AIRFOIL FANS - Aerovent

AIRFOIL FANS - Aerovent

AIRFOIL FANS - Aerovent

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Accessories<br />

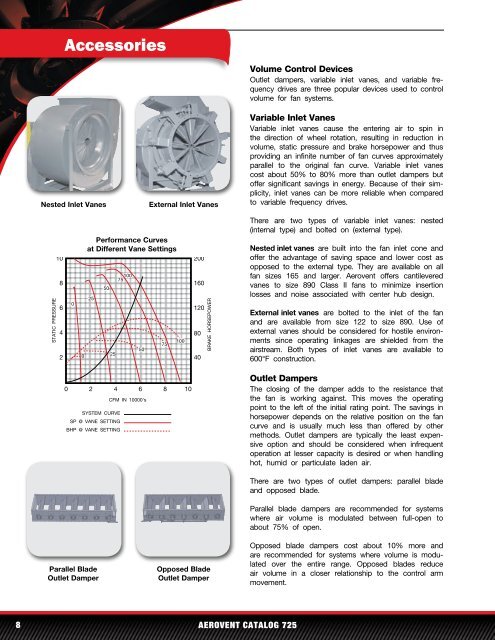

Nested Inlet Vanes<br />

External Inlet Vanes<br />

Volume Control Devices<br />

Outlet dampers, variable inlet vanes, and variable frequency<br />

drives are three popular devices used to control<br />

volume for fan systems.<br />

Variable Inlet Vanes<br />

Variable inlet vanes cause the entering air to spin in<br />

the direction of wheel rotation, resulting in reduction in<br />

volume, static pressure and brake horsepower and thus<br />

providing an infinite number of fan curves approximately<br />

parallel to the original fan curve. Variable inlet vanes<br />

cost about 50% to 80% more than outlet dampers but<br />

offer significant savings in energy. Because of their simplicity,<br />

inlet vanes can be more reliable when compared<br />

to variable frequency drives.<br />

STATIC PRESSURE<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0<br />

Performance Curves<br />

at Different Vane Settings<br />

25<br />

50<br />

25<br />

100<br />

75<br />

50<br />

75<br />

100<br />

200<br />

160<br />

120<br />

80<br />

40<br />

BRAKE HORSEPOWER<br />

There are two types of variable inlet vanes: nested<br />

(internal type) and bolted on (external type).<br />

Nested inlet vanes are built into the fan inlet cone and<br />

offer the advantage of saving space and lower cost as<br />

opposed to the external type. They are available on all<br />

fan sizes 165 and larger. <strong>Aerovent</strong> offers cantilevered<br />

vanes to size 890 Class II fans to minimize insertion<br />

losses and noise associated with center hub design.<br />

External inlet vanes are bolted to the inlet of the fan<br />

and are available from size 122 to size 890. Use of<br />

external vanes should be considered for hostile environments<br />

since operating linkages are shielded from the<br />

airstream. Both types of inlet vanes are available to<br />

600°F construction.<br />

0 2 4 6 8 10<br />

CFM IN 10000's<br />

SYSTEM CURVE<br />

SP @ VANE SETTING<br />

BHP @ VANE SETTING<br />

Outlet Dampers<br />

The closing of the damper adds to the resistance that<br />

the fan is working against. This moves the operating<br />

point to the left of the initial rating point. The savings in<br />

horsepower depends on the relative position on the fan<br />

curve and is usually much less than offered by other<br />

methods. Outlet dampers are typically the least expensive<br />

option and should be considered when infrequent<br />

operation at lesser capacity is desired or when handling<br />

hot, humid or particulate laden air.<br />

Parallel Blade<br />

Outlet Damper<br />

Opposed Blade<br />

Outlet Damper<br />

There are two types of outlet dampers: parallel blade<br />

and opposed blade.<br />

Parallel blade dampers are recommended for systems<br />

where air volume is modulated between full-open to<br />

about 75% of open.<br />

Opposed blade dampers cost about 10% more and<br />

are recommended for systems where volume is modulated<br />

over the entire range. Opposed blades reduce<br />

air volume in a closer relationship to the control arm<br />

movement.<br />

8 <strong>Aerovent</strong> Catalog 725