Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Autumn/Winter ’06<br />

Volume 42/No.2<br />

Launching Our New Identity

Contents<br />

Articles<br />

View from the MD’s Desk 4<br />

Rupert Hogg charts a fundamental process of change within<br />

the Group’s structure and communications systems.<br />

Rethinking the Brand 6<br />

Creating a consistent look and feel for all our businesses.<br />

Project Lily 10<br />

Flowers go East.<br />

The Interaction Factor 11<br />

JF (Colombo) moves Human Resources up the agenda.<br />

Open Sesame! 12<br />

A dramatic new look for 186 Vauxhall Street, Colombo.<br />

Linking the Coffee Chain 14<br />

‘Our purpose is to serve our farmers’: a fresh view of<br />

the Colombian market.<br />

‘A Special Place in the Heart’ 16<br />

Revisiting the High Range, ‘a jewel in the former Finlay crown’.<br />

Pensioners’ Reunion 18<br />

Friends and former colleagues catch up.<br />

<strong>News</strong><br />

Head Office 19<br />

Tea Estates 19<br />

Tea Trading 22<br />

Tea Extracts 23<br />

Beverages 23<br />

Flowers 26<br />

Sri Lanka 27<br />

US 28<br />

Pakistan 29<br />

Announcements<br />

Births & Marriages 30<br />

Deaths inside back cover<br />

Front Cover A fresh new look for <strong>Finlays</strong>, but tea remains a constant.<br />

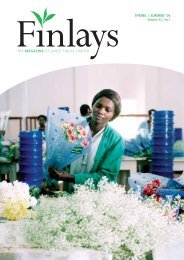

Inside Front Cover Roses, Flowers' primary crop, sleeved and ready for shipment.<br />

Back Cover Instant identification, from London to Nanjing: a soluble tea product sports<br />

