Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Session A2 Paper 1018<br />

<strong>CONTROL</strong> <strong>SYSTEMS</strong> <strong>IN</strong> <strong>MODERN</strong> <strong>ROBOTICS</strong><br />

Derek Ebersole (dle13@pitt.edu) and Ben Guise (bag44@pitt.edu)<br />

Abstract – This paper will focus on the control systems used<br />

in mobile robotics, possessing an emphasis on controlling<br />

their stabilization. This paper will touch base on possible<br />

improvements of control systems from an engineer’s<br />

standpoint.<br />

We will initially start with the basics of enabling robots<br />

with ―brains‖ through the applications of control systems.<br />

After dissecting control systems, we will discuss how sensors<br />

help robots get information to make decisions. Once control<br />

systems and sensors are fully conveyed to the audience, we<br />

will then look at an example of advanced control systems<br />

such as BigDog: Boston Dynamic’s robot, which can<br />

maneuver itself over various terrains without tumbling over.<br />

Much of what interests us is the ability for new robots to<br />

detect an imbalance in their weight and make the necessary<br />

adjustments to withhold from falling. Through the<br />

application of BigDog, the significance of the continued<br />

research in the field will be justified.<br />

Key Words – Control Systems, Data Processing, Robotics,<br />

Sensors, Stabilization, Legged Robotics<br />

EARLY <strong>ROBOTICS</strong>: THE UNREALIZED DREAM<br />

In late 2001, the research necessary for creating a fully<br />

mobile intelligent robot was declared complete, and the<br />

fictional dreams of movies, such as the Star Wars series or<br />

The Terminator series, seemed to become possibilities. But<br />

since this time, mobile robots have stayed confined to the<br />

home. Robot vacuum cleaners, such as Electrolux’s<br />

Trilobite, possess various sensors and control systems to<br />

navigate around a room, keeping track of the path taken<br />

without bumping into anything, while cleaning every<br />

particle of dust. Similarly, Friendly Robotics’ Robomower<br />

traverses a yard without hitting any obstructions while<br />

evenly cutting grass to the owner’s specification [1].<br />

While each of these examples possesses the basic form an<br />

intelligent mobile robot should have, the potential of this<br />

technology seems to be poorly utilized. In many cases, users<br />

note the inconsistent cleaning path and the unreliability these<br />

mobile cleaners possess. Aside from problems in design,<br />

these robots fail to live up to the expectation of what an<br />

intelligent robot should be. We still have no Terminator or<br />

C3PO like in Star Wars: machines that are capable of<br />

automatically determining the terrain they are traversing and<br />

acting appropriately. Therefore, the research in the field of<br />

robotics is not complete; otherwise the world would have<br />

seen the applications we have been fantasizing about.<br />

We have failed in reaching the science-fiction dream.<br />

Mobile robots need to be able to detect data with speed and<br />

precision, as well as balance themselves while traveling over<br />

treacherous terrain. Without these abilities and proper<br />

control systems to input and output data, robots will never<br />

reach the goal set forth in most science fiction films.<br />

THE <strong>CONTROL</strong> SYSTEM<br />

Types of Control Systems<br />

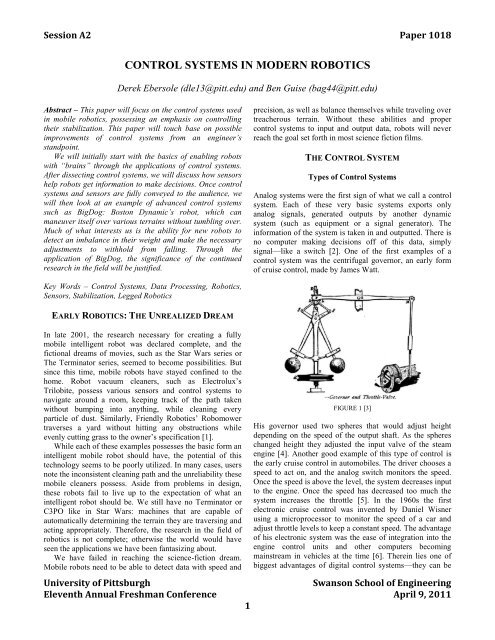

Analog systems were the first sign of what we call a control<br />

system. Each of these very basic systems exports only<br />

analog signals, generated outputs by another dynamic<br />

system (such as equipment or a signal generator). The<br />

information of the system is taken in and outputted. There is<br />

no computer making decisions off of this data, simply<br />

signal—like a switch [2]. One of the first examples of a<br />

control system was the centrifugal governor, an early form<br />

of cruise control, made by James Watt.<br />

FIGURE 1 [3]<br />

His governor used two spheres that would adjust height<br />

depending on the speed of the output shaft. As the spheres<br />

changed height they adjusted the input valve of the steam<br />

engine [4]. Another good example of this type of control is<br />

the early cruise control in automobiles. The driver chooses a<br />

speed to act on, and the analog switch monitors the speed.<br />

Once the speed is above the level, the system decreases input<br />

to the engine. Once the speed has decreased too much the<br />

system increases the throttle [5]. In the 1960s the first<br />

electronic cruise control was invented by Daniel Wisner<br />

using a microprocessor to monitor the speed of a car and<br />

adjust throttle levels to keep a constant speed. The advantage<br />

of his electronic system was the ease of integration into the<br />

engine control units and other computers becoming<br />

mainstream in vehicles at the time [6]. Therein lies one of<br />

biggest advantages of digital control systems—they can be<br />

University of Pittsburgh Swanson School of Engineering<br />

Eleventh Annual Freshman Conference April 9, 2011<br />

1

