Vuyk Versatile Vessel - Vuyk Engineering Rotterdam bv

Vuyk Versatile Vessel - Vuyk Engineering Rotterdam bv

Vuyk Versatile Vessel - Vuyk Engineering Rotterdam bv

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

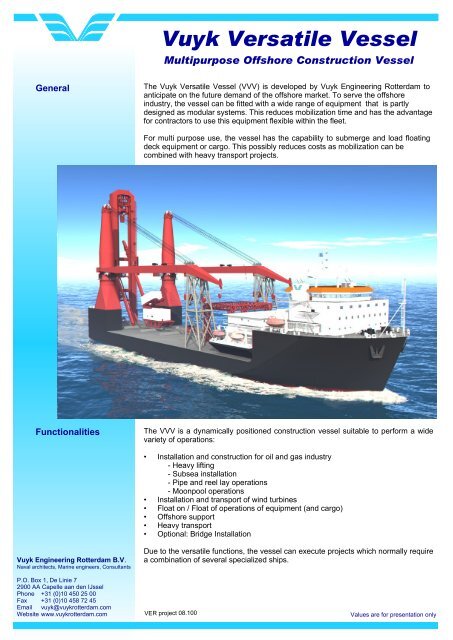

<strong>Vuyk</strong> <strong>Versatile</strong> <strong>Vessel</strong><br />

Multipurpose Offshore Construction <strong>Vessel</strong><br />

General<br />

The <strong>Vuyk</strong> <strong>Versatile</strong> <strong>Vessel</strong> (VVV) is developed by <strong>Vuyk</strong> <strong>Engineering</strong> <strong>Rotterdam</strong> to<br />

anticipate on the future demand of the offshore market. To serve the offshore<br />

industry, the vessel can be fitted with a wide range of equipment that is partly<br />

designed as modular systems. This reduces mobilization time and has the advantage<br />

for contractors to use this equipment flexible within the fleet.<br />

For multi purpose use, the vessel has the capability to submerge and load floating<br />

deck equipment or cargo. This possibly reduces costs as mobilization can be<br />

combined with heavy transport projects.<br />

Functionalities<br />

The VVV is a dynamically positioned construction vessel suitable to perform a wide<br />

variety of operations:<br />

• Installation and construction for oil and gas industry<br />

- Heavy lifting<br />

- Subsea installation<br />

- Pipe and reel lay operations<br />

- Moonpool operations<br />

• Installation and transport of wind turbines<br />

• Float on / Float of operations of equipment (and cargo)<br />

• Offshore support<br />

• Heavy transport<br />

• Optional: Bridge Installation<br />

<strong>Vuyk</strong> <strong>Engineering</strong> <strong>Rotterdam</strong> B.V.<br />

Naval architects, Marine engineers, Consultants<br />

Due to the versatile functions, the vessel can execute projects which normally require<br />

a combination of several specialized ships.<br />

P.O. Box 1, De Linie 7<br />

2900 AA Capelle aan den IJssel<br />

Phone +31 (0)10 450 25 00<br />

Fax +31 (0)10 458 72 45<br />

Email vuyk@vuykrotterdam.com<br />

Website www.vuykrotterdam.com<br />

VER project 08.100<br />

Values are for presentation only

<strong>Vuyk</strong> <strong>Versatile</strong> <strong>Vessel</strong><br />

Multipurpose Offshore Construction <strong>Vessel</strong><br />

Principal dimensions<br />

Length o.a.<br />

Length b.p.p.<br />

Breadth, moulded<br />

Depth, moulded<br />

Draught sailing<br />

Draught lifting<br />

Submerged draught<br />

Water level above deck in submerged condition<br />

Deadweight<br />

Accommodation<br />

161.50<br />

147.50<br />

42.00<br />

14.50<br />

7.50<br />

8.50<br />

22.50<br />

8.00<br />

14000<br />

50<br />

m<br />

m<br />

m<br />

m<br />

m<br />

m<br />

m<br />

m<br />

ton<br />

p<br />

Cargo Capacity<br />

Deck area<br />

Deck load<br />

Payload<br />

4700<br />

15.00<br />

10000<br />

m2<br />

ton/m2<br />

ton<br />

Lifting Equipment<br />

The vessel is fitted with two heavy lift mast cranes which gives the advantage of<br />

