'Thin films & coatings' Roadmap - Nano Mahidol

'Thin films & coatings' Roadmap - Nano Mahidol

'Thin films & coatings' Roadmap - Nano Mahidol

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

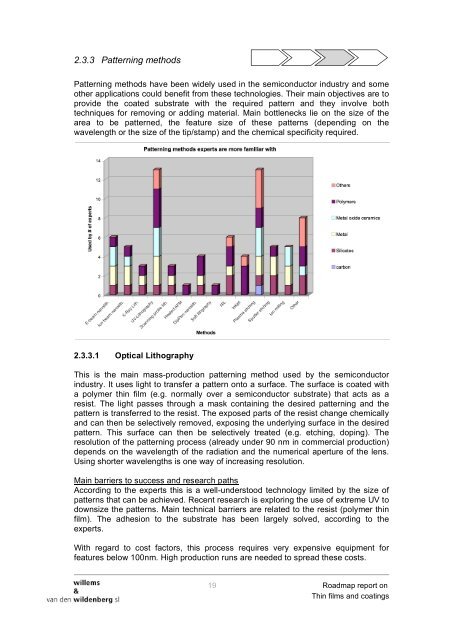

2.3.3 Patterning methods<br />

Patterning methods have been widely used in the semiconductor industry and some<br />

other applications could benefit from these technologies. Their main objectives are to<br />

provide the coated substrate with the required pattern and they involve both<br />

techniques for removing or adding material. Main bottlenecks lie on the size of the<br />

area to be patterned, the feature size of these patterns (depending on the<br />

wavelength or the size of the tip/stamp) and the chemical specificity required.<br />

2.3.3.1 Optical Lithography<br />

This is the main mass-production patterning method used by the semiconductor<br />

industry. It uses light to transfer a pattern onto a surface. The surface is coated with<br />

a polymer thin film (e.g. normally over a semiconductor substrate) that acts as a<br />

resist. The light passes through a mask containing the desired patterning and the<br />

pattern is transferred to the resist. The exposed parts of the resist change chemically<br />

and can then be selectively removed, exposing the underlying surface in the desired<br />

pattern. This surface can then be selectively treated (e.g. etching, doping). The<br />

resolution of the patterning process (already under 90 nm in commercial production)<br />

depends on the wavelength of the radiation and the numerical aperture of the lens.<br />

Using shorter wavelengths is one way of increasing resolution.<br />

Main barriers to success and research paths<br />

According to the experts this is a well-understood technology limited by the size of<br />

patterns that can be achieved. Recent research is exploring the use of extreme UV to<br />

downsize the patterns. Main technical barriers are related to the resist (polymer thin<br />

film). The adhesion to the substrate has been largely solved, according to the<br />

experts.<br />

With regard to cost factors, this process requires very expensive equipment for<br />

features below 100nm. High production runs are needed to spread these costs.<br />

19 <strong>Roadmap</strong> report on<br />

Thin <strong>films</strong> and coatings