integrated into other systems and share data, therefore<br />

making devices more reliable, safer, and often more<br />

accurate.<br />

The next step in the complex line of control systems is<br />

the sampled-data system. Here, analog signals, sampled data,<br />

and pulse-modulated signals are put together and used<br />

simultaneously. An advantage to this is the sharing ability<br />

between equipment and signals [2].<br />

The most popular of these types is the digital system,<br />

which houses the ability to use analog signals, sampled data,<br />

and digital data. This code represents values in sequences,<br />

which help determine the actual value of digital information.<br />

Computers compare data and actually “think” about what the<br />

best adjustment is for the system. When more complicated<br />

control must be utilized, the digital direction is the obvious<br />

choice, as it can keep track of a lot of data and give<br />

calculated outputs based on logic switches [2]. A good<br />

example is automatic flight control in airplanes. The system<br />

must take into account a wide variety of data, such as lateral<br />

height, vertical height, and various forms of disturbances. To<br />

account for these, the main control system is a digital<br />

computer that acquires data from three independent systems<br />

monitoring these values. This proves the luxury that a digital<br />

system offers, as it can read many varieties of information at<br />

once and make smart choices based off of them [7].<br />

Control System Thought Process<br />

All control systems work on the same basic principle: they<br />

monitor output of a system and alter input to keep output<br />

consistent. Figure 2 illustrates the thought process behind<br />

how these systems go about analyzing information. An<br />

important factor is that this chart is a loop, which means the<br />

outputs and inputs are continuously monitored. In analog<br />

systems this is represented by mechanical or electrical<br />

signals and for digital systems a computer is preset to<br />

monitor this information at a given rate. The faster this<br />

monitoring process is performed, the more precise and<br />

accurate the output adjustments are for the system [8].<br />

FIGURE 2 [2]<br />

A necessary ability control systems must have is quick,<br />

logical reaction to unusual data. An engineer designs a<br />

system to be efficient and safe. Safety is important, and if a<br />

dangerous machine needs to be stopped, the control must<br />

react quickly and accurately. Consider a robot lawnmower<br />

once more. If the machine for some reason turns over, the<br />

Paper 1018<br />

blades would need to shut down, otherwise someone could<br />

get hurt. A control system in this scenario would need to be<br />

told to shut down all systems, otherwise the mower would be<br />

deemed unsafe for the public.<br />

SENSORS: ACQUIR<strong>IN</strong>G DATA<br />

The first step in a control system is to input data from the<br />

system. Sensors allow robots and control systems to see<br />

what is happening in the environment around them. A<br />

variety of sensors are available for different types of<br />

functions including movement, vision, balance and scientific<br />

data collection. What is relevant for control systems<br />

handling locomotion are sensors that deal with the first three<br />

functions of the list [9].<br />

Early robots used pegs at fixed points to stop movement.<br />

This proved inefficient over time as more technical and agile<br />

robots were made, and servo motors were implemented.<br />

Servo motors handle movement while also providing<br />

feedback. These motors read an encoder disk that has slits at<br />

defined points, as shown in Figure 3. Light sensors see when<br />

these points pass by and the time increment information<br />

gathered tells the motor how far it has turned. The robot is<br />

therefore able to detect the distance a leg or arm has moved,<br />

send this information to the control system, and make a<br />

decision to continue or stop motion [9][2]. Encoder disks are<br />

sometimes used alone as a means to find the angle of<br />

rotation in a system. In both applications, the more slits that<br />

are present in the disk, the more accurate the measurements<br />

are for the angles. An important note here is that in order for<br />

a robot to determine the change in angle, it must first know<br />

the number of slits present in the disk, otherwise calculations<br />

will be incorrect [10].<br />

FIGURE 3 [10]<br />

Potentiometers can also be used for sensing joint<br />

displacements. A potentiometer functions by comparing an<br />

output voltage to an input voltage. These devices incorporate<br />

a resistive track made out of carbon film, conductive<br />

ceramic, or wound wire. The distance through this track that<br />

the electricity must travel is changed by the physical location<br />

of a wiper that slides across the track. This change in<br />

distance causes a voltage change. Potentiometers are usually<br />

used as volume controls in stereos and can measure a change<br />

in angle caused by something rotating. Linear<br />

potentiometers also exist, which track a distance by moving<br />

