Pad ROLâ¢200 Series - Johnstech

Pad ROLâ¢200 Series - Johnstech

Pad ROLâ¢200 Series - Johnstech

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Pad</strong> ROL200<br />

<strong>Series</strong><br />

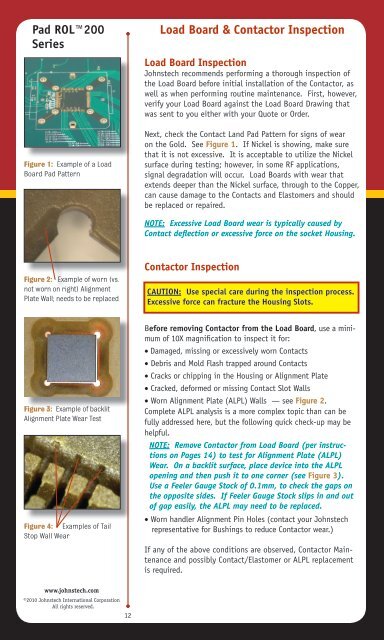

Figure 1: Example of a Load<br />

Board <strong>Pad</strong> Pattern<br />

Load Board & Contactor Inspection<br />

Load Board Inspection<br />

<strong>Johnstech</strong> recommends performing a thorough inspection of<br />

the Load Board before initial installation of the Contactor, as<br />

well as when performing routine maintenance. First, however,<br />

verify your Load Board against the Load Board Drawing that<br />

was sent to you either with your Quote or Order.<br />

Next, check the Contact Land <strong>Pad</strong> Pattern for signs of wear<br />

on the Gold. See Figure 1. If Nickel is showing, make sure<br />

that it is not excessive. It is acceptable to utilize the Nickel<br />

surface during testing; however, in some RF applications,<br />

signal degradation will occur. Load Boards with wear that<br />

extends deeper than the Nickel surface, through to the Copper,<br />

can cause damage to the Contacts and Elastomers and should<br />

be replaced or repaired.<br />

NOTE: Excessive Load Board wear is typically caused by<br />

Contact deflection or excessive force on the socket Housing.<br />

Figure 2: Example of worn (vs.<br />

not worn on right) Alignment<br />

Plate Wall; needs to be replaced<br />

Contactor Inspection<br />

CAUTION: Use special care during the inspection process.<br />

Excessive force can fracture the Housing Slots.<br />

Figure 3: Example of backlit<br />

Alignment Plate Wear Test<br />

Figure 4: Examples of Tail<br />

Stop Wall Wear<br />

Before removing Contactor from the Load Board, use a minimum<br />

of 10X magnification to inspect it for:<br />

· Damaged, missing or excessively worn Contacts<br />

· Debris and Mold Flash trapped around Contacts<br />

· Cracks or chipping in the Housing or Alignment Plate<br />

· Cracked, deformed or missing Contact Slot Walls<br />

· Worn Alignment Plate (ALPL) Walls — see Figure 2.<br />

Complete ALPL analysis is a more complex topic than can be<br />

fully addressed here, but the following quick check-up may be<br />

helpful.<br />

NOTE: Remove Contactor from Load Board (per instructions<br />

on Pages 14) to test for Alignment Plate (ALPL)<br />

Wear. On a backlit surface, place device into the ALPL<br />

opening and then push it to one corner (see Figure 3).<br />

Use a Feeler Gauge Stock of 0.1mm, to check the gaps on<br />

the opposite sides. If Feeler Gauge Stock slips in and out<br />

of gap easily, the ALPL may need to be replaced.<br />

· Worn handler Alignment Pin Holes (contact your <strong>Johnstech</strong><br />

representative for Bushings to reduce Contactor wear.)<br />

If any of the above conditions are observed, Contactor Maintenance<br />

and possibly Contact/Elastomer or ALPL replacement<br />

is required.<br />

www.johnstech.com<br />

©2010 <strong>Johnstech</strong> International Corporation<br />

All rights reserved.<br />

12