You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

Het Bijvank 251a, 7544 DB Enschede, The Netherlands<br />

P.O. Box 40175, 7504 RD Enschede, The Netherlands<br />

Phone: +31 53 4762619 Fax: +31 53 4771905<br />

E-mail: info@humeca.nl Web: www.humeca.nl<br />

General remark<br />

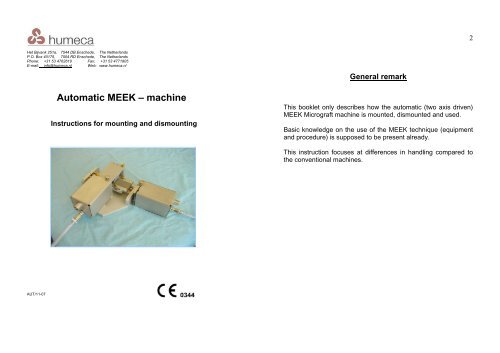

<strong>Automatic</strong> <strong>MEEK</strong> <strong>–</strong> <strong>machine</strong><br />

Instructions for mounting and dismounting<br />

This booklet only describes how the automatic (two axis driven)<br />

<strong>MEEK</strong> Micrograft <strong>machine</strong> is mounted, dismounted and used.<br />

Basic knowledge on the use of the <strong>MEEK</strong> technique (equipment<br />

and procedure) is supposed to be present already.<br />

This instruction focuses at differences in handling compared to<br />

the conventional <strong>machine</strong>s.<br />

AUT/11-07

Contents<br />

3<br />

I. The basic parts of the automatic <strong>machine</strong><br />

4<br />

I. The basic parts of the automatic <strong>machine</strong> 4<br />

II. Assembling the <strong>machine</strong><br />

II-1. Placing the pneumatic motors 5<br />

I-1a. Placing the motor for drive of the cutting axis 5<br />

I-1b. Placing the motor for drive of the spindle 7<br />

II-2. Connecting the air hoses for pneumatic drive 8<br />

III. Using the <strong>machine</strong> 10<br />

Fig. 1 The basic parts of the automatic <strong>MEEK</strong> <strong>machine</strong><br />

The automatic <strong>MEEK</strong> <strong>machine</strong> consists of the following main parts:<br />

1 The frame with cutting block (single or double)<br />

2 Two identical stainless steel motor housings<br />

3 A pneumatic motor to drive the spindle<br />

4 A pneumatic motor driving the cutting axis (the picture<br />

shows a block motor, but the motor might also be one of<br />

the cylindrical type).<br />

5 A foot pedal (not shown in the picture)<br />

6 A splitted hose with 3 connectors (not shown either).<br />

Attention: The motors are not to be sterilized!!

II. Assembling the <strong>machine</strong><br />

5<br />

6<br />

II-1. Placing the pneumatic motors<br />

A new automatic <strong>MEEK</strong> <strong>machine</strong> is provided with two motors.<br />

However, if your existing motor driven <strong>machine</strong> was modified to an<br />

automatic model, probably your original motor was suitable to reuse<br />

it to drive the cutting axis.<br />

Fig. 3. The motor is placed in the<br />

motor housing<br />

Fig. 4. The motor in correct position<br />

in its housing<br />

Fig. 2. the two motors that are supplied in case of a new <strong>machine</strong><br />

Fig. 2 shows both motors of a new <strong>machine</strong>. Please note that the<br />

couplings of the motors (the round plastic parts) are not the same<br />

size. The motor with the smallest coupling is the one for drive of<br />

the cutting axis; the other motor will drive the spindle (movement of<br />

the cutting block). The two motor housings are identical.<br />

Now place the casing with the motor inside on the <strong>machine</strong> in a<br />