our new logo.<br />

3

4<br />

View from the MD’s Desk Rupert Hogg<br />

The decision to make this move has not<br />

been taken lightly. <strong>Finlays</strong> is an old and<br />

venerable Scottish company, established<br />

as long ago as 1750, only five years after<br />

the battle of Culloden. During much of<br />

the ensuing 250 years the company<br />

has played a prominent role in the civic<br />

and commercial affairs of the city of<br />

Glasgow as well in the communities of<br />

Catrine and Deanston.<br />

However, we have not had a Scottish-based<br />

operational business for a decade and the<br />

larger of those former businesses were<br />

closed or sold in the decades prior<br />

to that. It is also the case that many of<br />

the smaller businesses that were started<br />

during the same period, such as Flowers,<br />

Tea Trading and Tea Extracts, have grown or<br />

evolved considerably to become significant<br />

businesses in their own right and have real<br />

prospects for rapid growth.<br />

First steps into China: the new joint venture tea extracts<br />

plant at Nanjing takes shape. Tony Barcroft (r) is seen here<br />

with George Chan (l), Director <strong>Finlays</strong> Hong Kong and<br />

David Jiang, Chairman of the Damin International Group.<br />

There is much going on at present, both within James Finlay<br />

and the broader markets in which we operate; I will make<br />

mention of some of these trends later in this article. However,<br />

without question, the most important piece of news that I have<br />

to report is tinged with sadness: that is the fact that the Head<br />

Office and Glasgow operations of James Finlay Limited are to<br />

move to London as of the middle of next year.<br />

These businesses are now led and managed<br />

from London. In addition, as some of the<br />

articles in this edition may illustrate, many<br />

of the competitive and consumer trends to<br />

which the individual group companies<br />

identify and respond now require a far<br />

greater degree of coordination across the<br />

Group than has been the case in the past.<br />

Thus, the driving thrust behind the decision<br />

to move the head office closer to some of<br />

our subsidiaries is underpinned by the<br />

desire to improve our ability to coordinate<br />

and communicate internally and therefore<br />

to improve the products and services that<br />

we offer our customers externally.<br />

That is the rationale behind the decision to<br />

move the head office to London and that is<br />

what we intend to achieve by so doing.<br />

However, none of this diminishes the fact<br />

that the move represents the end of an era<br />

and that, more importantly, it is likely to<br />

mean redundancies for the great majority of<br />

the current team that have worked in the<br />

Glasgow office and contributed so much to<br />

<strong>Finlays</strong>. I can only state that the Directors<br />

and Shareholders appreciate this and that<br />

the writing of this article offers me the<br />

opportunity to publicly thank those<br />

concerned for that contribution and for<br />

their continued support until the transition<br />

is complete.<br />

I hope that the reader will notice that this<br />

edition of <strong>Finlays</strong> Magazine has a new look<br />

and that the traditional tea leaf motif has<br />

evolved too. These changes result from a<br />

re-branding exercise that is described<br />

elsewhere in this edition (page 6).<br />

While the outcome may be visually striking,<br />

the exercise itself is but a logical step in a<br />

more fundamental process of change<br />

within <strong>Finlays</strong>.<br />

The first objective has been to move<br />

towards a functional and divisional<br />

structure and away from the Group’s<br />

traditional geographic basis. This process is<br />

incomplete as yet but, as an indication,<br />

several of the subsidiary businesses now<br />

have Managing Directors who are<br />

responsible for all of the activities of their<br />

division on a global basis, a much simpler<br />

and more customer-focused proposition.<br />

The second objective, to which I have<br />

already referred, comes from within the<br />

Group itself: the need for the Group to be<br />

more cohesive and coordinated in its<br />

approach to the market and to our major<br />

customers on issues that impact us all and<br />

which are important to that wider customer<br />

base. From a communications perspective,<br />

the inference of such trends is obvious; we<br />

need a common look and feel across the<br />

Group and we need to become more<br />

uniform and consistent in the way in which<br />

we present ourselves. I believe that this<br />

exercise has managed that evolution well<br />

and injected a desirable dose of freshness<br />

and modernity to our ‘look’ in the process.<br />

<strong>Finlays</strong> has a fine record for social and<br />

environmental responsibility; I hope that<br />

what we do on the ground demonstrates<br />

that there is real substance behind such a<br />

claim. To a great degree, the Fairtrade<br />

accreditation scheme, of which many<br />

consumers are aware, acknowledges these<br />

credentials. All of our flower farms and<br />

some of our tea estates have either obtained<br />

or are in the final stages of obtaining

Tea Estates Tea Trading Tea Extracts Beverages Flowers Logistics Services<br />

Kenya UK<br />

Tea<br />

Decaffeination<br />

UK<br />

UK UK<br />

Uganda<br />

Kenya<br />

China<br />

Sri Lanka Kenya<br />

Sri Lanka<br />

Malawi<br />

USA<br />

China<br />

USA<br />

Gulf<br />

Vietnam<br />

Kenya<br />

Fairtrade accreditation and they also<br />

comply with a series of other bodies that<br />

audit against material evidence of social<br />

and environmental standards.<br />

This is important for <strong>Finlays</strong>, not least<br />

because it resonates with our values and<br />

beliefs, but also because it is important to<br />

our customers; they take their<br />

responsibilities seriously in this regard. It is<br />

quite clear that they wish to source<br />

products from suppliers who can<br />

demonstrate a proven track record and who<br />

are genuinely interested in improving<br />

further in these areas; we are placing<br />

additional resources and a high priority on<br />

our Corporate Social Responsibility<br />

programme as a result.<br />

The current debate on climate change adds<br />

further impetus in this regard. There is<br />

broad consensus within <strong>Finlays</strong> that man’s<br />

activities have influenced and continue to<br />

influence the world’s climate and there is a<br />

strong desire to ensure that we do our bit<br />

to minimise our own impact. It is equally<br />

important that any plans that we develop<br />

are informed by fact and we have<br />

commissioned a Group-wide study to<br />

determine <strong>Finlays</strong> ‘carbon footprint’: what<br />

we emit but also what we might absorb, and<br />

to give us a quantifiable baseline from<br />

which to improve. I am confident we can<br />

make real progress here too; opportunites<br />

in the area of clean energy provision is one<br />

example of where work is already at a<br />

relatively advanced stage.<br />

From an operational and business<br />

development perspective there is activity<br />

aplenty too. The year 2007 will mark the<br />

Omniflora<br />

Germany<br />

USA<br />

Jetflowers<br />

Kenya<br />

Sri Lanka<br />

Temperature<br />

Controlled<br />

Logistics<br />

USA<br />

Inventory<br />

Management<br />

first stage of the Group’s expansion into<br />

China. There are two projects of note: the<br />

first, the establishment of a flower farm in<br />

Kunming is reported on (page 10).<br />

Sri Lanka<br />

Agencies<br />

Environmental<br />

Services<br />

Insurance<br />

Pakistan<br />

The second initiative is the establishment of<br />

a joint venture with the Damin Group to<br />

build and operate a tea extracts plant in<br />