University of Pittsburgh Swanson School of Engineering<br />

Eleventh Annual Freshman Conference April 9, 2011<br />

2

a wiper over a straight track rather than around a circle<br />

[2][10].<br />

FIGURE 4 [10]<br />

Radial potentiometer<br />

FIGURE 5 [10]<br />

Linear potentiometer<br />

Gyroscopes, both mechanical and electrical, are used to<br />

determine if an object is balanced. Early examples include<br />

the Sperry autopilot, which use gyroscopes to handle the<br />

horizontal and vertical pitch of an airplane, enabling the<br />

pilot to walk safely across the wings without manually<br />

adjusting the pitch of the airplane [5]. Newer electronic<br />

gyroscopes are used in commercial products like the Apple<br />

iPhone to output the orientation of the device [11].<br />

These gyroscope sensors are applications of Newton’s<br />

second law for rotation, which states that net torque equals<br />

angular acceleration multiplied by the moment of inertia.<br />

= Ι<br />

EQUATION 1<br />

A disk spun about a frictionless axis is suspended in a<br />

gimbal or a cage, which will retain its orientation. Because<br />

this gimbal is mounted freely in a rigid body, one can<br />

measure the angle between the gimbal and the moved body<br />

to find the pitch or roll of the object being stabilized [2].<br />

Often robots require force sensors for grasping objects or<br />

for determining the weight of an object. This information is<br />

useful for finding the amount of weight supported by each<br />

leg of a robot. Load cells are used to determine the<br />

magnitude of force. These are made with a dielectric<br />

material between two plates. As a force acts on this system,<br />

the distance between the plates increases or decreases,<br />

inversely changing the capacitance [10].<br />

C =<br />

EQUATION 2<br />

Paper 1018<br />

These sensors become especially important for robots with<br />

legs or arms, as this allows the robot to see how much<br />

weight is being supported by each arm or leg and react<br />

according to weight shifts or imbalances.<br />

Vision sensors come in a variety of types from simple<br />

light detectors to cameras. Basic light detectors differentiate<br />

between light and dark; images and color are not sensed.<br />

These are often used with the aforementioned coding disks<br />

or for simple light detection. More complex image sensors<br />

can produce a black and white image, which can then be<br />

passed on to a computer for data analysis. The most<br />

important area for complex vision is the sensor placement<br />

and data processing rather than the types of sensors used<br />

[5][10].<br />

The topic of robot vision is complicated because, while it<br />

is easy to input visual data, interpreting it for actual use is<br />

difficult and requires software. In humans, the retina<br />

converts light into electrochemical energy, which is then<br />

sent to the brain for processing. In robots a common vision<br />

sensor used today is a charge-coupled device, or CCD<br />

camera. These are ideal for robots because they are<br />

lightweight and small, consume little electricity, and have a<br />

high sensitivity over the light spectrum. A CCD array is<br />

made using an array of metal oxide semiconductor fieldeffect<br />

transistors, or MOSFETs, as seen in Figure 6.<br />

FIGURE 6 [12]<br />

MOSFET array<br />

The basic idea behind this type of vision sensor is that an<br />

array of MOSFETs stores a series of charges that correspond<br />

to the light intensity at that point. Positive semiconductor<br />

nodes are placed in a negative substrate. A depletion region<br />

separates each positive node, and then the entire array is<br />

covered in silicon dioxide. Light photons hitting the<br />

depletion region free electrons, which create a net positive<br />

University of Pittsburgh Swanson School of Engineering<br />

Eleventh Annual Freshman Conference April 9, 2011<br />

3

charge. Each individual charge is transferred the next cell by<br />

a clock pulse. This electrical signal then comprises the video<br />

signal [12].<br />

Stereo vision, which is being employed by more robots,<br />

is useful because it allows for the possibility of two and<br />

three dimensional vision. By comparing the picture output<br />

by two cameras, it is possible to see depth and further<br />

analyze the environment [10]. However, a large part of what<br />

makes robot vision work is the software behind it. Any robot<br />

can input a picture of a tree, but it takes software<br />

programming for the robot to know what a tree really is.<br />

With all of these sensors inputting much information into<br />

the control system, one could argue that robots should easily<br />

have human like abilities in balancing, motion, and vision.<br />

One can give a control system all kinds of information but<br />

without a fast computer to interpret this information, this<br />

data is rendered useless. Furthermore, advanced software is<br />

required to enable a computer to handle these functions and<br />

correctly process input.<br />

<strong>CONTROL</strong> <strong>SYSTEMS</strong> <strong>IN</strong> OUTER SPACE<br />

