tcaes 230÷4160 thae - Rhoss

tcaes 230÷4160 thae - Rhoss

tcaes 230÷4160 thae - Rhoss

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

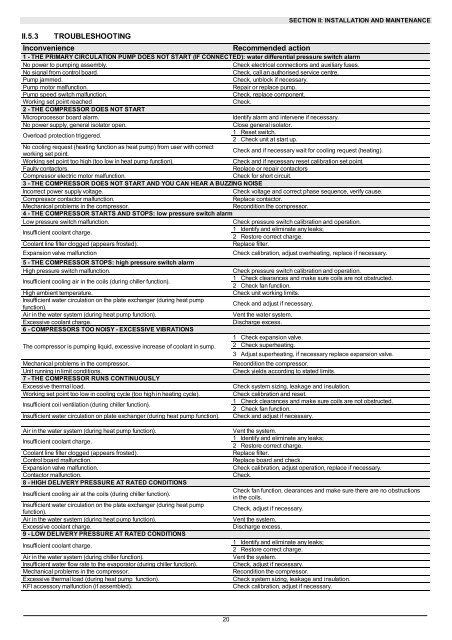

II.5.3<br />

TROUBLESHOOTING<br />

SECTION II: INSTALLATION AND MAINTENANCE<br />

Inconvenience<br />

Recommended action<br />

1 - THE PRIMARY CIRCULATION PUMP DOES NOT START (IF CONNECTED): water differential pressure switch alarm<br />

No power to pumping assembly.<br />

Check electrical connections and auxiliary fuses.<br />

No signal from control board.<br />

Check, call an authorised service centre.<br />

Pump jammed.<br />

Check, unblock if necessary.<br />

Pump motor malfunction.<br />

Repair or replace pump.<br />

Pump speed switch malfunction.<br />

Check, replace component.<br />

Working set point reached<br />

Check.<br />

2 - THE COMPRESSOR DOES NOT START<br />

Microprocessor board alarm.<br />

Identify alarm and intervene if necessary.<br />

No power supply, general isolator open.<br />

Close general isolator.<br />

Overload protection triggered.<br />

1 Reset switch.<br />

2 Check unit at start up.<br />

No cooling request (heating function as heat pump) from user with correct<br />

working set point.<br />

Check and if necessary wait for cooling request (heating).<br />

Working set point too high (too low in heat pump function).<br />

Check and if necessary reset calibration set point.<br />

Faulty contactors.<br />

Replace or repair contactors<br />

Compressor electric motor malfunction.<br />

Check for short circuit.<br />

3 - THE COMPRESSOR DOES NOT START AND YOU CAN HEAR A BUZZING NOISE<br />

Incorrect power supply voltage.<br />

Check voltage and correct phase sequence, verify cause.<br />

Compressor contactor malfunction.<br />

Replace contactor.<br />

Mechanical problems in the compressor.<br />

Recondition the compressor.<br />

4 - THE COMPRESSOR STARTS AND STOPS: low pressure switch alarm<br />

Low pressure switch malfunction.<br />

Check pressure switch calibration and operation.<br />

Insufficient coolant charge.<br />

1 Identify and eliminate any leaks;<br />

2 Restore correct charge.<br />

Coolant line filter clogged (appears frosted).<br />

Replace filter.<br />

Expansion valve malfunction<br />

5 - THE COMPRESSOR STOPS: high pressure switch alarm<br />

High pressure switch malfunction.<br />

Insufficient cooling air in the coils (during chiller function).<br />

High ambient temperature.<br />

Insufficient water circulation on the plate exchanger (during heat pump<br />

function).<br />

Air in the water system (during heat pump function).<br />

Excessive coolant charge.<br />

6 - COMPRESSORS TOO NOISY - EXCESSIVE VIBRATIONS<br />

The compressor is pumping liquid, excessive increase of coolant in sump.<br />

Mechanical problems in the compressor.<br />

Unit running in limit conditions.<br />

7 - THE COMPRESSOR RUNS CONTINUOUSLY<br />

Excessive thermal load.<br />

Working set point too low in cooling cycle (too high in heating cycle).<br />

Insufficient coil ventilation (during chiller function).<br />

Insufficient water circulation on plate exchanger (during heat pump function).<br />

Check calibration, adjust overheating, replace if necessary.<br />

Check pressure switch calibration and operation.<br />

1 Check clearances and make sure coils are not obstructed.<br />

2 Check fan function.<br />

Check unit working limits.<br />

Check and adjust if necessary.<br />

Vent the water system.<br />

Discharge excess.<br />

1 Check expansion valve.<br />

2 Check superheating.<br />

3 Adjust superheating, if necessary replace expansion valve.<br />

Recondition the compressor.<br />

Check yields according to stated limits.<br />

Check system sizing, leakage and insulation.<br />

Check calibration and reset.<br />

1 Check clearances and make sure coils are not obstructed.<br />

2 Check fan function.<br />

Check and adjust if necessary.<br />

Air in the water system (during heat pump function).<br />

Insufficient coolant charge.<br />

Coolant line filter clogged (appears frosted).<br />

Control board malfunction.<br />

Expansion valve malfunction.<br />

Contactor malfunction.<br />

8 - HIGH DELIVERY PRESSURE AT RATED CONDITIONS<br />

Insufficient cooling air at the coils (during chiller function).<br />

Insufficient water circulation on the plate exchanger (during heat pump<br />

function).<br />

Air in the water system (during heat pump function).<br />

Excessive coolant charge.<br />

9 - LOW DELIVERY PRESSURE AT RATED CONDITIONS<br />

Insufficient coolant charge.<br />

Air in the water system (during chiller function).<br />

Insufficient water flow rate to the evaporator (during chiller function).<br />

Mechanical problems in the compressor.<br />

Excessive thermal load (during heat pump function).<br />

KFI accessory malfunction (if assembled).<br />

Vent the system.<br />

1 Identify and eliminate any leaks;<br />

2 Restore correct charge.<br />

Replace filter.<br />

Replace board and check.<br />

Check calibration, adjust operation, replace if necessary.<br />

Check.<br />

Check fan function, clearances and make sure there are no obstructions<br />

in the coils.<br />

Check, adjust if necessary.<br />

Vent the system.<br />

Discharge excess.<br />

1 Identify and eliminate any leaks;<br />

2 Restore correct charge.<br />

Vent the system.<br />

Check, adjust if necessary.<br />

Recondition the compressor.<br />

Check system sizing, leakage and insulation.<br />

Check calibration, adjust if necessary.<br />

20