way that the two screws 10 slide into the two slits 3a at the<br />

bottom side of the casing (marked with red colour in fig. 5).<br />

Push the plastic coupling of the motor over the corresponding<br />

metal coupling of the knives axis and push further until the<br />

screw 9 comes into the slot 3b of the casing (fig. 6). Fasten<br />

screw 9 by hand (fig. 7).<br />

Attention: prevent the motor from falling out of the casing!<br />

II-1a. Placing the motor for drive of the cutting axis<br />

This procedure is not different from the one already known:<br />

See fig. 3 and 4. A circulating nurse places the unsterile motor<br />

into the sterile casing, which is held in position by authorized<br />

personnel. The motor is placed in the casing in such a way that<br />

the sound reducer (the cylinder with porous material at the back<br />

of the motor) comes in the little pipe at the back of the casing.<br />

Fig. 5. The screws 10 must slide<br />

into the slits 3a<br />

Fig. 6. Placing the motor for drive of<br />

the cutting axis on the <strong>machine</strong>

7<br />

8<br />

Fig. 7. Fixing the motor housing with motor inside to the <strong>machine</strong><br />

II-1b. Placing the motor for drive of the spindle<br />

Put the motor with the larger coupling in the second motor<br />

housing (procedure same as shown in fig. 3 and 4). Push the<br />

plastic coupling of the motor over the corresponding metal<br />

coupling of the spindle axis and push further until the screw 9a<br />

comes into the slot 3b of the casing (fig. 8 and 9). Fasten screw<br />

9a (fig. 10).<br />

Fig. 10. Fixing the motor housing with motor inside to the <strong>machine</strong><br />

II-2. Connecting the air hoses for pneumatic drive<br />

The automatic <strong>MEEK</strong> <strong>machine</strong> was supplied with a hose with Y-<br />

crossing and 3 connectors. Two connectors are identical and<br />

one is different. Connect the 2 identical connectors to the two<br />

motors of the <strong>machine</strong> (simply push the connectors over the<br />

motor inlets, as shown in fig. 11).<br />

Fig. 8. Placing the motor for driving<br />

the spindle axis on the <strong>machine</strong><br />

Fig. 9. Motor in correct position<br />

Fig. 11. Coupling the<br />

hose to the motor

9<br />

The foot pedal has two connections. One hose is already fixed<br />

to a connection. Connect the other end of that hose to the third<br />

connector of the hose supplied with the <strong>machine</strong> (fig. 12).<br />

III. Using the <strong>machine</strong><br />

After having filled the cutting block with a cork plate and graft, put<br />

the block on the <strong>machine</strong> at the side of the motor that will drive the<br />

spindle. Now press the foot pedal. You will notice that the block will<br />

not move instantly. This is for safety reasons. The block will start<br />

running after you push it a little in the direction of movement while<br />

pressing the foot pedal (see fig. 14).<br />

10<br />

Fig. 12. Coupling the hose of the <strong>machine</strong> to the hose of<br />

the foot pedal<br />

Connect the inlet of the foot pedal to the pressure air outlet in<br />

the operating theatre. Because there is a large variety in hose<br />

diameters and connectors in use at hospitals, we cannot supply<br />

the air hose between the foot pedal and the pressure system in<br />

the operating room. Please arrange a suitable hose for that<br />

purpose yourself. We’re happy to assist you if necessary. A<br />

pressure of 5-6 bar is required to run the motors.<br />

The apparatus is now ready<br />

for use (fig. 13). Lubricate<br />

the <strong>machine</strong> as usual.<br />

For dismounting the<br />

<strong>machine</strong>, you act in reverse<br />

order.<br />

Fig. 14. For safety reasons the block will only move after a<br />

gentle push<br />

When the block reaches the other side of the <strong>machine</strong>, it will stop<br />

automatically. Please take it off and go ahead with a second block<br />

if you like. Of course the cutting procedure is speeded up when<br />

two blocks are used, especially if both blocks are double blocks.<br />

Fig. 13. <strong>Automatic</strong> <strong>MEEK</strong><br />

<strong>machine</strong> after assemblage