controlled tandem hoisting with maximum load and redundancy for single crane<br />

operations. The arrangement of the cranes also provides space for modular<br />

equipment and deck load to be positioned and operated between the cranes.<br />

Optionally the vessel can be fitted with a longboom, used for installation of bridges<br />

and civil constructions.<br />

2x Heavy Lift Crane<br />

Lifting capacity<br />

Lifting height above water level<br />

Longboom<br />

Lifting capacity<br />

Lifting height above water level<br />

2x 1500<br />

90<br />

800<br />

240<br />

ton<br />

m<br />

ton<br />

m<br />

<strong>Vuyk</strong> <strong>Engineering</strong> <strong>Rotterdam</strong> B.V.<br />

Naval architects, Marine engineers, Consultants<br />

P.O. Box 1, De Linie 7<br />

2900 AA Capelle aan den IJssel<br />

Phone +31 (0)10 450 25 00<br />

Fax +31 (0)10 458 72 45<br />

Email vuyk@vuykrotterdam.com<br />

Website www.vuykrotterdam.com<br />

VER project 08.100<br />

Values are for presentation only

<strong>Vuyk</strong> <strong>Versatile</strong> <strong>Vessel</strong><br />

Multipurpose Offshore Construction <strong>Vessel</strong><br />

Modular Equipment<br />

The vessel can be fitted with following modular equipment:<br />

- J-Lay equipment<br />

- Reel lay equipment<br />

- Trenching equipment<br />

The vessel is self supporting with respect to fitting and dismounting the modular<br />

equipment. This can be done by lifting the equipment to deck, skidding/rolling onto<br />

the unobstructed deck, or submerging the vessel when using floating modules.<br />

Modular<br />

Accommodation<br />

The standard accommodation is suitable for 50 persons, including ship's crew. In<br />

most cases this is not sufficient for working with modular equipment. To expand the<br />

accommodation capacity, the vessel can be fitted with a modular accommodation unit<br />

for 100 persons. This unit is self-floating so it can be floated on the submerged<br />

vessel. Positioned directly aft of the forecastle, a large deck remains for fitting<br />

equipment and storage of pipes/product.<br />

<strong>Vuyk</strong> <strong>Engineering</strong> <strong>Rotterdam</strong> B.V.<br />

Naval architects, Marine engineers, Consultants<br />

P.O. Box 1, De Linie 7<br />

2900 AA Capelle aan den IJssel<br />

Phone +31 (0)10 450 25 00<br />

Fax +31 (0)10 458 72 45<br />

Email vuyk@vuykrotterdam.com<br />

Website www.vuykrotterdam.com<br />

This module provides more flexibility, as during transport maximum free deck area is<br />

available, while during installation work the accommodation capacity is increased<br />

significantly.<br />

VER project 08.100<br />

Values are for presentation only

<strong>Vuyk</strong> <strong>Versatile</strong> <strong>Vessel</strong><br />

Multipurpose Offshore Construction <strong>Vessel</strong><br />

Arrangement<br />

The vessel consists of a mono hull fitted with a large forecastle and buoyancy<br />

casings to generate the submersible functionality. On the aft buoyancy casings two<br />

heavy lift mast cranes are fitted. This location minimizes “loss” of deck space by the<br />

crane pedestals .<br />

The deckhouse is positioned on the forecastle deck where it provides a perfect<br />

overview on the large workdeck aft. Below deck the engine room, thruster rooms,<br />

forward pump room and all required service spaces are located.<br />

The midship consists completely of ballast and fuel tanks. For access two corridors<br />

from forward to aft are arranged. Also a moonpool is fitted in the midship area as the<br />

motions of the vessel are lowest in this region. This location contributes to a higher<br />

workability through the moonpool. The moonpool can be closed at deck so an<br />

unobstructed deck is available for installation and transport projects.<br />

In the aftship the propulsion room and aft pump room are located in between the<br />

crane pedestals. The adjacent spaces below the buoyancy casings can be used for<br />

extra winch capacity for the mast cranes.<br />

Hull form<br />

<strong>Vuyk</strong> <strong>Engineering</strong> <strong>Rotterdam</strong> B.V.<br />