Imagine a bullet fired from a gun in outer space. This bullet<br />

will continue traveling in the same direction until it enters a<br />

gravitational field from other masses. Now add a small<br />

control system whose goal is to keep it on its initial path. It<br />

detects motion traveling away from the path and fixes it.<br />

These fixes are done every now and then, but there is not<br />

necessarily a continual need for them.<br />

In outer space, once you let it go, it must fix itself; there<br />

is no more human directional interaction. There is an<br />

element of simplicity and an element of complexity in this.<br />

The National Aeronautics and Space Association (NASA)<br />

has dealt with these issues for years. Voyagers 1 and 2 are<br />

examples of NASA engineering at its finest, given that they<br />

have been operational for thirty-four years without any<br />

serious human interventions or breakdowns. Both of these<br />

probes are on a path to interstellar space and have very<br />

infrequent path corrections because in space, once an object<br />

begins to move in a certain direction, it will continue on that<br />

path almost infinitely. When corrections are necessary, there<br />

is usually enough time to perform calculations to fix the<br />

problem; mainly because the potential threats are detected<br />

long before they are encountered. All of this means that<br />

space probes require little computational power to operate.<br />

The Voyager probes use three different computers, each<br />

with a redundant pair, for a total of six computers in each<br />

probe. The total memory for all of these computers is about<br />

sixty-eight kilobytes, which is much less than a common<br />

flash drive or even a standard three and a half inch floppy<br />

disk [13][14]. A more recent example is Sojourner, a Mars<br />

rover utilizing a 100-kilohertz Intel 80C85 processor with<br />

512 kilobytes of memory, which was first produced in 1977<br />

[15]. Clearly, this is not a very powerful computer. Because<br />

Sojourner moves with six wheels, a very simple system, it<br />

Paper 1018<br />

does not need a complex computer. This illustrates an<br />

important factor in the continued development of robotics—<br />

robots with complex motion systems must be able to<br />

perform calculations to adjust movement in varying terrains<br />

using smaller, more powerful computers so that outside<br />

computing is not necessary, as this would increase the size<br />

and response time of a robot.<br />

FIGURE 7 [14]<br />

Depiction of the Voyager space probe<br />

These space-bound computers are not capable of massive<br />

amounts of data processing. However, any serious<br />

calculations could be performed on Earth and beamed up to<br />

the satellites given that we would have advance notice of a<br />

probe headed towards a large planet or other celestial body.<br />

One of the problems with this is the time necessary for<br />

transmission. A signal traveling to or from Voyager 2<br />

currently takes about thirteen hours to transmit one way<br />

[16]. This means that NASA cannot intervene quickly if<br />

something goes wrong; therefore, probes must be selfsufficient<br />

to a degree and very reliable (as the Voyager<br />

probes have proven to be over their thirty-four year<br />

missions). The problem of communication latency was<br />

especially frustrating in the recent incident with Voyager 2,<br />

where a single flip of a bit in memory from a zero to a one<br />

corrupted data being sent back to Earth. Because of this, it<br />

took NASA engineers weeks to diagnose and fix the<br />

problem [17]. Thanks to redundant computers and alternate<br />

operation modes, the spacecraft was able to continue<br />

operating through this situation. This shows that control<br />

systems and computers used in space probes and<br />

autonomous robots alike need to be reliable and powerful<br />

enough—whether that power comes through software or<br />

hardware—to handle even the most catastrophic system<br />

failures or unexpected circumstances. Furthermore, space<br />

probes and vehicles have been an area where low power,<br />

small form factor, and high reliability computers—an almost<br />

ideal combination for robotics—have been implemented for<br />

decades.<br />

University of Pittsburgh Swanson School of Engineering<br />

Eleventh Annual Freshman Conference April 9, 2011<br />

4

STABILIZATION ON EARTH<br />

Gravitational Woes<br />

Outer space is a unique environment to work in, as there is<br />

no gravity. On Earth, what goes up must come down.<br />

Therefore, continuous fixing of direction is needed, as we<br />

are constantly fighting a force keeping us from hovering<br />

above ground. Imagine, once again, the bullet situation, only<br />

this time shot from a gun parallel to the ground. Even though<br />

this bullet is travelling at an immense speed, it is being<br />

pulled downward, and will hit the ground. Now imagine a<br />

tiny control system with rockets directed opposite gravity.<br />

When it detects a fall in height, the rockets push the bullet<br />

upwards and then let off once the original height is reached<br />

again, so that the bullet stays in a straight line. The<br />

difference between these bullet scenarios is an example of<br />

the continuous re-fixing that needs to be done on Earth.<br />

Gravity forces a repositioning of the system at almost a<br />

