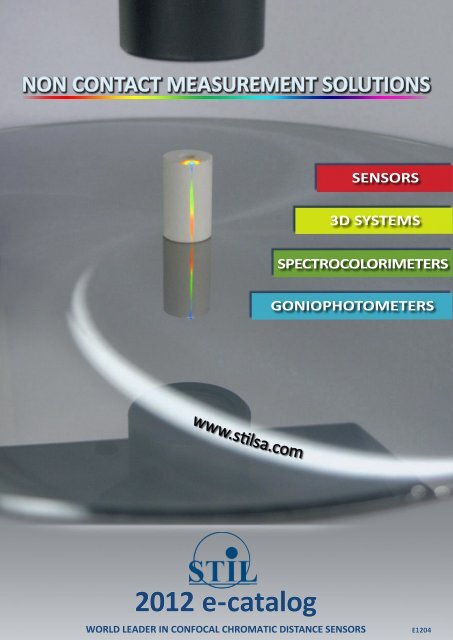

2012 e-catalog - STIL

2012 e-catalog - STIL

2012 e-catalog - STIL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NON CONTACT MEASUREMENT SOLUTIONS<br />

SENSORS<br />

3D SYSTEMS<br />

SPECTROCOLORIMETERS<br />

GONIOPHOTOMETERS<br />

www.stilsa.com<br />

<strong>2012</strong> e-<strong>catalog</strong><br />

WORLD LEADER IN CONFOCAL CHROMATIC DISTANCE SENSORS<br />

E1204

Coming soon<br />

SELECTION<br />

GUIDE<br />

<strong>2012</strong>, A SIGNIFICANT BREAKTROUGH FOR VISION SYSTEM<br />

• CONFOCAL CHROMATIC VISION FOR Automatc Optcal Inspecton: 3D VISION (*)<br />

(*) 3D VISION system combines a real 3D measurement and microscopy image:<br />

- Confocal chromatc measurement in TTL (through the lens),<br />

- High contrast,<br />

- High lateral resoluton,<br />

- Perfect focus in the extended measuring range.<br />

Table of contents<br />

SENSORS<br />

3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Selecton guide<br />

• Selecton guide.................................................................................4<br />

• 3D Metrology products.......................................................................4<br />

Precision class.....................................................................................4<br />

Applicaton type..................................................................................5<br />

Measuring rate.................................................................................6<br />

Scanning mode.................................................................................6<br />

Multi-channel operation......................................................................6<br />

Optical specifications.........................................................................6<br />

Electronic / Software specificatons...............................................................7<br />

Mechanical specificatons.........................................................................7<br />

Value-for-Cost..................................................................................7<br />

Non-contact «point» sensors<br />

• Introducing Chromatc Confocal technology..............................................8<br />

Optcal principle...................................................................................8<br />

Applicatons.......................................................................................9<br />

Product Lines..................................................................................10<br />

• «Bundle» Chromatc Confocal sensors......................................................11<br />

<strong>STIL</strong> Inital sensor line........................................................................11<br />

• Configurable Chromatc Confocal sensors............................................13<br />

The CCS Controller line........................................... .........................13<br />

The CHR Controller line..........................................................................15<br />

Modular optcal pens (CL-MG line)..............................................................18<br />

Classical optcal pens (OP line)...................................................................19<br />

Miniature optcal pens (ENDO line)..............................................................20<br />

• Introducing Spectral Confocal Interferometry technology............................22<br />

Optcal principle...................................................................................22<br />

The DUO controller line..........................................................................23<br />

Interferometric optcal pens (OPILB line)........................................................25<br />

• Fiber optc cables................................................................................26<br />

• Accessories......................................................................................27<br />

• Software...........................................................................................29<br />

4<br />

8<br />

2<br />

www.stlsa.com

SELECTION<br />

GUIDE<br />

SENSORS 3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Table of contents<br />

Non-contact «line» sensors<br />

34<br />

• MPLS180 «line» sensors.........................................................................34<br />

MPLS180 optcal principle.........................................................................34<br />

Basic sensor consttuton..........................................................................35<br />

Optoelectronic controllers: technical specificatons..............................................35<br />

• Optcal heads.....................................................................................36<br />

Non-contact 3D Measurement Systems<br />

• MICROMESURE 2 Systems...................................................................38<br />

Applicatons......................................................................................39<br />

Industrial and Research Laboratories Fields....................................................39<br />

Optons & Accessories...........................................................................39<br />

• Technical specificatons......................................................................39<br />

Scanning system Specificatons.................................................................39<br />

Optoelectronic Controllers Specificatons .....................................................40<br />

Optcal Pens and video camera Specificatons.................................................40<br />

• Software.........................................................................................41<br />

Control and Acquisiton Software Functons....................................................41<br />

Post Processing Software Functons............................................................. 42<br />

38<br />

Non-contact Spectrocolorimeter<br />

• Introducing Colorimetry.........................................................................44<br />

Applicatons..................................................................................... 44<br />

• RUBY Spectrocolorimeter...................................................................44<br />

• Technical specificatons............ ................................................... 45<br />

• Software.......................................................................................46<br />

DLL for RUBY controllers.......................................................................46<br />

RUBY MANAGER software......................................................................47<br />

Goniophotometers<br />

• REFLET introducton and features ....................................... ............. 48<br />

REFLET technical specificatons and applications.......................................... 49<br />

• DIAMOND introducton and applications........................................... 50<br />

• Optons......................................................................................... 51<br />

44<br />

48<br />

Outline dimensions<br />

• Point sensors.................................................................................. 53<br />

• Line sensors...................................................................................68<br />

• Goniophotometers..........................................................................71<br />

52<br />

www.stlsa.com 3

Selecton guide<br />

SELECTION<br />

GUIDE<br />

General selection guide<br />

Application<br />

See<br />

• Measure the Shape of a sample<br />

• Measure the Distance of a sample (auto-focusing)<br />

• Measure the Thickness of a sample or a coating<br />

• Measure the Roughness of a surface<br />

3D Metrology Products<br />

Selecton Guide<br />

(on this page)<br />

SENSORS<br />

• Measure or compare the Color of a sample<br />

• Measure the Spectrum reflected,<br />

transmitted or emitted from a sample or a light source<br />

• Measure the Angular distribution of light beam reflected, transmitted or emitted<br />

from a sample (BRDF/BTDF)<br />

Non Contact spectrocolorimeter<br />

(page 44)<br />

Goniophotometers<br />

(page 48)<br />

3D SYSTEMS<br />

3D Metrology products selection guide<br />

<strong>STIL</strong> SA proposes a large number of products for high quality 3D metrology.<br />

For selectng the right product one should consider several criteria:<br />

• Precision class,<br />

• Applicaton type,<br />

• Measuring rate,<br />

• Scanning mode,<br />

• Mult-channel operaton,<br />

• technical specificatons,<br />

• Value-for-Cost.<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Precision class<br />

Class Axial Resolution (1) Measuring Range Technology Products<br />

Sub-nano-Metrology from 0.3 nm up to 135 µm<br />

Nano-Metrology<br />

from 8.0 nm<br />

(1) Smallest measurable step.<br />

(2) Alone or mounted on a MICROMESURE 3D measuring system.<br />

Several measuring<br />

ranges available:<br />

from 130 µm to<br />

42 mm<br />

CONFOCAL<br />

SPECTRAL<br />

INTERFEROMETRY<br />

(page 22)<br />

CHROMATIC<br />

CONFOCAL<br />

IMAGING<br />

(page 8)<br />

<strong>STIL</strong>-DUO controller (2) with OPILB optcal pen<br />

CCS-PRIMA, <strong>STIL</strong>-INITIAL, <strong>STIL</strong>-DUO or CHR-<br />

150L controller (2) with a CL-MG, OP or Endo<br />

series optcal pen<br />

MPLS 180 sensor<br />

4<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SENSORS 3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Selecton guide<br />

Application type<br />

Application<br />

Products<br />

MEASURING THE SHAPE OR DISTANCE OF A SAMPLE<br />

General case<br />

• A point sensor controller (1)(2) with a CL-MG- series<br />

• MPLS 180 sensor<br />

Long working distance<br />

• CCS-Prima, <strong>STIL</strong>-Duo, CHR-150L controller (2) with a OP- series optcal pen<br />

Inside a cavity (diam. from 7 mm)<br />

• A point sensor controller (1)(2) with a miniature (Endo series) optcal pen<br />

Rough metallic samples<br />

• A point sensor controller (1)(2) with any optcal pen. Optmal performances are achieved with an optcal pen<br />

whose spot size is inferior to 7 µm<br />

• MPLS 180 sensor. Optcal performances are achieved with the Microview optcal head<br />

