download baltimore instruction manual

download baltimore instruction manual

download baltimore instruction manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

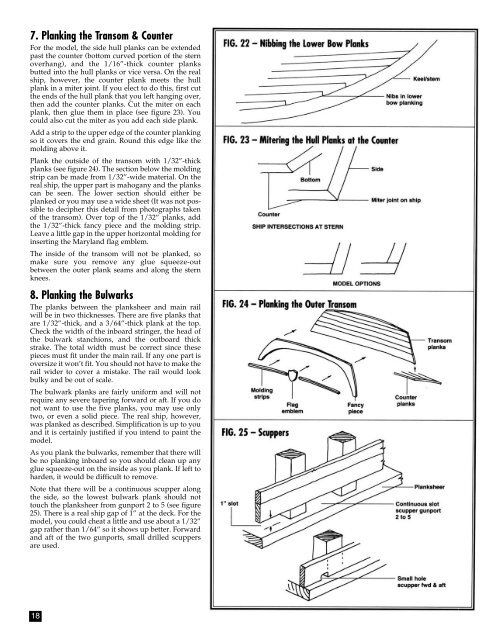

7. Planking the Transom & Counter<br />

For the model, the side hull planks can be extended<br />

past the counter (bottom curved portion of the stern<br />

overhang), and the 1/16”-thick counter planks<br />

butted into the hull planks or vice versa. On the real<br />

ship, however, the counter plank meets the hull<br />

plank in a miter joint. If you elect to do this, first cut<br />

the ends of the hull plank that you left hanging over,<br />

then add the counter planks. Cut the miter on each<br />

plank, then glue them in place (see figure 23). You<br />

could also cut the miter as you add each side plank.<br />

Add a strip to the upper edge of the counter planking<br />

so it covers the end grain. Round this edge like the<br />

molding above it.<br />

Plank the outside of the transom with 1/32”-thick<br />

planks (see figure 24). The section below the molding<br />

strip can be made from 1/32”-wide material. On the<br />

real ship, the upper part is mahogany and the planks<br />

can be seen. The lower section should either be<br />

planked or you may use a wide sheet (It was not possible<br />

to decipher this detail from photographs taken<br />

of the transom). Over top of the 1/32” planks, add<br />

the 1/32”-thick fancy piece and the molding strip.<br />

Leave a little gap in the upper horizontal molding for<br />

inserting the Maryland flag emblem.<br />

The inside of the transom will not be planked, so<br />

make sure you remove any glue squeeze-out<br />

between the outer plank seams and along the stern<br />

knees.<br />

8. Planking the Bulwarks<br />

The planks between the planksheer and main rail<br />

will be in two thicknesses. There are five planks that<br />

are 1/32”-thick, and a 3/64”-thick plank at the top.<br />

Check the width of the inboard stringer, the head of<br />

the bulwark stanchions, and the outboard thick<br />

strake. The total width must be correct since these<br />

pieces must fit under the main rail. If any one part is<br />

oversize it won’t fit. You should not have to make the<br />

rail wider to cover a mistake. The rail would look<br />

bulky and be out of scale.<br />

The bulwark planks are fairly uniform and will not<br />

require any severe tapering forward or aft. If you do<br />

not want to use the five planks, you may use only<br />

two, or even a solid piece. The real ship, however,<br />

was planked as described. Simplification is up to you<br />

and it is certainly justified if you intend to paint the<br />

model.<br />

As you plank the bulwarks, remember that there will<br />

be no planking inboard so you should clean up any<br />

glue squeeze-out on the inside as you plank. If left to<br />

harden, it would be difficult to remove.<br />

Note that there will be a continuous scupper along<br />

the side, so the lowest bulwark plank should not<br />

touch the planksheer from gunport 2 to 5 (see figure<br />

25). There is a real ship gap of 1” at the deck. For the<br />

model, you could cheat a little and use about a 1/32”<br />

gap rather than 1/64” so it shows up better. Forward<br />

and aft of the two gunports, small drilled scuppers<br />

are used.<br />

18