constant rate, meaning its control system needs to be fast<br />

enough to process the data and act quickly. Achieving<br />

mobility in robots is consequently made much more<br />

difficult, as robot body parts must be constantly adjusted to<br />

keep from falling to the ground, especially on ice or a<br />

crumbling hill [18].<br />

Benefits of Robots with Legs<br />

What makes the gravity problem even more difficult is the<br />

necessity for legged robots rather than treaded or wheeled<br />

ones. Early robots moved on treads, which are successful in<br />

simple motion, but fail on steep hills and blunt objects, such<br />

as dragon’s teeth, shown in Figure 8. Robots with legs have<br />

proven to be more mobile, as their abilities to move are far<br />

more enhanced. Legs offer an active suspension, allowing<br />

the center of mass to shift around to handle various<br />

movements of the robot. A good example of this is a car<br />

with wheels. Cars will travel very quickly on a paved road,<br />

however in even slightly rough and unstable terrain vehicles<br />

with treads such as tanks are more agile. But given a steep<br />

cliff or constantly changing terrain such as a field of bricks<br />

in the aftermath of an earthquake a legged vehicle has the<br />

advantage because it can step over obstacles, jump, and even<br />

climb over changing terrain. A mountain goat can maneuver<br />

in a rocky environment with large boulders, but a tank or a<br />

car would be rendered useless. This complex system means<br />

that stabilizing the robot is much more difficult [18].<br />

Paper 1018<br />

FIGURE 8 [19]<br />

Dragon’s Teeth—a defense structure used in World War II to stop tanks<br />

Animals have many attributes enabling them to balance<br />

themselves when standing, walking, or running, and these<br />

are characteristics that would enhance a robot greatly.<br />

Important things to note about animals are their symmetric<br />

body, their flexible limbs, and their coordination. Applying<br />

these skills to a robot is quite difficult, but the better it is<br />

done, the more stable and agile a robot can be. Symmetry<br />

does not only apply to standing, but also to walking and<br />

running. Flexibility does not simply mean stretching and<br />

shrinking, but also twisting and bending. Coordination<br />

between legs when walking and running is one of the most<br />

important factors, and keeping these things synchronized in<br />

robotics requires much more work than a robot with treads<br />

would [18].<br />

Therefore, legs are inherently more complicated than<br />

wheels because the movements of a leg are extremely<br />

complex, as a wheel simply turns. As an example, wheel<br />

movement can be measured with an encoding disk, as<br />

mentioned before, while a leg requires force and traction<br />

sensors. Mass amounts of calculation need to be done, and<br />

an extremely fast control system is necessary to keep the<br />

robot from collapsing.<br />

THE COMPUTER’S POWER<br />

Initially, computers were too slow to be used as robot<br />

controllers. But once electrical and computer engineers<br />

switched from vacuum tubes to transistors, computers began<br />

to become small and powerful enough to function as robot<br />

controllers [9]. As we have recently seen on “Jeopardy!,”<br />

computers are now powerful enough to answer questions in<br />

under three seconds. International Business Machines, or<br />

IBM, created the supercomputer named Watson for this task.<br />

It was built using ninety IBM Power 750 servers with a total<br />

of sixteen terabytes of memory and 2,880 processor cores.<br />

This immense computing power is necessary for Watson to<br />

University of Pittsburgh Swanson School of Engineering<br />

Eleventh Annual Freshman Conference April 9, 2011<br />

5

achieve its three-second-answer time for every “Jeopardy!”<br />

question. If Watson were to use one processor, it would take<br />

about two hours for it to answer just one question. What<br />

allows Watson to achieve this speed is a combination of<br />

hardware and software. IBM used the Apache Unstructured<br />

Information Management Architecture to sort through the<br />

large amount of information that Watson has stored on its<br />

hard drive. This architecture allows Watson to spread the<br />

processing load across all 2,880 of its processor cores at<br />

once.<br />

Watson has proven that a computer is able to interpret<br />

text and use data that it already knows to answer a question<br />

given the right hardware and software, which is great for<br />

business and computing applications. This is also promising<br />

for the field of robotics in that robots could benefit from the<br />

ability to process this much data all at once and to interpret<br />

visual commands and search an internal database to<br />

determine the best course of action. One way to make robots<br />

more capable is to enable them to make decisions on how to<br />

use their hardware based on the task at hand. For example,<br />

traversing over snow, ice, mud, and sand all require different<br />

movement techniques and if a robot were to move through<br />

this terrain without compensating for the instability of snow<br />

or the slickness of ice, it could get stuck or fall and become<br />

damaged.<br />

While Watson is a good example of computing methods<br />

for rapidly inputting information and finding the best<br />