Mirror-like samples / Low-reflectivity samples<br />

• A point sensor controller (1)(2) with an optcal pen whose photometric efficiency is low / high respectvely<br />

• MPLS 180 sensor.<br />

Sub-Nanometrology applications<br />

(see «precision class»)<br />

• <strong>STIL</strong>-DUO controller (2) with an OPILB- series distance-mode optcal pen<br />

Special requirements (3)<br />

Contact us<br />

MEASURING ROUGHNESS<br />

Measurable Ra:<br />

from 12 nm (with CL1MG210 optcal pen)<br />

from 50 nm (with CL3MG140 optcal pen)<br />

• A point sensor controller (1)(2) with a CL-MG- series or OP- series optcal pen whose spot size is inferior to 7 µm<br />

Sub-nanometric applications<br />

Measurable Ra: from 0.75 nm<br />

• <strong>STIL</strong>-DUO controller (1)(2) with a OPILB- series distance-mode optcal pen<br />

MEASURING THICKNESS<br />

• Measurable Thickness limits:<br />

7.5 µm-175 µm (with CL1MG210 optcal pen)<br />

0.6 mm-34 mm (with CL6MG35 optcal pen)<br />

• A point sensor controller (1)(2) with a CLMG- series or an OP- series optcal pen<br />

• Resolution: 35 nm (with CL1MG210 optcal pen)<br />

Thin films / Very high precision<br />

Measurable Thickness limits: 0.4 µm-90 µm<br />

Resolution: from 0.3 nm<br />

• <strong>STIL</strong>-DUO controller (1)(2) with a OPILB- series thickness-mode optcal pen<br />

(1) Point sensor controller = CCS-Prima, <strong>STIL</strong>-Initial, <strong>STIL</strong>-Duo or CHR-150L controller.<br />

(2) Alone or mounted on a MICROMESURE 3Dmeasuring system.<br />

(3) Measuring through a window or through a coatng, Side-looking optcal pen, Vacuum chamber, Harsh environments, Highly diffusing samples...<br />

E1204<br />

www.stlsa.com 5

Selecton guide<br />

SELECTION<br />

GUIDE<br />

Measuring rate<br />

Ultra-high rate<br />

Requirement Measuring rate Products<br />

Up to 324,000 points/s<br />

(1800 lines/s)<br />

• MPLS 180 sensor<br />

Standard rate<br />

Up to 2,000 points/s<br />

Up to 1,000 points/s<br />

• CCS-Prima, <strong>STIL</strong>-Initial, <strong>STIL</strong>-Duo controllers (*)<br />

• CHR-150L controller (*)<br />

(*) With a suitable optcal pen, alone or mounted on a MICROMESURE 3D measuring system<br />

SENSORS<br />

3D SYSTEMS<br />

Scanning mode<br />

Measuring an area<br />

Requirement Type Products<br />

Measuring a linear or circular profile<br />

Measuring a single point over time<br />

3D<br />

(X,Y,Z)<br />

2D<br />

(X,Z)<br />

1D<br />

(Z)<br />

Multi-channel operation<br />

• MICROMESURE system with any point sensor (*)<br />

• Scanning (3D) MPLS180 sensor<br />

• Static(2D) MPLS180 sensor with the sample on a conveyor belt<br />

• Any point sensor (*) mounted on a user-machine which has at least 2 moton axes<br />

• MICROMESURE system with any point sensor (*)<br />

• Static (2D) MPLS180 sensor<br />

• Any point sensor (*) with the sample on a conveyor belt<br />

• Any point sensor (*) mounted on a user-machine which has at least 1 moton axis<br />

• Any point sensor (*)<br />

(*) Point sensors: CCS-Prima, <strong>STIL</strong>-Duo, <strong>STIL</strong>-Initial or CHR150-L controller with a suitable optcal pen.<br />

Sensor<br />

Multi-channel operation<br />

CHR-150L controller 1,2 or 4 simultaneous channels (1)(2)<br />

SPECTRO<br />

COLORIMETERS<br />

CSS-Prima controller 1,2 or 4 multiplexed channels (1)(3)<br />

<strong>STIL</strong>-Duo controller<br />

<strong>STIL</strong>-Initial controller<br />

MPLS180 sensor<br />

Optical specifications<br />

1 channel for a chromatic confocal optical pen and<br />

1 channel for a interferometric optical pen<br />

The two channels are multiplexed (3)<br />

Single-channel operation only<br />

(1) The number of channels should be specified while ordering, no upgrade is possible later.<br />

(2) Simultaneous channels: all the channels measure at the same tme.<br />

(3) Multplexed channels: all optcal pens may be connected to the controller at the same tme, but only one of them measures.<br />

GONIO<br />

PHOTOMETERS<br />

Optical specifications<br />

• Measuring range<br />

• Axial resolution and accuracy<br />

• Lateral resolution (spot size)<br />

• Working distance<br />

• Maximal measurable slope (°) on specular samples<br />

• Photometric efficiency<br />

• Min/Max measurable thickness<br />

• Min. measurable roughness<br />

See:<br />

• For CCS-Prima, <strong>STIL</strong>-DUO, <strong>STIL</strong>-Initial sensors: See Chromatc Confocal<br />

optcal pen specificatons (Pages 18, 19, 21)<br />

• For <strong>STIL</strong>-Duo sensor: See Interferometric optcal pen specificatons (Pages 26)<br />

• For MPLS180 sensor: See optcal head specificatons (Page 36)<br />

6<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SENSORS 3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Selecton guide<br />

Electronic/Software specifications<br />

Electronic/Software specifications<br />

• Measuring rate<br />

• Digital output type<br />

• Analog outputs<br />

• Trigger options<br />

• Available software<br />

See:<br />

• For Point sensors:<br />

See controller specificatons (Pages 12, 16, 24)<br />

• For MPLS180 sensor:<br />

See controller specificatons (Pages 35)<br />

Mechanical specifications<br />

For Outline dimensions of all products, see pages (53-70).<br />

Value-for-Cost<br />

• The mult-channel point sensors (multplexed CCS-Prima and simultaneous-channel CHR-150L) allow significant saving<br />

compared to 2 or 4 independent sensors.<br />

• The <strong>STIL</strong>-Duo controller combines 2 complementary technologies (Confocal Spectral Interferometry and Chromatic<br />

Confocal Imaging) in the same controller.<br />

• The <strong>STIL</strong>-Initial sensor («bundle» product suitable for first-tme users and for lab applicatons) is proposed at a very attractve<br />

price. This sensor has some limitatons when compared to the other chromatc confocal point sensors as shown<br />

in the table below.<br />

<strong>STIL</strong>-Initial CCS-Prima CHR-150L<br />

Number of optical pens that are interchangeable on<br />

the same controller<br />

1 (1) up to 20 (2) Up to 6 (2)<br />

Available chromatic confocal optical pen models Some models (3) All models All models<br />

Multi-channel operation No Opton (4) Opton (4)<br />

Output type Digital Digital & Analog Digital & Analog<br />

External Encoder reading capability No Yes No<br />

Controller box type Desktop Industrial Desktop<br />

(1) The optcal pen of the <strong>STIL</strong>-Inital is selected when ordering, no replacement is possible later.<br />

(2) Optcal pens may be connected and disconnected from the controller easily. New optcal pens may be added later to the CCS-Prima and the CHR-150L controllers,<br />

but they should be calibrated at factory on the customer’s controller.<br />

(3) See page (11).<br />

(4) See «Mult-channel operaton» on this selecton guide.<br />

E1204<br />

www.stlsa.com 7

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

SENSORS<br />

Introducing Confocal Chromatic technology<br />

The fruits of more than fifteen years of research and development by<br />

our engineers, <strong>STIL</strong>’s optcal sensors offer the best of technology in<br />

response to the most demanding needs in terms of non contact dimensional<br />

measurements.<br />

Based on an innovatve optcal principle which uses the chromatc coding<br />

of space (invented and patented by <strong>STIL</strong>), our sensors allow users<br />

to make measurements on nearly any kind of materials, with an exceptonal<br />

accuracy.<br />

<strong>STIL</strong>’s sensors find applicatons in almost all sectors of industry, be it as<br />

high precision instruments in metrology or research laboratories, or as<br />

quality control tools on producton lines.<br />

Designed for use in industrial environments, the different ranges of<br />

<strong>STIL</strong>’s sensors will appeal to integrators thanks to their easy interfacing<br />

on measurement and inspecton machines, made possible thanks to<br />

the DLL/ dynamic link libraries provided with each instrument.<br />

3D SYSTEMS<br />

Optical principle<br />

Our optcal sensors are based on the highly innovatve Confocal Chromatc Imaging principle (<strong>STIL</strong> SA’s patent).<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

