well-oiled machine,<br />

though their workload was heavy.<br />

Rob Binkley, Crane<br />

Operator<br />

Biggest Challenges<br />

Upon being assigned to the Wolfe Island<br />

Project, I became responsible for mobilizing<br />

and demobilizing cranes, coordinating crane<br />

movements (including assembly and disassembly),<br />

and building crawler pads for<br />

cranes to stand on. In the down time, I also<br />

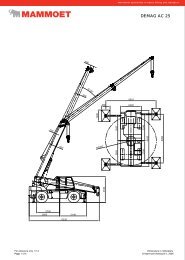

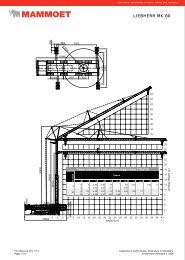

operated different types of cranes, including<br />

the CC 2800, LT 1550, AC 500 and LTM<br />

1300, for various parts of the turbine lifts.<br />

The safety and well-being of my fellow<br />

employees, as well as the crew and<br />

Rob Binkley<br />

28 29 Visit <strong>Mammoet</strong>’s