solution, the fact that it takes up over 180 cubic feet and<br />

consumes as much power as a laundromat makes computer<br />

processing at this scale impossible for mobile robots. Ideally<br />

the parallel processing power and statistical analysis of<br />

Watson would be combined with the size, power<br />

requirement, and reliability of Voyager’s computers.<br />

Nonetheless, lessons such as building computers for a<br />

specific purpose and using distributed computing could be<br />

applied at a smaller scale, making robots more autonomous<br />

[20].<br />

THE PERFECT EXAMPLE: BIGDOG<br />

What is BigDog?<br />

Finally, after discussing control systems, sensors to give<br />

them information, and the benefit of further engineering<br />

research in the speed of computers, we come to a vital<br />

example that exhibits all of these: BigDog. Released in<br />

2008, BigDog is Boston Dynamics’ four-legged robot. The<br />

BigDog project’s goal is to create a robot that can travel<br />

anywhere an animal or human can go. BigDog’s control<br />

system must balance, navigate, and regulate all forms of<br />

movement. Three areas were emphasized in the area of<br />

control: supporting the body through bouncing, controlling<br />

attitude of the body with torques, and key placement of feet<br />

to keep the body symmetric. By utilizing this state of the art<br />

technology with a complex quadruped, BigDog exemplifies<br />

Paper 1018<br />

the correct direction in which intelligent robotics research<br />

should be going [21].<br />

FIGURE 9 [22]<br />

BigDog’s Sensing Ability<br />

BigDog has the ability to sense its surroundings and react to<br />

them in order to keep from falling. It also has the ability to<br />

detect future movements, such as good foot placement.<br />

When a human walks over ice, they do so carefully, looking<br />

for good footing while not shifting too much weight onto a<br />

foot. A robot can hardly know exactly where to place a foot,<br />

and therefore the ability to foresee future movements are<br />

vital.<br />

BigDog has been equipped with close to seventy sensors.<br />

About fifty of these sensors are located on the hips, knees,<br />

ankles, and legs, measuring aspects such as joint<br />

dislocations, force approximations, and servo current.<br />

Without these necessary sensors, BigDog would collapse<br />

when traversing even the easiest terrain. Aside from leg<br />

sensors, six others are gyroscopes used to measure the<br />

body's balance, while three more are used for vision<br />

approximations, such as avoiding obstacles, measuring the<br />

ground slope, or finding patterns in the motion of the<br />

surroundings [22].<br />

BigDog has been proven to have good stability, even<br />

when walking across ice or up an unstable hill. These<br />

sensors are a large portion of the reason why the machine is<br />

so successful, as the data sent to the control system must be<br />

accurate. But, even with an extreme amount of information,<br />

if the computer cannot process and make decisions quickly,<br />

the machine as a whole will still fail.<br />

BigDog’s Stabilization<br />

As previously stated, a legged robot can travel on more<br />

difficult terrain than a treaded one due to its ability to<br />

compensate for small mounds or ditches, but the difficulty of<br />

balancing these robots is great. BigDog's torso weighs about<br />

University of Pittsburgh Swanson School of Engineering<br />

Eleventh Annual Freshman Conference April 9, 2011<br />

6

100 pounds and is able to carry over 300 pounds, meaning<br />

that each leg must do a lot of work to hold it up, especially<br />

when the body is majorly off balance and certain legs are<br />

given much more weight to hold. In order for these things to<br />

happen, symmetry, coordination, and flexibility must be<br />

utilized so that BigDog does not plummet to the ground [21].<br />

BigDog's legs are syncronized in movement. The<br />

machine is extremely symmetrical, taking the form of an<br />

actual dog: If one of the legs were made slightly different<br />

than the rest, the machine would be inherently off balance<br />

and the model would fail. When fixing its balance, the legs<br />

move at the same time so that any lapse in weight being held<br />

is alleviated. As BigDog stumbles, it knows to lower its<br />

body onto its knees simultaneously, lowering the center of<br />

mass and regaining stability, before lifting up again once<br />

balance is achieved. Since the legs act like the limbs of an<br />

animal with numerous amounts of joints, these legs are able<br />

to reach wherever they need to in order to provide good<br />

footing when balance begins to fail.<br />

Each of these abilities is only possible through the<br />

computer's power. Without ample speed for the control<br />

system to decide to tell the legs to bend down on the knees<br />

after processing data indicating the need to do so, correction<br />

would not happen, and BigDog would fall. Therefore, the<br />

most important part of the machine is the control system, as<br />

it must tell which body parts to move after retrieving,<br />

deciding, and reacting at extremely fast rates based on data<br />

[21]. This illustrates the importance of further engineering in<br />

the control system field, making their thought process faster<br />

and more reliable to make machines more capable.<br />

BigDog’s Control System<br />