Nanjing. The Tea Extracts division has<br />

worked closely and productively with<br />

Damin over the last two years. In addition<br />

to other businesses, Damin International, a<br />

Xiamen-based company, is the largest<br />

producer of tea extracts in China and has<br />

expanded rapidly and successfully in the<br />

domestic PRC market. <strong>Finlays</strong> and Damin<br />

have had a joint sales agreement to<br />

promote and sell each other’s products in<br />

their respective markets for some time. The<br />

new plant in Nanjing will allow both parties<br />

to strengthen their ties and to offer a<br />

broader product range to their mutual<br />

customers. The plant is due to be<br />

commissioned in 2007.<br />

2006 has been a satisfactory year for<br />

<strong>Finlays</strong>: the results reflect a mix of fortunes<br />

across the various companies but, overall,<br />

the highs outweigh the lows and we have<br />

made real progress against our business<br />

plans in all of the subsidiaries.<br />

It only remains for me to acknowledge that<br />

Pat Lockett, who has held the position of<br />

Group Finance Director for the last 11 years,<br />

has decided that he would prefer not to<br />

make the move to London and has instead<br />

opted to leave <strong>Finlays</strong> at the end of this<br />

year. This, I hope and suspect, does not<br />

mean that his active life in Scottish business<br />

circles will not continue. Pat has held an<br />

instrumental position over a period of<br />

<strong>Finlays</strong>' move away from its traditional<br />

geographic basis towards a functional and<br />

divisional structure is reflected by its new and<br />

consistent brand image.<br />

great change,<br />

encompassing the<br />

change of<br />

ownership and the<br />

transition from<br />

being a public to a<br />

private company;<br />

also the rapid<br />

development of<br />

many of the<br />

Pat Lockett<br />

subsidiary<br />

businesses.<br />

The Group has benefited from his presence<br />

and I know that he will be missed on a<br />

personal basis by many employees, past<br />

and present. Pat has promised to write an<br />

article for the next edition, reflecting on<br />

his time with the company; in the meantime<br />

we send him and Erica our best wishes for<br />

the future.<br />

5

6<br />

Rethinking the Brand Simon Large<br />

At the beginning of 2006 we decided to conduct<br />

a review of our brand. That is, we wanted to take<br />

a long hard look at how and what we communicate<br />

to our employees, customers and stakeholders,<br />

in order to understand how we are perceived<br />

and what we stand for.<br />

Having called upon the services of<br />

a London-based brand consultancy –<br />

FutureBrand – and many people<br />

across different parts of the business,<br />

it became immediately apparent<br />

that our current visual identity was<br />

inconsistently applied. Across the<br />

globe we have different company<br />

names, logos, websites, typefaces,<br />

taglines and signage (see above).<br />

This was delivering an inconsistent<br />

message and tone of voice.<br />

One of the main reasons for the<br />

lack of consistency was the limited<br />

guidelines and advice previously<br />

provided to the Group on the<br />

application and delivery of a clear,<br />

single, visual message. With the<br />

growth, expansion and increasing<br />

competition that we are experiencing,<br />

it was imperative to re-establish our<br />

brand’s personality, institute a<br />

clearer set of values and develop<br />

a new and unified visual brand identity.<br />

To start with, a detailed questionnaire<br />

was circulated to different people<br />

across the group, and supported<br />

with creative workshops. This work<br />

not only helped to evaluate us against<br />

our competition and establish what<br />

makes us unique, it enabled us to<br />

agree what we should stand for,<br />

going forward.<br />

Three main themes arose from<br />

this exploratory phase. First, we<br />

established that our rich heritage<br />

and tradition is fundamental to<br />

what we are today, and we are<br />

unanimously proud of it.<br />

Secondly, our knowledge and our<br />

passion for our products are equally<br />

prevalent. Thirdly, the care we<br />

have for the environment, our<br />

people and our communities is<br />

integral to our organisation and<br />

the way we behave. These values<br />

were considered along with our<br />

natural, contemporary and<br />

multicultural personality to inform<br />

and shape our new visual brand<br />

identity and the way we will<br />

communicate in the future.

Going forward, we will be identified<br />

as a single brand, with a single name –<br />

<strong>Finlays</strong> – which will be applied right<br />

across the Group. This conveys a<br />

strong, simple and consistent branded<br />

message to all stakeholders: that we<br />

are proud of the <strong>Finlays</strong> name and all<br />

that it has come to stand for. Therefore,<br />

all functions within the business, from<br />

Tea Extracts, to Flowers to Logistics,<br />

will adopt the ‘<strong>Finlays</strong>’ brand.<br />

We have created a new visual identity<br />

that’s fresh and contemporary, that will<br />

be consistently applied across all<br />

touchpoints, and supported with a<br />

set of clear and comprehensive<br />

guidelines. The visual identity still<br />

retains strong links with our heritage<br />

and exudes naturalness through a<br />

core green colour palette.<br />

One of the main drivers for refreshing<br />

our visual identity was our current<br />

corporate logo. Despite the fact that<br />

the tea leaf icon is representative<br />

of our heritage and experience in<br />

cultivating, distributing and packaging<br />

tea, it is not distinctive (many companies<br />

now have tea leaf logos), and no<br />

longer accurately reflects our diverse<br />

business functions. Our new logo is<br />

unique, contemporary and impactful,<br />

and more aligned with all our<br />

business divisions.<br />

Continued overleaf...<br />

7

8<br />

Pullout to go in here lorem ipsum<br />

dolor consequet, lorem ipsum alore.<br />

Support headline in here lorem ips<br />

dol nommy et. Nommy esqueirtes<br />

rioeters et. Lorem ipsum dolor con,<br />

lorem ipsum et alore.<br />

Introduction to go here era eget orcit leo. Lorem ipsum dolor conus, volpat<br />

sed loremipsumet alore. Mauis amety eget san eget orci. Sed sed nunc<br />

erat laor congue arcute tempor pulvi dolor placer tin sedent sagitis imperdie.<br />

Introduction to go here era eget orcit leo. Lorem ipsum dolor conus, volpat<br />

sed loremipsumet alore. Mauis amety eget san eget orci. Sed sed nunc<br />

rcute tempor pulvi dolor placer tin sedent sagitis imperdie.<br />

Introduction to go here era eget orcit leo. Lorem ipsum dolor conus, volpat<br />

sed loremipsumet alore. Mauis amety eget san eget orci. Sed sed n<br />

Introduction to go here era eget orcit leo. Lorem ipsum dolor conus, volpat<br />

sed loremipsumet alore. Mauis amety eget san eget orci. Sed sed nunc<br />

erat laor congue arcute tempor pulvi dolor placer tin sedent sagitis imperdie.<br />

Introduction to go here era eget orcit leo. Lorem ipsum dolor conus, volpat<br />

sed loremipsumet alore. Mauis amety eget san.<br />

To enable our offices and employees<br />

to create and develop platforms<br />

and materials for communications,<br />

we have created a range of applications<br />

along with our new brand guidelines.<br />

This includes new corporate<br />

stationery, printed literature,<br />

signage, vehicle livery and<br />

photography (which will be<br />

expanded in the future), all of<br />

which have the consistency that<br />

was previously lacking. We have<br />

also established clear standards<br />

for the application of the Swire<br />

brand to endorse the <strong>Finlays</strong><br />

brand. Again this was an area<br />

which had previously been very<br />

erratic due to the lack of guidelines.