An incident white light pinhole is imaged through a<br />

chromatc objectve into a contnuum of monochromatc<br />

images along the Z-Axis, thus providing a «color coding»<br />

along the optcal axis.<br />

When an object is present in this «colored» field, a<br />

unique wavelength is perfectly focused at its surface<br />

and then reflected into the optcal system.<br />

This backscattered beam passes through a filtering<br />

pinhole into a spectrograph, which determines the<br />

wavelength has been perfectly focused on the object,<br />

and then accurately determine its positon in the<br />

measuring field.<br />

The Confocal Chromatc Imaging gives access to reliable,<br />

accurate and reproducible dimensional measurements<br />

with extremely high resoluton.<br />

8<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

A wide range of applications<br />

Roughness measurement<br />

Our sensors are fully compliant with<br />

the new ISO25178 regulaton and are<br />

able to measure roughness values<br />

down to a few nanometers.<br />

They allow to acquire roughness profiles<br />

much faster than a classical tactle<br />

probe, and without any risk of marking<br />

the surface.<br />

Profilometry & Microtopography<br />

Interfaced with 3D scanning devices, <strong>STIL</strong>’s sensors<br />

give acess to full 2D and 3D measurements of complex<br />

objects or assemblies with submicronic accuracy.<br />

Thickness measurement<br />

The very innovatve Confocal Chromatc<br />

Imaging principle allows measurement<br />

of the thickness of transparent materials,<br />

with extremely high accuracy,<br />

using one single sensor. The thickness<br />

is directly measured from one<br />

side of the<br />

sample.<br />

Autofocus<br />

Thanks to their extended measuring range, <strong>STIL</strong>’s<br />

sensors are the perfect soluton for an accurate<br />

autofocus in vision systems.<br />

Level control<br />

Thanks to their non-contact technology,<br />

our sensors allow detecton and measurement<br />

of fluids’ level.<br />

Online inspection<br />

<strong>STIL</strong> SA’s optcal sensors allow systematc control<br />

on producton lines thanks to their very high<br />

measuring rates and advanced interfacing<br />

capabilites with the manufacturing<br />

chain or the custom inspecton machine.<br />

Vibrometry<br />

Thanks to very high measuring frequencies and nanometric<br />

resoluton, our sensors allow the measurement<br />

of vibratons in objects under test. Their<br />

non-contact design avoids disturbance of the system<br />

under test, and allows analysis and measurement of<br />

difficult to access areas.<br />

E1204<br />

www.stlsa.com 9

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

SENSORS<br />

3D SYSTEMS<br />

Characteristics<br />

High resoluton non contact optcal sensors for 3D measurement with a wide range of applicatons.<br />

Advantages<br />

Characteristics<br />

Confocal setup<br />

Coaxial setup<br />

Chromatic coding/decoding<br />

Optical fiber system<br />

Measuring modes<br />

Benefits<br />

- Exceptonal signal-to-noise rato (SNR)<br />

- High resoluton<br />

- No shadowing effects<br />

- Capability of measuring highly polished surfaces<br />

- No Z scanning required<br />

- High precision<br />

- Small, light weight, passive optcal probe («optcal pen»)<br />

connected to the controller by a fiber optcs cable<br />

- «Distance» (Z-coordinate)<br />

- «Thickness» measurement of transparent materials<br />

- Measure on any type of material (metal, glass, ceramics, semiconductors, paper),<br />

- Measure on polished surfaces (mirrors, wafers) and on rough ones,<br />

- Insensitve to ambient lightng,<br />

- Compatble with harsh environments (high temperature / high pressure / irradiaton),<br />

- ISO 25178 standard compliant,<br />

- Large choice of measuring ranges (100 µm to 42 mm ranges),<br />

- Large choice of optcal pens for specific requirements («endoscopic» pens / radial pens / large working distance /<br />

steep slope / small spot size / through-window measurement...),<br />

- Free software toolkit for an easy interfacing («CCS Manager» utlity, c++ and .net DLL SDK).<br />

Product lines<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Product lines<br />

<strong>STIL</strong> Initial<br />

CCS controller<br />

+ Optical pen(s)<br />

+ Fiber optics cable(s)<br />

CHR controller<br />

+ Optical pen(s)<br />

+ Fiber optics cables(s)<br />

Features<br />

- «Bundle» products including everything you need<br />

- Recent design, many advandced features<br />

- Ideal for first-tme users and research laboratories<br />

- Exceptonal Value-for-Price<br />

- Configurable sensors<br />

- Large choice of interchangeable optcal pens<br />

- Recent design, many advandced features<br />

- Ideal for OEM users and Industrial applicatons<br />

- Very wide range of applicatons<br />

- 2 & 4 selectable-channels models available<br />

- Configurable sensors<br />

- Large choice of interchangeable optcal pens<br />

- 2 & 4 simultaneous-channels models available<br />

10<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

«Bundle» Chromatic Confocal sensors<br />

These sensors measure the alttude (z coordinate) of the sample point located on their optcal axis and the thickness of<br />

transparent samples.<br />

Advantages<br />

- «Bundle» products including everything required for launching a measurement immediately: a controller, an optcal pen<br />

(probe), a fiber optc cable, electrical cables, software tools and a comprehensive user manual,<br />

- Best choice for first-tme users and for research lab applicatons,<br />

- High precision, high resoluton,<br />

- Exceptonal value for price.<br />

<strong>STIL</strong> Initial Sensor Line<br />

<strong>STIL</strong> Inital is a new line of high-resoluton chromatc confocal sensors. 5 models are available, each with a different optcal<br />

pen. Contact us for advice on the best model for your applicaton.<br />

Specifications (*) <strong>STIL</strong> Initial 0.4 <strong>STIL</strong> Initial E1.2 <strong>STIL</strong> Initial E1.2/90 <strong>STIL</strong> Initial 4.0 <strong>STIL</strong> Initial 12<br />

Optical Pen Model CL2-MG140 ENDO 1.2 ENDO 1.2/90° CL4-MG35 CL5-MG35<br />

Measuring Range 0.4 mm 1.2 mm 1.2 mm 4.0 mm 12.0 mm<br />

Working Distance 11.0 mm 2.4 mm 0.4 mm 16.4 mm 29 mm<br />

Axial Resolution 22 nm 100 nm 160 nm 130 nm 400 nm<br />

Accuracy 80 nm 300 nm 800 nm 300 nm 900 nm<br />

(*) See detailed specificatons next page<br />

The <strong>STIL</strong> Inital controller is highly sophistcated, it features extensive synchronizaton opton and advanced measuring modes.<br />

Here are a few examples.<br />

Functions<br />

Application<br />

«Auto-LED» : The LED brightness<br />

adapts itself automatcally<br />

Samples with variable slope e.g lenses<br />

«First peak» : The sensor locks on<br />

the first surface<br />

Topography on transparent objects or<br />

coated samples<br />

«Double Frenquency» : The sensor<br />

selects the optmal measuring rate<br />

automatcally<br />

Samples with high sharp reflectvity variatons,<br />

e.g. mask for microelectronics<br />

«Hold Last Value» : Output data<br />

smoothing<br />

Very difficult samples with many non<br />

measurable points<br />

E1204<br />

www.stlsa.com 11

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

SENSORS<br />

<strong>STIL</strong> Initial: Technical specifications<br />

Controllers<br />

<strong>STIL</strong> initial Series<br />

Model <strong>STIL</strong> Initial 0.4 <strong>STIL</strong> Initial E1.2 <strong>STIL</strong> Initial E1.2 /90 (1) <strong>STIL</strong> Initial 4.0 <strong>STIL</strong> Initial 12<br />

OPTICAL PEN (PROBE)<br />

Model CL2-MG140 ENDO 1.2 ENDO 1.2/90 (1) CL4-MG35 CL5-MG35<br />

Measuring Range 0.4 mm 1.2 mm 1.2 mm 4.0 mm 12.0 mm<br />

Working Distance 11.0 mm 2.4 mm 0.4 mm 16.4 mm 29 mm<br />

Spot Diameter 3.4 µm 15 µm 13 µm 7.2 µm 16.5 µm<br />

Max. Slope Angle (2) (3) +/- 28° +/- 14° +/- 9° +/- 21° +/- 14°<br />

Weight 190 g 10 g 10g 155 g 175 g<br />

Dimensions x L 27mm x 208.9mm 6 mm x 75.2 mm 6 mm x 82 mm 27 mm x 145.5 mm 27 mm x 145.5 mm<br />