BigDog's control system exemplifies the reasons why<br />

improvements in control systems are needed. Through all of<br />

the analysis that has been covered on sensors and stability,<br />

the control system has an important job in legged robots.<br />

BigDog's onboard computer is small and must perform<br />

control, sensing, data collection, communications, and the<br />

electric power distribution. Put together, BigDog's control<br />

system must basically do two things: coordinate kinematics<br />

to ground movement processed while correcting instability<br />

[21].<br />

The system uses sensors from the joints to determine the<br />

amount of load each foot should have with each and every<br />

step. Posture is controlled by relating the kinematics of each<br />

leg to the forces of the legs in contact with the ground. With<br />

kinematics in relation to ground forces, BigDog's control<br />

system can regulate body roll, pitch, and its height above<br />

ground, which allows BigDog to adapt to variations in<br />

terrain [21].<br />

BigDog tackles steep terrain by utilizing the ability just<br />

explained. When the path gets steeper, the control system<br />

leans the body forward to account for an off-based center of<br />

mass, as well as leaning back when the path steepens<br />

Paper 1018<br />

downward. More impressively, as BigDog runs along the<br />

side of a hill, the control leans the body towards the hill,<br />

minimizing the torque on the bottom legs, keeping the body<br />

more stable [21]. The ability to shift weight front to back<br />

and side to side proves the necessity of legged robots, as a<br />

treaded one would fall due to its off balance center of mass<br />

on steep slopes.<br />

All of this is just one step of a four step process. First the<br />

control system must retrieve data from the sensors, then<br />

process the data, make a decision of action, and finally tell<br />

BigDog's parts what to do. If this process is not performed<br />

fast enough, BigDog falls. On top of all of this, the control<br />

system must do this over and over again, as it is constantly<br />

fighting gravity and occasionally dealing with unstable<br />

terrain. What is truly remarkable about BigDog is how fast it<br />

can repeat this process. BigDog's sensors gather information<br />

about 1,000 times every second, and the control system<br />

performs this four step process about 200 times every<br />

second. The engineering behind the control has sped up the<br />

system’s ability to correct itself, which is ultimately the<br />

reason for BigDog's success in not falling [22].<br />

A SUSTA<strong>IN</strong>ABLE SYSTEM<br />

Sustainability in a broader sense can be environmental in<br />

regards to conservation or it can involve changing the<br />

environment in a beneficial way. Robots such as BigDog are<br />

showing their value in this latter definition. Through<br />

application of advanced sensors, computer hardware and<br />

software, robots such as iRobot’s Roomba and Segway’s<br />

line of vehicles have come to fruition. The Roomba can<br />

clean houses without any more input than turning it on. This<br />

means that it can vacuum floors, giving its owner the time<br />

for other tasks. This saved time means not only a more open<br />

schedule for humans but also a cleaner living space since a<br />

Roomba can clean more frequently than a human with a<br />

vacuum could on his or her own.<br />

Also improving the human condition are Segway’s<br />

products, which allow people to travel through buildings,<br />

cities, and even nature trails with little effort. The creators of<br />

BigDog hope that it will benefit humans in a similar manner<br />

by carrying equipment through varying and difficult terrain<br />

that wheeled and treaded robots could not handle. Without<br />

the added mobility and stability enabled by the sophisticated<br />

control systems and computers, BigDog could not handle<br />

snow, steep terrain, and elevation changes present in rubble<br />

and rocks as easily as it does. Boston Dynamics has already<br />

proposed that BigDog would be useful for soldiers who<br />

often have hundreds of pounds of supplies and equipment to<br />

carry.<br />

Computers utilizing smaller, faster control systems can<br />

also make buildings more efficient, improving conditions for<br />

their occupants while also reducing unnecessary energy<br />

usage. Control systems define how economically efficient a<br />

process is, as it controls what is turned on and what is turned<br />

University of Pittsburgh Swanson School of Engineering<br />

Eleventh Annual Freshman Conference April 9, 2011<br />

7

off. Companies have switched to a digital control system,<br />

giving them the ability to control multiple processes at the<br />

same time. These central computers provide companies with<br />

the ability to utilize more than one factor in computation<br />

than just one like an older system. Aspects such as heating<br />

and cooling systems, ventilation systems, lighting, etc. can<br />

all be constantly monitored to find the most economical<br />

setting that the company is looking for. By implementing<br />

faster control in smaller spaces, multiple apparatuses do not<br />

have to be implemented into control processes, saving<br />

energy [23].<br />

The faster these control systems are, the more complex<br />

information these systems can have. Their ability to<br />