Naval architects, Marine engineers, Consultants<br />

In order to reduce the resistance of this relatively wide vessel, the midship coefficient<br />

is minimized by a sloped side. This has the advantage of a smaller waterline at<br />

sailing draught and the maximum waterline breadth at lifting draught.<br />

The foreship is fitted with a bulbous bow to achieve lower resistance in free sailing<br />

conditions. The bow is designed with a V-shape with little flare, to minimize bow<br />

impact. The aftship has a mild V-shaped bottom which, in combination with the<br />

sloped sides, provides good flow to the propellers.<br />

P.O. Box 1, De Linie 7<br />

2900 AA Capelle aan den IJssel<br />

Phone +31 (0)10 450 25 00<br />

Fax +31 (0)10 458 72 45<br />

Email vuyk@vuykrotterdam.com<br />

Website www.vuykrotterdam.com<br />

VER project 08.100<br />

Values are for presentation only

<strong>Vuyk</strong> <strong>Versatile</strong> <strong>Vessel</strong><br />

Multipurpose Offshore Construction <strong>Vessel</strong><br />

Propulsion<br />

Dynamic Positioning<br />

The vessel is equipped with a sophisticated propulsion system. This system is<br />

balanced for the power requirement in free sailing conditions and during dynamic<br />

positioning . The system consists of following propellers:<br />

Aft azimuth thrusters<br />

Fwd azimuth thrusters<br />

Fwd tunnel thruster<br />

3 x 3350<br />

3 x 2200<br />

1 x 1600<br />

With the aft propellers in use, the vessel can reach a service speed of 14 knots.<br />

A class 2 dynamic positioning system is fitted on the vessel.<br />

kW<br />

kW<br />

kW<br />

The system is designed for the following environmental conditions with all propulsion<br />

equipment operating:<br />

Significant wave height : 3 m<br />

Current speed : 2 knot<br />

Wind speed<br />

: 6 Bft.<br />

DP capability plot<br />

(max. sig. wave height)<br />

310<br />

320<br />

330<br />

340<br />

350<br />

7.0<br />

6.0<br />

5.0<br />

0<br />

10<br />

20<br />

30<br />

40<br />

50<br />

290<br />

300<br />

4.0<br />

3.0<br />

2.0<br />

60<br />

70<br />

All thrusters operating<br />

FWD C thruster failure<br />

280<br />

270<br />

1.0<br />

z<br />

0.0<br />

80<br />

90<br />

AFT PS thruster failure<br />

260<br />

100<br />

250<br />

110<br />

240<br />

120<br />

230<br />

130<br />

220<br />

140<br />

Power Generation<br />

210<br />

200<br />

A diesel-electric propulsion and power generation system is favourable as the power<br />

demand varies in the different operating conditions. This system minimizes fuel<br />

consumption while availability of power is preserved.<br />

190<br />

180<br />

170<br />

160<br />

150<br />

Machinery<br />

Main generator sets<br />

Auxiliary power<br />

4x 4300<br />

1x 1500<br />

kW<br />

kW<br />

<strong>Vuyk</strong> <strong>Engineering</strong> <strong>Rotterdam</strong> B.V.<br />