Distance Measurement<br />

Axial Resoluton (4)<br />

- With no averaging<br />

- With Averaging 10<br />

22 nm<br />

8 nm<br />

100 nm<br />

35 nm<br />

160 nm<br />

60 nm<br />

130 nm<br />

50 nm<br />

400 nm<br />

180 nm<br />

Accuracy (5) 80 nm 300 nm 800 nm 300 nm 900 nm<br />

Measuring rough metalic samples (9) R NR NR NR NR<br />

Roughness measurement (10)<br />

Min. measurable Ra<br />

30nm NR NR NR NR<br />

3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Thickness Measurement (6)<br />

Min. Measurable Thickness (7)(8) 16 µm 75 µm NA 110 µm 450 µm<br />

Max. Measurable Thickness (7)(8) 510 µm 1600 µm NA 5700 µm 16500 µm<br />

CONTROLLER BOX<br />

Measuring Modes<br />

Measuring Rate<br />

Digital Outputs<br />

Digital Resoluton<br />

Synchronizaton<br />

Advandced Features<br />

Power supply / Consumpton<br />

Weight<br />

Dimensions W x H x D<br />

FIBER OPTICS CABLE<br />

«Distance» and «Thickness»<br />

100 Hz to 2000Hz<br />

USB 2.0 and RS232 (up to 460800 baud)<br />

In «Distance» mode: 30 bits<br />

In «Thickness» mode: 15 bits<br />

Input and Output 0V - 5V TTL synchronizaton signals<br />

Extensive trigger capacites<br />

«Double frequency» mode<br />

«Auto LED» mode<br />

«First peak» mode<br />

«Hold last value» mode<br />

«Thickness calibraton»<br />

100V to 240 V AC 50-60 Hz / 25W<br />

1920 g<br />

199 mm x 123.5 mm x 277 mm<br />

(1) Radial (90°) measuring optcal pen.<br />

(2) The maximal angular slope applies to specular (mirror-like) surfaces only. For Diffusing surfaces the maximal slope angle is higher (up to 87° for perfect diffusers).<br />

(3) Measured on a mirror at 100 Hz, with no averaging.<br />

(4) Axial resoluton is defined as the RMS Noise level measured at optmal rate on a statc sample located at the center of the measuring, with no averaging.<br />

(5) Accuracy is defined as the max. error over the entre measuring range, measured immediately after distance calibraton at the following conditons: “Auto-adaptve LED”<br />

mode, optmal rate, slope angle=0°, averaging factor= measuring rate/10.<br />

(6) For obtaining metrological performances in this mode it is recommended to carry out a calibraton on a thickness standard.<br />

(7) These values are for a refractve index of 1.5 (for measuring air gap thickness divide by 1.5).<br />

(8) Typical values, measured at the center of the measuring range at optmal rate, with no averaging.<br />

(9) R = Recommended for measuring rough metallic samples (these samples can be measured with full performances)<br />

NR = Not recommended for measuring rough metallic samples (these samples may be measured, but with reduced performances)<br />

(10) The precise value of the min measurable Ra depends on the characteristcs of the sample. The values given in the table are typical..<br />

N.B. : the values are subject to change without notce.<br />

12<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

Configurable Chromatic Confocal «point» sensors<br />

These sensors measure the alttude (z coordinate) of the sample point located on their optcal axis.<br />

They can also measure the thickness of transparent samples.<br />

They consist of a controller (1), an «optcal pen» (optcal probe) (2) and a fiber optc cable (3).<br />

2 controller lines (CCS & CHR), 3 optcal pen lines (CL-MG, OP & ENDO) and different fiber optc cable models are available.<br />

A single controller may be ordered with several interchangeable optcal pens.<br />

(1)<br />

(3)<br />

(2)<br />

Advantages<br />

- Select the CCS or CHR controller, as well as the optcal pen and the fiber optcs cable best suited for your applicaton.<br />

- Large choice of measuring ranges (110 µm - 20 mm),<br />

- Large choice of optcal pens satsfying specific requirements («endoscopic» / radial pens / large working distance / steep<br />

slope / small spot size / through-window measurement..)<br />

The CCS controller line<br />

3 controllers for configurable chromatc confocal sensors featuring different number of channels are available:<br />

- the CCS PRIMA (1 channel), CCS PRIMA 2 (2 channels) and CCS PRIMA 4 (4 channels).<br />

Advantages<br />

- High precision, high resoluton,<br />

- Compatble with all chromatc confocal optcal pens,<br />

- Up to 20 different optcal pens interchangeable on the same controller,<br />

- Digital and analog outputs,<br />

- Synchronized reading of external digital encoders.<br />

CCS PRIMA controllers<br />

- The leading chromatic confocal sensor worldwide,<br />

- The most sophisticated chromatic confocal sensor on the market,<br />

- Recommended for OEM User and Industrial applicatons,<br />

- Improved performances in thickness mode thanks to a specific Thickness calibraton,<br />

- Long lifetme light source,<br />

- Measuring rates: 100 Hz to 2000 Hz.<br />

E1204<br />

www.stlsa.com 13

SPECTRO<br />

COLORIMETERS<br />

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

The CCS PRIMA controller is higly sophistcated, it offers extensive synchronizaton optons and advanced measuring modes.<br />

SENSORS<br />

Functions<br />

«Auto-LED» : The LED brightness<br />

adapts itself automatcally<br />

«First peak» : The sensor locks on<br />

the first surface<br />

«Double Frenquency» : The sensor<br />

selects the optmal measuring rate<br />

automatcally<br />

«Hold Last Value» : Output data<br />

smoothing<br />

Application<br />

Samples with variable slope e.g lenses<br />

Topography on transparent objets<br />

Samples with high sharp reflectvity<br />

variatons, e.g. mask for microelectronics<br />

Very difficult samples with many non<br />

measurable points<br />

3D SYSTEMS<br />

2 and 4 CCS Prima Multiplexed Channel Models<br />

- Up to 4 optcal pens connected to a single CCS PRIMA controller<br />

- Multplexed channels, Commutaton tme < 400ms,<br />

- Ideal for automatc inspecton applicatons,<br />

- Save up to 62 % compared to 4 independent controllers.<br />

GONIO<br />

PHOTOMETERS<br />

4 multplexed channels<br />

CCS PRIMA4 Controller<br />

2 multplexed channels<br />

CCS PRIMA2 Controller<br />

14<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

The CHR Controller Line<br />

CHR150-L controllers<br />

- High precision, high resoluton,<br />

- Measuring rate up to 1 KHz,<br />

- Compatble with all optcal pens,<br />

- Long lifetme light source,<br />

- Intergrated control panel.<br />

CHR150 controllers<br />

- Tungsten Halogen light source<br />

2 and 4 CHR150 or CHR150-L simultaneous channel models<br />

- Up to 4 optcal pens connected to a single CHR150-L controller<br />

- All channels measure simultaneously,<br />

- Each channel may be configured independently,<br />

- Save up to 44% compared to 4 independent controllers.<br />

2 Channels CHR150 Controller<br />

E1204<br />

www.stlsa.com 15

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

Controllers for configurable chromatic confocal point sensors:<br />

Technical specifications<br />

Controllers CHR Series CCS Series<br />

Model CHR150 CHR150-L CCS-PRIMA<br />

Measuring frequency<br />

From 30 to 1000 points/sec<br />

User defined<br />

From 30 to 1000 points/sec<br />

User defined<br />

From 100 to 2000 points/sec<br />

User defined<br />

Multchannel version (1) Available (2 & 4 channels) Available (2 & 4 channels) Available (2 &4 channels)<br />

SENSORS<br />

Light source Halogen White LED White LED<br />

Light source brightness setting None Manual Programmable<br />

Advandced Features:<br />

«Lock on first surface»<br />

«Hold Last Value»<br />

«Thickness calibraton»<br />

«Auto LED» (2)<br />

«Autodark» functon (3)<br />

«Double frequency»<br />

No<br />

No<br />

No<br />

No<br />

No<br />

Up to 489 Hz<br />

No<br />

No<br />

No<br />

No<br />

No<br />

Up to 489 Hz<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

Up to 1850 Hz<br />

Measuring modes<br />

Distance<br />

Thickness<br />

Distance<br />

Thickness<br />

Distance<br />

Thickness<br />

Calibraton tables (max) 6 20<br />

3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Encoders input (4) No No Yes (up to 3 axes) - TTL signals input - 30 bits counters (> 1 billion steps count)<br />

