tcaes 230÷4160 thae - Rhoss

tcaes 230÷4160 thae - Rhoss

tcaes 230÷4160 thae - Rhoss

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

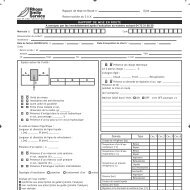

SECTION II: INSTALLATION AND MAINTENANCE<br />

Electrical connection of a motor-driven<br />

pump/secondary circulation pump (VERSION PU-<br />

PU/DP)<br />

DANGER!<br />

Electrical connection must be carried out by<br />

qualified personnel in compliance with the<br />

regulations in effect in the country where the unit is<br />

installed. RHOSS shall not be held liable for<br />

damage to persons or things caused by incorrect<br />

electrical connection.<br />

IMPORTANT!<br />

Refer to the wiring diagrams enclosed with the unit<br />

which highlight the terminals to be set up by the<br />

installer.<br />

If one of the pumps stops running, act on the<br />

backup pump selector on the control board to<br />

enable the backup pump.<br />

II.2.5 REMOTE MANAGEMENT USING<br />

CONNECTIONS SET UP BY THE INSTALLER<br />

DANGER!<br />

Electrical connection must be carried out by<br />

qualified personnel in compliance with the<br />

regulations in effect in the country where the unit is<br />

installed. RHOSS shall not be held liable for<br />

damage to persons or things caused by incorrect<br />

electrical connection.<br />

IMPORTANT!<br />

Refer to the wiring diagrams enclosed with the unit<br />

which highlight the terminals to be set up by the<br />

installer.<br />

SCR - Remote control selector.<br />

SEI – Remote summer-winter selector (THAE-THAES only)<br />

LF – Compressor function lamp.<br />

LB – General malfunction lamp.<br />

• Remote ON/OFF enablement (SCR)<br />

Remove the jumper between the terminals (35 and 36 on models<br />

TCAE-TCAES-THAE-THAES 470÷4160, 21 and 22 on models TCAE-<br />

TCAES-THAE-THAES 230÷260) on the user interface terminal board<br />

and connect the remote control ON/OFF selector cables.<br />

CAUTION<br />

Open contact: the unit is OFF.<br />

Closed contact: the unit is ON.<br />

IMPORTANT!<br />

When the unit is switched OFF using the remote<br />

control, E00 is displayed.<br />

II.2.6 NOISE REDUCTION<br />

IMPORTANT!<br />

The unit is designed for outdoor installation;<br />

therefore local and national standards in force<br />

regulating noise levels must be complied with.<br />

Incorrect positioning or installation may cause an<br />

amplification of the noise or vibrations produced<br />

while the unit is running.<br />

○ During installation it is IMPORTANT to bear in mind the following:<br />

• non-soundproofed reflecting walls near the unit (such as balcony<br />

walls or the perimeter walls of a building), may increase the total sound<br />

pressure level reading near the appliance by as much as 3 dB(A) for<br />

every surface (e.g. 2 corner walls cause an increase of 6 dB(A);<br />

• install suitable vibration-damping supports under the unit to avoid<br />

transmitting vibrations to the building structure;<br />

• rigid frames may be installed on the top floor of the building to<br />

support the unit and transmit its weight to the load bearing structures of<br />

the building;<br />

• carry out all water connections using elastic joints. Pipes must be<br />

firmly supported by solid structures. If the pipes are routed through<br />

walls or panels, insulate with elastic sleeves.<br />

○ If there are any structural vibrations in the building (after the unit<br />

has been installed and has started to run) which provoke such strong<br />

resonance that noise is generated in other points of the building, consult<br />

a qualified acoustic technician for a complete analysis of the problem.<br />

II.3 OPERATION AND ADJUSTMENT<br />

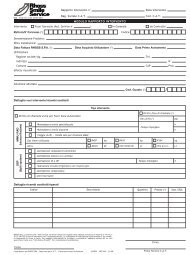

II.3.1 CONTROL BOARD<br />

The control board features a general isolator with door interlock. The<br />

230 V auxiliary circuit power supply and the 12 V control power supply<br />

is shunted internally by the three phase power supply. The layout of<br />

electrical components in the control board is illustrated in Fig. 7 and Fig.<br />

8.<br />

CE1 = microprocessor controller<br />

IA = auxiliary switch<br />

IC = compressor switch<br />

IG = main switch<br />

IV = fan switch<br />

KC = compressor contactor<br />

KV = fan contactor<br />

TR = transformer<br />

IP = accumulation pump switch<br />

KP = accumulation pump contactor<br />

MF = phase monitor<br />

Control board layout on TCAE-TCAES-THAE-THAES 230÷260 units<br />

• Remote Summer/ Winter enablement on THAE-THAES (SEI)<br />

Change parameter H49 (from 0 to 1) and connect the remote<br />

Summer/Winter selector cables between the terminals (33 and 34 on<br />

models THAE-THAES 470÷4160, 19 and 20 on models THAE-THAES<br />

230÷260) on the user interface terminal board.<br />

CAUTION<br />

Open contact: heating cycle.<br />

Closed contact: cooling cycle.<br />

IMPORTANT!<br />

When the unit is switched OFF using the remote<br />

control, E00 is displayed.<br />

• LF-LB lamp remote control<br />

To remote control the two signals, connect the two lamps according to<br />

the instructions provided in the wiring diagram supplied with the<br />

machine.<br />

Fig. 7<br />

12