We have created a distinctive<br />

visual identity for our Flowers,<br />

Services and Logistics businesses,<br />

in order to differentiate them<br />

from the tea and beverages<br />

businesses within the Group and<br />

provide them with a stronger<br />

presence within their markets.<br />

They retain the Group brand<br />

identity, but feature colour<br />

palettes that are inspired by their<br />

products, services and<br />

environments. The Flowers visual<br />

identity – comprising warm tones<br />

– is inspired by the flowers we<br />

grow and nurture on our estates<br />

in Kenya, whilst the colour palette<br />

for our Services and Logistics<br />

businesses – comprising cool tones –<br />

has been inspired by the<br />

functions of the cold storage and<br />

logistics business.<br />

Developing our new visual identity<br />

and creating the guidelines was<br />

the first necessary stage in<br />

re-launching the brand. The next<br />

crucial steps will be its consistent<br />

implementation across the Group,<br />

as well as our future adherence to<br />

these new standards.<br />

Simon Large<br />

Commercial Director<br />

Temperature<br />

Controlled<br />

Logistics<br />

Site A<br />

Support copy would go in this area<br />

lorem ipsum dolor consequet<br />

Temperature<br />

Controlled<br />

Logistics<br />

www.finlays.com<br />

Support copy would go in this area<br />

lorem ipsum dolor consequet<br />

Pullout to go in here lorem ipsum<br />

dolor consequet, lorem ipsum alore.<br />

Support headline in here lorem ips<br />

dol nommy et. Nommy esqueirtes<br />

rioeters et. Lorem ipsum dolor con,<br />

lorem ipsum et alore.<br />

Support copy would go in this area<br />

lorem ipsum dolor consequet<br />

Introduction to go here era<br />

eget orcit leo. Lorem ipsum<br />

dolor conus, volpat sed lorem<br />

ipsumet alore. Mauis amety<br />

eget san eget orci. Sed sed nunc<br />

erat laor congue arcute tempor<br />

pulvi dolor placer tin sedent<br />

sagitis imperdie.<br />

Headline to go here<br />

Introduction to go here era<br />

Lorem ipsum dolor conus,<br />

lorem ipsum et alore mauis<br />

eget orci. Sed sed nunc erat<br />

arcu tempor pulvinar dolor<br />

Vivamu sagitis imperdie.<br />

Nunc ut velit non neque placerat ullamcorper. Mauris eget orci. Sed adipiscing. Integer metus. Aliquam ante leo, volutpat a, mollis<br />

Sed sed nunc et arcu tempor pulvinar. Vivamus sagittis imperdiet sed, porta id, ipsum. Quisque neque leo, aliquam faucibus, gravida<br />

augue. Aenean urna. Aenean id sem. Sed a mauris sed mauris et, nonummy id, justo. In dolor nisi, vehicula id, consequat at,<br />

condimentum faucibus. Ut nunc sapien, imperdiet non, vehicula bibendum eget, odio. Vestibulum et nibh. Suspendisse porttitor<br />

eget, dignissim sit amet, massa. Aliquam ac mi id erat eleifend accumsan ante. Integer ante lectus, imperdiet eu, congue eget,<br />

consequat. Phasellus feugiat dolor sed lorem. Nam consectetuer sagittis sit amet, lacus. Curabitur pellentesque egestas purus. Nam<br />

velit quis pede. Maecenas convallis libero. Suspendisse potenti. erat. Maecenas eu tortor. Curabitur lobortis aliquet augue. Curabitur<br />

Praesent massa purus, convallis euismod, placerat ac, tristique vel, laoreet justo quis ipsum. Sed pede massa, vulputate eget, tincidunt<br />

purus. Suspendisse potenti. Sed molestie, metus rhoncus vehicula sed, vulputate a, orci.<br />

porta, risus nibh pretium eros, id blandit leo nisi non erat.<br />

Praesent sed metus consequat nisl iaculis euismod. Aliquam erat<br />

Praesent sed metus consequat nisl iaculis euismod. Aliquam erat volutpat. Nulla facilisi. Suspendisse enim felis, consequat porttitor,<br />

volutpat. Nulla facilisi. Suspendisse enim felis, consequat porttitor, vehicula sit amet, eleifend sit amet, orci. Suspendisse potenti.<br />

vehicula sit amet, eleifend sit amet, orci. Suspendisse potenti. Donec Donec magna magna, sodales sed, facilisis id, dignissim vel, turpis.<br />

magna magna, sodales sed, facilisis id, dignissim vel, turpis. Sed nisl Sed nisl elit, lobortis eget, laoreet eu, egestas id, magna. Donec<br />

elit, lobortis eget, laoreet eu, egestas id, magna.<br />

feugiat, erat in ullamcorper porta, sem lacus lobortis quam, a<br />

tempus justo mi id urna. Suspendisse nulla. Donec varius aliquet<br />

Nunc ut velit non neque placerat ullamcorper. Mauris eget orci. pede. Proin viverra ipsum eu risus. Aliquam erat volutpat. Donec<br />

Sed sed nunc et arcu tempor pulvinar. Vivamus sagittis imperdiet adipiscing dolor in massa.<br />

augue. Aenean urna. Aenean id sem. Sed a mauris sed mauris<br />

condimentum faucibus. Ut nunc sapien, imperdiet non, vehicula Praesent sed metus consequat nisl iaculis euismod. Aliquam erat<br />

eget, dignissim sit amet, massa. Aliquam ac mi id erat eleifend volutpat. Nulla facilisi. Suspendisse enim felis, consequat porttitor,<br />

consequat. Phasellus feugiat dolor sed lorem. Nam consectetuer vehicula sit amet, eleifend sit amet, orci. Suspendisse potenti.<br />

velit quis pede. Maecenas convallis libero. Suspendisse potenti. Donec magna magna, sodales sed, facilisis id, dignissim vel, turpis.<br />

Praesent massa purus, convallis euismod, placerat ac, tristique vel, Sed nisl elit, lobortis eget, laoreet eu, egestas id, magna.<br />