Digital outputs 15 bits resoluton 30 bits resoluton<br />

Analog outputs 2 configurable outputs [0 – 10 V] - 12 bits resoluton 2 configurable outputs [0 - 10V] - 16 bits resoluton<br />

Digital I/O RS232 (up to 115200 baud») serial link USB2 and RS232/RS422 (up to 46800 baud)<br />

Synchronizaton I/O 1 Synchro input (TTL) / 1 Synchro output (TTL) 1 Synchro input (TTL) / 1 Synchro output (TTL)<br />

Optcal fiber connector<br />

Compatble Optcal pens<br />

E2000 type («push-pull») with «Autoprotect» system<br />

All chromatc confocal pen types<br />

Power supply / consumpton From 85 to 240 V AC / 100 W From 85 to 240 V AC / 25 W 24 V DC / 20 W<br />

Temperature in use 5°C - 40°C<br />

Storage temperature -30°C – 70°C<br />

Relatve humidity in use<br />

5%-80% HR without condensaton<br />

Protecton type IP 40<br />

EMC<br />

EN 61000-6-3 and EN 61000-6-2 compliant<br />

Weight (5) 3.4 kg 1.4 Kg<br />

Dimensions (w x h x d) 316mm x 96mm x 235mm 168mm x 138mm x 120mm<br />

Mechanical interface Table top controller Integrated DIN rail mountng interface<br />

(1) Multplexed channels (CCS) Vs simultaneous multple channels (CHR):<br />

- CCS PRIMA4 multplexed sensor: 1 (out of 4) optcal pen can measure at a tme, the sensor can switch to another optcal<br />

pen in about 400 ms.<br />

- CHR150-2 and CHR150-4 Multple channels: All the optca l pens (2 or 4) can measure simultaneously.<br />

(2) The «Auto Led» functon allows the CCS Prima controller to dynamically adjust the LED light power in order to permanently adapt<br />

it according to the reflectvity of the measured object.<br />

(3) The «Autodark» functon allows a constant and automatc regulaton of the Dark signal level of the CCS controller.<br />

(4) The incremental encoders input port allows the acquisiton of the instant positon of the measuring system moton axes (3 axes<br />

maximum). These measurements are synchronized with the measuring frequency of the sensor.<br />

(5) The specified weight does not include the external light source for the CCS Ultma model.<br />

N.B. : the values are subject to change without notce.<br />

16<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

3D measurement examples: chromatic confocal technology<br />

Intra occular lens (IOL) - Z range: 750µm<br />

3D measurement examples: confocal spectral interferometry<br />

Through Silicon Vias (TSV) array - Via diameters: 5µm to 20µm - Z range 100µm<br />

E1204<br />

www.stlsa.com 17

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

Modular optical pens (CL-MG Line)<br />

CL-MG Line *<br />

Model CL1 CL2 CL3 CL4 CL5 CL6<br />

Measuring range (1) [µm] 130 400 1400 4000 12000 24000<br />

Working distance (2) [mm] 3.3 11 12.7 16.4 29 22<br />

Max. object slope (3) [deg] +/- 42.5° +/- 28° +/- 25° +/- 21° +/- 14° +/- 8.5°<br />

Reference plate (4) - No Yes Yes Yes Yes No<br />

SENSORS<br />

Axial model (5)<br />

-<br />

Radial model (5) -<br />

Standard<br />

Optonal<br />

Magnifier model MG210 MG140 MG210 MG140 MG70 MG140 MG70 MG35 MG20 MG35 MG20 MG35 MG20<br />

LATERAL (XY) PROPERTIES<br />

Spot size (diameter)<br />

Lateral resoluton (6)<br />

[µm]<br />

[µm]<br />

1.9<br />

0.9<br />

2.8<br />

1.4<br />

2.3<br />

1.2<br />

3.4<br />

1.7<br />

6.9<br />

3.5<br />

4<br />

2<br />

8<br />

4<br />

8<br />

4<br />

14<br />

7<br />

14<br />

7<br />

24.5<br />

12.3<br />

16<br />

8<br />

28<br />

14<br />

PHOTOMETRIC EFFICIENCY (7)<br />

Collected energy (relatve) - 5.8 13 5.5 11.5 46 14 56 30 76 40 100 19.2 48<br />

3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

MECHANICAL INTERFACE<br />

Length (8)<br />

Diameter (8)<br />

Weight<br />

Performances (9)<br />

DISTANCE MEASUREMENT<br />

Axial resoluton (10)<br />

With no averaging<br />

With averaging 10<br />

Accuracy (11)<br />

Measuring rough metal surface (12)<br />

[mm]<br />

[mm]<br />

[g]<br />

[nm]<br />

[nm]<br />

[nm]<br />

-<br />

253.1<br />

27<br />

268<br />

8<br />

2.7<br />

35<br />

R<br />

217.1<br />

27<br />

195<br />

243.3<br />

27<br />

248<br />

208.9<br />

27<br />

190<br />

22<br />

8<br />

80<br />

R<br />

ROUGHNESS MEASUREMENT<br />

Min. measurable Ra (13) [nm] 12 30 90 170 600 1100<br />

THICKNESS MEASUREMENT (14)<br />

Min. measurable thickness (15)<br />

Max. measurable thickness (15)<br />

[µm]<br />

[µm]<br />

7.5<br />

175<br />

9<br />

175<br />

14<br />

510<br />

14<br />

510<br />

176.1<br />

27<br />

189<br />

22<br />

510<br />

205.9<br />

27<br />

215<br />

R<br />

38<br />

2000<br />

60<br />

20<br />

200<br />

176.1<br />

27<br />

214<br />

NR<br />

40<br />

2000<br />

145.5<br />

27<br />

155<br />

110<br />

5700<br />

130<br />

50<br />

300<br />

NR<br />

131.7<br />

27<br />

140<br />

120<br />

5700<br />

145.5<br />

27<br />

175<br />

350<br />

16500<br />

400<br />

180<br />

800<br />

NR<br />

131.7<br />

27<br />

160<br />

550<br />

16500<br />

167.6<br />

27<br />

195<br />

590<br />

34000<br />

780<br />

300<br />

1500<br />

NR<br />

151.8<br />

27<br />

180<br />

725<br />

34000<br />

GONIO<br />

PHOTOMETERS<br />

N.B. : the values are subject to change without notce.<br />

18<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SENSORS 3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Non-contact «point» sensors<br />

Classical optical pens (OP Line)<br />

OP Line<br />

Model OP300VM OP6000 OP8000 OP10000 OP24000 OP42000<br />

Measuring range (1) [µm] 300 6 000 8000 10 000 24 000 42 000<br />

Working distance (2) [mm] 5 28.8 37.2 66.9 223 518<br />

Max object slope (3) [deg] +/- 25° +/- 22° +/- 16° +/- 12° +/- 5° +/- 2.5°<br />

Reference plate (4) - No No Yes Yes Yes No<br />

Axial model (5)<br />

Radial model (5) -<br />

Standard<br />

Optonal<br />

Standard<br />

No<br />

Standard<br />

No<br />

Standard<br />

Optonal<br />

Standard<br />

Optonal<br />

Standard<br />

No<br />

LATERAL (XY) PROPERTIES<br />

Spot size (diameter)<br />

Lateral resoluton (6)<br />

[µm]<br />

[µm]<br />

8<br />

4<br />

12.5<br />

6.25<br />

34<br />

17<br />

51<br />

25.5<br />

100<br />

50<br />

110<br />

55<br />

MECHANICAL INTERFACE<br />

Length (8)<br />

Diameter (8)<br />

Weight<br />

[mm]<br />

[mm]<br />

[g]<br />

127<br />

15<br />

25<br />

205.5<br />

60<br />

727<br />

150<br />

40<br />

400<br />

189<br />

50<br />

640<br />

172.5<br />

59<br />

360<br />

287.2<br />

85<br />

1700<br />

Performances (9)<br />

DISTANCE MEASUREMENT<br />

Axial resoluton (10)<br />

Accuracy (11)<br />

[nm]<br />

[nm]<br />

10<br />

90<br />

250<br />

600<br />

400<br />

800<br />

450<br />

900<br />

1500<br />

3000<br />

4000<br />

40000<br />

Min. measurable thickness (15) [µm] 25 200 300 425 1570 2500<br />

(1) The measuring range depends on the controller model. The numerical values in this table are nominal values for a CCS Prima controller.<br />

(2) The working distance depends on the controller model. The numerical values given in this table are typical values for a CCS-Prima controller.<br />

