tcaes 230÷4160 thae - Rhoss

tcaes 230÷4160 thae - Rhoss

tcaes 230÷4160 thae - Rhoss

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

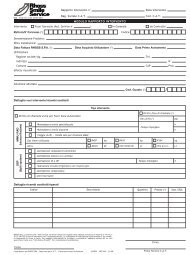

SECTION II: INSTALLATION AND MAINTENANCE<br />

II<br />

SECTION II: INSTALLATION AND<br />

MAINTENANCE<br />

IMPORTANT!<br />

The unit will only function correctly if the<br />

instructions for use are scrupulously followed, if<br />

the clearances are complied with during installation<br />

and if the operating restrictions indicated in<br />

Paragraph II.1.2 are strictly adhered to.<br />

II.1.1 MACHINE DESCRIPTION<br />

II.1.1.1 Construction features<br />

○ Chassis made of aluminium profiles with Peraluman panelling,<br />

models 230 ÷ 260 are insulated on the inside with sound insulation<br />

material; models 470 ÷ 4160 feature a steel base.<br />

○ Scroll hermetic rotary compressors complete with thermal overload<br />

protection.<br />

○ Limiting as indicated in the following table:<br />

MODEL Compressors/N° of steps N° of circuits<br />

230 ÷ 260 2/2 1<br />

470 ÷ 4160 4/4 2<br />

○ Evaporator or condenser/evaporator featuring stainless steel plates<br />

complete with antifreeze heating element and closed cell foamed<br />

polyurethane rubber insulation.<br />

○ Differential pressure switch to protect the unit from any interruptions<br />

in the flow of water.<br />

○ Male threaded water connections on all models.<br />

○ Air condenser or evaporator/condenser featuring copper coils and<br />

aluminium fins.<br />

○ Axial flow fans complete with protective grilles.<br />

○ Phase controller to protect the compressor.<br />

○ Cooling circuit featuring mild copper piping welded with precious<br />

alloys. Supplied complete with: dehydrator filter, charge connections,<br />

high pressure switch with manual reset, low pressure switch with<br />

automatic reset, liquid-moisture sight-glass, thermostatic expansion<br />

valve, pressure transducer (on THAE-THAES), cycle inversion valve<br />

(on THAE-THAES), non return valve (on THAE-THAES) and a liquid<br />

receiver (on THAE-THAES).<br />

○ Unit complete with:<br />

• R 407c refrigerant charge.<br />

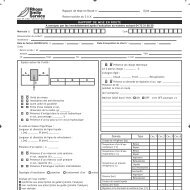

II.1.1.2 Control board features<br />

○ The control board can be accessed from a front panel in<br />

compliance with IEC standards.<br />

Waterproof box supplied with special key and complete with:<br />

• electrical wiring for the 400V-3ph+N-50Hz power supply;<br />

• power supply to auxiliaries: 230V-1ph-50Hz;<br />

• control power supply: 12V-1ph-50Hz;<br />

• power contactors;<br />

• remote appliance controls;<br />

• general isolator with door interlock on the power supply;<br />

• automatic overload cut-out on each compressor and fan;<br />

• automatic overload cut-out on the auxiliary circuit.<br />

○ Programmable microprocessor electronic circuit board managed<br />

from the keyboard on the appliance.<br />

The electronic circuit board manages the following functions:<br />

• adjustment and management of inlet/outlet water temperature<br />

settings; safety delays; hour meters for each compressor; automatic<br />

inversion of compressor start up sequences, defrosting cycles, (on<br />

THAE-THAES); circulation or service pump; electronic antifreeze<br />

protection; the functions controlling the working intervention modes of<br />

each device constituting the appliance.<br />

• complete protection of the unit, including the possibility of switching<br />

off the machine and the display of all triggered alarms;<br />

• display of the programmed set points, the inlet/outlet water<br />

temperature and alarms. LED display of working devices, cooling or<br />

heat pump mode function or defrosting in progress (on THAE-THAES);<br />

• self-diagnosis with continuous verification of unit working<br />

conditions.<br />

○ Advanced functions:<br />

• pre-arrangement for serial connection with RS 485 output for<br />

interconnection with building automation systems, centralised systems<br />

and supervision networks.<br />

• computer assisted machine tests.<br />

II.1.2<br />

WORKING RESTRICTIONS<br />

For a description of working restrictions, refer to the relative chapters in<br />

SECTION I: USER (Chapters I.1.3.1 and I.1.3.2).<br />

II.1.3 FACTORY FITTED ACCESSORIES<br />

STANDARD VERSION:<br />

DS15 – Desuperheater.<br />

RC50 – Partial heat regenerator.<br />

RC100 – Total heat regenerator.<br />

FI10 – Proportional electronic device for continuous adjustment of fan<br />

rotation speed depending on the condensation pressure, up to an<br />

external air temperature of -10°C in cooling function mode.<br />

TRD - Thermostat with display showing the regenerator or<br />

desuperheater outlet water temperature with the possibility of<br />

programming the activation set point of an external adjustment device.<br />

Documentation regarding factory fitted accessories is enclosed with the<br />

documentation of the accessorised units.<br />

VERSION WITH INTEGRATED PUMP ASSEMBLY<br />

DS15 (*) - Desuperheater.<br />

RC50 (*) - Partial heat regenerator.<br />

RC100 (*) - Total heat regenerator.<br />

FI10 - Proportional electronic device for continuous adjustment of fan<br />

rotation speed depending on the condensation pressure, up to an<br />

external air temperature of -10°C in cooling function mode.<br />

TRD (*) - Thermostat with display showing the regenerator or<br />

desuperheater outlet water temperature with the possibility of<br />

programming the activation set point of an external adjustment device.<br />

Documentation regarding factory fitted accessories is enclosed with the<br />

documentation of the accessorised units.<br />

(*) units 230÷260 only.<br />

VERSION WITH MOTOR-DRIVEN PUMP<br />

DS15 – Desuperheater.<br />

RC50 – Partial heat regenerator.<br />

RC100 – Total heat regenerator.<br />

FI10 – Proportional electronic device for continuous adjustment of fan<br />

rotation speed depending on the condensation pressure, up to an<br />

external air temperature of -10°C in cooling function mode.<br />

TRD - Thermostat with display showing the regenerator or<br />

desuperheater outlet water temperature with the possibility of<br />

programming the activation set point of an external adjustment device.<br />

Documentation regarding factory fitted accessories is enclosed with the<br />

documentation of the accessorised units.<br />

II.1.4 ACCESSORIES SUPPLIED SEPARATELY<br />

IMPORTANT!<br />

Only use original spare parts and accessories.<br />

RHOSS S.p.a. shall not be held liable for damage<br />

caused by tampering or work carried out by<br />

unauthorised personnel or malfunctions caused by<br />

the use of non-original spare parts or accessories.<br />

KSA - Vibration-damping rubber supports.<br />

KTR – Remote control keyboard with exactly the same functions as the<br />

keyboard on the appliance.<br />

KIS - RS 485 serial interface for interconnection with building<br />

automation systems, centralised systems and supervision networks.<br />

KRP – Protective mesh.<br />

KGM – High and low pressure gauges for every circuit complete with<br />

capillaries.<br />

KCH - RS 232 hardware key for connection to supervision systems, to<br />

be combined with one or more KIS serial interface modules if the units<br />

are managed on a centralised basis.<br />

Documentation regarding accessories supplied separately is enclosed<br />

with the documentation of the accessorised units.<br />

8