purus. Suspendisse potenti. Sed molestie, metus rhoncus vehicula<br />

porta, risus nibh pretium eros, id blandit leo nisi non erat.<br />

Praesent sed metus consequat nisl iaculis euismod. Aliquam erat<br />

volutpat. Nulla facilisi. Suspendisse enim felis, consequat porttitor,<br />

vehicula sit amet, eleifend sit amet, orci. Suspendisse potenti. Donec<br />

magna magna, sodales sed, facilisis id, dignissim vel, turpis. Sed nisl<br />

elit, lobortis eget, laoreet eu, egestas id, magna. Donec feugiat, erat<br />

in ullamcorper porta, sem lacus lobortis quam, a tempus justo mi id<br />

urna. Suspendisse nulla. Donec varius aliquet pede. Proin viverra<br />

ipsum eu risus. Aliquam erat volutpat. Donec adipiscing dolor in<br />

massa.<br />

9

10<br />

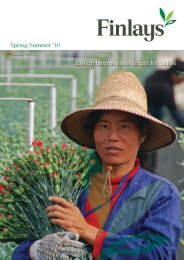

Project Lily Nev Harries<br />

In 1996 Finlay Flowers established a joint<br />

venture with Hilverda Plant Technology, a<br />

well known and respected Dutch company<br />

specialising in the breeding and<br />

propagation of carnation, alstroemeria and<br />

limonium plants. The joint venture is<br />

involved in the production of standard<br />

and spray carnation cuttings here on our<br />

tea estates in Kericho. From a production<br />

area of 3 Ha, over 20 million cuttings are<br />

produced annually, of which a substantial<br />

proportion are exported to international<br />

markets including Japan.<br />

In an increasingly competitive market,<br />

rising airfreight rates represent a major<br />

cost. As a result, Hilverda are considering<br />

setting up satellite production facilities<br />

closer to key markets and have been<br />

exploring the potential of establishing a<br />

production facility in China. Since the start<br />

of our joint venture the relationship<br />

between our two companies has grown from<br />

strength to strength; Hilverda approached<br />

<strong>Finlays</strong> last year with a proposal to develop<br />

a project together in China where the<br />

former would operate a cuttings production<br />

facility in partnership with a <strong>Finlays</strong> cut<br />

flower project. A visit to Kunming was<br />

arranged in April this year when Tim<br />

Blackburn and I accompanied Hilverda<br />

Directors Jan Hilverda and Marius Tas and<br />

their China Representative Pieter Strooper.<br />

Kunming is the capital of Yunnan province,<br />

located in the south west of China. The<br />

Province has been at the forefront of cut<br />

flower development in China. Due to a<br />

unique combination of climate, topography<br />

and altitude, which enable a wide variety of<br />

flowers to be grown year round, the area<br />

surrounding Kunming and nearby Yuxi<br />

cities is ideally suited for cut flower<br />

production. The growth in this sector has<br />

been very rapid in Yunnan. Amazingly, the<br />

first farms were started as recently as the<br />

late ’eighties; yet, today, there are over<br />

4,000 Ha of flowers cultivated in this<br />

region, accounting for over 50% of China’s<br />

total cut flower production. In 2002 alone<br />

over 2 billion flowers were produced.<br />

The ten-year old joint<br />

venture between<br />

Finlay Flowers and<br />

Hilverda Plant<br />

Technology has put<br />

out a promising new<br />

shoot. Nev Harries,<br />

Assistant Executive<br />

Finlay Flowers,<br />

goes East.<br />

Yoshikazu Suzuki (Fuji-Plants), Yuuki Ban (Florist), Jan<br />

Hilverda, Pieter Strooper (Hilverda B.V.), Yoshihiro Sugai<br />

(Nissho Iwai), Marius Tas (Hilverda B.V.), Tim Blackburn,<br />

Nev Harries (<strong>Finlays</strong>) and representatives of Yingmao.<br />

The rapid development of the domestic<br />

market and proximity to regional markets,<br />

Japan in particular, are key factors in the<br />

success of the proposed venture, where<br />

<strong>Finlays</strong> would be looking to produce<br />

certified, premium quality cut flowers for<br />

niche markets. With this in mind we visited<br />

several farms to review operations. Whilst in<br />

Kenya it is not uncommon for flower farms<br />

to be in excess of 50 hectares, the majority<br />

of farms in Yunnan are family-run<br />

smallholdings, varying in size from a few<br />

hundred square metres up to half a hectare<br />

with very few projects over ten hectares.<br />

The visit highlighted the potential of this<br />

venture and the significant advantages<br />

which our Kenyan experience could afford.<br />

Since this initial visit we have been working<br />

closely with our Swire colleagues in Beijing<br />

and Hong Kong and with representatives of<br />

the Yunnan Flower Association to identify<br />

potential locations for the development of a<br />

commercial project. At this stage two<br />

potential sites have been identified with the<br />

preferred candidate situated approximately<br />

one hour’s drive northwest of Kunming in<br />

the Songming area. In addition to excellent<br />

road and utilities infrastructure, an<br />

additional advantage of this potential site is<br />

that the new Kunming Airport, due to be<br />

completed in 2009, is located on the<br />

Songming side of the city, presenting rapid<br />

and convenient access to market. At the<br />

time of writing, a further visit to Kunming<br />

was planned for November.

The Interaction Factor Mithraka Fernando<br />

A conscious effort has been made to foster<br />

open, two-way communication through a<br />

number of initiatives. For the past 15<br />

months, a monthly Core Team Brief by the<br />

Chairman has successfully disseminated<br />

important news and information to the<br />

Executive Committee. Thereafter, each<br />

divisional head adds a local brief and<br />

communicates the findings to all staff.<br />

Recently this process was extended to<br />

cover all manual workers as well. At the<br />

local brief, employees are encouraged to<br />

ask questions. Those that divisional heads<br />

are unable to answer are referred to the<br />

directors for answers.<br />

The new Chairman Kumar Jayasuriya, who<br />

assumed office in April this year, has<br />

initiated discussions with staff officers,<br />

sharing his vision for the Company and also<br />

listening to their ideas and answering<br />

questions. It is hoped to maintain this new<br />

line of open communication by repeating<br />

the exercise twice a year.<br />

A suggestion scheme, branded<br />

“Brainwaves”, was launched in May, with an<br />

encouraging 118 suggestions being received.<br />

Cash prizes were awarded to those who<br />

made the eight best suggestions which the<br />

Company felt able to implement.<br />

Special Brainwaves boxes have been<br />

installed prominently in every location<br />

to make the submission process simple.<br />

The competition will be held twice a year<br />

in future, with the winners being<br />

rewarded, recognized and featured in<br />

the Company <strong>News</strong>letter.<br />

A formal grievance-handling process is in<br />

the development stage; this, it is hoped, will<br />

provide employees with a channel through<br />

which complaints can be addressed and<br />

minor issues prevented from escalating into<br />

bigger problems. In the interim, anyone with<br />

a grievance has been requested to write to<br />

the HR division; he or she has the promise<br />

of a written response after consultations<br />

with the necessary personnel.<br />

Beginning with the October 2006 issue, the<br />

company newsletter <strong>Finlays</strong> <strong>News</strong> aims to<br />

reach out to the bulk of the workforce by<br />

publishing two pages in Sinhala. The<br />

circulation of the newsletter was also<br />

increased with every single employee<br />

receiving an individual copy. Depending on<br />

feedback, the next step is likely to be the<br />

launch of a separate, Sinhala language<br />

publication, tailor-made for its readership.<br />

The newsletter, in addition to disseminating<br />

information, also acts as a forum where<br />

employees are able to express their views<br />

and exercise their creative talents. Typically,<br />

employees would take the newsletter home,<br />

offering management a means by which to<br />

communicate with the former’s family<br />

members as well.<br />

The resounding success of the inaugural<br />

<strong>Finlays</strong> Kiddies’ Art Competition in 2005<br />

has made the event an annual feature,<br />

providing an opportunity for children of<br />

all employees, whether director or worker,<br />

to sit together and take part in the fun as<br />

members of a single family. The featuring<br />

of winning entries as Christmas cards acts<br />

as an added incentive for employees to<br />

enter their children for the competition.<br />

The traditional year-end party, hitherto<br />

confined to higher-ranking staff, will be<br />

thrown open, from this year onwards, to<br />

cover every single employee of the Group.<br />

The Company hired an entertainment<br />

park in Colombo for this year’s event at<br />

which around 1500 <strong>Finlays</strong> employees and<br />

their family members converged (see page<br />

27). Other Group-wide sports and<br />

recreational activities have included a<br />

six-a-side cricket tournament in July and a<br />

Sports Carnival in September where<br />

For over a century James Finlay<br />

& Co. (Colombo) has focused on<br />

steady growth. Today, says Mithraka<br />

Fernando, Head of Human Resources<br />

Development, ambitious new targets<br />

and objectives centre on the<br />

workforce, currently identified as<br />

the key element in transforming<br />

the Company’s future.<br />

The Childrens’ Art Competition: fun for one big family.<br />

employees were given the opportunity to<br />

display their sporting prowess.<br />

The refurbishment of the Colombo office<br />

(see page 12) has been carried out in line<br />

with the open office concept - breaking<br />

down physical barriers and providing an<br />

environment which enables people to<br />

interact and work across divisions. The<br />

concept initially resulted in culture shock;<br />

most employees were used to working in<br />

office environments with rooms and<br />

cubicles! However, it is hoped that the<br />

obvious advantages of the open office<br />

system will, in the long term, foster<br />

increased integration and interaction.<br />

The training and development activities of<br />

the Company have been accelerated, the<br />

emphasis being on creating a ‘learning’<br />

organization. Two noteworthy initiatives in<br />

this regard were the JF Management<br />

Proficiency Program and the JF Certificate in<br />

Basic Management which saw around 50<br />

managers and executives taken through an<br />

eight-session, management development<br />

program. Group assignments were set, with<br />

each group having to write a report on<br />

<strong>Finlays</strong>-specific topics and to make a<br />

presentation to the Executive Committee.<br />

Ongoing training initiatives for all<br />

categories include productivity based<br />

training, safety and health, and a Groupwide<br />

awareness program on HIV/AIDS. A<br />

guest lecture series was also inaugurated so<br />

that employees in the executive grade could<br />

learn from the success stories of those in<br />

business as well as other areas.<br />

In keeping with the Company’s tag line:<br />

“Enriched by the past, transforming the<br />

future”, the HR initiatives described above<br />

will, it is hoped, transform working life for<br />

the people in whose hands lies <strong>Finlays</strong>’<br />

exciting future.<br />

11

12<br />

Designing an open plan office to promote greater<br />

interaction between <strong>Finlays</strong> Colombo staff was the<br />

challenge recently undertaken by Srinath Jayasuriya,<br />

Manager Buildings Division. He and his team had<br />

previously done re-modeling jobs on minor sections<br />

of the premises, but here was something far more<br />

exciting. The results, says Srinath, were to prove<br />

well beyond expectations.