Naval architects, Marine engineers, Consultants<br />

A setup of four similar generator sets is chosen. Depending on the operation three or<br />

four sets are in use. During dynamic positioning operations this configuration<br />

provides sufficient redundancy to ensure positioning of the vessel, in case of failure<br />

of one generator set.<br />

P.O. Box 1, De Linie 7<br />

2900 AA Capelle aan den IJssel<br />

Phone +31 (0)10 450 25 00<br />

Fax +31 (0)10 458 72 45<br />

Email vuyk@vuykrotterdam.com<br />

Website www.vuykrotterdam.com<br />

VER project 08.100<br />

Values are for presentation only

<strong>Vuyk</strong> <strong>Versatile</strong> <strong>Vessel</strong><br />

Multipurpose Offshore Construction <strong>Vessel</strong><br />

Workability<br />

Construction vessels require superior seakeeping behaviour to achieve maximum<br />

workability. Therefore this vessel is fitted with large bilge keels and passive anti-roll<br />

tanks in the hull.<br />

Depending on the operational area and type of work the workability of the vessel can<br />

be determined. Depending on the loading condition, the anti-roll tanks are adjusted<br />

for maximum effect.<br />

Figure below gives a workability plot for a J-lay operation in the Gulf of Mexico.The<br />

workability for 3 headings is shown by the coloured lines through the scatter table.<br />

Hs (m)<br />

7.5<br />

6.5<br />

5.5<br />

4.5<br />

3.5<br />

2.5<br />

1.5<br />

0.5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

WORKABILITY<br />

Condition - Modular J-lay Equipment<br />

Limits Area 32 - Gulf of Mexico Workability<br />

Pitch angle : N.A. deg Heading 180 deg : 100%<br />

Roll angle : N.A. deg Heading 150 deg : 97%<br />

X-acceleration : 2.00 m/s2 Heading 90 deg : 82%<br />

Y-acceleration : 1.50 m/s2<br />

Z-acceleration : 2.50 m/s2<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

0<br />

2<br />

20<br />

261<br />

0<br />

1<br />

6<br />

40<br />

230<br />

1139<br />

3<br />

17<br />

92<br />

435<br />

1734<br />

5573<br />

6141 16733<br />

14<br />

70<br />

306<br />

1143<br />

3513<br />

8299<br />

16195<br />

26<br />

114<br />

426<br />

1344<br />

3419<br />

6413<br />

8965<br />

27<br />

104<br />

349<br />

971<br />

2142<br />

3359<br />

3594<br />

18<br />

66<br />

203<br />

515<br />

1016<br />

1383<br />

1187<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18<br />

10<br />

33<br />

94<br />

223<br />

403<br />

488<br />

348<br />

Tz (sec)<br />

4<br />

14<br />

38<br />

84<br />

142<br />

156<br />

95<br />

2<br />

5<br />

13<br />

29<br />

46<br />

47<br />

25<br />

1<br />

2<br />

5<br />

9<br />

14<br />

14<br />

6<br />

0<br />

1<br />

1<br />

3<br />

4<br />

4<br />

2<br />

0<br />

0<br />

0<br />

1<br />

1<br />

1<br />

0<br />

-<br />

0<br />

0<br />

0<br />

0<br />

0<br />

0<br />

-<br />

-<br />

-<br />

0<br />

0<br />

0<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

180 deg<br />

150 deg<br />

90 deg<br />

Optional<br />

Dynamic Positioning Class 3<br />

To provide more redundancy the DP system can be upgraded to a class 3 system.<br />

This can be achieved by dividing the engine and propulsion rooms into watertight<br />

zones. The electrical system must be divided into fire zones to generate redundancy<br />

after flooding or fire in any compartment.<br />

This concept is developed as starting point for further specification on clients requirements.<br />

These will be incorporated in the basic design to follow.<br />

<strong>Vuyk</strong> <strong>Engineering</strong> <strong>Rotterdam</strong> B.V.<br />

Naval architects, Marine engineers, Consultants<br />

P.O. Box 1, De Linie 7<br />

2900 AA Capelle aan den IJssel<br />

Phone +31 (0)10 450 25 00<br />

Fax +31 (0)10 458 72 45<br />

Email vuyk@vuykrotterdam.com<br />

Website www.vuykrotterdam.com<br />

VER project 08.100<br />

Values are for presentation only