(3) The max measurable slope angle applies to specular (mirror-like) surfaces only. For scattering surfaces the maximal slope angle is higher (up to 87° for perfect diffusers); however<br />

the intensity of the collected signal decreases with increasing slope angle. The values given in this table were measured on a mirror at a rate of 100 Hz, with no averaging.<br />

(4) The reference plate is a glass window that can be either located inside the optcal pen, or fixed on the same surface.<br />

(5) For “axial” optcal pens the measuring range is parallel to the mechanical axis of the pen.<br />

For “radial” optcal pens the measuring range is normal to the mechanical axis, allowing to measure inside holes.<br />

(6) The lateral resoluton is defined as half the spot diameter.<br />

(7) The photometric efficiency is the amount of energy collected by different optcal pens when measuring the same sample, in relatve units. The numerical values in this table are<br />

typical, they are given only as a guide for selectng the magnifier model: For measuring a highly-reflectng sample, select a model with low photometric efficiency in order to avoid<br />

saturaton. For measuring diffusive or low-reflectng samples, select a model with high photometric efficiency in order to avoid a poor signal-to-noise rato.<br />

(8) Length and weight excluding the fiber optcs cable. The values given here are for the “axial” model.<br />

(9) The performances given in this table were measured for a CCS Prima controller.<br />

(10) Axial resoluton is defined as the RMS noise level measured on a statc sample. Measurement is performed at optmal rate on a sample located at the center of the measuring<br />

range. Two values are given, with internal averaging set to 1 and to 10, respectvely. This parameter is measured immediately after distance calibraton and is specified on the<br />

calibraton certficate which is delivered with each sensor.<br />

(11) The accuracy is the max error observed in the entre measuring range when comparing the distance measured by the sensor with sample positon determined by a 1-nm<br />

accurate encoder. This parameter is measured with the following settings: “Auto-adaptve LED” mode, optmal rate, slope angle=0°, internal averaging = measuring rate/10.<br />

This parameter is measured immediately after distance calibraton and is specified on the calibraton certficate which is delivered with each sensor.<br />

(12) R = Recommended for measuring rough metallic samples (these samples can be measured with full performances)<br />

NR = Not recommended for measuring rough metallic samples (these samples may be measured, but with reduced performances)<br />

(13) The precise value of the min measurable Ra depends on the characteristcs of the sample. The values given in the table are typical.<br />

(14) Performances in thickness mode, and in partcular the accuracy of thickness measurement, depend on the characteristcs of the sample as well as on a procedure of “Thickness<br />

calibraton” that should be performed by the user. For more informaton contact us.<br />

(15) Typical values measured at the center of the measuring range at optmal rate, with no averaging.<br />

These values are for a sample with a refractve index = 1.5 (When measuring the thickness of an air-gap they should be divided by 1.5)<br />

N.B. : the values are subject to change without notce.<br />

E1204<br />

www.stlsa.com 19

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

Miniature optical pens (ENDO Line)<br />

SENSORS<br />

3D SYSTEMS<br />

<strong>STIL</strong> introduce ENDO, a new line of confocal chromatc pens providing an amazing tny size.<br />

The ENDO optcal pens are ideal for non-contact measurements applicaton in reduced space environnements.<br />

These miniature pens are very useful fot the measurement of holes or cavites with small diameter.<br />

Thanks to their small size (6 mm diameter), their integraton in inspecton machines in the producton line is made easier.<br />

SPECTRO<br />

COLORIMETERS<br />

Working with any <strong>STIL</strong> optoelectronic controllers, the ENDO series allow performing a precise measurement with submicron resoluton.<br />

GONIO<br />

PHOTOMETERS<br />

Axial measuring directon configuraton<br />

20<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

Miniature Series<br />

Model ENDO0.1 ENDO0.3/90 ENDO1.2 ENDO1.2/90 ENDO1.5 ENDO1.5/90<br />

Nominal measuring range (1) [µm] 100 300 1200 1200 1500 1500<br />

Working distance [mm] 1.1 0.8 2.3 0.4 2.1 0.5<br />

Minimum radius measurable (2) [mm] - 3.8 - 3.4 - 3.5<br />

Axial resoluton in distance mode [µm] 0.02 * 0.1 0.15 0.1 *<br />

Axial accuracy in distance mode [µm] 0.05 * 0.2 0.25 0.2 *<br />

Max object slope (3) [deg] +/-24° +/-10° +/- 13° +/- 11° +/- 13° +/- 10°<br />

Spot size diameter [µm] 6.2 6 15 15 7.1 20<br />

Lateral resoluton [µm] 3.1 3 7.5 7.5 3.5 10<br />

Length (4) [mm] 58.9 69.8 75.2 82 100.6 90<br />

Weight (4) [g] 10 * 10 10 12 12<br />

Mechanical diameter [mm] 6 6 6 6 6 6<br />

Measuring directon - Axial Radial Axial Radial Axial Radial<br />

(1) The precise values of the measuring range, the resoluton and the working distance depend on the controller type. The values in these tables are for the<br />

CCS PRIMA controller.<br />

(2) The minimum radius measurable is the distance from the axial axis to the beginning of the measuring range for radial configuraton.<br />

(3) The values in these tables are for specular samples, for diffusive samples, the maximum slope can be much higher. The values are theoretcal.<br />

(4) The length and weight do not include the optcal fiber.<br />

(*) These parameters will be soon available, contact us.<br />

Radial measuring directon configuraton (zoom)<br />

N.B. : the values are subject to change without notce.<br />

E1204<br />

www.stlsa.com 21

GONIO<br />

PHOTOMETERS<br />

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

SENSORS<br />

Introducing Spectral Confocal Interferometry technology<br />

The measurement accuracy in non contact profilometric techniques is generally limited by mechanical vibratons and by positonal<br />

inaccuracies of the micro-scanning table. In order to free the measurement from these environnemental perturbatons, <strong>STIL</strong> has<br />

developed a new vibraton insensitve interferometric method. With this new type of interferometric system, the potental subnanometric<br />

accuracy of interferometric microscopy is effectve.<br />

Moreover this new sensor can be used for measuring transparent films that are too thin to allow the “Chromatc Confocal” technique<br />

to be used. The minimum measurable thickness is 0.4 µm.<br />

3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

Confocal Spectral Interferometry principle<br />

The <strong>STIL</strong> interferometric method is based on Spectroscopic Analysis of White Light Interferograms (SAWLI). It consists in analysing<br />

the interference signal observed on a spectrometer in order to measure the air gap thickness between the reference plate and the<br />

sample. The originality of the developed system lies in the fixaton of the reference plate on the inspected object. As reference<br />

plate and sample are fixed together, the mechanical vibratons do not affect the measurements.<br />

The interferometric signal is a channelled spectrum. From this signal, the spectral phase is calculated using a numerical seven<br />

points phase shifting algorithm allowing the measurement of the local height of the analyzed surface with a subnanometric<br />

resoluton.<br />

22<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

The <strong>STIL</strong> DUO controller line<br />

The new sensor <strong>STIL</strong> DUO double technology, a new standard in the world of dimensional measurement.<br />

The sensor <strong>STIL</strong> DUO is the first system in the world that offers two simultaneous measurement technologies: the Confocal<br />

Chromatc and the White Light Spectral Interferometry with an original confocal setup.<br />

By associatng these two technologies (two <strong>STIL</strong> processes) the sensor <strong>STIL</strong> DUO creates a new standard in the world of dimensional<br />

measurement because it allows the user to get the very best out of these two operatng principles:<br />

- <strong>STIL</strong>’s Confocal Chromatc principle makes it possible to work with a large measurement scale going from 130 µm<br />

to 42 mm. This characteristc is perfect for rugosity and surface topography measurements, which give very high<br />

precision results on any type of material, be it reflectve or diffusing. The measurement is in compliance with the<br />

new ISO 25178 standard.<br />

- <strong>STIL</strong>’s Confocal Spectral Interferometry process gives access to sub-nanometric resolutons (

GONIO<br />

PHOTOMETERS<br />

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

SENSORS<br />

Advantages<br />

- Vibraton insensitve (OPILB-RP optcal pen),<br />

- High signal to noise rato (OPILB-RP optcal pen),<br />

- No vertcal scanning required,<br />

- Minimum measurable thickness 0.4 µm,<br />

- Subnanometric resoluton inherent to the optcal principle,<br />

- No cross talk between neighbouring points, thanks to confocality,<br />

- Exceptonnal performances in thickness measurement (0.3 nm resoluton, 10 nm accuracy)<br />