Open Sesame! Srinath Jayasuriya<br />

I count myself fortunate in having been<br />

chosen to coordinate almost all of such<br />

transformations at 186 Vauxhall Street,<br />

between my stints at the Tea Warehouse<br />

and stage one of the Cold Storage, located<br />

in Welisara. Looking back: in 2002, what<br />

had been the tea blending floor for many<br />

years underwent a dramatic change in<br />

becoming the present office of Cathay<br />

Pacific, our Airline Division. Two years<br />

later the upper floor of the same building,<br />

having languished as storage space for the<br />

paper sacks which replaced the traditional<br />

tea chests, was transformed for renting as<br />

top-of-the-range office space.<br />

So, in April this year, I and the handful<br />

of colleagues who formed the Buildings<br />

Department, took it upon ourselves to<br />

re-seat virtually all of the divisions in<br />

Colombo on two floors of the same<br />

main office building.<br />

Our new chairman, Kumar Jayasuriya,<br />

required a model, open-plan office, to<br />

promote staff interaction and<br />

communication, a concept that had<br />

already shaped many of the business<br />

houses in Colombo.<br />

Contracting out the various tasks was<br />

quickly done but it took weeks to work out<br />

when the last person would take his seat.<br />

The logistics were very demanding; given<br />

the fact that some people already<br />

working on the ground floor were<br />

awaiting relocation to the floor above,<br />

the refurbishment had to be tackled in<br />

two stages.<br />

Noise, dust and the lack of air conditioning<br />

were potential irritants but our colleagues<br />

deserve high praise for the great degree of<br />

tolerance they displayed towards me and<br />

my support staff.<br />

The supplier of furniture to <strong>Finlays</strong> for<br />

many years produced drawing after<br />

drawing, determined, with every change, to<br />

achieve an ideal outcome. The final tally, for<br />

both floors, was a mind-blowing 30<br />

drawings. I even had a temporary desk at<br />

the supplier’s office at which I spent a good<br />

part of the first few days of the project.<br />

We now accommodate six different divisions<br />

of the Company on the ground floor and<br />

seven on the upper floor, each with varying<br />

head counts. Both floors have meeting<br />

rooms in keeping with their particular<br />

requirements, also separate document<br />

storage areas; these latter will subsequently<br />

be racked as their contents grow.<br />

Although the office looks compact with<br />

regard to the positioning of staff, there is<br />

provision for reasonable expansion within<br />

each division The bright, white walls will<br />

soon be hung with prints of the now<br />

diversified Finlay operations. In years gone<br />

by these same walls lent their ears to the<br />

sounds of grading, tasting and sampling,<br />

the main operation here before the Tea<br />

Division re-located to Welisara.<br />

Window blinds are of pinhead perforation<br />

which permits ample daylight and provides<br />

a welcome view of the well laid out garden,<br />

cherished and admired by generations of<br />

Finlay employees. Energy saving fixtures<br />

control the electricity, cutting out the use of<br />

unnecessary artificial lighting.<br />

We did not forget the washrooms which<br />

have been re-modeled to the highest<br />

standards, with the latest in modern<br />

washroom hygiene gadgetry chosen by<br />

Thushara Agus who heads the Healthcare<br />

division. Taking the initiative here,<br />

Thushara led an almost all-ladies team,<br />

which moved into occupation during the<br />

stages of work-in-progress. They even went<br />

to the extent of celebrating the occasion by<br />

organizing a traditional breakfast of milk<br />

rice and sweetmeats for all ‘colleagues to<br />

be’ in this shared working environment.<br />

Among the many other stalwarts who put<br />

their shoulders to the wheel, appreciation is<br />

due to Mithraka Fernando, the Head of HR,<br />

who perfectly timed two workshops on the<br />

‘5S’ method of office procedure for every<br />

one of us. I should also mention the<br />

commitment of the young IT team lead by<br />

Vamadevan Parthiban. During times of night<br />

work, we relied on such knowledgeable<br />

gentlemen as Sudesh Wijethilaka and the<br />

new recruit Nimantha Arambegedera, who<br />

coordinated the cabling works for power,<br />

telephones and computers.<br />

We now run a system of access control<br />

for the office by means of redesigned<br />

Company ID cards which operate on<br />

proximity readers.<br />

With interaction the name of the game, the<br />

tea breaks provide all of us with an<br />

opportunity to meet on the top floor while<br />

preparing our own cups of tea. It’s farewell<br />

to memories of a khaki-clad tea boy pouring<br />

from a kettle! Remarkably, this new form of<br />

tea service has turned out to be popular<br />

with all levels of staff. Another popular<br />

innovation has been the creation of an<br />

office pastry shop in an area with main<br />

road frontage; we now have a place to pick a<br />

lunch or order a birthday cake on behalf of<br />

a colleague.<br />

With the refurbished office up and running<br />

and given plenty of enthusiasm for change,<br />

we are all working in the utmost harmony!<br />

13

Clockwise:<br />

Colombian farmer, Orlando, examining his coffee crop.<br />

Alan Davies (r) gets to work with Expocafe’s chief<br />

taster, Steven Diaz.<br />

Orlando shows the visitors his coffee pulping machine.<br />

Alan with Expocafe’s Trading and Operations Chief,<br />

Alvaro Ramirez.

Linking the Coffee Chain Alan Davies and Michael Pennant-Jones<br />

Finlay Beverages is the largest private label roast and ground coffee packer in<br />

the UK supplying private label coffee to major retailers. Colombia is important<br />

to us, as the single largest origin for our business and a crucial component of<br />

many of our blends. Finlay Beverages purchase over 700mt of Colombian coffee<br />

per annum, and yet staff had little first-hand experience of how the coffee was<br />