determine the most efficient solution at a fast pace to<br />

problems given will save time, money and resourses. This<br />

will also help to reduce the large amount of waste disposal<br />

some manufacturing processes posses [23]. Improving the<br />

speed of control will improve human life and save mass<br />

amounts of energy.<br />

Control systems have allowed for reduced waste and<br />

resources in manufacturing processes and thermal control in<br />

buildings, but the control systems themselves are also<br />

representing a reduction in waste. Figure 2 illustrates one of<br />

the first control systems used for controlling an engine’s<br />

speed, which was replaced by a small computer chip.<br />

Changes such as this from analog to digital have made<br />

products more environmentally friendly as they use less<br />

material for their internal systems. This is an oftenoverlooked<br />

benefit of these modern control systems.<br />

POSSIBILITIES FOR THE FUTURE<br />

The control system is an extremely powerful device, giving<br />

users the ability to manipulate robots and make them do<br />

what they want. Through the addition of advanced sensors<br />

giving control systems vital information for making<br />

decisions, robots are able to have legs. With legs, robots like<br />

BigDog have much greater mobility than any robot we have<br />

ever seen before, traveling up slopes, over ice, and through<br />

tough terrain. These advanced sensors and appendages<br />

combined with more powerful computer hardware and<br />

software will make robots of the future more capable,<br />

reliable, and autonomous than ever. Robots like BigDog<br />

show that we are close to having mobile robots that can<br />

handle some of the toughest terrain and recover from slips<br />

and falls without any human intervention, indicating how<br />

close we are to achieving the ultimate science fiction goal:<br />

having a C3PO or iRobot that is capable of inputting<br />

environment data and acting accordingly.<br />

REFERENCES<br />

[1] J. Fulcher L. C. Jain. (2004). Applied Intelligent Systems. Berlin,<br />

Germany: Springer-Verlag.<br />

Paper 1018<br />

[2] C. W. deSilva. (1989). Control Sensors and Actuators. Englewood<br />

Cliffs, NJ: Prentice Hall.<br />

[3]http://upload.wikimedia.org/wikipedia/commons/1/1e/Centrifugal_gover<br />

nor.png<br />

[4] J. Maxwell. (1868). “On Governors”. Proceedings of the Royal Society.<br />

No. 100 p. 1.<br />

[5] K. J. Astrom and R. M. Murray. (2008). Feedback Systems. Princeton,<br />

NJ: Princeton University Press.<br />

[6] Patent: Wisner, D. A. (1968). U.S. Patent No. 3,511,329. Washington,<br />

DC: U.S. Patent and Trademark Office.<br />

[7] C. Phillips, T. Nagle. (1990). “Digital Control: System Analysis and<br />

Design‖. Englewood Cliffs, NJ: Prentice Hall.<br />

[8] B. Barraclough K. Dutton S. Thompson. (1997). The Art of Control<br />

Engineering. Harlow, England: Addison-Wesley.<br />

[9] J. L. Fuller. (1999). Robotics: Introduction, Programming, and<br />

Projects. Upper Saddle River, NJ: Prentice Hall.<br />

[10] S. R. Ruocco. (1987). “Robot Sensors and Transducers‖. New York-<br />

Toronto: Halsted Press.<br />

[11] “iPhone 4: Technical Specs”. Apple. [Online]. Available:<br />

http://www.apple.com/iphone/specs.html<br />

[12] A. C. Staugaard, Jr. (1987). Robotics and AI. Englewood Cliffs, NJ:<br />

Prentice Hall.<br />

[13] (1987, April). “Voyager-The Flying Computer Center”. NASA.<br />

[Online]. Available: http://history.nasa.gov/computers/Ch6-2.html<br />

[14] (2011, February 25). “Frequently Asked Questions”. Jet Propulsion<br />

Laboratory. [Online]. Available: http://voyager.jpl.nasa.gov/faq.html<br />

[15] M. Bajracharya, M.Maimone, D. Helmick. (2008, December).<br />

“Autonomy for Mars Rovers: Past, Present, and Future”. Computer Vol. 41<br />

No. 12 p. 45.<br />

[16] C. Cook. (2010, June 28). “Voyager 2 at 12,000 Days: The Super-<br />

Marathon Continues”. NASA. [Online]. Available:<br />

http://www.nasa.gov/mission_pages/voyager/voyager20100628.html<br />

[17] C. Cook. (2010, May 24). “Engineers Diagnosing Voyager 2 Data<br />

System—Update”. Jet Propulsion Laboratory. [Online]. Available:<br />

http://www.jpl.nasa.gov/news/news.cfm?release=2010-151<br />

[18] M. Raibert. (1986). “Legged Robots That Balance‖. Cambridge,<br />

Massachusetts: MIT Press.<br />

[19]http://upload.wikimedia.org/wikipedia/commons/1/10/Dragons_Teeth_<br />

at_Waverley_Abbey.JPG<br />

[20] “What Powers Watson?” IBM. [Online]. Available: http://www-<br />

03.ibm.com/innovation/us/watson/watson-for-a-smarter-planet/watsonschematic.html<br />

[21] M. Raibert, K. Blankespoor, G. Nelson, R. Playter, and the BigDog<br />

Team. (2008, April 8). “BigDog, the Rough-Terrain Quadruped Robot.”<br />

Boston Dynamics. [Online]. Available:<br />

http://www.bostondynamics.com/bd_index.html<br />

[22] Boston Dynamics. (2008). BigDog Powerpoint Slides. [Online].<br />

Available: http://www.bostondynamics.com/bd_index.html<br />

[23] Pierce, Julia. (2007, Aug. 13). “Sweet Solutions”. Engineer . Vol. 293<br />

Issue 7730, p46-48<br />

ACKNOWLEDGEMENTS<br />

We would like to thank our parents for inspiring our interest<br />

in the field of robotics. Also, we would like to thank our<br />

session co-chair Caitlin Magley and session chair Greg<br />

Wunderley for supporting us during the research process.<br />

University of Pittsburgh Swanson School of Engineering<br />

Eleventh Annual Freshman Conference April 9, 2011<br />

8