Configurations<br />

The sensor consists of:<br />

- A <strong>STIL</strong> DUO controller,<br />

- One or more interference optcal pen(s),<br />

- One or more chromatc confocal optcal pen(s) (optonal),<br />

- a fiber optc cable for each optcal pen.<br />

3D SYSTEMS<br />

<strong>STIL</strong>-DUO controller: technical specifications<br />

DUO<br />

Measuring frequency<br />

up to 2000 Hz<br />

Wavelength range<br />

400-900 nm<br />

Spectral resoluton<br />

0.6 nm / pixel<br />

SPECTRO<br />

COLORIMETERS<br />

Light Source<br />

Digital outputs<br />

Synchronizaton I/O<br />

Optcal fiber connectors<br />

Humidity limits<br />

Temperature in use<br />

Dimensions<br />

Weigth<br />

Measuring mode:<br />

Distance/Thickness<br />

Tungsten halogen lamp and White LED<br />

Ethernet / RS232<br />

1 input (TTL) / 1 output (TTL)<br />

E2000<br />

5%-80% HR without condensaton<br />

5 - 50° C<br />

376mm x 363mm x 114mm<br />

6 Kg<br />

1- Confocal Chromatc<br />

2- Confocal spectral Interferometry<br />

24<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SENSORS 3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Non-contact «point» sensors<br />

Interferometric optical pens (OPILB line)<br />

OPILB Line<br />

Model OPILB-RP OPILB-LWD-D OPILB-LWD-T OPILB<br />

Measuring mode - Distance Distance Thickness Thickness<br />

Measuring range [µm] 135 135 - -<br />

Working distance [mm] 5.3 5.3 5.3 42<br />

Max. object slope [deg] +/- 7° +/- 7° +/- 7° +/- 7°<br />

Reference plate (1) - Yes No No No<br />

Magnifier model MG210 MG140 MG210 MG140 MG70 MG35 MG20 -<br />

LATERAL (XY) PROPERTIES<br />

Spot size (diameter)<br />

Lateral resoluton (2)<br />

[µm]<br />

[µm]<br />

3.8<br />

1.9<br />

5.6<br />

2.8<br />

3.8<br />

1.9<br />

5.6<br />

2.8<br />

11.4<br />

5.7<br />

22.8<br />

11.4<br />

40<br />

20<br />

40<br />

20<br />

MECHANICAL INTERFACE<br />

Length (4)<br />

Diameter (4)<br />

Weight<br />

[mm]<br />

[mm]<br />

[g]<br />

200<br />

27<br />

200<br />

164<br />

27<br />

127<br />

200<br />

27<br />

200<br />

164<br />

27<br />

127<br />

131<br />

27<br />

126<br />

100<br />

27<br />

67<br />

84<br />

27<br />

52<br />

145.5<br />

27<br />

155<br />

Performances<br />

DISTANCE MEASUREMENT<br />

Axial resoluton (5)<br />

Accuracy (6)<br />

Measuring rough metal surface (7)<br />

[nm]<br />

[nm]<br />

-<br />

0.5<br />

10<br />

NR<br />

2<br />

10<br />

NR<br />

- -<br />

ROUGHNESS MEASUREMENT<br />

Min. measurable Ra (8) [nm] 0.5 3 - -<br />

THICKNESS MEASUREMENT<br />

Min. measurable thickness (9)<br />

Max. measurable thickness (9)<br />

Axial resoluton (5)<br />

Accuracy (6)<br />

[µm]<br />

[µm]<br />

[nm]<br />

[nm]<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

0.4<br />

90<br />

0.3<br />

10<br />

0.4<br />

90<br />

0.3<br />

10<br />

0.4<br />

90<br />

0.3<br />

10<br />

0.4<br />

90<br />

0.3<br />

10<br />

(1) The reference plate is placed directly on the sample. The reference plate of the OPILB-RP acts as an absolute reference. It compensates for the mechanical imperfectons<br />

of the scanning system.<br />

(2) The lateral resoluton is defined as half the spot diameter.<br />

(3) The photometric efficiency is the amount of energy collected by different optcal pens when measuring the same sample, in relatve units. The numerical values in this<br />

table are typical, they are given only as a guide for selectng the magnifier model: For measuring a highly-reflectng sample, select a magnifier model with low photometric<br />

efficiency in order to avoid saturaton. For measuring diffusive or low-reflectng samples, select a magnifier with high photometric efficiency in order to avoid a poor<br />

signal-to-noise rato.<br />

(4) Length and weight excluding the fiber optcs cable.<br />

(5) Axial resoluton is defined as the RMS noise level measured on a statc sample. Measurement is performed at optmal rate on a sample located at the optmal poston.<br />

(6) The accuracy is the max error observed in the entre measuring range when comparing the distance measured by the sensor with sample positon determined by a<br />

1-nm accurate encoder.<br />

(7) R = Recommended for measuring metallic samples (these samples can be measured with full performances)<br />

NR = Not recommended for measuring metallic samples (these samples may be measured, but with reduced performances)<br />

(8) The precise value of the min measurable Ra depends on the characteristcs of the sample. The values given in the table are typical.<br />

(9) These values are for a sample with a refractve index = 1.5 (When measuring the thickness of an air-gap they should be multplied by 1.5)<br />

E1204<br />

www.stlsa.com 25

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

SENSORS<br />

Fiber optic cables<br />

E2000 «push/pull» connector<br />

Model Length Core Ø Ø max Sheath Connector type<br />

E50-3 3 m 50/125 µm 2.8 mm Standard E2000<br />

E50-5 5 m 50/125 µm 2.8 mm Standard E2000<br />

E50-10 10 m 50/125 µm 2.8 mm Standard E2000<br />

E20-2 2 m 10/20 µm 1.9 mm Standard E2000<br />

E50-3-M 3 m 50/125 µm 5 mm Metal armored E2000<br />

E50-5-M 5 m 50/125 µm 5 mm Metal armored E2000<br />

E50-10-M 10 m 50/125 µm 5 mm Metal armored E2000<br />

E50-20-M 20 m 50/125 µm 5 mm Metal armored E2000<br />

3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

Standard E2000 connector optcal fiber<br />

Metallic armored E2000 connector optcal fiber<br />

FC/APC connector<br />

Model Length Core Ø Ø max Sheath Connector type<br />

F50-3 3 m 50/125 µm 2.8 mm Standard FC/APC<br />

F50-4 4 m 50/125 µm 2.8 mm Standard FC/APC<br />

F50-10 10 m 50/125 µm 2.8 mm Standard FC/APC<br />

F20-2 2 m 10/20 µm 1.9 mm Standard FC/APC<br />

F50-3-M 3 m 50/125 µm 5 mm Metal armored FC/APC<br />

F50-4-M 4 m 50/125 µm 5 mm Metal armored FC/APC<br />

F50-10-M 10 m 50/125 µm 5 mm Metal armored FC/APC<br />

F20-4-M 4 m 10/20 µm 5 mm Metal armored FC/APC<br />

F20-10-M 10 m 10/20 µm 5 mm Metal armored FC/APC<br />

F50-5-M 5 m 10/20 µm 5 mm Metal armored FC/APC<br />

F50-10-M 10 m 10/20 µm 5 mm Metal armored FC/APC<br />

GONIO<br />

PHOTOMETERS<br />

Standard FC/APC connector optcal fiber<br />

Metallic armored FC/APC connector optcal fiber<br />

26<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

Accessories<br />

Mechanical accessories<br />

Model<br />

ST3<br />

DT3x3<br />

Description<br />

Single turreti<br />

Mechanical assembly allowing to combine one magnifier with three different chromatc lenses.<br />

Double turreti<br />

Mechanical assembly allowing to combine three magnifiers with three different chromatc lenses.<br />

The new concept of Modular Optcal Pen (consistng of the combinaton of a<br />

chromatc objectve and an achromatc magnifier) offers the major opportunity<br />

to design a more flexible combinaton : the MULTIPEN which can be available in<br />

two different configuratons : ST and DT.<br />

Based on a microscope turret, the MULTIPEN ST consists of the combinaton of<br />

one achromatc magnifier with three different chromatc lenses, thus offering<br />

three different depths of field in one single mechanical assembly.<br />

The MULTIPEN DT (for double turret) comprises a second turret equipped with<br />

three different magnifiers, thus offering three different spot sizes for each of<br />

the three chromatc objectves. This corresponds to nine different Modular<br />

Optcal Pens in one single mechanical assembly.<br />

Light source and exchange bulbs<br />

Model<br />

XS300<br />

LED300<br />

LED100<br />

XE-300<br />

HL50W<br />

Description<br />

300 Watts Xenon Arc Generatori<br />

External light source for CCS and CHR controllers<br />

Multchannel illuminator: 18 LEDS (5W, white light) including a bundle of fibers, lightng area:<br />