processed, sourced and marketed. Coffee Buyer and Blender Alan Davies and<br />

CSR Manager Michael Pennant-Jones set off to explore the coffee chain.<br />

The high Andean mountains stretch from<br />

the borders of Ecuador and Peru in the<br />

South to the Caribbean Sea in the North,<br />

abutting the Pacific Ocean in the West and<br />

the rainforests of the Amazon Basin in the<br />

East. This vast area accommodates a host<br />

of micro climates and soil types which<br />

facilitate the production of a rich and<br />

diverse variety of an important crop for<br />

<strong>Finlays</strong>, coffee.<br />

Colombia is the largest producer of fully<br />

washed arabica coffee in the world, with<br />

an average crop of over 11 million bags<br />

(660,000 mt). The majority of the coffee<br />

that we purchase comes from the Central<br />

Andean growing areas, forming a triangle<br />

cornered by Bogota, Periera and Medellin,<br />

and marketed under the generic name of<br />

“Medellin Excelso”. These plantations are<br />

amongst the oldest in Colombia, being<br />

established in the 19th century; they<br />

produce a full bodied coffee with a nutty<br />

flavour and light acidity.<br />

Our visit took in meetings with the<br />

marketing bodies, the Federation of<br />

National Coffee Growers (FNC) and<br />

Expocafe; the farmers’ representatives from<br />

whom we buy our coffee directly; farmers in<br />

both the Periera and Bogota areas; and the<br />

mills where the coffee is sorted and bagged.<br />

‘Our purpose is to serve our farmers’,<br />

remarked an employee of the FNC during a<br />

presentation at the Federation’s offices.<br />

Typical marketing speak, some might say;<br />

however, after a few days in Colombia we<br />

realised that this philosophy genuinely<br />

underpins the country’s coffee industry. It<br />

explains why Colombia has one of the most<br />

sophisticated and successful smallholder<br />

systems in the world, renowned for its<br />

consistent high quality of coffee.<br />

Founded over 80 years ago, the FNC was set<br />

up to organise small farmers in the coffee<br />

industry. Its ownership is a complex web,<br />

stretching between the farmers, their cooperatives<br />

and mills to ensure that there<br />

are checks and balances at all levels.<br />

This cross-ownership gives a stable<br />

platform but also allows freedom for the<br />

farmer to sell coffee to anyone, and to do<br />

what is best for him. Intense market<br />

competition within a heavily organised<br />

sector, focused at all levels on serving the<br />

farmers, has resulted in growth and huge<br />

benefits for the latter and for the country.<br />

The FNC guarantees not only a minimum<br />

price for Colombian coffee, based on<br />

international markets, but also guarantees<br />

to purchase that coffee at the minimum<br />

price; this ensures that all competitors have<br />

to buy above it. Guaranteeing a minimum<br />

price is not enough to ensure that this<br />

system works; thus, only high quality<br />

coffees can be exported from Colombia,<br />

after first being checked by the FNC.<br />

An amazingly multi-functional organisation,<br />

the FNC not only works as a support and<br />

trading house for coffee, but also<br />

undertakes shipment checks on all coffee<br />

exported, to ensure that nothing of substandard<br />

quality leaves the country.<br />

Additionally, it also works on agricultural<br />

extension, infrastructure projects,<br />

purchasing coffee, trading and shipping<br />

coffee around the world and has<br />

shareholdings in all member co-operatives.<br />

Interestingly, at the time when FNC<br />

purchased 80% of Colombian coffee there<br />

was a realisation that this was not good for<br />

the farmer as there was little competition.<br />

The solution was to set-up another<br />

company, Expocafe, to compete with them<br />

in buying coffee from smallholders. Today<br />

Finlay Beverages source directly from both<br />

these companies.<br />

Overall, we were deeply impressed with the<br />

professionalism and organisation of the<br />

farmers who are truly passionate about<br />

their coffee; also with the excellent levels of<br />

quality control and, at the end of the day,<br />

with a superb range of coffees. It has to be<br />

said Colombian coffee will never taste the<br />

same again.<br />

Orlando, owner of a coffee smallholding on<br />

a mountainside in the Risaralda, took us on<br />

a tour of his property. The coffee grows on<br />

steep slopes, with riparian strips by a<br />

stream; bamboo is planted to absorb the<br />

water and provide building material; there<br />

are a couple of hectares of coffee and<br />

washing and drying areas for the crop, all<br />

laid out with good practices in mind.<br />

On the plateau below, large areas of<br />

grassland now under cattle were, until a few<br />

years ago, largely coffee farms. These are<br />

disappearing not only because the lower<br />

quality of coffee they produce is prone to<br />

disease, but also due to a growing economy<br />

where labour costs have risen substantially.<br />

On Orlando’s farm the extended family is<br />

used to assist at cropping times; and the<br />

personal attention he can give to the bushes<br />

helps keep disease to a minimum and<br />

farming sustainable.<br />

In common with many smallholders,<br />

Orlando is continually investing in his farm;<br />

the standards he maintains compare<br />

favourably with some of the larger farms.<br />

Sustainable practices are well evident, with<br />

minimal use of chemicals through increased<br />

inspection and management of the bushes.<br />

The FNC provides technical support even to<br />

the level of developing mycorrhizas to<br />

replace fertiliser. To support smallholders<br />

like Orlando the FNC have been exploring<br />

product diversification programmes<br />

including the growing of fruit trees,<br />

macadamia nuts, and bamboo for building;<br />

also partnerships with large companies<br />

such as Dole of the USA on plantain.<br />

All this ongoing work and constant<br />

improvement will, hopefully, assist farmers<br />

like Orlando to continue to meet the<br />

expectations of the market, yet allow him to<br />

profit from his investment in and his<br />

attention to a high quality product that is<br />

the mainstay of <strong>Finlays</strong> coffees.<br />

15

16<br />

‘A Special Place in the Heart’ William Henderson<br />

The historic landscape of tea in the Indian<br />

Subcontinent has recently undergone<br />

seismic change. After more than 120<br />

years, <strong>Finlays</strong> called a halt to its<br />

operations in Bangladesh (see our last<br />

edition). Meanwhile, an employee buy-out<br />

by the 12000-strong work force in 2005<br />

once again changed the fortunes of Tata<br />

Tea Limited’s South India Plantation<br />

Division, founded in 1878 by James Finlay<br />

& Co. Ltd., and run by the company until<br />

its Indian estates were finally sold to Tata<br />

in 1982. We asked Bill Henderson, a<br />

former High Range General Manager and<br />

co-author of ‘Facets of a Hundred Years<br />

Planting’, to take a nostalgic look back at<br />

early days in South India’s incomparably<br />

beautiful Kanan Devan Hills, a place<br />

regarded by an earlier generation as the<br />

jewel in the company’s crown.<br />

The original company was formed in 1895<br />

within the area of the Kanan Devan<br />

Concession - some 230 square miles, first<br />

granted in 1877 to one John Daniel Munro.<br />

The area, known as the High Ranges, by<br />

virtue of their wild and rugged nature,<br />

includes Aneimudi, the highest mountain in<br />

India south of the Himalayas. All this was to<br />

be transformed, by generations of<br />

venturesome planters into a veritable<br />

Shangri-la.<br />

Under the Finlay umbrella, former<br />

proprietary plantations were developed and<br />

new extensions opened, initially in rubber,<br />

chinchona and coffee. Life in those times for<br />

both planter and labourer was no sinecure:<br />

travel in and out of the hills was by bullockcart,<br />

horse-back, 'dooly' (litter) or, in<br />

extremis, 'shanks pony'.<br />

Torrential monsoon rains often washed out<br />

bridges and roads. The year 1924 saw a<br />

particularly savage monsoon devastate great<br />

swathes of the district, take many lives and<br />

go down in High Range history as a date<br />

never to be forgotten. The Light Railway had<br />

to be discontinued after extensive damage,<br />

factories were destroyed along with labour<br />

lines, bridges, buildings and people.<br />

The flood nevertheless resulted in the<br />

development of district-wide roads and,<br />

later, an aerial ropeway. These greatly aided<br />

the Munnar township's ability to provide<br />

basic necessities to management, staff and<br />

labour, previously frequently bereft of<br />

supplies for weeks on end.<br />

It also focused attention on the urgent<br />

necessity of improving health measures in<br />

the face of plague and cholera, both<br />

prevalent in the low-country and brought in<br />

by recruited labour, despite the installation<br />

of plague check-posts. The General Hospital,<br />

established in the early days just outside the<br />

town, was completely renovated and moved<br />

into the town centre, while medical facilities<br />

were extended to each plantation. As selfsufficiency<br />

became vital, plans were laid for<br />

the establishment of a farm in the Kundaly<br />

Valley and for a store at Munnar. Thus, the<br />

MSA or Munnar Supply Association came<br />

into being and remains so today.<br />

Finlay's forged ahead with a programme of<br />

improvement; by 1915 there were 16<br />

modernised tea factories, some hydro<br />

driven, others by electricity supplied by two<br />

power houses built in 1900 and 1910 at<br />

Pullivassal and Periakanal; other motive<br />

power derived from turbines and waterdriven<br />

Pelton wheels. Side by side with these

improvements, transportation for the<br />

movement of leaf, teas and machinery<br />

evolved slowly, until the arrival of the<br />

tractor transformed plucking and<br />

processing standards.<br />

The horse, however, was the planter's<br />

mainstay for decades, until motorcycles<br />

became generally available. In 1904, a<br />

Mounted Infantry Company known as The<br />

Southern Provinces Mounted Rifles(SPMR)<br />

was formed; this led to the introduction of<br />

horses to the High Range where they<br />

rapidly became integral not only to<br />

plantation supervision, but to the planters’<br />

social life, facilitating visits to neighbours<br />

and to the Club.<br />

Stories of such visits, some perhaps<br />

apocryphal, abound. One evening, after<br />

much conviviality, two senior planters exited<br />

the Club, mounted up, bade each other<br />

goodnight and rode off - each to wake up<br />

the following morning in the other's<br />

bungalow! From the Club, a path meanders<br />

up through the tea to a junction of several<br />

other routes where it was customary for a<br />

group to pause for a last smoke before<br />

heading back to their respective estates,<br />

their path lit only by the glow of a stirruplantern.<br />

This was, and to this day still is,<br />

called Cigarette Point.<br />

In 1910, an allowance of Rupees 30 was paid<br />

to maintain a horse, but inflationary spirals<br />

took their toll as always and, in 1971, the<br />

last allowance paid was Rupees 300. It is<br />

interesting to note that in the same year,<br />

an Assistant Manager received, on marrying,<br />

only an additional Rupees 125 on his<br />

Dearness Allowance - but then horses<br />

do eat more!<br />

Travel times, of course, decreased with the<br />

introduction of the motorcycle, car, lorry<br />

and tractor. In the 1920s, planters going<br />

from Munnar to play rugby in the Nilgiri<br />

Hills, required to take a week's leave as the<br />

150 mile journey alone took three to four<br />

days. The same journey, by car today is<br />

achieved in about four to five hours.<br />

The early planters may have worked and<br />

played hard but did not neglect the<br />

spiritual. The absence of a church resulted<br />

in one committee minute recording: "One<br />

gentleman remarked that he had heard<br />

discontent voiced at the Club library being<br />

made use of for church services, thus<br />

preventing members from making use of<br />

the billiard room".<br />

A pretty little church was duly built and<br />

consecrated in 1911. Despite inconsistencies<br />

of religious enthusiasm over the years,<br />

Christ Church continues to be used by all<br />

Protestant denominations, including the<br />

local Tamil and Malayali congregations.<br />

New Assistants had always been required to<br />

learn the Tamil language; in the 1950s, the<br />

reward was either Rupees 1000 - or a re-sit;<br />

failure earned a passage home! One such<br />

new entrant, a decade earlier, was advised<br />

by the then General Manager of this<br />

requirement. His manager helpfully chimed<br />

in, "Yes sir, of course. I actually learnt my<br />

Tamil from 'Inge Va' (a local textbook whose<br />

title translates as 'Come Here'). In answer<br />

the GM roared: "I don't care what her name<br />

was. This boy must learn the vernacular!"<br />

The High Range has always held a special<br />

place in the hearts of its planters and was<br />

the envy of many other districts: primarily<br />

for the sheer natural beauty of its situation,<br />

its social life and its renowned hospitality to<br />

all incomers. Those of us who spent long<br />

periods of our lives there were privileged to<br />

have experienced a unique existence.<br />

William Henderson<br />

St Andrews<br />

17

18<br />

Pensioners’ Reunion<br />

The lunch party to celebrate <strong>Finlays</strong> Pensioners’ 26th annual Reunion was<br />

held on 30 June. Almost 100 guests: present-day directors, executives and<br />

staff, as well as former employees, gathered in the graceful surroundings<br />

of The Painters’ Hall in the City of London to catch up with old friends and<br />

