comparative study for mrr on die-sinking edm using electrode ... - ijater

comparative study for mrr on die-sinking edm using electrode ... - ijater

comparative study for mrr on die-sinking edm using electrode ... - ijater

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Internati<strong>on</strong>al Journal of Advanced Technology & Engineering Research (IJATER)<br />

. μsec work piece<br />

(gm)<br />

Tool<br />

(gm)<br />

Wwb Wwa Wtb Wta<br />

1 4 1 50 354.760 354.470 28.923 28.921<br />

2 4 2 50 354.470 353.595 28.921 28.919<br />

3 4 3 50 353.595 352.103 28.919 28.918<br />

4 4 4 50 352.103 350.662 28.918 28.916<br />

5 4 5 50 350.662 349.415 28.916 28.914<br />

D C = Diameter of copper <strong>electrode</strong>,<br />

I = Current,<br />

Wwb = Weight of the workpiece be<str<strong>on</strong>g>for</str<strong>on</strong>g>e machining<br />

Wwa = Weight of the workpiece after machining<br />

Wtb = Weight of the tool be<str<strong>on</strong>g>for</str<strong>on</strong>g>e machining<br />

Wta = Weight of the tool after machining<br />

N. (mm) (A) (μsec) (mm3/min) (gm/min)<br />

1 4 1 50 0.743 1.67E-05<br />

2 4 2 50 1.942 1.67E-05<br />

3 4 3 50 3.199 1.67E-05<br />

4 4 4 50 3.144 3.33E-05<br />

5 4 5 50 2.800 3.33E-05<br />

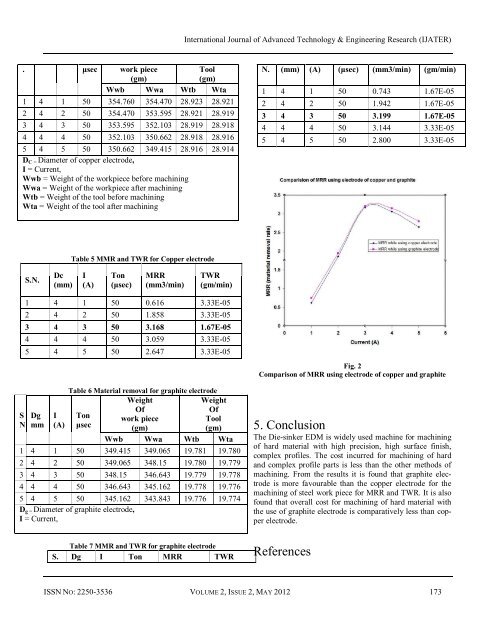

Table 5 MMR and TWR <str<strong>on</strong>g>for</str<strong>on</strong>g> Copper <strong>electrode</strong><br />

S.N.<br />

Dc<br />

(mm)<br />

I<br />

(A)<br />

T<strong>on</strong><br />

(μsec)<br />

MRR<br />

(mm3/min)<br />

TWR<br />

(gm/min)<br />

S<br />

N<br />

1 4 1 50 0.616 3.33E-05<br />

2 4 2 50 1.858 3.33E-05<br />

3 4 3 50 3.168 1.67E-05<br />

4 4 4 50 3.059 3.33E-05<br />

5 4 5 50 2.647 3.33E-05<br />

Dg<br />

mm<br />

I<br />

(A)<br />

Table 6 Material removal <str<strong>on</strong>g>for</str<strong>on</strong>g> graphite <strong>electrode</strong><br />

Weight<br />

Weight<br />

Of<br />

Of<br />

T<strong>on</strong> work piece<br />

Tool<br />

μsec (gm)<br />

(gm)<br />

Wwb Wwa Wtb Wta<br />

1 4 1 50 349.415 349.065 19.781 19.780<br />

2 4 2 50 349.065 348.15 19.780 19.779<br />

3 4 3 50 348.15 346.643 19.779 19.778<br />

4 4 4 50 346.643 345.162 19.778 19.776<br />

5 4 5 50 345.162 343.843 19.776 19.774<br />

D g = Diameter of graphite <strong>electrode</strong>,<br />

I = Current,<br />

Fig. 2<br />

Comparis<strong>on</strong> of MRR <strong>using</strong> <strong>electrode</strong> of copper and graphite<br />

5. C<strong>on</strong>clusi<strong>on</strong><br />

The Die-sinker EDM is widely used machine <str<strong>on</strong>g>for</str<strong>on</strong>g> machining<br />

of hard material with high precisi<strong>on</strong>, high surface finish,<br />

complex profiles. The cost incurred <str<strong>on</strong>g>for</str<strong>on</strong>g> machining of hard<br />

and complex profile parts is less than the other methods of<br />

machining. From the results it is found that graphite <strong>electrode</strong><br />

is more favourable than the copper <strong>electrode</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> the<br />

machining of steel work piece <str<strong>on</strong>g>for</str<strong>on</strong>g> MRR and TWR. It is also<br />

found that overall cost <str<strong>on</strong>g>for</str<strong>on</strong>g> machining of hard material with<br />

the use of graphite <strong>electrode</strong> is <str<strong>on</strong>g>comparative</str<strong>on</strong>g>ly less than copper<br />

<strong>electrode</strong>.<br />

Table 7 MMR and TWR <str<strong>on</strong>g>for</str<strong>on</strong>g> graphite <strong>electrode</strong><br />

S. Dg I T<strong>on</strong> MRR TWR<br />

References<br />

ISSN NO: 2250-3536 VOLUME 2, ISSUE 2, MAY 2012 173