11 mm x 0.2 mm. External light source for MPLS and vision system.<br />

Multuichannel illuminator: 9 LEDS (5W, white light) including a bundle of fibers, lightng area:<br />

4.8 mm x 0.2 mm. External light source for MPLS and vision system.<br />

300 W exchange Xenon Arc bulb<br />

Pack of 5 exchange Halogen lamps of 50 W (for CHR150 controllers)<br />

E1204<br />

www.stlsa.com 27

GONIO<br />

PHOTOMETERS<br />

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

XS300 Light source<br />

SENSORS<br />

3D SYSTEMS<br />

LED300 Light source<br />

SPECTRO<br />

COLORIMETERS<br />

Measurement standards<br />

Model<br />

Description<br />

GS10 10 µm depth groove (non calibrated, optonal DKD calibraton certficate)<br />

RS08 Roughness standard, Ra~0.8µm (optonal DKD calibraton certficate)<br />

FS140 140 mm diameter optical flat (ZERODUR uncoated)<br />

28<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SENSORS 3D SYSTEMS<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

Non-contact «point» sensors<br />

Softwares<br />

Model<br />

Description<br />

CCSMAN CCS Manager software<br />

CHRMON CHR Monitor software<br />

CHRSET CHR Setup Software<br />

<strong>STIL</strong>DLL <strong>STIL</strong>DLL (Dynamic Link Library) for CHR 150 and CCS controllers<br />

OPTMIMAX Min/Max software for CHR 150<br />

OPTLVDT LVDT-type output for CHR 150<br />

DLL for <strong>STIL</strong> point sensors:<br />

The “<strong>STIL</strong>DLL” provides a powerful high-level software development toolkit enabling an easy interfacing of <strong>STIL</strong>’s sensors to<br />

custom applicatons.<br />

It may be used with all <strong>STIL</strong> point sensors<br />

DLL Compatbility<br />

- ANSI-C programs<br />

- Microsoft Visual C++ Tm (versions 6, 2005, 2010)<br />

- .NET (framework 3.5) languages<br />

The main features of the DLL are:<br />

- Initalize and connect to the sensor through RS232, Ethernet or USB2;<br />

- Get/Set the sensor settings, e.g.:<br />

• Sampling rate,<br />

• Measuring mode (Distance/Thickness),<br />

• Optcal pen selecton,<br />

• Digital output settings (data selecton, ascii/binary mode, baud rate...)<br />

• Analog output settings (data selecton, scaling of the data on the 0-5V range),<br />

- Measure the sensor «Dark» signal,<br />

- Enable/disable hardware trigger mode,<br />

- Launch measurement with other processes,<br />

- Synchronize the measurement with other processes,<br />

- Get the sensor status and the «last error» parameter.<br />

The “<strong>STIL</strong>DLL” is delivered with a detailed User Manual and a large number of code samples.<br />

E1204<br />

www.stlsa.com 29

SPECTRO<br />

COLORIMETERS<br />

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

CHR Setup Software<br />

CHR Setup is a useful software utlity to configure the CCS and the CHR sensors, to display and save the measured data.<br />

The CHR Setup Software offers a full palette of advanced features, including real<br />

tme visualizaton of the signals delivered by the sensor on-board spectrometer.<br />

The user-friendly interface enables the operator to view and to modify all the<br />

sensor’s settings:<br />

SENSORS<br />

- Acquisiton rate and temporal averaging,<br />

- Optcal pen selecton,<br />

- Measuring mode (distance or thickness measurement),<br />

- Digital output configuraton,<br />

- Analog output configuraton.<br />

These signals may be captured, saved and compared with reference signals.<br />

This feature is very useful for adjustng the positon of the optcal pen relatvely to the sample, or for analyzing the sensor<br />

performance in partcularly difficult measuring conditons ( very low signal to noise rato, sample located at the very end of the<br />

measuring range, measuring the thickness of thin layers,…).<br />

3D SYSTEMS<br />

This interface comprises a dedicated Command Terminal allowing to send ASCII commands to the sensor and to view its response.<br />

Example: by typing in “$TRG”, the operator may implement and test the triggered operaton mode.<br />

Thanks to this software, measurements may be easily configured (sensor rate, number of points to measure, trigger mode) and<br />

launched. The operator may select the data for display: Distance, Thickness, Intensity… This data is displayed in real tme in the<br />

graphic window. Moreover, it may be saved on the hard disk or sent to the printer.<br />

At the end of the measurement, statstcal informaton (minimum, maximum, average, standard deviaton) is automatcally<br />

displayed.<br />

This utlity facilitates maintenance tasks, by a single mouse click the operator may interrogate the sensor for its serial number<br />

or send a new firmware version.<br />

GONIO<br />

PHOTOMETERS<br />

Minimal computer configuraton<br />

Windows XP TM<br />

512 MB RAM, 1 GHz<br />

RS232, Ethernet or USB port (depending on the sensor type)<br />

30<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

CHR Monitor Software<br />

The CHR Monitor software allows to display, to print and to save the signal delivered by CHR sensors.<br />

A simple mouse click offers the possibility to:<br />

- Launch the Dark Signal acquisiton;<br />

- Select:<br />

• The optcal pen connected to the CHR sensor,<br />

• The parameters to be displayed (alttude, intensity…),<br />

• The Acquisiton and sampling rates,<br />

• The temporal averaging factor.<br />

Available operatng modes<br />

Contnuous visualizaton<br />

Acquisiton (N measurements) at a constant sampling rate<br />

Acquisiton in CMM mode (alttude statement)<br />

Licence<br />

The program requires a “dongle” (hardware) to be installed on the parallel port. A printer or any other parallel port device<br />

may stll be connected to the parallel port through the “dongle”.<br />

Minimal computer configuraton<br />

Windows 2000 / NT<br />

256 MB RAM, 1 GHz<br />

Serial port<br />

E1204<br />

www.stlsa.com 31

SPECTRO<br />

COLORIMETERS<br />

Non-contact «point» sensors<br />

SELECTION<br />

GUIDE<br />

CCS Manager Software<br />

The CCS Manager software is a powerful software which allows to start measuring with your new CCS-Prima sensor, <strong>STIL</strong>-Inital<br />

or <strong>STIL</strong>-Duo in minutes.<br />

Thanks to its very user-frendly interface, the CCS Manager software<br />

is the simplest way to get accurate measurements from the sensor<br />

and to have a full control over all the settings of your CCS sensor.<br />

Moreover, CCS Manager provides advanced maintenance functons :<br />

SENSORS<br />

- Update of the sensor’s firmware to take advantage of the latest<br />

enhancements and the new functons developped by <strong>STIL</strong>’s engineers.<br />

- In situ calibraton of your controller.<br />

- Download to the sensor’s memory of additonal calibraton tables<br />

allowing to use more optcal pens with your CCS controller.<br />

- Unique «Diagnostcs» functon, allowing to record the current status of the sensor into a file, which can be directly sent<br />

by email to <strong>STIL</strong>’s Applicaton and Support department. Thanks to these detailed informaton, our engineers are able to<br />

give help and advice in minutes, even if the product is used thousands of kilometers away from our premises.<br />

GONIO<br />

PHOTOMETERS<br />

3D SYSTEMS<br />

Minimal computer configuraton<br />

Window XP TM ,Windows 7 TM -32 bits, 7 TM -64 bits<br />

512 MB RAM, 1 GHz<br />

RS232 or USB port (depending on the sensor type)<br />

32<br />

www.stlsa.com<br />

E1204

SELECTION<br />

GUIDE<br />

SPECTRO<br />

COLORIMETERS<br />

GONIO<br />

PHOTOMETERS<br />

SENSORS 3D SYSTEMS<br />

Non-contact «point» sensors<br />

3D measurement examples: chromatic confocal technology<br />

Human Skin measurement<br />

Surface microtopography of a TF insert<br />

3D measurement examples: confocal spectral interferometry<br />

Commercial gratng<br />

Solar cells<br />

E1204<br />

www.stlsa.com 33

Non-contact «line» sensors<br />

SELECTION<br />

GUIDE<br />

SENSORS<br />

MPLS180 «line» sensors<br />

The MPLS180 is the first «line» chromatc confocal sensor in the world.<br />

It pushes one step forward the amazing non-contact sensing technology<br />