colleagues, hear the latest news of developments within the group and<br />

enjoy a superb meal.<br />

Those present....<br />

DIRECTORS, EXECUTIVES AND STAFF<br />

JAMES FINLAY LIMITED<br />

Michael & Caroline Todhunter<br />

Rupert Hogg<br />

Michael Ferguson<br />

Duncan Gilmour<br />

James Hughes-Hallett<br />

Peter Johansen<br />

Simon Large<br />

Pat Lockett<br />

Giles Weaver<br />

Tim & Susie Blackburn<br />

Nev Davies<br />

Paul Wythe<br />

Debbie Burke<br />

FINLAY TEA SOLUTIONS UK LIMITED<br />

Richard & Marie-Alice Darlington<br />

Tony & Maureen Barcroft<br />

Rob Corsan<br />

Mike & Clare Jones<br />

Mike Mellins<br />

Anna Schiavo<br />

Sue Wills<br />

FINLAY BEVERAGES LIMITED<br />

Neil Willsher<br />

Paul Jasper<br />

PENSIONERS OF JAMES FINLAY LIMITED<br />

Albert Baigent<br />

Clifford & Dorothy Bell<br />

Val Homer<br />

Ronnie Monk<br />

Peter & Jan Smail<br />

Bill & Maureen Stone<br />

PENSIONERS OF FINLAY BEVERAGES<br />

Irene & Harry Adams<br />

Audrey Arnold<br />

John & June Bryant<br />

Margaret Burrows<br />

Terry Cheetham<br />

Tony & Dorothy Clark<br />

Barbara Cromarty<br />

Ethna Duffy<br />

Honor Elvin<br />

Jan Feltham<br />

Shirley & Bob Garnett<br />

Barry & Susan Gibson<br />

Dorothie Hardy<br />

John & Rita Heath<br />

Gordon & Rhona Hill<br />

Ted Jones & Marilyn Carpenter<br />

Ernie Morgan<br />

Raymond & Anneke Orr<br />

Elfi & Fred Osborn<br />

Sidney & Gladys Paine<br />

David & Hilary Payne<br />

Olive Rimmer & Rosemary Lacey<br />

Mike & Mari Robbins<br />

Ron & Sylvia Smith<br />

John Tomlinson & Jenny Tomlinson Walsh<br />

Eric Webb<br />

Elsie Wilshire & Diana Childs<br />

PENSIONERS OF TEA COMPANIES<br />

Tim & Anthea Barton<br />

Jim Coutts<br />

Geoff Field<br />

Norman & Fleur Frew<br />

Chris & Mitzi Marley<br />

Gillian Ryan<br />

Leslie & Pat Stewart-Smith<br />

Hugo & Gillie Yorke-Davies<br />

PENSIONERS OF S H LOCK & CO LIMITED<br />

William & Caroline Atkins<br />

John & Pearl Large<br />

PENSIONERS OF BUCHANANS<br />

WAREHOUSES LIMITED<br />

Roy Olive<br />

John Reid

<strong>News</strong><br />

Head Office<br />

Glasgow Office Outing<br />

Tea Estates<br />

Kenya Update Nev Davies<br />

At the time I<br />

prepared the last<br />

update, Kenya was<br />

recovering from a<br />

severe drought which<br />

had very significantly<br />

reduced the<br />

availability of all<br />

grades of tea on the Mombasa auction.<br />

By the end of March, production of leaf<br />

tea had fallen to 45% of budget. There<br />

was an upside to this, however, in that<br />

prices returned to levels that had not<br />

been experienced since the late ’90’s,<br />

and although crop levels on the JF(K)<br />

estates were well below budget,<br />

nevertheless the good prices have more<br />

than compensated for the shortfall over<br />

the balance of the year. By late August<br />

the much stronger tea supply position<br />

in Mombasa had resulted in a fall in the<br />

prices for all teas; however, they have<br />

remained reasonably firm and at levels<br />

better than budget. The JF(K) estates<br />

have recovered well from the effects of<br />

the drought, and production is now at<br />

normal levels.<br />

The old adage states that every cloud has<br />

a silver lining but, in the case of JF(K),<br />

some Estate Managers have come to<br />

associate that ‘silver’ with hail. The<br />

damage as a result of hail-stones has<br />

been particularly bad this year, with<br />

some areas being repeatedly subjected to<br />

severe storms and hail damage. In years<br />

gone by, attempts were made to reduce<br />

the severity of hail damage by ‘seeding’<br />

the storm clouds with microscopic<br />

crystals, launched from sky-rockets, but<br />

the cost of doing so usually exceeded any<br />

benefit. The problem with hail is that it<br />

affects everything from a pluckable shoot<br />

down to a new bud; it takes about two<br />

months for a shoot to form from a new<br />

bud.<br />

As a strategic response to the long-term<br />

trend of falling tea prices, rapidly<br />

escalating labour costs and a stubbornly<br />

strong Kenya Shilling, the decision had<br />

been taken to significantly expand the<br />

area being mechanically harvested. On<br />

the one hand, this offered an opportunity<br />

to significantly lower costs of production,<br />

but the programme has not been without<br />

its challenges. Although the Company<br />

The Full <strong>Finlays</strong>!<br />

Glasgow staff (l-r)<br />

Pat Lockett, Duncan<br />

Gilmour, Kerr Napier<br />

and Peter Stabler<br />

strut their stuff at the<br />

office outing to a local<br />

adventure centre on<br />

25 August.<br />

had repeatedly stated that employees<br />

would not be made redundant as a result<br />

of this change of policy, unfortunately<br />

this development was interpreted by<br />

various parties as being against the best<br />

interests of the Government and the<br />

Trade Union movement. Fortunately, this<br />

issue has now been amicably resolved<br />

and the mechanisation programme is<br />

being successfully introduced.<br />

A very thorough study has been<br />

completed, which revealed that the<br />

estates do not have sufficient reserves of<br />

eucalyptus to provide the renewable<br />

energy requirements for the future needs<br />

of the Kericho-based businesses. JF(K) has<br />

now embarked on a five-year programme<br />

which will see a large area of the old, lowyielding<br />

tea replaced with eucalyptus.<br />

Some of the old tea will be replaced with<br />

new varieties of high-yielding clonal tea,<br />

to ensure an adequate supply of leaf to<br />

both the black tea factories and the Tea<br />

Extracts Division. The clonal tea is much<br />

better suited to mechanical harvesting,<br />

and this advantage provides a much more<br />

attractive return on the very significant<br />

investment required.<br />

19

20<br />

<strong>News</strong><br />

Tea Estates continued...<br />

Kenya <strong>News</strong><br />

A Home for Kericho's Orphans Duncan Gilmour<br />

It is a sad fact that the spread of HIV/Aids<br />

and related illnesses is now the most<br />

frequent cause of death in Kenya. All too<br />

often this results in an ever increasing<br />

number of orphaned children, many of<br />

whom are also born with the disease.<br />

For a number of years James Finlay (Kenya)<br />

has collaborated with the Walter Reed<br />

Foundation to help fight HIV/Aids by the<br />

provision of medicines and appropriate<br />

education programmes. For some time,<br />

however, Nev Davies and his team have<br />

been considering how best to help some of<br />

the many orphaned children in Kericho and<br />

the surrounding community. In particular<br />

they wanted to provide a facility which<br />

would give the children the opportunity to<br />

build the secure future they might otherwise<br />

be denied.<br />

To this end they conceived the idea of<br />

building a children’s home on a plot of land<br />

on the Company’s Estate, with construction<br />

and running costs being met by way of<br />

charitable donations. Almost before the<br />

idea got off the ground, the project<br />

received an amazing boost as a result<br />

of the generosity shown by participants<br />

on the 2006 Executive Programme at<br />

Stanford University in California.<br />

Rupert Hogg, who had been on this course<br />

in 2005 and was aware that a fund raising<br />

Uganda Update Laurie Davies<br />

After a very<br />

disappointing<br />

performance in 2005, this<br />

year looks set to be a<br />

record year for JFU,<br />

certainly in terms of<br />

average selling prices for<br />

our black tea and in<br />

profitability.<br />

The regional drought that was experienced at<br />

the end of last year, going into the first quarter<br />

of this year, was less severe in the west of<br />

Uganda than in many other parts of the region.<br />

As a result, tea production volumes were not<br />

significantly below targets, while the auction<br />

prices ratcheted up significantly due to the<br />

shortage of teas in Mombasa.<br />

This higher level of auction prices was<br />

sustained for the first eight months of the<br />

year, but has more recently dropped back to<br />

lower levels. The outcome for JFU was a very<br />

strong performance in the first three quarters,<br />

which will not be matched in the final quarter,<br />

but will still result in a very satisfactory<br />

outcome for the year.<br />

event would be held at the end of the<br />

programme, asked JB Rae-Smith of Swire<br />

Pacific Offshore, who attended this year’s<br />

programme, to persuade his colleagues to<br />

adopt the children’s home as a focus for<br />

this year’s fund raising efforts. They did<br />

not need much persuasion; as a result in<br />

excess of US $200k was raised, a sum<br />

which, initial estimates suggest, should be<br />

sufficient to fund substantially all of the<br />

construction costs.<br />

Running for young lives (l-r): Ivan Chu, Wing Cheuk, Lars<br />

Moerch, Martin Zing, Morten Nielsen, Eric Jackson and<br />

Dominiek Arnout.<br />

In Kenya, a task force headed by Nev’s wife<br />

Petalynn has been investigating similar<br />

homes in and around Nairobi to ensure that<br />

the Kericho home incorporates all those<br />

features and facilities found to best enhance<br />

the quality of life for the children as well as<br />

ensuring the right working environment for<br />

carers and staff.<br />

A by-product of the regional drought was a<br />

drop in the water levels of Lake Victoria,<br />

which is the source of the hydro generated<br />

electricity for Uganda. This factor, together<br />

with other capacity constraints, has lead to a<br />

severe shortage of utility electricity<br />

throughout the country; this has impacted<br />

on our factories, all of which have had to<br />

adapt to these trying circumstances. To the<br />

credit of the factory and engineering staff,<br />

the challenge has been met with minimal loss<br />

of production volume or quality, although<br />

cost of production has been impacted.<br />

As it seems that such power shortages will<br />

remain a feature for several years, there is an<br />

increasing interest in the gasifier trial being<br />

conducted at our Muzizi factory. This<br />

technology uses renewable eucalyptus<br />

firewood from our forest areas to produce<br />

gas fuel for a generator engine at a much<br />

lower unit cost than the traditional diesel<br />

generators. The Muzizi trial was<br />

commissioned at the end of last year and has<br />

been undergoing a period of testing and<br />

performance evaluation. Despite teething<br />

Getting a generous<br />

ball rolling: the<br />

president of the<br />

auction committee,<br />

Kim Wright-Violich.<br />

A site has now been<br />

identified and preliminary<br />

plans drawn up with the<br />

aim of starting<br />

construction before the<br />

end of the year. The initial<br />

intention is to build a<br />

home for approximately<br />

20 children. In addition to<br />

the home itself,<br />

accommodation will be<br />

required for carers and<br />

staff. All being well the home should be<br />

ready to welcome its first children before<br />

the end of next year.<br />

As the project begins to take shape, those<br />

involved have become increasingly aware of<br />

the considerable amount of work required<br />

to ensure success but all are relishing the<br />

challenge. Work is being carried out to<br />

agree an appropriate legal structure and<br />

on drafting a constitution which will<br />

include guidelines covering the criteria<br />

for admission.<br />

Readers will be kept up to date with<br />

progress on the construction of this much<br />

needed facility. The generosity of those<br />

attending the Stanford Executive Programme<br />

cannot be overestimated. It is largely due to<br />

their efforts that the project will be realised<br />

sooner than might have been expected.<br />

problems, there is optimism that a<br />

successful operating level can be sustained.<br />

Nigel Leakey has joined JFU as Field<br />

Executive and with his family, is a welcome<br />

addition to the Mwenge community. He had<br />

previously been involved in <strong>Finlays</strong> Flowers<br />

in Kericho and, much more recently, as a<br />

Buildings and Civil Engineering consultant at<br />

JFU. His input into Field operations is<br />

targeted at raising yields and husbandry<br />

standards around all the estates. Nick<br />

Paterson, with his many years of experience<br />

in Kenya, has been enlisted as a Visiting<br />

Agent to assist Nigel in his new post. Nick<br />

knows JFU from its early days, during the<br />

factory and field rehabilitation phase, and<br />

is proving invaluable in planning with<br />

Nigel the next phase of optimizing the<br />

field operations.<br />

There is every hope that progress with the<br />

initiatives referred to above will be reflected<br />

in the results for next year.

Sri Lanka Update Naresh Ratwatte<br />

It has been an<br />

interesting nine months<br />

for <strong>Finlays</strong> Sri Lanka Tea<br />

Estates which, first and<br />

most importantly, have<br />

seen an improved<br />

financial performance<br />

over those of the past<br />

five years; secondly, a successful debt restructuring<br />

and, thirdly, the move of the<br />

Estates’ head office from Ratnapura to a<br />

state of the art new building in Ingiriya,<br />

one and a quarter hours’ drive, south of<br />

the capital city of Colombo.<br />

The strong tea prices for the small leaf<br />

grades and the boom in the rubber market<br />

during the first nine months of the year,<br />

strengthened by the contribution from the<br />

sale of timber, have resulted in a healthy<br />

financial performance to date this year with<br />

both companies exceeding budget.<br />

The reduction in tea production during the<br />

first half of the season is yet to be recouped.<br />