The Apex SE Click Pen (PKVPEN) - Penn State Industries

The Apex SE Click Pen (PKVPEN) - Penn State Industries

The Apex SE Click Pen (PKVPEN) - Penn State Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

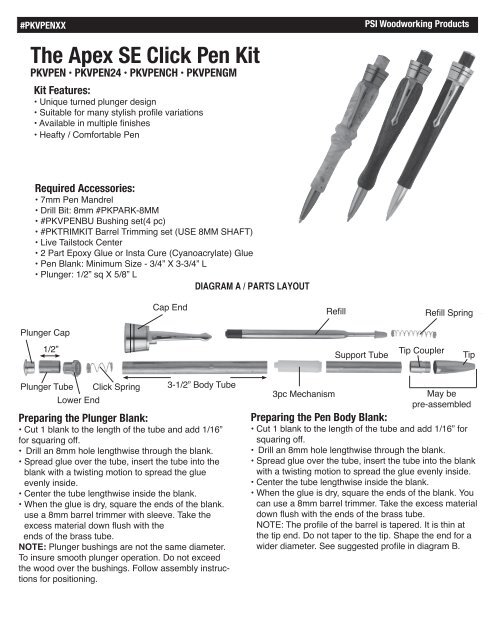

#<strong>PKVPEN</strong>XX<br />

<strong>The</strong> <strong>Apex</strong> <strong>SE</strong> <strong>Click</strong> <strong>Pen</strong> Kit<br />

<strong>PKVPEN</strong> • <strong>PKVPEN</strong>24 • <strong>PKVPEN</strong>CH • <strong>PKVPEN</strong>GM<br />

Kit Features:<br />

• Unique turned plunger design<br />

• Suitable for many stylish profile variations<br />

• Available in multiple finishes<br />

• Heafty / Comfortable <strong>Pen</strong><br />

PSI Woodworking Products<br />

Required Accessories:<br />

• 7mm <strong>Pen</strong> Mandrel<br />

• Drill Bit: 8mm #PKPARK-8MM<br />

• #<strong>PKVPEN</strong>BU Bushing set(4 pc)<br />

• #PKTRIMKIT Barrel Trimming set (U<strong>SE</strong> 8MM SHAFT)<br />

• Live Tailstock Center<br />

• 2 Part Epoxy Glue or Insta Cure (Cyanoacrylate) Glue<br />

• <strong>Pen</strong> Blank: Minimum Size - 3/4” X 3-3/4” L<br />

• Plunger: 1/2” sq X 5/8” L<br />

Plunger Cap<br />

Cap End<br />

DIAGRAM A / PARTS LAYOUT<br />

Refill<br />

Refill Spring<br />

1/2”<br />

Support Tube<br />

Tip Coupler<br />

Tip<br />

Plunger Tube <strong>Click</strong> Spring<br />

Lower End<br />

3-1/2” Body Tube<br />

Preparing the Plunger Blank:<br />

• Cut 1 blank to the length of the tube and add 1/16”<br />

for squaring off.<br />

• Drill an 8mm hole lengthwise through the blank.<br />

• Spread glue over the tube, insert the tube into the<br />

blank with a twisting motion to spread the glue<br />

evenly inside.<br />

• Center the tube lengthwise inside the blank.<br />

• When the glue is dry, square the ends of the blank.<br />

use a 8mm barrel trimmer with sleeve. Take the<br />

excess material down flush with the<br />

ends of the brass tube.<br />

NOTE: Plunger bushings are not the same diameter.<br />

To insure smooth plunger operation. Do not exceed<br />

the wood over the bushings. Follow assembly instructions<br />

for positioning.<br />

3pc Mechanism<br />

May be<br />

pre-assembled<br />

Preparing the <strong>Pen</strong> Body Blank:<br />

• Cut 1 blank to the length of the tube and add 1/16” for<br />

squaring off.<br />

• Drill an 8mm hole lengthwise through the blank.<br />

• Spread glue over the tube, insert the tube into the blank<br />

with a twisting motion to spread the glue evenly inside.<br />

• Center the tube lengthwise inside the blank.<br />

• When the glue is dry, square the ends of the blank. You<br />

can use a 8mm barrel trimmer. Take the excess material<br />

down flush with the ends of the brass tube.<br />

NOTE: <strong>The</strong> profile of the barrel is tapered. It is thin at<br />

the tip end. Do not taper to the tip. Shape the end for a<br />

wider diameter. See suggested profile in diagram B.

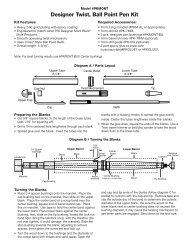

#<strong>PKVPEN</strong>XX<br />

PSI Woodworking Products<br />

Head Stock<br />

Cap Bushing<br />

DIAGRAM B / TURNING THE BLANKS<br />

Tip Bushing<br />

Larger dia. Plunger-<br />

Bushing<br />

Taper<br />

Knurled Nut<br />

Live Center<br />

7mm Spacer<br />

Bushings<br />

Profile<br />

Blank<br />

Avoid turning to thickness<br />

of bushing<br />

7mm Spacer Bushings<br />

as required<br />

Turning the Blank<br />

• You may turn the pen blank and the plunger on the same mandrel together.<br />

<strong>Pen</strong> Blank: Turn the barrel to a pleasing profile. You may design a oversized bead on top and curve the wood at the tip to<br />

avoid the thin wall if turned straight to the bushing.<br />

Plunger: 2 bushings are of different diameters. <strong>The</strong> wide bushing is also larger in diameter. Turn a straight profile<br />

NOTE: Do not leave wood on the plunger to exceed the bushings otherwise it will effect the plunging and sliding. Sand smooth<br />

up to the bushings.<br />

Assembly<br />

• Layout parts according to diagram A<br />

PEN BARREL:<br />

• Insert the mechanism assembly, threaded end in first through the narrow end of the barrel.<br />

• Follow with the support tube into the same opening.<br />

Screw the tip into the tip coupler (may be pre-assembled). Press the assembly into the same opening until the base of the tip<br />

bottoms onto the barrel.<br />

• Press the cap end into the wide turned end of the barrell.<br />

• Unscrew the tip, Insert the refill into the opening at the tip. Affix the refill spring. Screw the tip over.<br />

PLUNGER:<br />

• Press the lower end (wider) into the wide end of the plunger.<br />

• Press the plunger cap into the (narrower) opposite opening.<br />

• Drop the click spring into the opening at the cap end. Place the plunger, threaded side in first and screw over the spring onto<br />

the mechanism to bottom.<br />

• <strong>The</strong> pen is ready to use by clicking on the plunger to advance or retract the refill. Unscrew the tip to replace refill.<br />

Diagram C / Bushings #<strong>PKVPEN</strong> BU<br />

Blank<br />

Profile<br />

Smaller dia.<br />

Plunger Bushing<br />

Mandrel<br />

ø<br />

.600”<br />

CAP BUSHINGS<br />

ø<br />

.288”<br />

PLUNGER BUSHINGS<br />

ø ø<br />

.404” .288”<br />

.248” Holes through<br />

ø<br />

.288”<br />

ø<br />

.330”<br />

ø<br />

ø<br />

.288” .394”<br />

© 2012 PSI Woodworking Philadelphia PA 19115 - v10/12