tcaes 230÷4160 thae - Rhoss

tcaes 230÷4160 thae - Rhoss

tcaes 230÷4160 thae - Rhoss

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SECTION II: INSTALLATION AND MAINTENANCE<br />

II.1.11<br />

STORAGE CONDITIONS<br />

The units are wrapped in a shrink-wrap nylon sheath which guarantees<br />

protection when the unit is stored in sheltered areas where it is not<br />

exposed to frequent changes in temperature. If the appliance has to be<br />

stored outdoors, remove the shrink-wrap nylon sheath to avoid the<br />

formation of condensate. If the unit is exposed to sunlight, peel off the<br />

protective film on the panelling.<br />

II.2 INSTALLING THE UNIT<br />

DANGER!<br />

Installation may only be carried out by skilled<br />

technicians, qualified to work with conditioning and<br />

cooling products.<br />

Installation personnel must comply with all<br />

applicable local or national legislation in effect<br />

when the appliance is commissioned.<br />

DANGER<br />

The corners of the unit and the finned surface of the<br />

banks may cause injury if the due care and<br />

attention is not paid during installation.<br />

II.2.1 CLEARANCES<br />

IMPORTANT!<br />

The unit must be positioned in compliance with the<br />

minimum recommended clearances and bearing in<br />

mind access to water and electrical connections.<br />

Failure to observe the recommended clearances during installation will<br />

prevent the unit from running efficiently, causing an increase in the<br />

power input and a considerable drop in the cooling power due to an<br />

increase in condensing pressure.<br />

The area above the unit must be free of any obstacles. If the unit is<br />

completely surrounded by walls, the indicated distances still apply as<br />

long as two adjacent walls are no higher than the unit itself. If more than<br />

one unit is installed, a 2 m minimum distance must be provided<br />

between the finned coils to avoid interference with the<br />

condensing/ventilating modules of each machine. Clearances greater<br />

than the clearances indicated in Fig. 5 and Fig. 6 must be taken into<br />

account to allow for handling any components that may require<br />

replacement.<br />

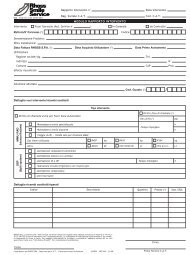

Fig. 6<br />

MODEL 470 490 4100 4110 4130 4140 4160<br />

Clearances<br />

L1 mm 1.200 1.200 1.200 1.200 1.200 1.200 1.200<br />

L2 mm 1.400 1.400 1.400 1.600 1.600 1.600 1.600<br />

L3 mm 800 800 800 800 800 800 800<br />

II.2.2<br />

WEIGHT DISTRIBUTION<br />

IMPORTANT!<br />

Correct installation and positioning includes<br />

levelling the appliance on a surface capable of<br />

bearing its weight.<br />

The unit may be installed at ground level or on the top of buildings.<br />

If the unit is installed on structures that may not be subjected to the<br />

effects of mechanical vibrations, the appliance must be insulated from<br />

the rigid support surface.<br />

Alternatively, the danger of transmitting vibrations through the support<br />

surface can be eliminated by installing vibration-damping rubber<br />

supports into the points provided under the frame of the unit. The<br />

vibration-damping rubber supports are supplied as accessories (KSA:<br />

vibration-damping supports).<br />

The weight of each unit is indicated in the tables in enclosed documents<br />

1, 2, and 3.<br />

IMPORTANT!<br />

If the problem of structural vibration transmission<br />

proves difficult to solve, consult a qualified<br />

technician for a complete analysis.<br />

II.2.3<br />

II.2.3.1<br />

WATER CONNECTIONS<br />

Connection to the system<br />

IMPORTANT!<br />

The water system and connection between the unit<br />

and the system must be carried out in compliance<br />

with the local and national regulations in effect.<br />

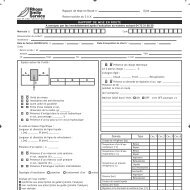

Fig. 5<br />

MODEL 230 235 245 250 260<br />

Clearances<br />

L1 mm 1.000 1.000 1.000 1.000 1.000<br />

L2 mm 800 800 800 800 800<br />

L3 mm 800 800 800 800 800<br />

The units feature 2”G male threaded water connections.<br />

Air vents and on-off valves must be installed on the inlet and outlet<br />

pipes of the unit to isolate the appliance from the rest of the system.<br />

This not only allows the heat exchanger to be emptied but also leaves<br />

enough space for any maintenance work or the removal of the heat<br />

exchanger. A filter must be assembled on the system return pipe and<br />

vibration-damping joints must be installed on the water connections.<br />

When all the connections have been carried out, make sure that none<br />

of the pipes have any leaks and bleed any air from the circuit.<br />

II.2.3.2 Installation and management of the P/P –DP<br />

circulation pump on the primary circuit<br />

The circulation pump installed on the chilled water circuit must be able<br />

to overcome, at the rated flow rate, the flow resistance of the entire<br />

system and the exchanger on the appliance.<br />

• The differential pressure switch protects the unit from any<br />

interruptions in the flow of water. The differential pressure switch is<br />

automatically rearmed; the unit automatically starts up again only when<br />

the water flow rate exceeds the calibrated differential set point.<br />

• Once the differential pressure switch has been triggered, the control<br />

panel continues to display the E41 alarm to indicate possible water<br />

system problems (Par. II.3.6).<br />

10