PKGRIND7 - Penn State Industries

PKGRIND7 - Penn State Industries

PKGRIND7 - Penn State Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

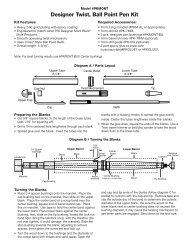

#<strong>PKGRIND7</strong><br />

Small Pepper Mill Kit<br />

Kit Features:<br />

• Easy to hold in the palm of your hand<br />

• Requires only drilling two hole sizes<br />

• Ceramic grinding parts can use salt or pepper<br />

• Only 3-3/4” tall<br />

PSI Woodworking Products<br />

Required Accessories:<br />

• 7mm Pen Mandrel<br />

• Drill Bit(s):<br />

1-1/16” #FBI-116 (For thru holes)<br />

36mm #FB36MM (For top recess)<br />

1-1/2” #FB150 (For bottom recess)<br />

• <strong>PKGRIND7</strong>BU Bushing set(2 pc)<br />

• Small Phillips Screw Driver<br />

• 60º Live Tailstock Center<br />

• Wood Blank Required: Minimum Size- 2” x 2” x 3-1/4” H<br />

Drilling the Blank<br />

• Square the ends of the blank to start.<br />

• Locate and mark the center of each end of the blank.<br />

• Bore a 36mm hole 3/16” deep in the top of the blank.<br />

• Bore a 1-1/16” hole half way through the top of the blank.<br />

• Bore a 1-1/2” hole 3/8” deep in the bottom of the blank.<br />

• Bore a 1-1/16” through the bottom of the blank to meet up with the top hole.<br />

DIAGRAM A / Drilling the Blank<br />

36mm<br />

3/16”<br />

3-1/4”<br />

0<br />

1-1/16”<br />

3/8”<br />

1-1/2”<br />

2”

#<strong>PKGRIND7</strong><br />

PSI Woodworking Products<br />

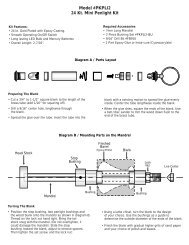

DIAGRAM B / Turning the Blank<br />

Bottom End<br />

Headstock<br />

Blank<br />

Top End<br />

Spacer Bushings<br />

Knurled Nut<br />

Spacer Bushings<br />

Live Center<br />

End Bushings<br />

Profile of your<br />

choice<br />

Turning the Blank (see diagram B)<br />

• Mount an end bushing wide end first on the mandrel.<br />

• Slide the blank on the mandrel onto the bushing.<br />

• Mount the other end bushing, narrow end in first into the blank.<br />

• Lock the setup tight on the mandrel, secure with the tail stock.<br />

• Turn the blank into the profile desired. Finish the wood with a food safe finish.<br />

NOTE: The wood is not turned down to meet the bushings<br />

End Bushings<br />

Diagram C Grind Assembly<br />

Grind Adj. Knob<br />

Crank Wheel<br />

Upper Cup<br />

Assembly<br />

• Layout parts according to diagram C<br />

• Glue the upper cup into the recess on the upper blank.<br />

• Insert the grinding assembly, shaft in first through the hole in the bottom. Push on<br />

the spring.<br />

• Mount the crank wheel over the extended rod. Screw the adjusting grind knob over<br />

the threads.<br />

• Line up the grinder housing rim shoulders to match the holes in the grinder base.<br />

Cover with the bottom plate, extended portion toward the bottom (see diagram E)<br />

Screw in through the grinder base and housing securely into the wood.<br />

• When filled with pepper or salt, to adjust the grind just loosen or tighten the knob.<br />

• To reload the mill, remove the knob and crank wheel and reload through the top.<br />

Diagram D / Bushings #<strong>PKGRIND7</strong>BU<br />

1/4”<br />

3/8”<br />

Housing<br />

Spring<br />

Grinder Mill<br />

Grinder Base<br />

Bottom Plate<br />

Mounting<br />

Screws<br />

Grinder<br />

Assembly<br />

.248 Holes through<br />

ø1.375”<br />

ø1.058”<br />

same<br />

Diagram E<br />

© 2012 PSI Woodworking Philadelphia PA 19115 - v03/13